| Nuts & Bolts (Darlaston)

Limited |

| The company was founded on 13th July, 1912, in Foster

Street, Darlaston, on the site of an old timber yard. One of

the co-founders was Alfred E. Owen.

Initially everything was hand-made. There were 12

treadle-operated 'Olivers' producing bolts. Nuts were

hand-forged and tapped. The first customers were mainly car

makers.

Within a short time, automatic machines were installed in

the factory, and in 1917 a cold-heading machine was

purchased from the USA.

Large numbers of horses were used in the hostilities in

World War One. During the war the factory fulfilled Ministry

orders for large numbers of frost studs for horseshoes, and

picketing pins for tethering horses. They were supplied to

all of the Allied forces. |

Mr. G. F. V. Richards, Managing

Director. From the Christmas 1949 edition of the staff

magazine "Goodwill". |

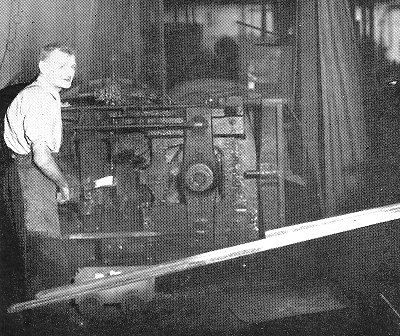

One of the original treadle-operated 'Olivers'.

From the Christmas 1949 edition of the staff magazine

"Goodwill". |

The furnaces, which were originally

coal-fired were replaced by more modern gas-burning types,

and semi-automatic machines were installed for tapping nuts.

In 1929 A.G.B. Owen became a Director on the death of his

father, and in 1934 the firm amalgamated with Evertite

Locknuts Limited to acquire manufacturing and distribution

rights for the well-known Evertite patent Evertite locknut,

millions of which were made at the works.

By the late 1930s the Darlaston factory

could no longer cope with the great demand for the company's

products, and so the decision was taken to open a new

factory at Tredegar, South Wales, an ideal location because

of the industrialisation in the area.

A suitable Government-owned site was

purchased by the company in Bridge Street, Tredegar. Before

the factory could be built, temporary premises were rented

from the Coal Board in order to begin production, and train

local employees. Production began in November 1937, when the

first nut ever produced in Tredegar came off the production

line. |

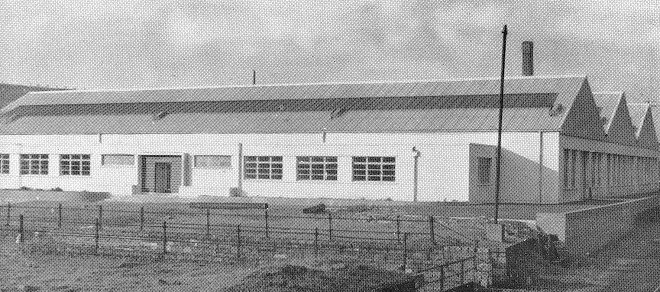

The Tredegar Factory. From the Christmas 1949

edition of the staff magazine "Goodwill".

The works canteen at Tredegar. From

the Christmas 1949 edition of the staff magazine "Goodwill". |

Toolroom staff and experts in production from Darlaston

temporarily took-up residence in Tredegar to ensure that

production got off to a good start. The new factory,

covering 33,000 square feet, opened in March 1949 with 40

male, and 40 female workers. Three key staff from Darlaston

permanently moved to the area to oversee production. |

| By 1940 the Darlaston firm was producing cold-headed

bolts with diameters of ¼ of an inch to ¾ of an inch.

In the Second World War, thanks to the firm's high level

of mechanisation, thousands of special bolts were made for

use in the assembly and maintenance of tanks. |

Part of the Tredegar factory. From the

Christmas 1949 edition of the staff magazine "Goodwill". |

|

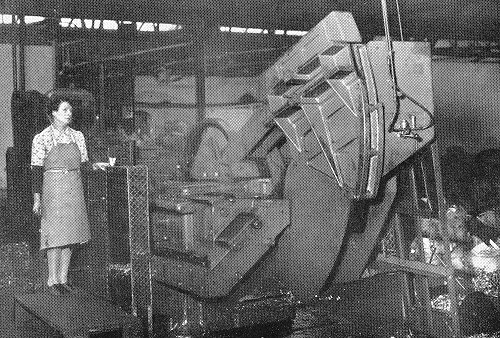

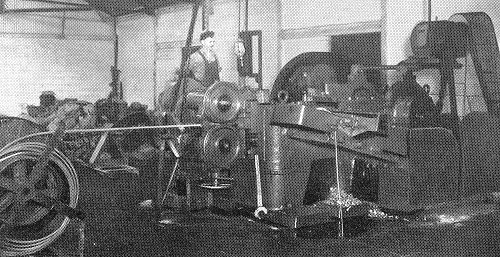

A Thread rolling machine at Darlaston. |

In 1945 Rubery Owen & Company Limited purchased the

total assets of Evertite, along with a controlling interest

in Nuts & Bolts (Darlaston) Limited. In the same year

E. W. B. Owen became a Director. |

| In the late 1940s, nuts and bolts made for railways,

rolling stock manufacturers, shipbuilders, structural

engineers, bridge builders, public works contractors, and

collieries, etc.

The firm supplied nuts and bolts to almost every country

including Africa, Australia, South America, and India. Around

30% of the total production was exported.

Nuts and bolts for special applications were made up to

several feet long, and several inches in diameter.

Products could be plated to the

customer's specification, or galvanised in the

company's spelter galvanising plant. |

An advert from 1946.

|

The firm took-out many patents including:

|

1948 |

Special furnace for heating pins or billets. |

|

1950 |

Furnaces for heating pins or billets. |

|

1951 |

Tool for cutting one axial half of an

internal groove in an open-ended hollow article. |

|

1951 |

Lock-nuts with an internal 'V' groove. |

|

1952 |

Improvements in tools for cutting internal

grooves. |

|

1953 |

Machine for cutting internal grooves in

open-ended hollow articles. |

|

1962, 1963 |

Locking or sealing nuts and bolts by

cementing. |

|

1965 |

Special dies for self-locking nuts. |

|

1965 |

Improved screw-threaded connections. |

| |

|

|

An advert from the mid 1950s. Courtesy

of Christine and John Ashmore. |

There were two subsidiary companies, Hartley &

Baldwin Limited, Willenhall Street, Darlaston, which

produced black bolts and nuts, and tie rods, and J.

Stanley & Company Limited, Wednesfield Road,

Willenhall, which produced drop forgings in all

steels, brass forging engineer's hammers, and small

tools. |

| Production at the

Darlaston Factory |

|

On the left, Mr. A. E. Garbett,

Works Engineer, on the right, Mr. Enoch Fields, operating a

bolt-heading machine. From

the autumn 1949 edition of the staff magazine "Goodwill". |

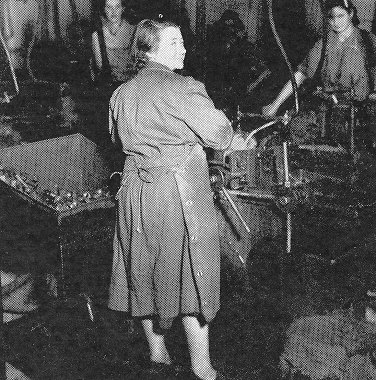

Nut frazing machine

operators. Left to right:

Jennie Norman, Katherine Bott, May Perkins, and Margaret

Stackhouse, who joined the firm in 1919.

From the autumn 1949 edition of the

staff magazine "Goodwill". |

|

|

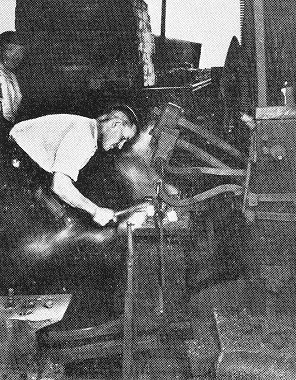

Mr. Sam Robinson forging Evertite

nut blanks. From the autumn

1949 edition of the staff magazine "Goodwill". |

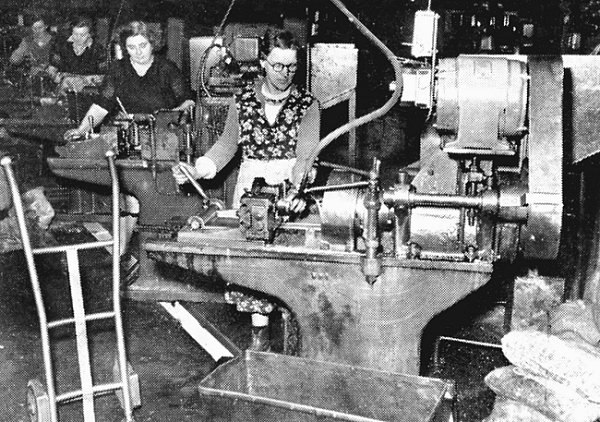

| Rolling bolt threads.

From the Christmas 1949 edition of the

staff magazine "Goodwill". |

|

|

Cutting the hexagon shape on the

heads of bolts. From the

Christmas 1949 edition of the staff magazine "Goodwill". |

| Cold-heading bolts.

From the Christmas 1949 edition of the

staff magazine "Goodwill". |

|

|

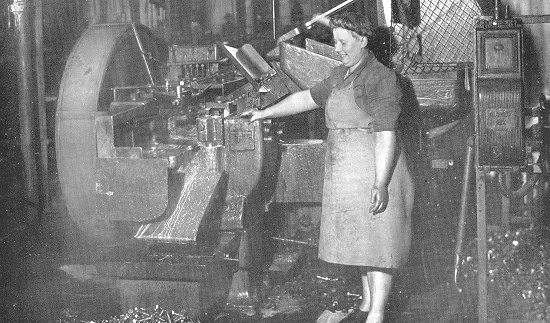

Mrs. Bray, who joined the company

in 1914, drilling holes in bolts for cotter pins.

From the Christmas 1949 edition of the

staff magazine "Goodwill". |

| Mrs. Vin. Foster who joined the

company in 1918, screwing bolts.

From the Christmas 1949 edition of the

staff magazine "Goodwill". |

|

|

The works canteen.

From the Christmas 1949 edition of the

staff magazine "Goodwill". |

|

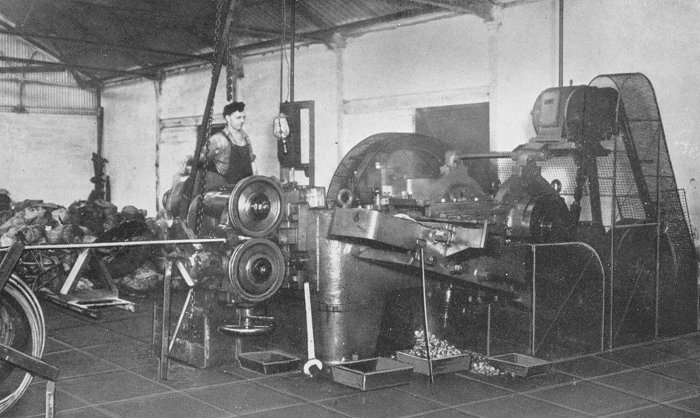

A cold-heading machine for

the automatic forging of bolt heads. |

|

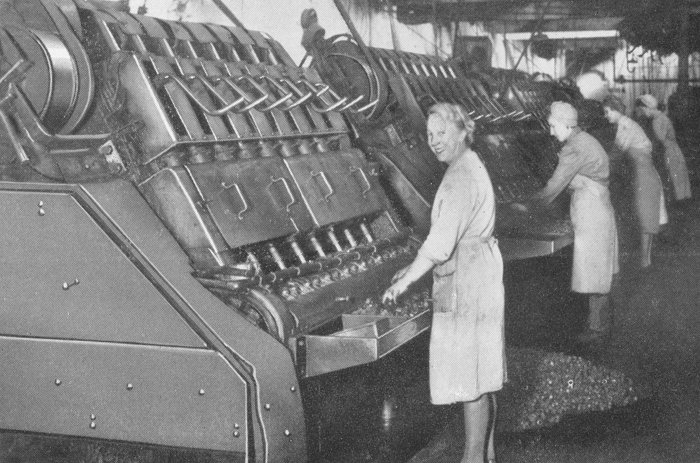

Nut threading machines. |

|

Part of the Screwing Machine Shop

in the mid 1950s. Courtesy of

Christine and John Ashmore. |

|

|

|

|

An

advert from 1972. |

|

An

advert from 1963. |

|

An advert from 1954.

|

In 1980 the Foster Street factory

closed, and production facilities were transferred to a

new company, Moxley

Fasteners Limited.

|

|

Return to

the

previous page |

|