|

The Steel Nut & Joseph Hampton Limited, of

Woden Works, Franchise Street, in Butcroft, was founded in 1851.

For most of its life the company was in Wednesbury, but in April

1966, under the terms of the Local Government Reform Act,

Wednesbury lost its status as a Municipal Borough, as did

Darlaston. The boundary between the towns changed, so that Kings

Hill, Butcroft, and Fallings Heath, joined Darlaston to become

part of Walsall, which is why I have included the company here.

|

|

| The business was founded by 27 years old Joseph

Hampton, who lived in Franchise Street. He had a tool

making business producing a wide range of products

including carpenters' bench screws, copying presses,

flooring cramps, lifting jacks, pipe wrenches, and

ratchet drill braces. In the 1881 census he is listed as

a tool maker employing twelve men, 6 boys, and a woman.

He lived with his wife Nancy and children Arthur and

Sarah. Joseph's eldest son William lived at number 19

Franchise Street with his wife Mary and children

Charles, Sarah, Thomas, Joseph, William, Rueben, and

Samuel. In the census William is described as a

cramp and tool maker, as is his eldest son Charles. It

seems that in 1897 the firm joined forces with The Steel

Nut Company, also based in Franchise Street, to form The

Steel Nut and Joseph Hampton Limited with its 'Woden'

trade mark. During the following year, William's sons

Charles and Joseph left the family business and moved to

Sheffield where they founded a firm called C & J

Hampton, based at Eagle Foundry, Livingston Road,

Sheffield. They initially produced marlin spikes, and

specialised castings, but by 1908 were making a range of

tools including woodworking vices, pipe vices, pipe

cutters, all kinds of cramps, wrenches, and jacks. The

firm became a limited company in 1908, and in 1909

registered the 'Record' trade mark, which became well

known. The two brothers soon fell out and so Joseph

returned to Wednesbury, leaving Charles to run the

business alone. He was soon joined by his two sons

Horace and Charles, and the business went from strength to

strength.

|

|

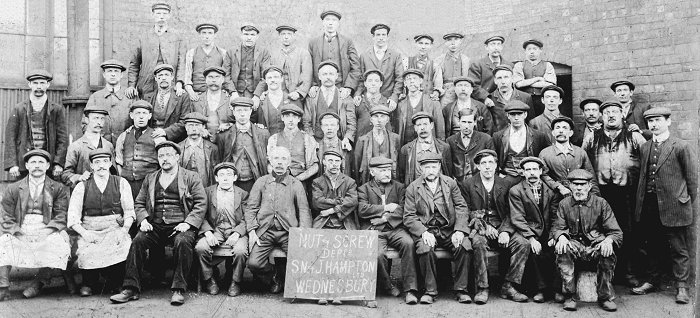

A group of workers, date unknown.

Courtesy of John & Christine Ashmore. |

| Back in Wednesbury a number of patents were taken out

for tools, and it seems that members of the family also

briefly produced cycles at the Hampton and Hampton Cycle

Works in Franchise Street, which is listed in the

circular directory in the 1901 edition of Ryder's

Annual. The factory initially covered a small area

on the northern side of Franchise Street, and slowly grew to

cover a large area of derelict land to the north, which extended

to the end of All Saints Road, off Walsall Road. It was known

locally as “The Woden”. |

|

The factory in 1901. |

By 1914 the nut and bolt department

produced a wide range of nuts, bolts, set screws, studs, and

washers, in bright, and semi-bright finishes,

from one eighth of an inch to three inches in diameter, manufactured from solid steel bar.

They were supplied to all kinds of

industries including shipbuilding, electrical

engineering, vehicle manufacturing, cycle manufacturing,

and met Admiralty specifications.

The

steel department produced bright drawn, and boiled mild bars in

rounds, squares, and hexagons etc., including versions that

complied with Admiralty specifications, suitable for high speed

machining and case hardening.

|

The tool department made a wide

range of joiners' and engineers' tools including vices, cramps,

tube cutters and lifting jacks.

The foundry produced castings in

the best malleable, and grey iron for such applications as ship

building, electrical engineering, mechanical engineering,

vehicle manufacturing, cycle manufacturing, and tramways.

In 1916 the company took out another patent, this

time for improvements to screw nuts.

| View some images

from the 1924 Woden catalogue |

|

|

The factory in 1938. |

An aerial view of the factory from the 1952

tools catalogue.

|

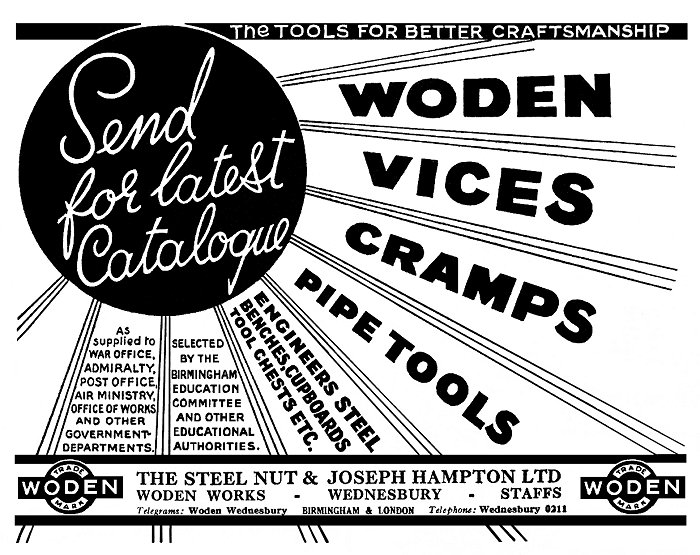

An advert from 1918. |

In 1937 patents were taken out for improvements

relating to vices, and the company had a stand at

the British Industries Fair held at Birmingham.

Products displayed included a wide range of nuts,

bolts, set screws, studs and washers; vices;

engineers', joiners, and pipe tools; sash and 'G'

cramps; bright-drawn, free-cutting steel shafting;

and a range of malleable grey iron and non-ferrous

castings.

It became a public company in 1938, and by that

time also produced bright drawn, free-cutting steel

shafting to Air Ministry and Admiralty specifications,

non ferrous castings, and introduced ebonising

as a protective finish. In 1939 at the outset of war, the company

concentrated on supplying products to the Admiralty,

the Air Ministry, the War Office, the aviation

industry, and produced heavy steel vices for many

manufacturers. After the war production returned to

normal, concentrating on nuts, bolts, and tools.

Parts of the factory were re-built and

modernised, and went into production in 1951. In the

same year a patent for improvements to quick release

vices was taken out, and in 1952 the firm took over

tool and hand plane manufacturer the W. S. Manufacturing

Company, at Quadrant Works, Sheepcote Street,

Birmingham. |

|

The following products are from the company's

1952 catalogue: |

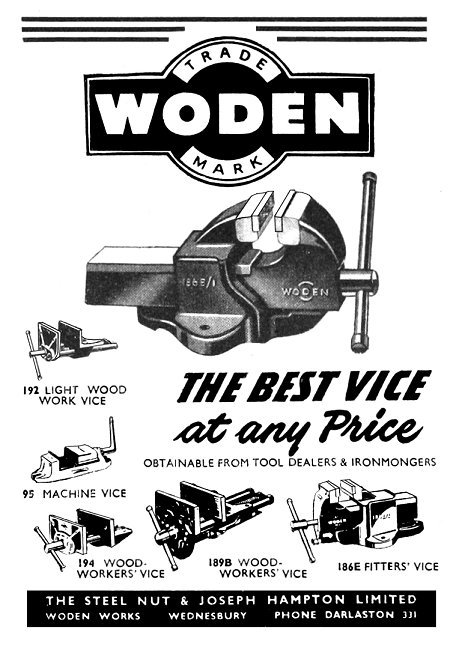

An advert from 1936.

|

An advert from 1953. |

Woden planes appeared on the market in early 1954,

around 18 months after the acquisition of Birmingham

hand plane manufacturer W. S. Manufacturing Company. The

range, including bench planes, rebate planes, and block

planes was very successful, thanks to the growing demand

for hand tools.

In 1957 the company founded Woden

Tools Limited, which took over the manufacture and

distribution of the hand tool part of the business.

The

tools continued to be manufactured at Woden Works, and

many new products were added, and advertised in a

separate Woden Tools catalogue, which included tools

made by other manufacturers.

|

An advert from 1956.

|

A 4 inch 'G' clamp. |

| Hand tool production continued at Woden Works until

early 1961 when Woden Tools Limited was taken over by

Record of Sheffield, which of course had been started by

two members of the Hampton family in 1898 and traded as C & J

Hampton Limited.

Production moved to Sheffield where

hand tools carrying the Woden name were produced until

the early 1970s. |

An advert from 1951. |

|

A letterhead from the mid

1950s. |

|

By 1961 The Steel Nut & Joseph Hampton

Limited had become one of the

larger local employers, employing 850 people. At the time the

nut and bolt department produced a wide range of products,

including the following:

Bright steel hexagon head set screws, or

bolts, with or without hexagon nuts, in lengths of three quarters

of an inch to six inches, and diameters of a quarter of an inch

to one inch.

Bright mild steel hexagon nuts in diameters

of three sixteenths of an inch to three quarters of an inch.

Also available as lock nuts, slotted nuts, or round top castle

nuts.

Bright steel engineers washers in diameters

of three sixteenths of an inch to five eights of an inch.

Bright mild steel studs in Whitworth or

B.S.F. threads, with diameters of three sixteenths of an inch to

one inch, and lengths of one inch to six inches.

|

| Other products included high tensile hexagon head bolts or set

screws in diameters of a quarter of an inch to half an inch, and

lengths of half an inch to four inches. High tensile bolts and set screws were also

available. They were made of medium carbon steel, and supplied

to engineering companies, particularly motor car and heavy

vehicle manufacturers. They were heat treated to withstand a

tensile strain of 45 to 55 tons per square inch.

The steel department produced a

range of bright drawn steel bars, as the raw

material for the nut and bolt department. In the

early 1960s the steel mill was extended, and became

one of the largest up-to-date plants in the country

for the production of bright steel bars.

They were made from

several different steels. Woden "XX" free cutting steel was

suitable for use in electrical fittings, car parts,

cycle parts, wireless and telephone equipment,

sparking plugs, screws, and many repetition parts.

It was available as rounds from three sixteenths of

an inch to three inches in diameter, hexagons

(across flats) from a quarter of an inch to two and

three quarters of an inch, and squares of a quarter

of an inch to two inches.

|

From an early 1960s catalogue. |

|

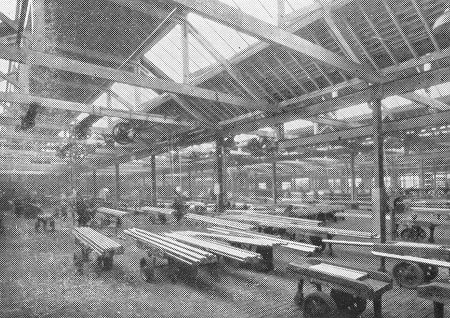

The steel department in the

1960s. |

The sections were available in lengths of 16 feet

(hexagons and squares), and up to 25 feet (rounds).

The same

products were also produced in Woden "HH" steel, a low carbon

mild steel, for general engineering purposes, and Woden "BB"

steel, a medium carbon steel, combining high tensile strength

with good elongation, and excellent machining properties.

The company also produced Woden shafting

steel, a bright drawn rolled bar, produced for overhead line

shafting. Steel bars were also produced to Air Ministry

specifications.

|

|

In 1965 the company was purchased by F. H. Tomkins, Limited. A

Walsall-based buckles and fasteners company.

The following year The Steel Nut & Joseph

Hampton Limited acquired steel stockholders Monkhouse and Brown,

which was sold to Hall Engineering (Dies) of Shrewsbury, in

1969.

In 1981 part of the company’s assets were

sold to Brasway, which was subsequently acquired by Essanbee

Products, a distributor of fasteners.

|

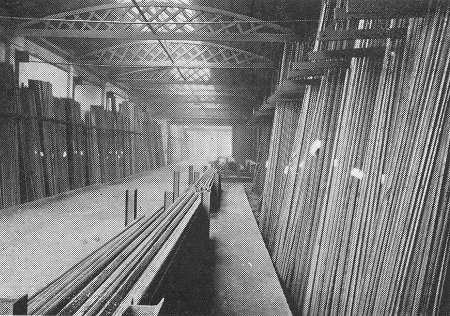

Another view of the steel

department in the 1960s. |

| After acquisition by Brasway, the Woden factory

specialised in a range of seamless steel and

stainless steel tubes. It became known as Brasway

Tube, and in the twelve months to 2nd May, 1992 made

a pre-tax profit of £182,000, but in the first six

months of the following financial year it lost

£157,000 and was put-up for sale. Much of the factory

was acquired by Corus and used as a steel warehouse. |

The factory in the 1960s.

|

The steel store. |

|

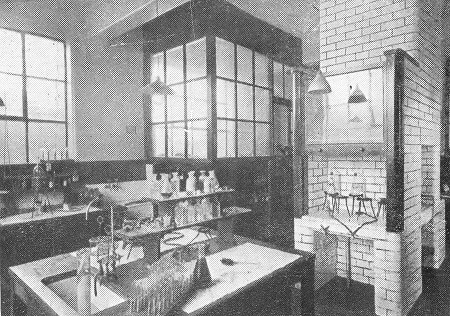

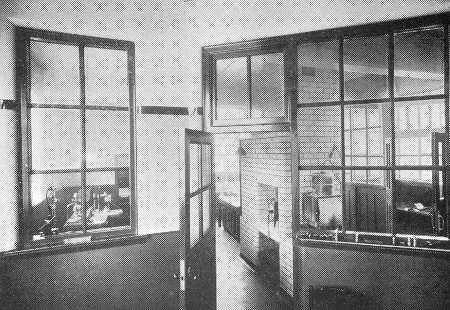

The

laboratory.

|

|

|

Another view of the

laboratory. |

|

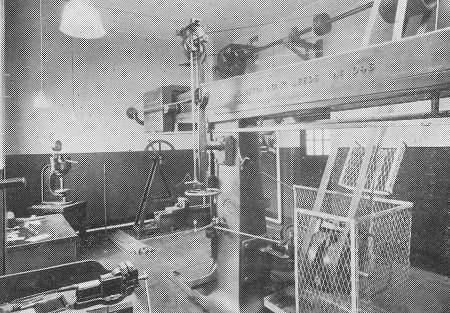

The test

house.

|

|

|

Return to

the

previous page |

|