|

The Wellman Smith

Owen Engineering Corporation Limited |

|

The business was founded in 1919 to acquire a major

share of the American company, Wellman-Seaver and Head,

steel works engineers and contractors; and also James

Smith Hoisting Machinery Company Limited, specialists in

dockside cranes and hoisting machinery.

The new corporation also took over the engineering

department of Rubery Owen. Mr A. E. Owen was chairman.

It became a public company in 1924, and had a number

of factories in the UK, including the one at Darlaston.

At this time the company introduced a range of coke oven

machinery including a coke charging car, and a combined

coke pusher, coal leveller, and door extracting machine,

the first of its kind in the country.

During the Second World War the company manufactured

shell forging machines, bridge laying equipment, cranes,

and shot furnaces.

The firm's shell forging machines were used in

Australia, Canada, India, and the USA. The machines

could produce in excess of 350 anti-aircraft, 3.7 inch

shell forgings an hour, and produced around 80 million

shell forgings during the war, using over two million

tons of steel.

Other war work included the production of machinery

for the Mulberry harbours, and the Pluto pipeline, and a

large number of steel smelting furnaces, and gas

producers.

|

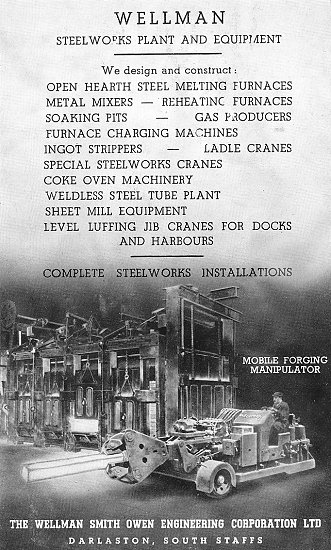

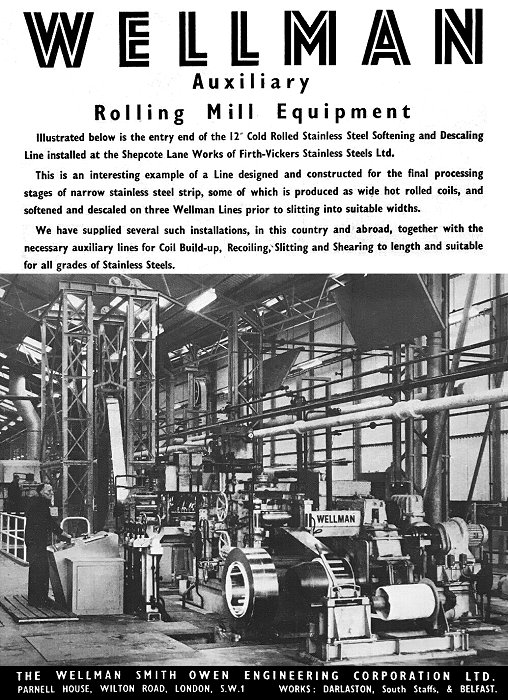

An advert from 1946. |

| A highlight for the staff was the annual Whitsun

works outing, which began in 1947. Several hundred

people consisting of staff and family members would

board a special train at James Bridge Station for the

journey to seaside resorts such as Blackpool, and a

four-day stay at a holiday camp. A minimum of three

hundred people was needed in order to book the special

train.

On one occasion 550 people went on an outing to

Middleton Towers holiday camp, and greatly enjoyed their

holiday. The outing was organised by the Fitting Shop,

and linked to the Darlaston shilling-a-week football

sweep. Funds from the sweep were shared out before the

outing. Fitting Shop foreman Mr. Ernie Ramsbottom ran

the fund for many years.

In December 1955 the Falls Foundry Engineering Works

in Belfast was acquired by the Wellman Smith Owen

Engineering Corporation, Limited. The factory consisted

of machine shops, erecting shops, a foundry, and

administrative buildings. The business was acquired to

provide increased manufacturing capacity, and to take

advantage of the plentiful supply of labour in Belfast,

and the financial assistance provided by the Government.

The completely new range of heavy and medium

engineering products that the factory was called upon to

produce involved a considerable amount of retraining of

the existing labour force, which proved adaptable and

co-operative.

|

|

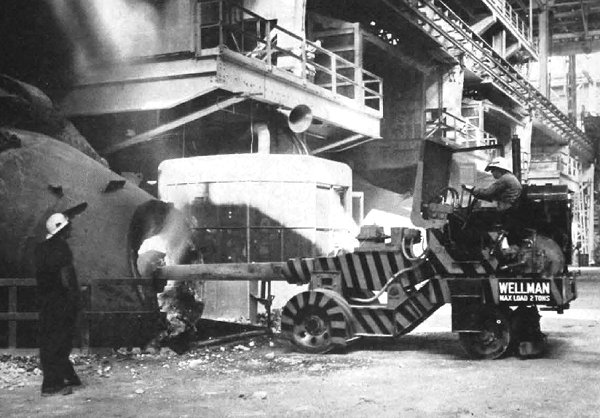

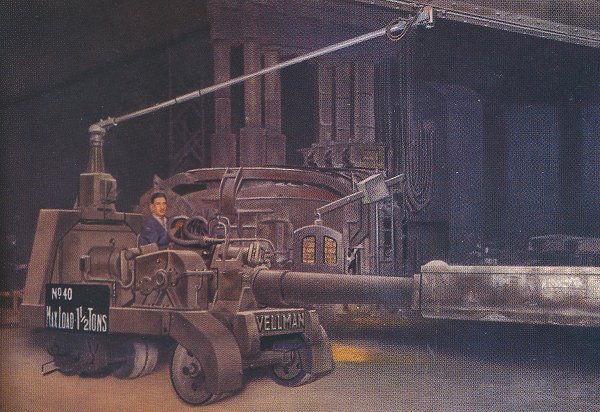

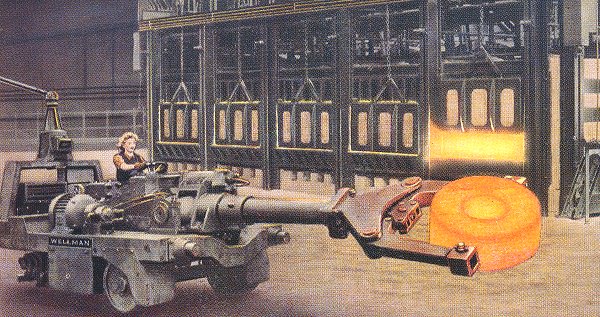

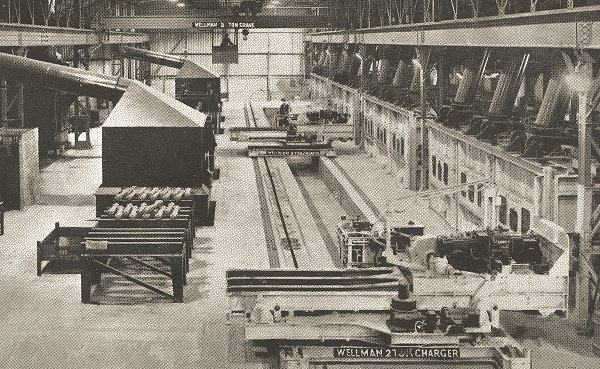

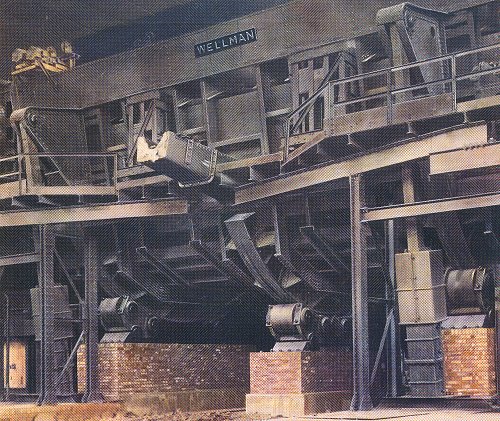

A Wellman 2 ton mobile, bar-turn,

furnace box-charging machine. |

An advert from the mid 1950s. Courtesy of

Christine and John Ashmore. |

To provide for the training of future personnel, an

apprenticeship scheme was established, and in order to

provide increased efficiency, and to deal with the

expanding demands on the Belfast establishment, the

engineering shops were modernised and almost completely

re-equipped with modern machine tools.

The factory concentrated on the production of the

lighter products in the Wellman range, such as

mechanical handling and processing units for the

production of steel strip, mobile charging and handling

machines, air control valves and component parts for the

heavy steel works equipment produced at the main works

in England. Typical of this equipment is the 2-ton

mobile bar-turn furnace box-charging machine shown

above, which was supplied to the Steel Company of Wales.

This machine is driven by a diesel engine and all of its

motions are hydraulically operated.

In August 1965 the firm's name was changed to the Wellman

Engineering Corporation, which consisted of five main

subsidiaries, including Wellman Machines Limited, and

the Wellman Incandescent Furnace Company, both based at

Darlaston.

The Darlaston factory closed in the 1980s and was

acquired by Wilkins and Mitchell.

Wellmans had

a London office in Victoria Station House, Victoria

Street, SW1, and offices in Australia, France, Holland,

Italy, New Zealand, South Africa, Switzerland, and

Turkey. |

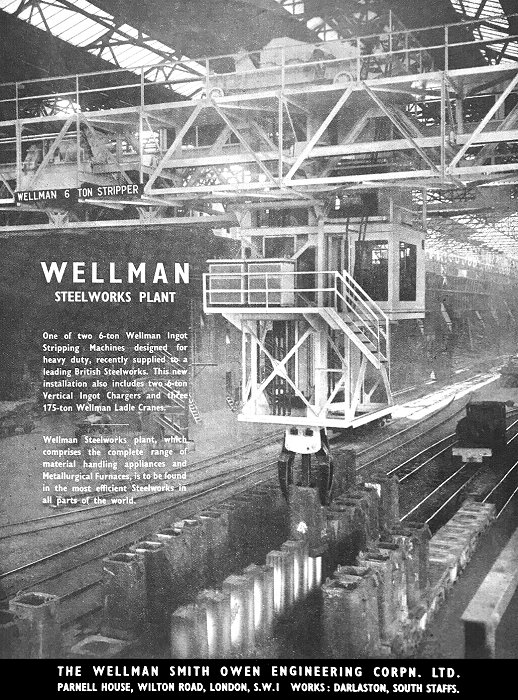

An advert from December 1960.

An advert from May 1953.

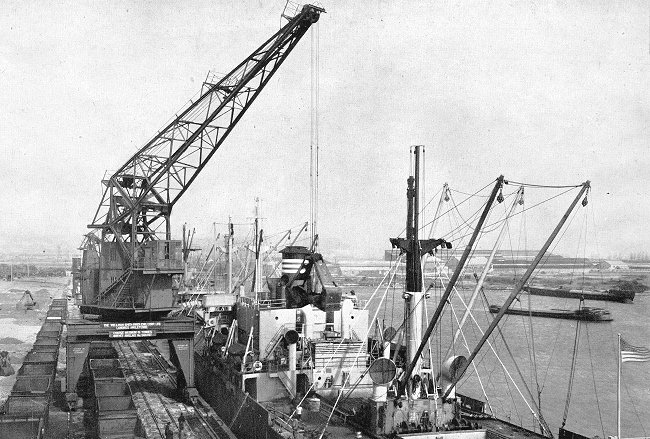

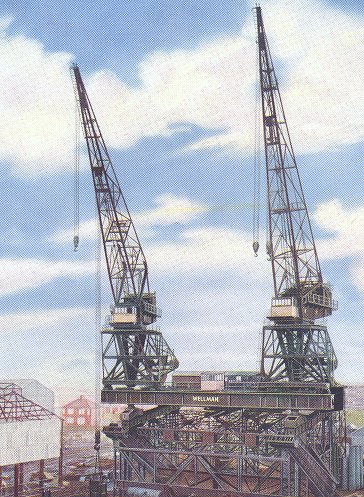

| Some of the Company's

Products Cranes:

Docks and harbours |

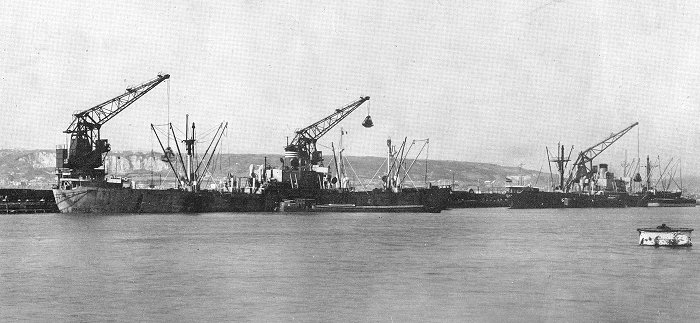

| The Wellman patent level luffing jib cranes were the

first British post-war dockyard cranes to be supplied to the

French Government for re-equipping ports devastated during

the war. They were supplied to the ports of Brest, Bizerta,

Cherbourg, Dakar, Le Havre, Lorient, Marseilles, Oran,

Rouen, and Toulon, and were also supplied to other countries

including Russia. |

One of the cranes in action.

A wellman crane in use at Le Havre.

Three of the cranes working at Le Havre.

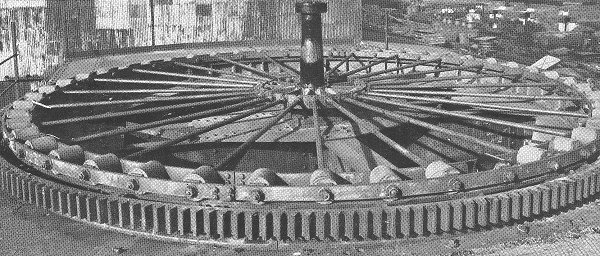

The roller path and centre pin.

|

A Wellman Smith Owen level-luffing

jib crane. |

The level luffing crane opposite uses the

company's patented gear which ensures that the hook remains at the same level whilst moving

the jib up and down. This crane was designed for the handling of

coal or iron ore, and could deal with loads of up to 15

tons.

It was electrically operated and ran on 10.5

metre-wide track. With ballast it weighed around 240

tons, had a hoisting speed of 35 metres per minute, and

could travel on the track at a speed of 35 metres per

minute. There were two 75 BHP. Metrovick motors, each

of which drove a winch. One of the winches raised and

lowered the grab, the other opened and closed it.

|

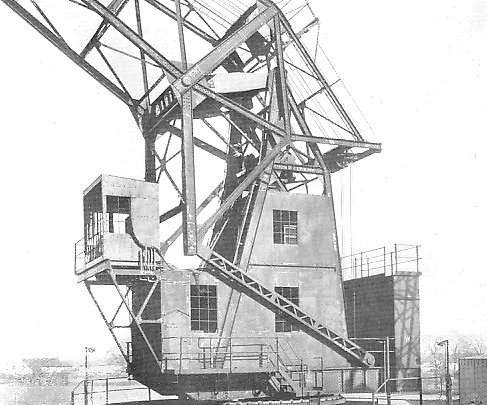

| The superstructure of the

crane. |

|

|

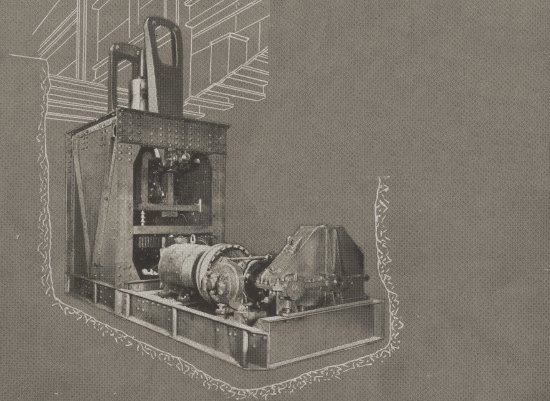

The crane legs and the

self-reeling drum for the power cable. |

| The crane was operated from a 3-phase 380 volt, 50

hertz supply, to which it was connected via a 60 metre

length of trailing C.T.S. flexible cable. The cable was

automatically payed-out and taken-up as the crane ran

along the track, by means of a weight-operated

self-reeling drum. Five 1kW heaters were fitted so

that the cranes could work in low temperatures. Three

were in the machinery house, and two in the operator's

cabin. |

The operator's cabin. |

|

|

|

| One of the two

122 ton capacity Wellman creeper cranes that were

used in the construction of Sydney Harbour Bridge.

|

|

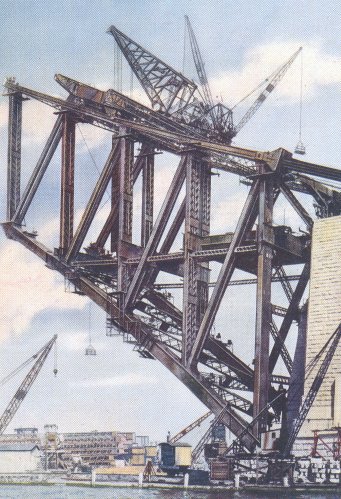

One of the two Wellman

crane assemblies used in the construction of the

Howrah Bridge at Calcutta. Each crane had a capacity

of 60 tons. |

|

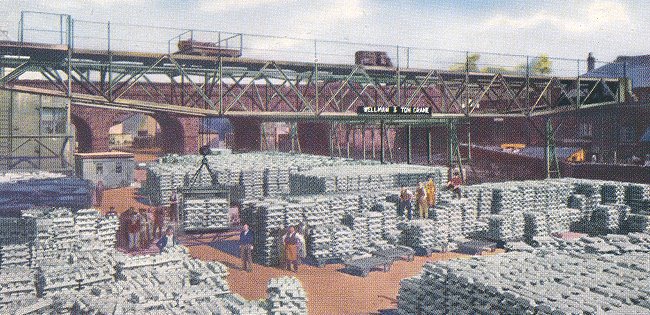

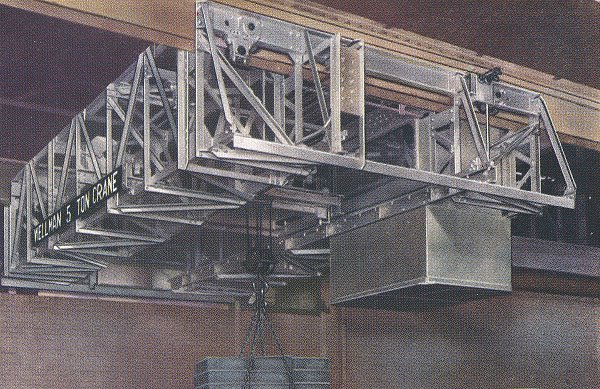

A 3 ton Wellman electric overhead travelling

crane with a 91 ft. span.

A 5 ton Wellman underslung overhead travelling

crane.

A standard Wellman 10 ton overhead travelling

crane.

| Charging and discharging

machines for steelworks: |

An overhead revolving charging machine for

open hearth furnaces.

A low ground charging machine with a capacity

of 5 tons.

A mobile floor charging machine for electric

furnaces.

A mobile charger for handling tyre cheeses,

blooms, and billets.

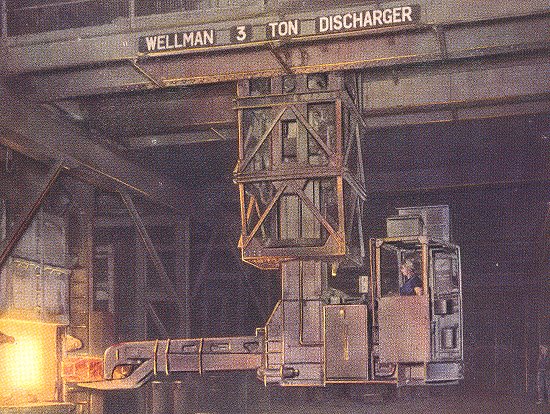

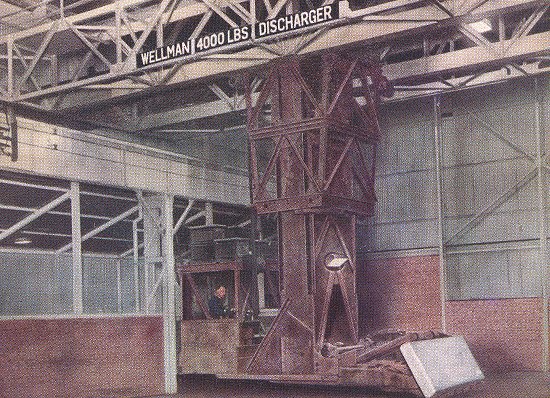

An ingot discharging machine.

An overhead billet and slab discharger.

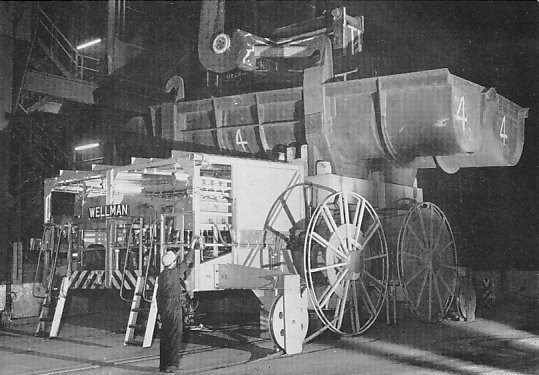

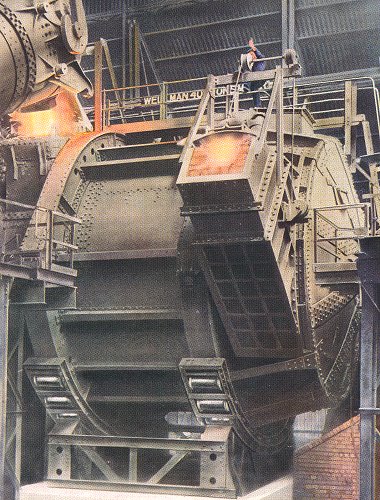

A Wellman 85 ton scrap charger in

use at Richard Thomas & Baldwins Limited, Spencer Works,

Llanwern, near Newport, South Wales. The 2 charging

boxes are being lowered onto the scrap charger. |

The company's many products included an

85 ton scrap charger. This was ideally suited for use

with LD convertors, a German designed refinement of the

Bessemer convertor, that blows pure oxygen instead of

air through the molten metal.. |

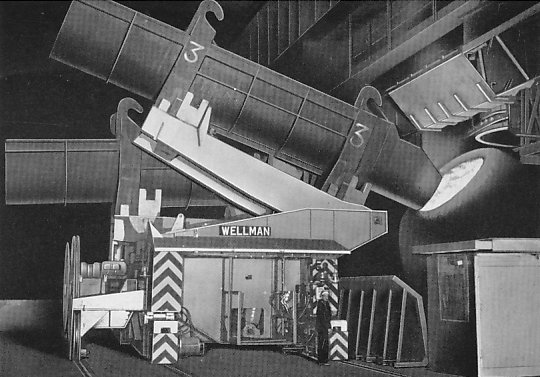

| One charging box is in the

tilted position to charge an LD convertor.

After charging, the box will be

lowered, and the electrically powered scrap charger,

which runs on rails, will be moved forward to position

the second charging box over the mouth of the convertor.

|

|

|

A final view of the scrap

charger, showing an empty charging box returning to the

horizontal position. |

| More machines for use

in steelworks: |

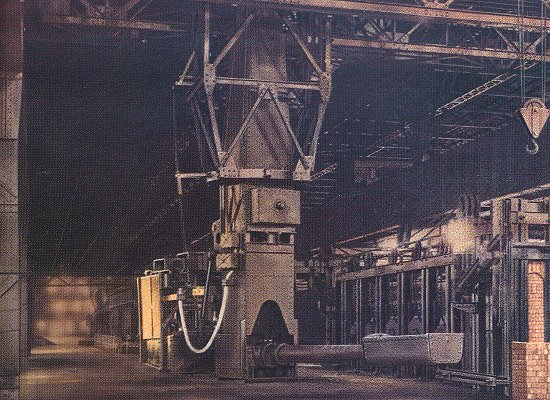

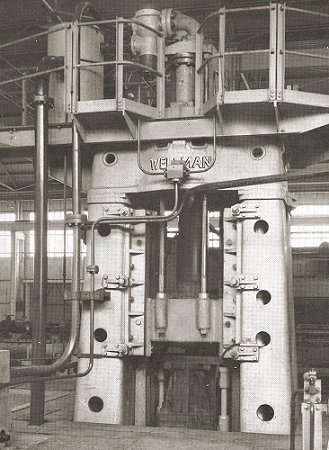

| Ingot stripping

machines and vertical charging machines serving

a large battery of soaking pits. |

|

|

The Wellman patent

ingot stripping and mould handling machine to

strip hot top ingots, and to handle ingot

moulds. After an

ingot has been stripped, the apparatus retained

the mould to prevent it falling back onto the

casting car. The operation of the mould tongs

was independent of the movement of the stripping

tongs. |

| A stationary ingot

stripper with an operational pressure of 100

tons. |

|

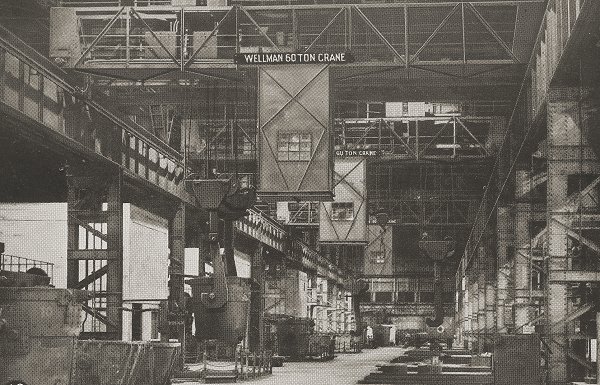

Three 60 ton ladle cranes.

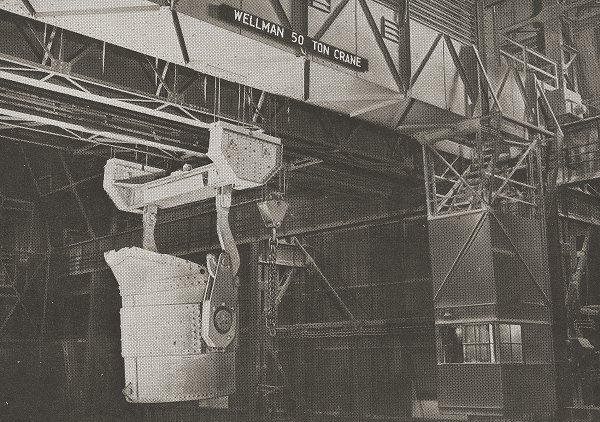

A 50 ton ladle crane.

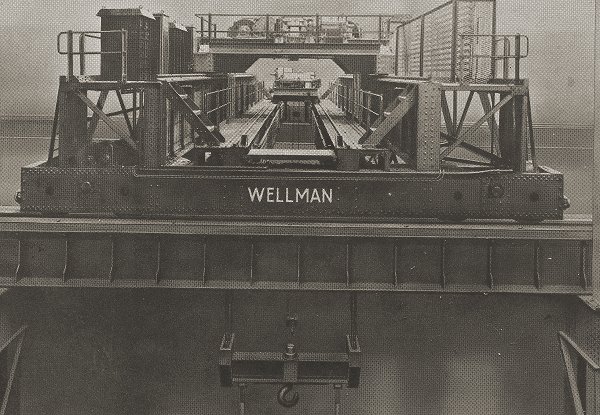

The main and auxiliary trolleys on

an overhead crane. |

A continuous reheating furnace, fired from

town gas.

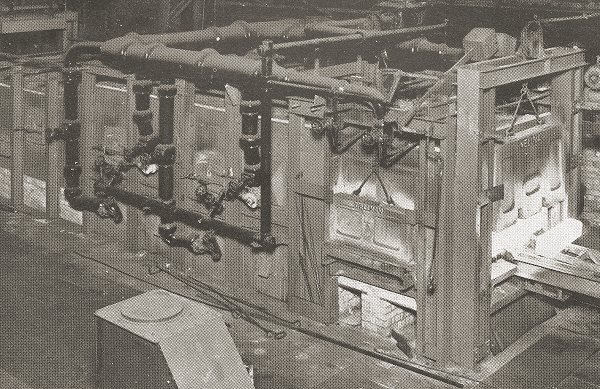

A battery of annealing furnaces for brass and

copper sheets.

A Wellman rotary hearth furnace, fired with

coke oven gas.

A continuous slab heating furnace.

An aluminium melting furnace with a chain

grate stoker.

A complete heat treatment plant.

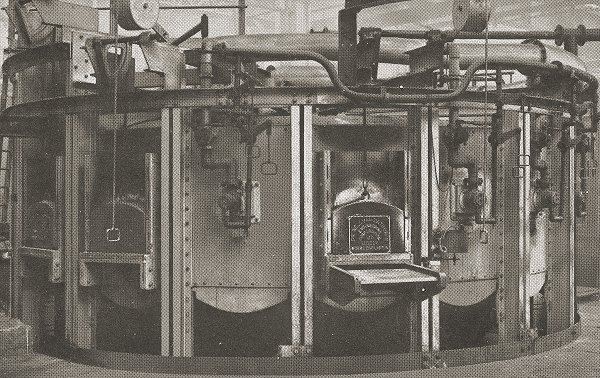

The charging side of a Wellman 'Venturi' open

hearth furnace.

|

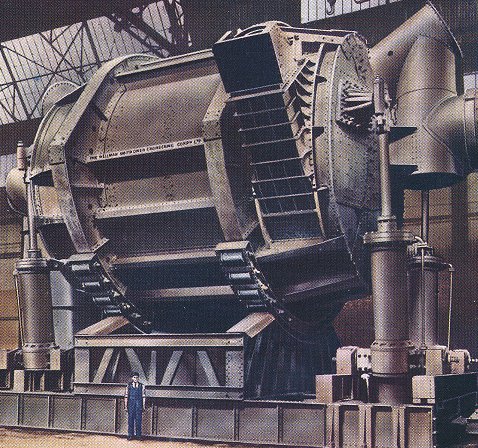

A 400 ton Wellman inactive metal

mixer that is fired with blast furnace gas through three

special burners. It

electrically tilts and rests on a roller track between the

rockers and the bearer girders. |

| A 300 ton tilting open hearth

furnace. It is electrically

tilted, water cooled, and has an electrical door lifting

mechanism. |

|

|

A Wellman 1,000 ton metal mixer

designed for use in a confined space.

The firm made metal mixers with

capacities of 150 to 1,000 tons. |

| General lifting and

handling equipment: |

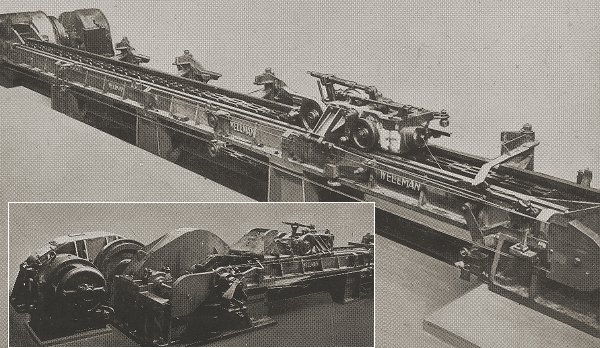

A combined coke pushing, coal levelling, and

door extracting machine.

|

|

|

|

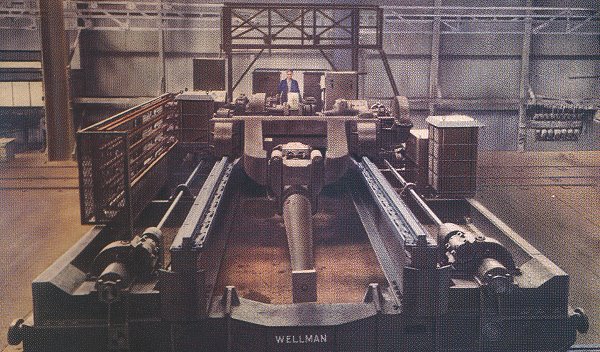

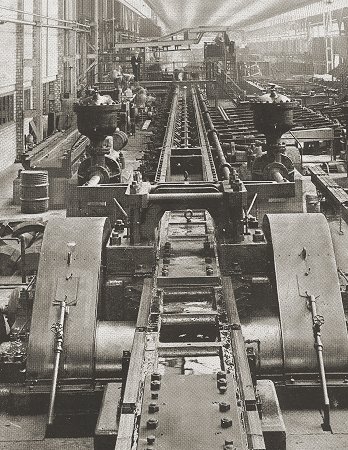

A 1,500 ton

piercing press. |

|

A complete

Wellman seamless tube plant. |

|

A 40 ton variable speed cold draw bench for

tubes.

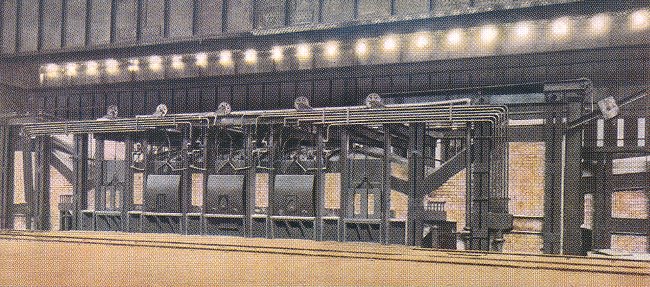

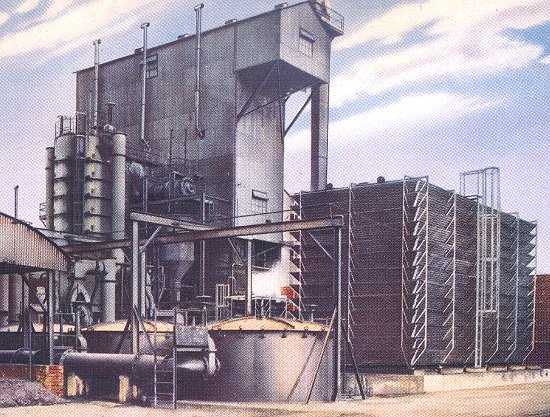

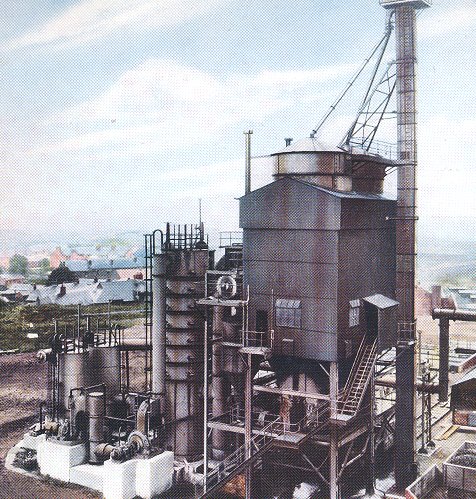

| Wellman-Galusha gas

producers: |

A Wellman-Galusha gas producing plant with

producers and a cleaning plant.

|

|

|

|

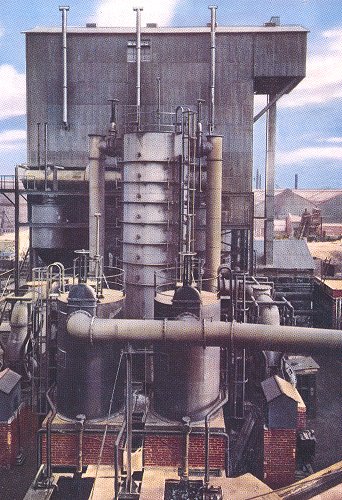

A Wellman-Galusha

gas producing plant. |

|

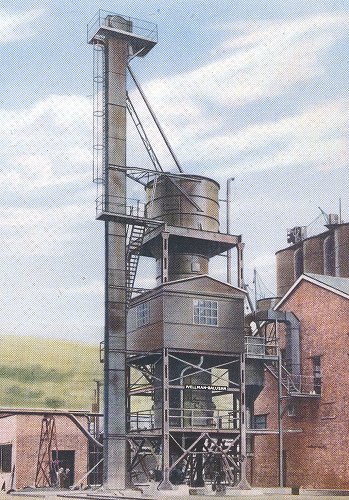

A single

unit for the production of hot gas. |

|

|

Two Wellman-Galusha gas producers

with auxiliary equipment. |

|

Return to

the

previous page |

|