| Bentley Hall Brick

Company Limited The company, founded on 28th

October, 1933, leased 80 acres of land from the Bentley Hall

Estate, on which to build a brick works, using the plentiful

supply of available clay. Production began in 1934, soon

after the completion of the kiln. In the following year the

company purchased the land from the Bentley Hall Estate,

plus an additional 3½ acres for

£10,000. |

| Production slowed during

World War 2 because of a shortage of labour, and the

reduction in house building. In July 1943 the works were

closed by order of the Ministry of Works as part of a

plan to concentrate production. In November 1944 Rubery

Owen & Company Limited acquired the business as part of A.

G. B. Owen's plan to build a garden village at Bentley. The

works reopened after the war, and the manufacturing process

was mechanised in order to increase production. The works

were situated to the north of the main Willenhall to Walsall

Road, beside where the M6 stands today. The manager was Mr.

G. Williams, and the company claimed to produce the finest

red bricks in the West Midlands. |

|

A Bentley Hall brick. Courtesy of

Paul Robinson. |

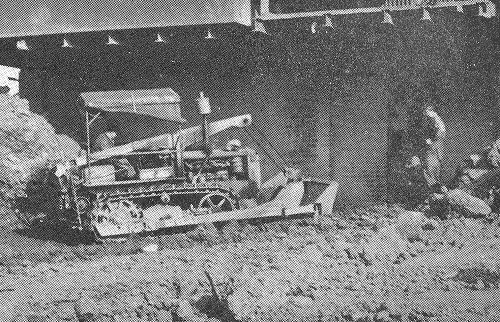

This photo, taken during the

building of the M6 Motorway at Bentley, includes the

once familiar view of the brickworks, that overshadowed

the motorway. |

|

The bulldozer. From the Christmas 1947

edition of the staff magazine "Yuletide". |

The clay from which the bricks were made was delivered

to the works by a tractor, bulldozer, and scraper.

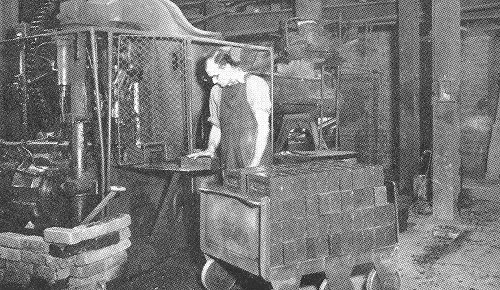

There were four automatic brick-making machines, each

capable of producing 1,150 bricks per hour.

The site also contained fine china clay which was also

exploited.

|

|

Another view of the bulldozer. |

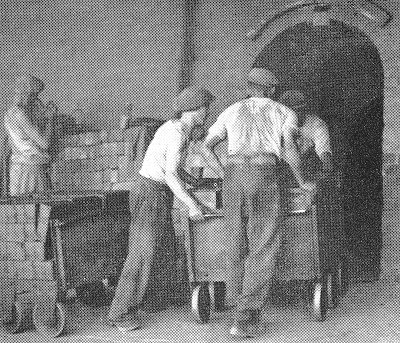

| There was a continuous Hoffman kiln with twenty two

chambers, capable of producing 170,000 bricks per week, and

two Scotch type open kilns, each capable of producing 20,000

bricks per week.

The drying and baking process in the electrically-powered

kilns took around twelve days. |

A brick-making machine. From the

Christmas 1947 edition of the staff magazine "Yuletide". |

Loading a kiln. From the

Christmas 1947 edition of the staff magazine "Yuletide". |

Each chamber in the Hoffman kiln held around 18,500

bricks, each of which contained around one pint of water

which had to be completely dried-out before firing.

This was done by blowing them with hot air. The final

baking temperature was 960 degrees Fahrenheit. The total

output in a good week was around 210,000 bricks per week.

At the time, the bricks were the cheapest and most

efficient building material produced. They sold (ex-works)

for less than one penny each, or around one pound per ton. |

|

Return to

the

previous page |

|