| Sand, Clay, Bricks

and Pots George Ward (Moxley) Limited is a well

known firm which was a significant employer in the town.

It was the last in a line of manufacturers to exploit

the rich glacial sand and clay deposits in the Moxley

area. Some of the deposits were alongside the Walsall

Canal, which allowed heavy loads to easily be

transported at a time when many roads were simple dirt

tracks.

The fine-grained sand deposits were ideal for use in

moulding boxes in local foundries, making it possible to

produce accurately detailed castings. Sand from the sand

beds was used for casting as early as the late 18th

century by John Wikinson at his Bradley foundry and

ironworks.

For much of the nineteenth century the clay was used

for brick-making, at a time when there was a great

demand for bricks, because most of the local towns were

rapidly expanding. The many brick makers included the

Wood family (John Wood, Thomas Wood, and William Wood)

who ran Moxley Brickworks, alongside a small canal basin

in between Baggott's Bridge and Darlaston Road Bridge;

Hodgins and Bromley, brick and tile makers, and sand

merchants; Price's Brickworks; W. R. Price & Hewitt Lime

& Brick Works; Murby's Brickworks at Moorcroft Wood;

David Rose alongside the Albert and Moxley Ironworks;

Martin & Foster; and Baggott's Bridge Brick Works near

to Baggott's canal bridge.

|

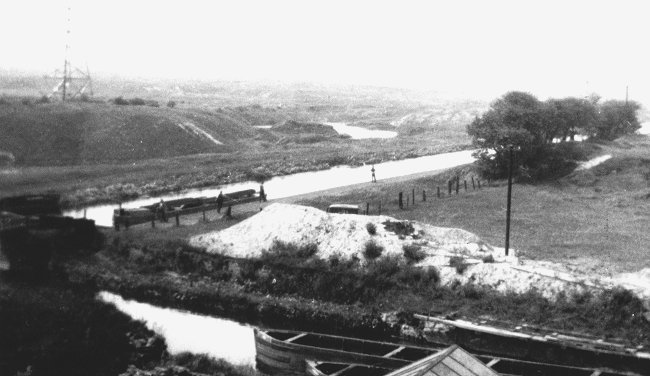

The canal basin that

ran into Wood's brick works. |

An advert from 1921.

Conditions in the early brickworks were

extremely basic, and work was hard. The report by the

Children's Employment Commission of 1864 includes the

following description of the girls who worked at Woods

Brickyard and David Rose's Brickyard:

| At Mr. David Rose's Yard, Moxley.

Anne Wooley: I began when I was 15. I

mould now. I am 24. I am paid by the

thousand. I have 2 girls to carry clay.

One is going 16 and the other going 15.

I make about 2,000 bricks in a day. I

have to work the

whole time from 6 to 6 to do that. I

always stop half an hour for breakfast

and 1 hour for dinner.

The clay carriers at this yard had to

carry the clay from the bottom of the

pit to the tables at the top; the ascent

was about 10 yards in 70 yards.

At Mr. Wood's Yard:

In this yard the girls had to carry

the clay up a steep rise of about 12

yards in 50 yards.

Mr. J. Swindley, currier, Freeth

Street, Oldbury: I have lived in the

town 30 years. I am well acquainted with

the habits and conditions of the girls

employed in the brickworks. The

employment of young females at this work

is looked upon as a shame by all us

tradesmen. The girls have to do men's

work along with the men, I have often

been shocked to hear the language and

indecent talk among these girls when

they work. After their work is over

which is generally about six o'clock,

they dress themselves in better clothes

and accompany the young men to the beer

shops. They are a good deal in the habit

of spending their earnings in beer shops

with the men. They are ignorant of all

household work, and quite uneducated. |

|

|

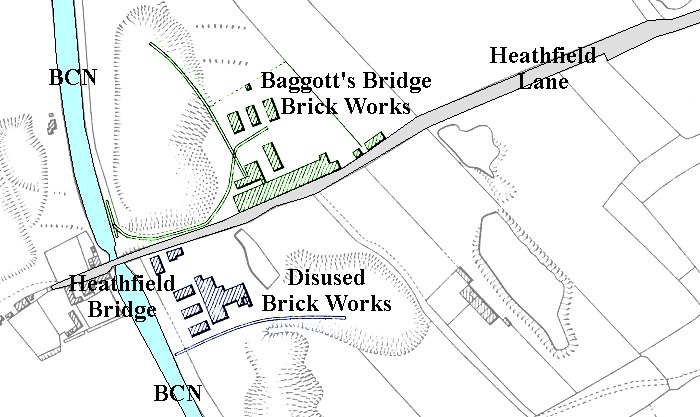

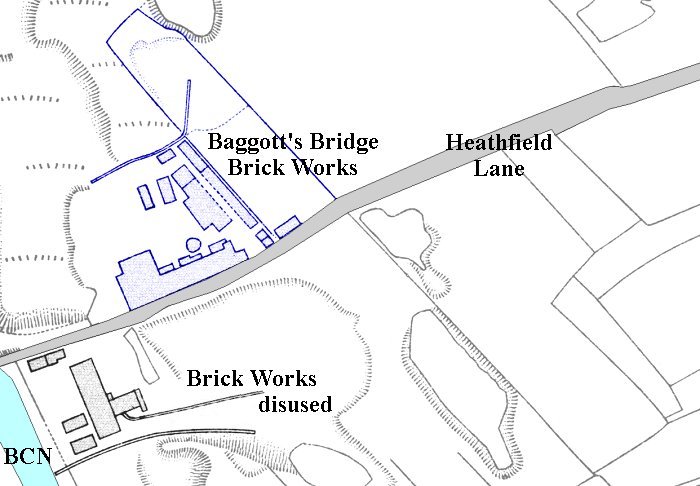

A map from 1901, based on the

Ordnance Survey map. At the time, Baggott's Bridge Brick

Works was run by Alfred Prosser, who is listed

as the owner in the Kelly's Staffordshire Directory of

1904 and again in 1912. Baggott's Bridge at the end of

Heathfield Lane, over the canal, was probably named

after the Baggott family who had a cottage and land on

the south side of the road, at its end. The owner in

1841 was Moses Baggott. The area was called Heathfield. |

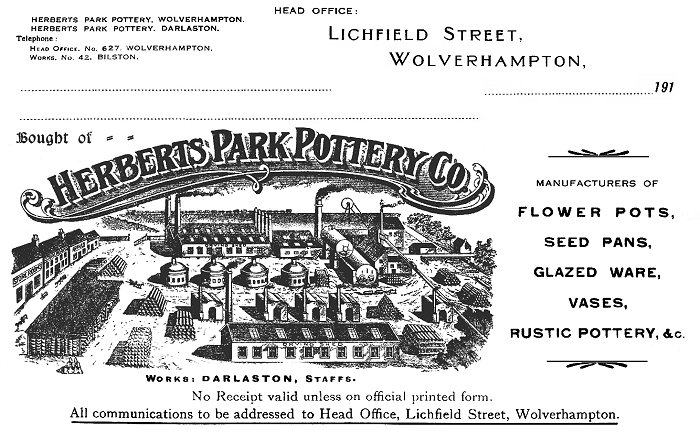

This bill head from 1910 to 1919

includes a good image of the site, with the canal and

Heathfield Bridge (also known as Baggott's Bridge) on the right. There were four kilns

and quite an extensive factory. In the 1921 Wednesbury &

Darlaston Blue Book and Directory, the site is listed

under two names, Prosser Brothers and George Ward. It

seems that George Ward initially purchased the disused

brick works on the southern side of Heathfield Lane and

later acquired the Herberts Park Pottery Company's site. |

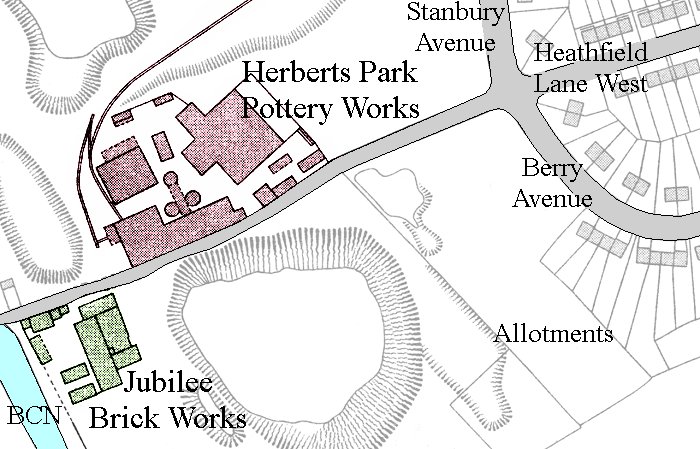

This map is based on the 1912

O.S. map on which the brick works to the south of

Heathfield Lane are marked as disused. |

This advert is from 1921 when

George Ward ran the Jubilee Brick and Sand Works at

the site of the disused brick works on the map

above. |

This map, based on the

1938 O.S. map, shows the Jubilee Brick Works and the

Herberts Park Pottery Works, both run by George Ward. |

| Some time before 1920, George

Ward took over the disused brick works on the southern

side of Heathfield Lane and opened the

Jubilee Brick & Sand Works, producing bricks and

supplying sand to foundries, and for polishing.

This part of Heathfield Lane became Heathfield Lane West

when the council houses were built. |

|

Edgar Ward. |

In 1920, George Ward was joined by his son Edgar, when

he had finished his schooling, first at Dorsett Road

Council School, then Queen Mary's Grammar School,

Walsall.

In the early 1920s the demand for bricks fell, and so

in 1921 Edgar developed a method of producing flowerpots

from the Moxley clay. Something that had been

unsuccessfully attempted previously.

The firm then began producing flowerpots, which were

very popular and sold in large quantities.

Edgar was also a member of Darlaston Council. He

represented the Catherine's Cross Ward, and lived at

Marlborough House, 59 Moxley Road, Darlaston.

In the late 1930s the family moved to 8 Ednam Road,

Wolverhampton and called their new house 'Darlas'. |

| In 1927 Edgar returned to his old school in

Dorsett Road to ask the headmistress if one of

the forthcoming school leavers would be suitable

to work for him and his wife as a housekeeper,

who would also look after his son, Edgar. My

mother got the job and worked for the Ward family for many

years, also looking after Edgar's younger

brother Malcolm.

She later worked at Ward's factory making

pots.

My grandfather also worked there in the

1930s, in the clay pit. |

Young Edgar Gordon Ward,

playing his harmonica. Sitting next to my

mother, Daisy. |

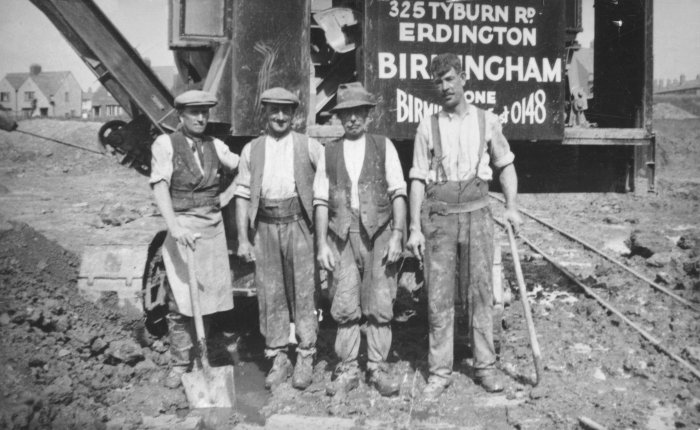

Digging clay in the clay

pit. Second from the right is my grandad Henry

Flavell. On the far right is the foreman, Jack

Kimberley. The crane was known as 'The Devil".

The houses in the background are in Berry

Avenue. |

| On the 29th October, 1973, some members of the

Ward family founded a private limited company called

Topfpots Limited. The company manufactured plastic

products including plant pots. The directors were

Edgar Ward, Muriel Ward (Malcolm Ward's wife), and

Peter Ward. The nature of the business quickly

changed. Clay pots continued to be produced for a

while, but were slowly phased out. At the end there

were only eight employees in the factory. Edgar

Ward retired in 1994 and spent his last day at work

with my mother as a guest at the factory. He settled

down to retirement in Trevean Way, Newquay, Cornwall

and eventually returned to the West Midlands, living

in Sunrise care home in Wergs Road, Tettenhall.

Sadly he died on the 28th May, 2020, at the age of

93.

His younger brother Malcolm Beverley Ward, born

in May 1931, became a Circuit Judge and lived with

his wife, Muriel, in Lothians Road, Tettenhall. He

was also a director of Wolverhampton Grammar School

Limited. Sadly he died on the 1st March, 2020, at

the age of 88. His wife Muriel Winifred Ward, died

on the 19th December 2018, at the age of 87. |

|

Workers at Ward's clay pit in the

1930s. Courtesy of John & Christine Ashmore. |

Producing a large pot on the potter's

wheel.

The fully-loaded kiln.

| Over the years, Wards produced all kinds of traditional clay pots

and became well known for their high quality products.

Eventually the firm moved with the times, adding plastic

pots to the product range. They were a

cheaper product and finally-took over from the clay

pots.

Wards had three rotational moulding machines, and

around 20 injection presses, mostly Windsor machines.

Most of the products were made from polypropylene or

high density polyethylene.

The later product range consisted of moulded

plastic plant pots, planters, propagators and watering

cans, much of which was exported.

The firm was finally taken over by Plysu in 1997.

After which production at Darlaston ended. The site

has now been redeveloped into a housing estate. |

An advert from 1972. |

|

Ward's clay pit in 2008. |

|

The factory in 2008. |

|

Return to

the

previous page |

|