| Camelinat and Company

Limited, Birmingham |

|

In 1890, twenty years old Eugene

Camelinat, started his business in Birmingham, as a

spinner to the gold and silver trade. He had been born

in France, but moved to England with his parents, in

about 1871, during the Franco-Prussian war.

His firm began to spin all metals,

and undertook copper smithing, polishing, plating and

built assemblies in sheet metal. As a result, the

business was quite successful. Eugene was among the

earliest pioneers to work in aluminium. At the time,

copper was extremely expensive, and so he pioneered a

method of copper plating zinc, which enabled the firm to

increase its production of art metal work.

By the late 1890s, cars and

motorcycles were beginning to appear. Eugene realised

their potential, and so began to produce a range of oil

and acetylene lamps, and later, electric lamps for both

cars and motorcycles. |

|

|

|

The First World War the firm made

engine cowlings for Handley-Page aircraft, manifold and

water fittings for aircraft engines, acetylene lighting

sets, hand grenades and petrol tanks.

By this time, Eugene’s four sons

had been working in the business, and learning the

trade. In 1922, Eugene took a back seat, and the four

brothers started to run the business.

In the Second World War the firm

produced steel helmets, smoke and signal bombs,

incendiaries, bomb tails, primers and exploders, mine

horns, gun cases, machine gun magazines, and many

pressings and assemblies for all the Government

departments.

In 1945, the firm joined the Owen

Organisation and began to specialise in the production

of metal products for the aircraft industry, for vehicle

manufacturers, and for the electrical industry,

shipbuilding industries, railways, and general

engineering. |

|

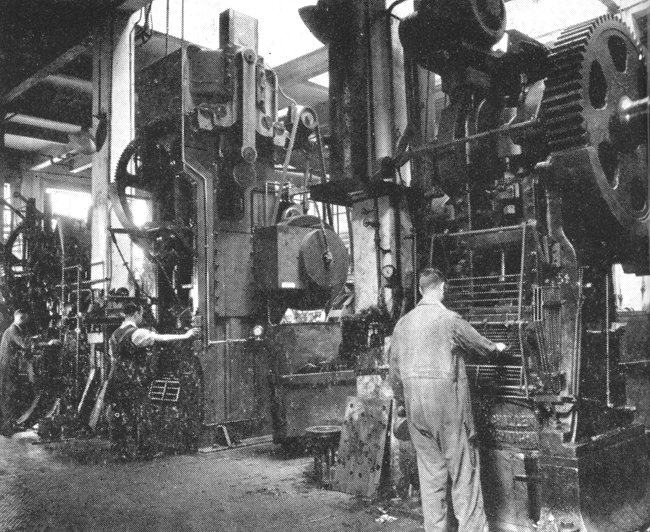

Part of the press shop. |

|

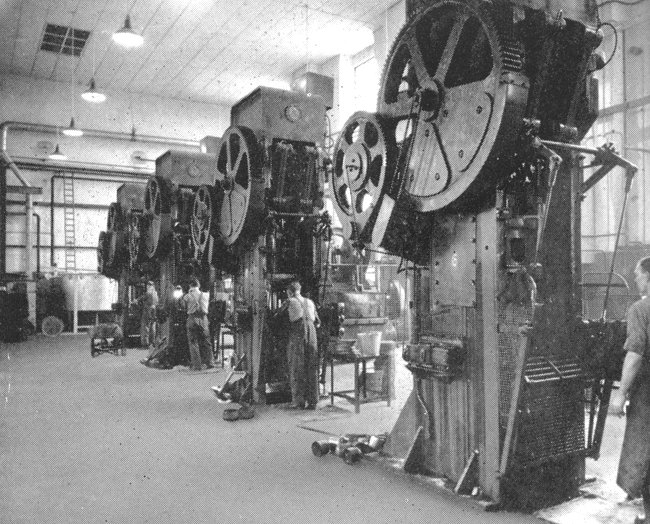

Another view of the press shop. |

|

The factory had the most up-to-date

machines, and could produce all types of deep drawn

pressings, light and medium pressings in steel, brass

and alloy, all using the firm's own press tools. Sheet

metal could be spun up to 50 inches in diameter, and bar

products up to 2 inches in diameter could be machined.

The press shop had over sixty presses. The single action

presses ranged from 20 to 400 tons capacity, the double

action presses could draw to a depth of 12 inches from a

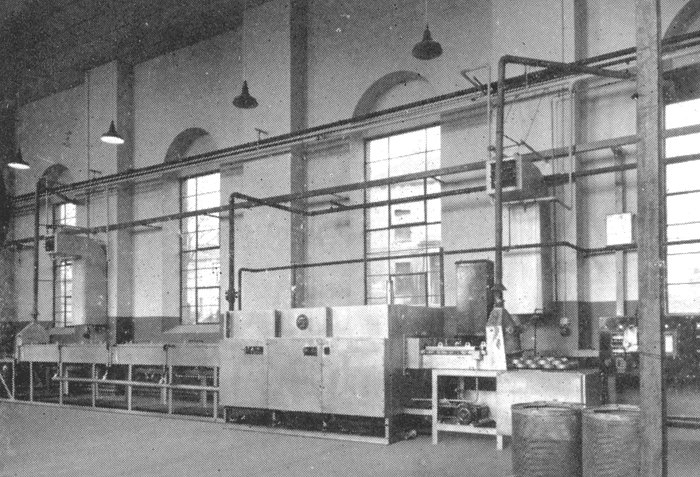

33 inch diameter blank. The firm also had electric

bright annealing furnaces for the heat treatment of

pressings between operations. There were also

departments specialising in electric and acetylene

welding, spray enamelling, polishing and electroplating.

In 1950 the business expanded with

the opening of a new factory at Dowlais, Glamorgan, for

the production of deep-drawn presswork. |

|

The heat treatment plant. |

|

Return to

the

previous page |

|