|

BSR was a household name in

the 1960s, 1970s and 1980s when vinyl records

were very popular and almost every household

possessed a gramophone. Tape recorders also

became popular in the 1960s, when many people

owned a BSR tape deck.

The business was started by

Daniel McDonald who was born in Fort William,

where his father ran the successful McDonald

Brothers grocery store. After attending Glasgow

University, Daniel McDonald got a job at B.T.H.

in Rugby, where he was involved in the design of

audio amplifiers for cinema projectors. He moved

to the West Midlands, when he was transferred to

the B.T.H. factory in Cakemore Road, Blackheath.

He soon became disillusioned with B.T.H. and left in

1930, determined to start his own business.

In Blackheath he lodged at

the home of Ben and Sadie Shephard in Highfield

Road and formed a relationship with their

daughter, Winifred, who worked in Oldbury Post

Office. They were later engaged and married in

1932. The Shephards also had a son, Percy, who

started working on small projects with Daniel,

such as audio amplifiers.

Daniel rented a small

workshop near his home, where bellows for local

nail manufacturers had been made. It was a brick

building with around 400 feet of floor space and so

was ideal for Daniel’s needs. He began making

audio amplifiers and radios, to order, and soon

got the contract to build a 120 watt public

address system for Blackburn greyhound stadium.

He also manufactured mains transformers and

audio output transformers and in January, 1932,

began to use the BSR name (Birmingham Sound

Reproducers). In May he took-on his

first employee, Nancy Rotham who looked after

the bookkeeping. In June, Percy Shephard left

his job as a toolmaker at Lench’s and joined

Daniel in the business.

In January 1933 the

business moved to part of a joinery yard in

Claremont Street, Old Hill, where there was a two

storey building with a floor area of 5,000

square feet. The first product made there was the

‘Ampligram’, a record player into which a

microphone could be plugged, so that it could

also be used as a public address system. Towards

the end of the year, BSR was also producing a

five valve radio and loudspeakers. In 1934 the

company launched the VS8 radiogram, followed in 1935 by

a range of audio amplifiers, turntables,

loudspeakers, microphones, mains transformers,

audio driver and output transformers and audio

signal generators.

|

|

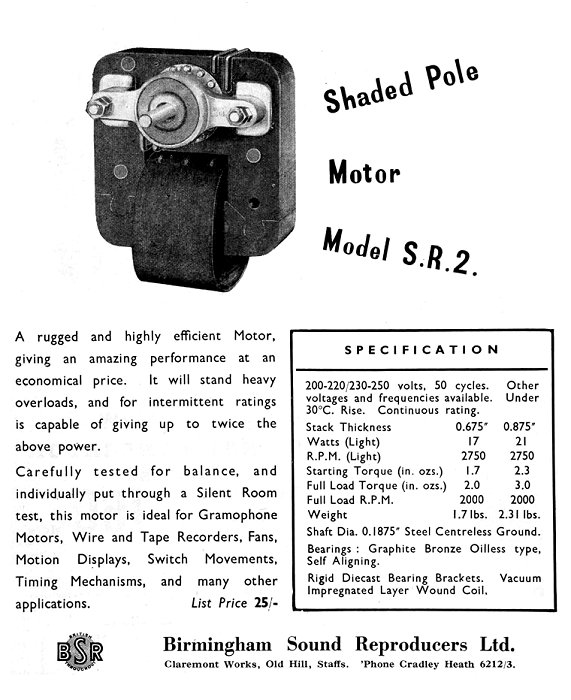

An advert from 1949. |

|

Product development

continued and more employees were taken on. An

audiometer to test people’s hearing was launched

in 1936 and in 1937 a cardio tachometer was

produced to diagnose heart disease. Around this

time, Daniel enrolled on a medical course at

Birmingham Medical School to increase his

medical knowledge.

During the Second World War

the company became involved in the design and

production of military equipment, including a

device to set off acoustic mines, an underwater

submarine detector and aerial trimmers for RAF

communication equipment. At the same time the

production of the BSR audio products continued

and the firm took-on a lot of extra staff. Some

of the government orders continued until the

early 1950s

In 1947, BSR developed a

shaded pole motor which would become an

essential component in future record and tape

decks. The firm also developed a portable disc

recording outfit, the DR66, the company’s first

venture into sound recording. BSR also operated

a portable recording studio, built into an

Austin van. Other new products at the end of the

1940s included the ‘Telemaster’ intercom set and

a loudspeaker and amplifier for use in police

cars.

In 1949 the company began

producing turntable units, initially for Decca,

but they soon appeared carrying the BSR name.

They were extremely successful and because of

the high volume of sales, the business had to

expand. The Board of Trade declined to let them

build a new factory in the West Midlands and so

alternative locations were examined. In the end

a new factory was built in Blighs Lane,

Londonderry.

|

|

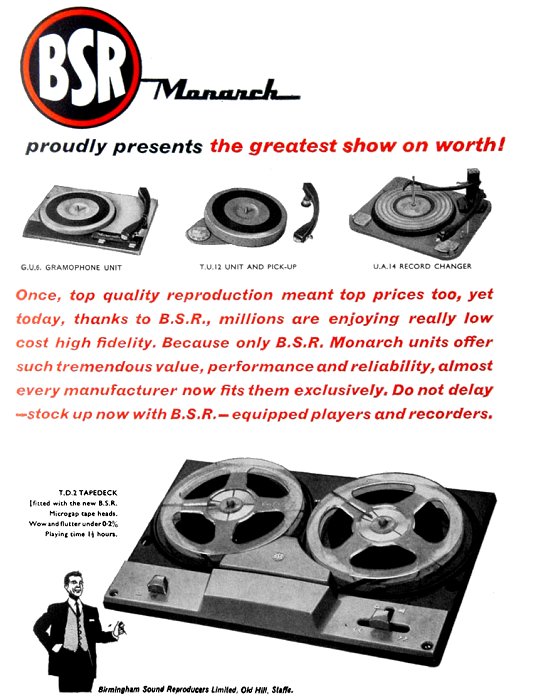

A BSR Monarch

autochanger. |

|

In 1951, a new single

storey building was added to the Claremont

Street site, to be used for the production of

record decks. At this time, BSR developed the

‘Monarch’ automatic record changer that could

handle seven inch, 10 inch, and 12 inch records

automatically in any order. One of the most

popular makes of portable record players at the

time was ‘Dansette’, many of which used BSR

turntables.

By 1953 the existing

factories at Old Hill and Londonderry were

working close to full capacity, so further

expansion was essential in order to keep up with

the growing demand. A new factory was opened at

Drumaho in Ireland, employing around 150 women

and girls. At the same time the Board of Trade

gave permission for the building of a new

factory in the Black Country and so land was

acquired in Powke Lane, Old Hill, where ‘Monarch

Works’ was built. The new factory opened in 1954

and machinery and around 120 members of staff

moved there from Claremont Street, along with

150 new employees. In the same year another

factory opened in Australia, employing around

120 people.

In 1959 BSR became a public

limited company, but all was not well with

production. It was discovered that a large

number of scrap products were piling up inside

the warehouses and so a shake-up of production

methods was essential. All of the offending

members in the management team were dismissed on

the spot, which had a devastating impact on the

workforce. Two hundred members of the workforce

of around one thousand were made redundant and

it took about six months to sort out the scrap

products and repair and save as much as

possible.

|

|

An advert from 1961. |

|

While this was happening,

orders still kept arriving, including five tons

of record changers for an American buyer. At

this time manufacturing centred on the

Londonderry factory.

Expansion continued with

the purchase of a piece of land at Wollaston,

Stourbridge, originally known as Wollaston Mill.

A 200,000 square feet factory was built on the

site to be used for the manufacture of

refrigerators and tape decks. The company

had also hoped to produce washing machines, but

both the washing machine and refrigerator plans

were cancelled.

In 1965 the company

launched the UA50 or ‘Minichanger’ portable

record player which was extremely successful.

Operations in Londonderry were blighted with

stoppages and walkouts by an increasingly

militant workforce, leading to a lot of

disruption to production. This couldn’t be

tolerated and so in February 1967 the factory

closed, putting the workforce of 2,000 out of a

job. Much of the machinery and production was

transferred to Old Hill, as were some of the

staff. Some production was transferred to a new

factory at East Kilbride that had opened on the

1st April, 1964.

Higher quality record

players soon followed including the UA70

launched in 1966. In 1969 industrial unrest was

causing problems at East Kilbride which

escalated into a strike lasting 16 weeks. The

McDonald family became disillusioned with such

problems and sold their shares, which raised

£16.25 million. John N. Ferguson took over as

Chairman and sales continued to grow. In 1971 BSR acquired Bulpitts Limited, manufacturers of

Swan Brand electric kettles and ran a

recruitment drive to attract more employees.

The site at Stourbridge was extended in 1972

when 1,000 new jobs were on offer. The firm also

launched an 8 track tape player called the TD8S.

New transcription quality

turntables were introduced and BSR acquired

Goblin Limited, makers of vacuum cleaners. BSR (Housewares) Limited was formed to oversee

the electric kettle and vacuum cleaner part of

the business. Although Daniel McDonald had left

the business, he reappeared when he opened a

company in Wollaston called ‘Glenburn’, that

manufactured high quality turntables in direct

opposition to BSR. Glenburn was very successful

and so BSR had no alternative but to attempt to

take over Glenburn. After lengthy discussions a

buy-out was agreed, which cost BSR £4 million.

|

|

A BSR P128 turntable. |

|

In 1975, work began on a

new factory in Garratts Lane, Old Hill, covering

370,000 square feet. In March 1976 the company

launched its most innovative turntable, the ADC Accutrac with direct drive and electronic track

selection. Expansion continued in 1977 with the

acquisition of holloware manufacturer, Judge

International.

The last years

There was much industrial

unrest in 1978 and far eastern companies began

to take a great interest in British

manufacturing. The strengthening value of

the pound against the dollar had a great impact

because America was the company’s biggest

market, so less money was earned. The sale of

electronic goods from the far east had a great

impact, particularly on BSR’s sales to America,

which greatly reduced. As orders fell, short

time working was introduced, followed by a four

day week, a three day week and voluntary

redundancies. In June 1980 the company was

forced to announce a further 2,300 redundancies

and the closure of the Waterfall Lane site at

Cradley Heath.

After loosing £17.8

million, the company attempted to diversify by

acquiring Capetronic, a manufacturer of computer

peripherals, monitors and modems in Taiwan and

Chicago and also Astec International, a Hong

Kong based manufacturer of power supplies,

mainly for computers.

Problems with

industrial unrest continued. On the 3rd

June, 1981, one hundred toolroom workers at

Stourbridge and Old Hill went on strike,

demanding a 5 percent pay rise. Two days

later they turned off the power at the local

factories and 4,000 workers had to be sent

home. A week later the company offered a pay

rise of 2 percent, which was rejected and

the strike continued. Within a week the

company accepted the striker's demands,

offering a 5 percent pay rise, back dated to

the 1st June, with 2 days extra annual

holiday and a promise of no more

redundancies until at least October of that

year.

By late October the

three day working week returned and there

were 1,600 redundancies. The future looked

bleak and so Astec International took

overall control of the business.

Things didn't improve and so in February

1983 there were 500 more redundancies and it

was announced that the Powke Lane factory

would soon close, with a loss of 1,100 jobs.

Production was mostly transferred to

Stourbridge and office and administration

staff moved to Garratts Lane.

There were now less

than 1,400 employees. Over the previous five

years the firm had lost 10,000 employees and

things looked worse than ever. Headquarters

was transferred to Hong Kong and the

company's name was changed to BSR

International plc. Locally 150 jobs were

created for the assembly of power supplies,

many for BBC computers. |

|

A BSR BDS80 turntable. |

|

The production of

turntables ended on the 25th June, 1984, but

began again two years later when Schneider in

Germany ordered around 60,000 linear turntables.

Production however was soon handed to a Chinese

company. In June 1989, BSR International plc

became Astec (BSR) plc and the BSR name was sold

to DAK, a manufacturer based in Los Angeles. The

company ceased to trade and the Wollaston site

was sold to Sunrise Medical Equipment. It was a

sad end to a once successful British Company

that had been defeated by cheap imports from the

far east.

|

|

Return to the

previous page |

|