| The Brooke Tool

Manufacturing Company Limited |

|

Brooke Tools of Warwick Road, Greet,

Birmingham was founded in 1903 to acquire two private

companies, the Brooke Tool and Stamping Company, and the

Brooke Tool Manufacturing Company.

In 1913 Alfred Owen acquired a

controlling interest, and the business went from strength to

strength.

Between 1922 and 1939 the turnover

increased twelve times, and by 1944 it had increased sixty

times.

|

Trade mark. |

|

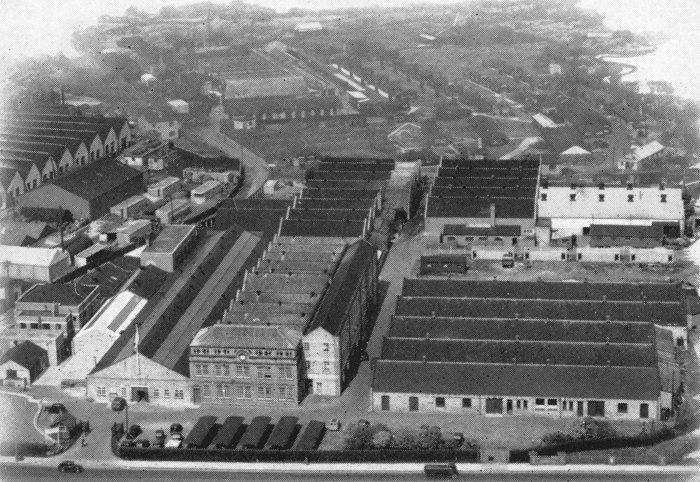

The Warwick Road factory. On the

right is the premises of A. G. Sutherland Limited,

another Owen Group member. |

|

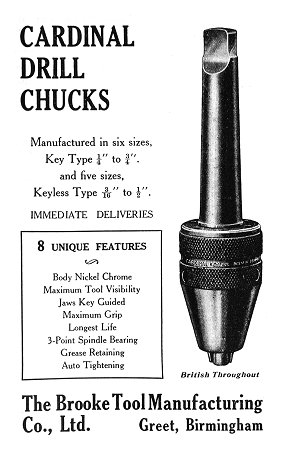

An advert from 1936. |

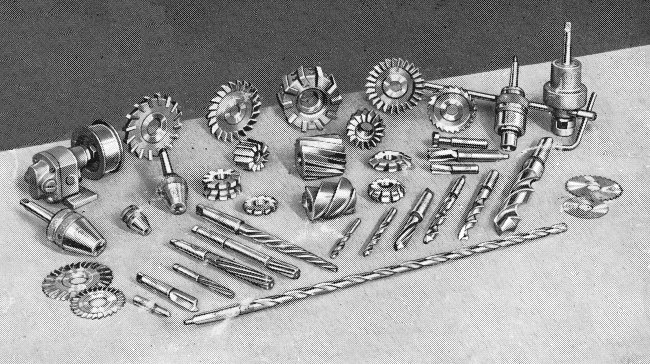

The firm produced a vast range of

engineers’ small tools under the 'Cardinal' name.

Products included twist drills, gauges,

reamers, milling cutters, counterbores, taps, slot drills,

drill chucks, machine vices, jigs, fixtures, suds pumps,

machines with multi-heads, metal slitting saws, and all

kinds of machine shop equipment.

The firm had a stand at the 1937

British Industries Fair displaying most of the company’s

range of engineers' small tools, and in 1938 became a public

company.

In 1941 Brooke Tools acquired lathe

maker T. S. Harrison & Sons Limited of Heckmondwike.

By 1961 the firm had 700 employees, and

had developed a range of special tools including non-slip

drill chucks, a tapping attachment with a Ferrodo clutch,

gear pumps for suds, oils or other fluids, and a cam action

vice with a swivel base and quick action jaws.

In February 1966 Rubery Owen increased

its shareholding, so as to own most of the company's shares. |

| The extensive range of 'Cardinal' tools included the

following: 'Cardinal bladed cutters in a standard

range of diameters of from 4 to 12 inches, with

blades of 18% tungsten high speed steel or of cobalt

alloy, amalgamated by fusion into a nickel chrome

shock-resisting body. Although cheaper, the tools had a

longer life than the standard solid cutters. Inserted

blade facing heads, in diameters of 4 to 14 inches had

blades of 18% high speed steel, or special cutting

alloys, held in position by screws and wedges.

'Cardinal' counter bores were

useful boxed sets of counter boring tools, complete with

pilots which fitted a single holding shank. They had a

range of diameters of

½ to 3 inches.

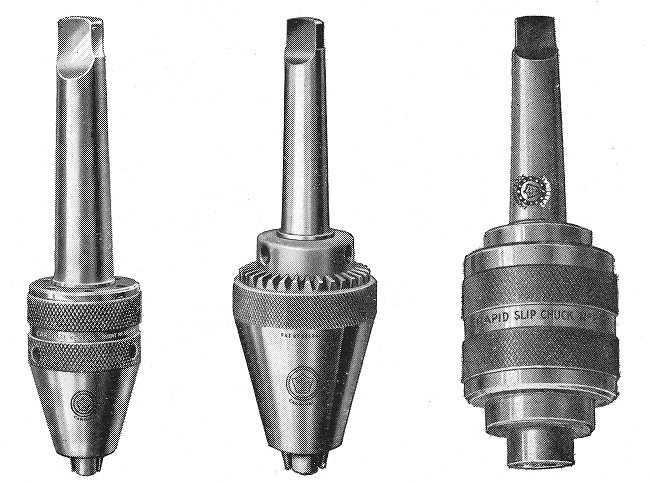

'Cardinal' Mark 1 drill chucks were

available in key operated or keyless forms. They were

self-tightening and had a range of capacities from three

sixteenths to three quarters of an inch. 'Cardinal' Mark

2 drill chucks ¼ to ¾ of an

inch.

|

|

'Cardinal' rapid slip chucks were

strong, reliable tools, made in five sizes with collets

giving a range from 0-5 morse tapers. 'Cardinal' tapping

attachments, in three sizes, had a range from

⅛ to ¾ of an inch, and had

an adjustable friction clutch, depth stop and

quick reverse gear.

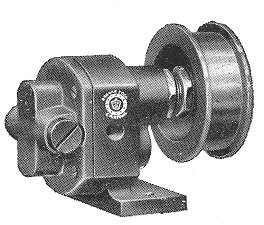

'Cardinal' gear pumps, although

primarily designed to supply coolants to machine tools,

were capable of adaption to meet many other pumping

requirements. Pressure pumps were also made, capable of

pressures up to 500 lbs. per square inch.

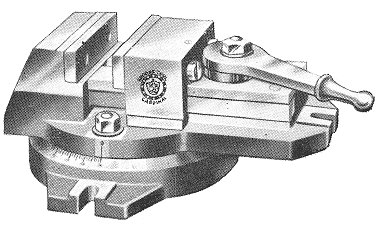

'Cardinal' machine vices had either

screw or cam action, and fixed or swivel bases. |

|

|

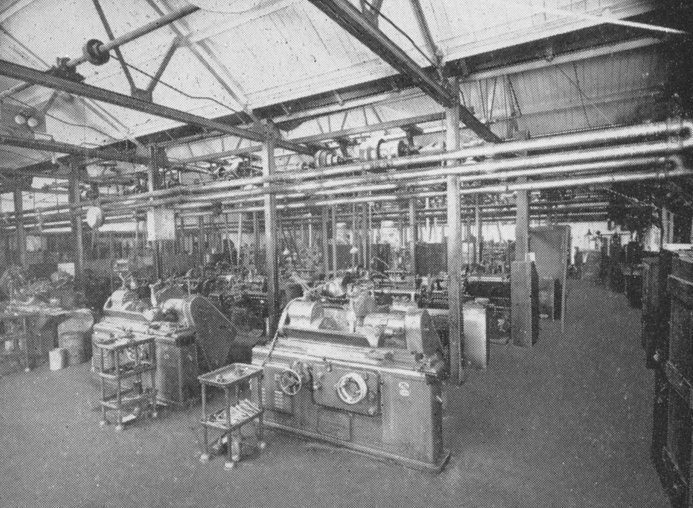

The turning section. |

|

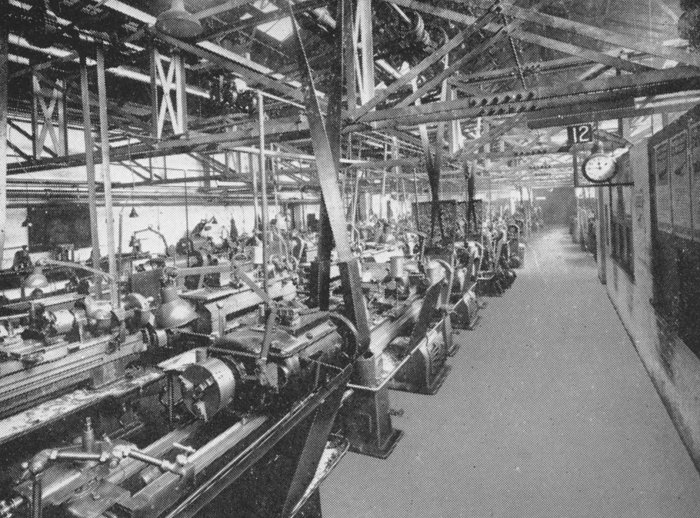

The milling section. |

|

The grinding section. |

|

A selection of 'Cardinal' tools.

From the summer 1947 edition of the staff magazine

"Pyramid". |

|

|

'Cardinal' 3-jaw drill chucks. |

Rapid

slip drill chuck. |

|

From the

summer 1947 edition of the staff magazine

"Pyramid". |

|

|

|

|

|

Cam action machine vice. |

|

Suds or oil gear pump. |

|

From the summer 1947 edition

of the staff magazine "Pyramid". |

|

|

T. S.

Harrison & Sons Limited, Heckmondwike

T. S. Harrison & Sons Limited was

established in 1898 at Heckmondwike, Yorkshire, midway

between Leeds and Huddersfield. The firm began as a

pattern-making business, supplying local foundries, but

quickly

developed into a general engineering business.

The company soon changed direction

again, becoming a machine tool manufacturer after the

production of the first Harrison centre lathe, in 1900.

Initially, single sets of castings and parts were machined

and fitted to one lathe at a time, but as production

increased, batches of 200 sets of components were precision

machined and sent for final assembly. The lathes were sold

both at home and abroad. A large percentage of them were exported.

In the 1930s depression, the company

extended its product range to cover a wide range of special

sizes of centre lathes, brass finishing lathes, grinding

machines, drilling machines, boring machines and hydraulic

jacks.

In the Second World War the firm

concentrated on the production of the Harrison 4½ inch

centre lathes, 'Union' double-ended grinding machines, bench

drilling machines, testing centres, surface plates, angle

plates and machine vices. Large numbers of lathes were

supplied to the Admiralty for mobile workshops, training

schools, and for use on ships, and in dockyards.

In 1941 the business was taken over by

the Brooke Tool Company, and became part of the Owen

Organisation. A. G. B. Owen becoming Chairman. Demand for

the company’s products rapidly grew, and so extra premises

were acquired in 1942 and 1944.

After the war, the product range was

again extended, and some of the discontinued items were

reintroduced, particularly the Union 'Jubilee' woodturning

lathe, greatly needed for the re-equipping of schools, and

also the Harrison 7 inch centre lathe, which had been a

popular pre-war machine. By this time, there was a great

demand for Harrison lathes, both at home and abroad. They

were exported to 23 different countries. |

|

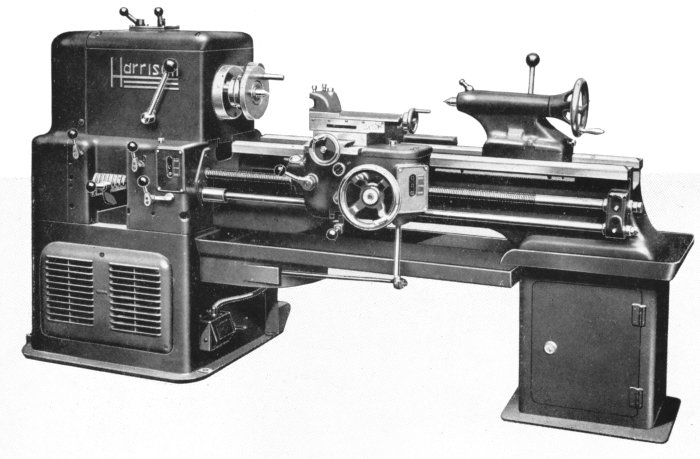

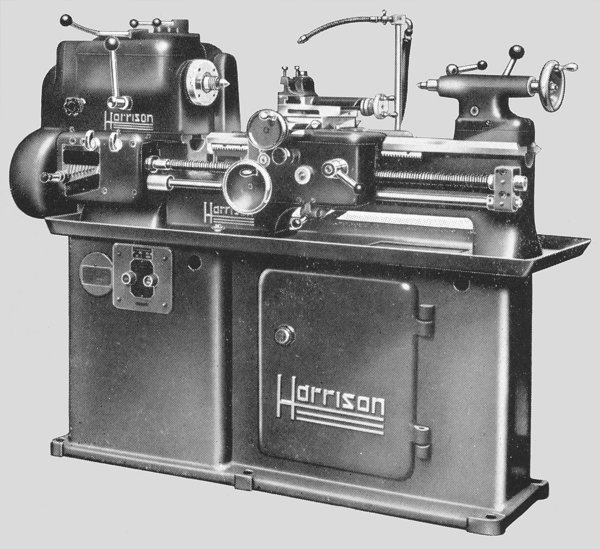

A Harrison 7 inch, all centre, geared

head, 12-speed, screw-cutting lathe. |

|

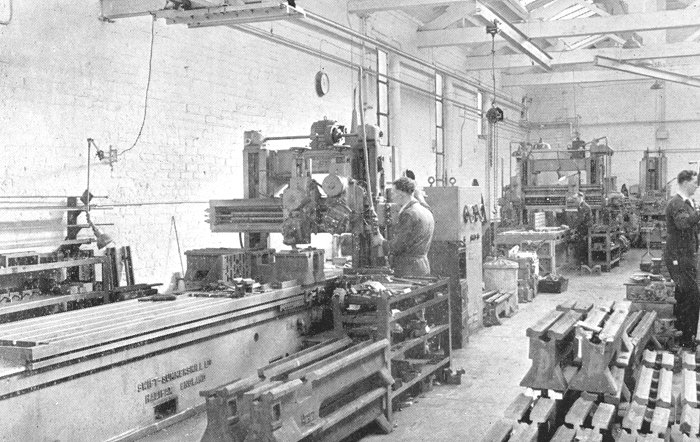

Planing lathe gaps in the machine

shop. |

|

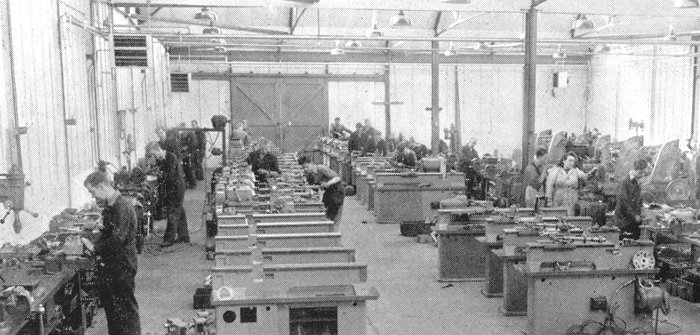

Assembling and fitting lathes. |

|

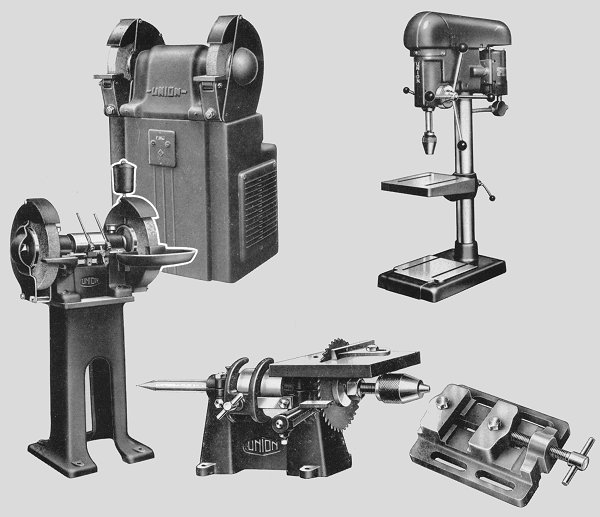

Some of the many tools produced by

the company. |

|

A Harrison 4½

inch centre, all-geared head, 8-speed screw cutting

lathe. |

|

Return to

the

previous page |

|