|

|

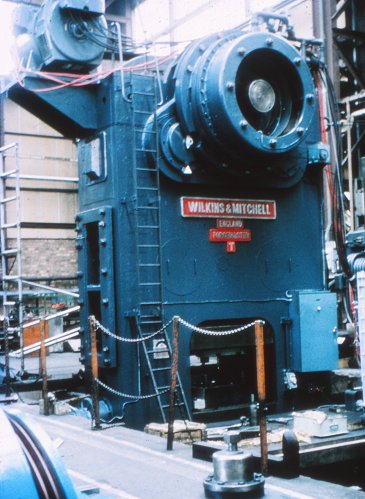

Other Heavy Industries

Although now thought of as an ex-nut &

bolt town, there were many other industries, some becoming

household names. One of Darlaston’s leading engineering

firms, employing over 1,000 people, was Wilkins and Mitchell

Limited, who became a well-known power press manufacturer.

Their presses were exported throughout the world, and many

are still in use today.

The business was founded in 1904 by two

friends, Walter Wilkins and Tom Mitchell who rented a small

factory in Bell Street, called Phoenix Works, from nut and

bolt maker Charles Richards. They began making all kinds of

machines including drilling machines, bolt heading machines,

and milling machines. In 1907 they built their first power

press, a hydraulically operated blanking press for Rubery

Owen, and four years later built their largest press to

date, a massive forming press, also for Rubery Owen. This

press revolutionised vehicle production in the UK because it

cold-pressed vehicle chassis frames, making mass production

possible in this country.

Because the machine was so successful,

others followed, and the company produced large numbers of

power presses, some of immense size. In 1910 the company

moved to Darlaston Green Works, and renamed it Pheonix Works

after their former factory. By 1914 the firm employed

between 60 and 70 people and continued to produce a wide

range of machinery, some of which was especially designed

for railway wagon and carriage companies

|

|

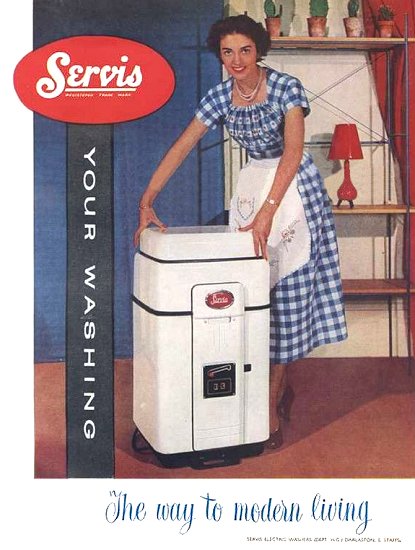

In his home at The Hollies, on the side

of Church Hill, Wednesbury, Walter Wilkins had a small experimental workshop

where he could work on new ideas and designs. In about 1926

he began thinking about building washing machines, and in

1929 founded Servis Limited in order to manufacture them.

Servis washing machines were a great success, and like the

power presses were sold at home and abroad.

Presses from 100 tons to 6,000 tons

were built at the Darlaston factory, and a modern London

office opened in Park Lane, where a display of Servis

washing machines could be seen. The premises also housed the

power press export section. The overseas market was

extremely important to the company.

By the early 1950s space was in short

supply at Phoenix Works and so a second factory was opened

in Darlaston Road, King’s Hill to produce washing machine

components. A few years later a large piece of land was

purchased at King’s Hill next to the existing factory, to

extend the factory, build a new office block, and

concentrate washing machine production on the site. A little

later another successful product, the Servis ‘Super Twin’

was launched. |

|

Extensions were added to the power

press factory, and single, and double action presses were

produced for a wide range of industries, including the motor

industry, the forging industry, the aircraft industry, and

the domestic appliance industry.

By the 1960s thousands of Servis washing machines were made each week, and a

subsidiary company called Wilkins Servis was set up to

manufacture washing machines in Australia.

In 1982 the UK manufacturing group,

Verson International, acquired Wilkins and Mitchell, and

sales continued to grow. The group built a new, larger

factory on a 15 acre site in Willenhall Road, formerly

occupied by Wellman Cranes. The new factory costing £6

million opened on 28th November, 1990 and the company’s name

was changed to Verson Wilkins. By this time the company had

come to rely on orders from UK vehicle manufacturers, but

with that industry in decline, orders fell, and the

Darlaston workforce was greatly reduced.

Due to still

declining orders, the factory closed on 2nd April, 1999, with

the loss of 64 jobs. The Servis factory survived until

October 2008, but has since been demolished.

|

A hot forging machine. |

|

Garringtons

Another of Darlaston's once-important

factories was Garringtons, based at Albert Works in

Willenhall Road. The large forging works was once a local

landmark, with a large workforce. The firm was founded by

John Garrington who started a small stamping business at

Phoenix Works, Catherine's Cross, in 1830, to produce forged

components for the gun trade. By 1851 he also produced nuts

& bolts and bed screws.

In 1912 Albert Works was acquired by

nut and bolt manufacturer F.W. Cotterill, and seven years

later became part of G.K.N. In the late 1930s the factory

was greatly extended, and drop forgings were produced for

aircraft, ships, locomotives, railway construction,

vehicles, and machine tools. Garringtons also specialised in

heat treatment. In the 1940s over 100,000 tons of forgings

were produced annually on the site.

In 1946 Garringtons acquired Deritend

Stamping Limited of Newton Works, Bromsgrove, and also

specialised in a wide range of hand tools. The factory

closed in the recession during the 1980s.

Rubery

Owen

Another once-well known manufacturer

was Rubery Owen based at Victoria Ironworks in Booth Street,

established in 1884 by John Tunner Rubery and his two

brothers. Nine years later the two brothers left, and John

was joined by Alfred Ernest Owen, an engineer from Wrexham.

In 1903 the firm became Rubery, Owen & Company and greatly

expanded the product range to produce structural steelwork,

motor car and aircraft components, pressings and

fabrications, agricultural products, propane gas cylinders,

and nuts and bolts.

In 1910 John Tunner Rubery resigned

from the partnership, and by 1912 the works had been divided

into five departments: Aviation, Engineering, Fencing, Motor

Frames, and Roofing. On April 14th, 1920 the firm became

Rubery, Owen & Company Limited, and a Metal Aircraft

Department, and a Structural Department were formed.

Expansion continued with the opening of

the Armour Plate Department, the purchase of Easiclene

Porcelain-Enamel (1938) Limited, the formation of the

Airframe Department, and the purchase of a hydraulics

company in Warrington, that became known as Rubery Owen

Conveyancer Limited.

The company’s many products included

pressings, fabrications, general aircraft components,

precision assemblies for aircraft, gas cylinders, nuts,

bolts, studs, and motor vehicle components, such as chassis,

axles, wheels, fuel tanks, and discs. Steel structures were

designed and made for all types of single and multi-storey

buildings, and the company's Structural Department was

responsible for a number of well-known buildings including

the London Passenger Transport Offices at Westminster, the

Palace Court Hotel, Bournemouth, Rootes Securities building,

Speke aircraft factory, and the Castle Bromwich aircraft

works. Local structures include the steel frame for

Wolverhampton's Civic Hall, the old South Bank Stand at

Molineux football ground, and Birmingham Tramways and

Omnibus Department's bus garage. The company also produced

pre-fabricated houses for local authorities.

Rubery Owen became one of the major

employers in the area, employing around 14,000 people by the

1960s. Unfortunately things started to go wrong during the

recession in the late 1970s. In June 1979 the company shed

400 employees at Darlaston, and 950 more in 1981. Sadly

things didn’t improve, and the Darlaston factory closed in

the same year.

|

An advert from 1931.

|

E. C. &

J. Keay Limited

Another well known company, E. C. & J.

Keay Limited was founded in 1879 at New Street, Birmingham.

They were builders and ironmongers. In 1884 they moved to

Cyclops Works, West Bromwich and began to manufacture

fencing, fittings, and steel fabrications.

In 1887 the company moved to "Bridge

Yard", James Bridge where they produced many products and

specialised in structural steelwork for all types of

buildings, such as schools, hospitals, factories, offices,

and warehouses. They also built bridges, hoppers, bunkers,

riveted platework, welded fabrications, and railway

signalling equipment.

In 1957 they became part of the Hingley

Group and were absorbed into F.H. Lloyds in 1960. Sadly they

were another victim of the 1980s’ recession. The F.H. Lloyd

group collapsed in 1982.

|

An advert from 1963.

|

Samuel Platt Limited

Samuel Platt Limited was based at Kings Hill Foundry, and

produced a wide range of products including machinery for

tube making, machines for nut and bolt making, drop hammers, stripping

presses, reeling and straightening machines, stamping

machines, and drop hammers. Other products included lathe

chucks, pulleys, mill gearing, shafting, shaft fittings, and

pressings. |

|

|

|

|

|

Return to

Nuts & Bolts |

|

Return to

contents |

|

Proceed to

Lighter Industries |

|