| F. H. Lloyd & Company

Limited - The First Sixty Years The Darlaston based Bills & Mills

steelworks at The Green were purchased by the Lloyd

family for a quarter of a million pounds when its

owner Samuel Mills retired. |

|

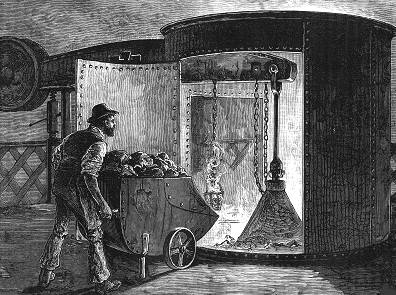

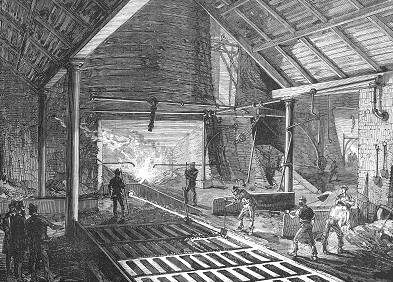

Charging a blast furnace. |

Mr. Sampson Lloyd of Wassel Grove, Stourbridge

became company Chairman and Mr. Francis Henry Lloyd, Managing

Director.

The name was changed to the Darlaston Iron & Steel

Company and rapidly expanded.

The number of puddling furnaces grew to 43 with 17

reheating furnaces, 8 rolling mills, a drawing-out

forge, 63 steam engines, including three 70hp.

blast engines for the blast furnaces. Rails were

laid to all parts of the works. |

| The company's collieries and mines, mining a 12

yards thick seam, covered 850 acres, 350 of which were

freehold and 500 leasehold. Some of the seams produced

what was called "Brooch" coal, and others "Heathen" coal.

The company survived until the depression in the 1880's.

After the closure, Francis Henry Lloyd brought a disused

timber yard and brickworks at James Bridge, and established a small

foundry which eventually became F. H. Lloyd's James

Bridge Steel Works. The original

shareholders were: engineer, John William Hall junior,

of Bilston; solicitor, John William Hall, of Bilston;

engineer, John Hemming of Wednesbury; traveller, Alfred

Essington Hemming of Wolverhampton; engineer, Francis

Henry Lloyd of Wood Green, Wednesbury; manufacturer,

Sampson Z. Lloyd of Arley Hall, Stourport, (brother of

F. H. Lloyd); banker, George Braithwaite Lloyd of

Birmingham; and surgeon, Samuel Ashley Smith of Bilston.

|

|

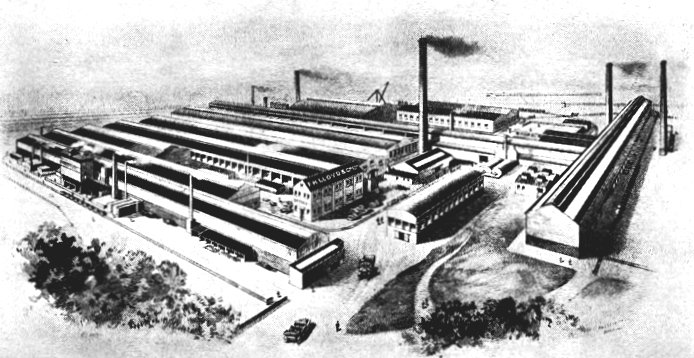

An early impression of James

Bridge Steel Works, from a long service award.

Courtesy of Wendy Marston. |

|

Soon after its opening in 1879, the factory consisted

of a steel foundry, three forges and a fitting shop.

Steel was melted and refined in a small gas-fired open

hearth furnace. A tilting machine was added for

drawing out steel and for making steel forgings. By 1900

the forges had been replaced by a machine shop and an

improved fitting shop.

|

Read an

illustrated article about

F. H. Lloyd & Co. Ltd. from the

"South Staffordshire Institutions and Trades

Illustrated" of about 1900. |

| The business was extremely successful and a

foundry for producing small castings was

added in 1909. By 1912 the factory produced

2,000 tons of steel castings each year, and

during the 1914-18 war, production

concentrated on cast steel shells. |

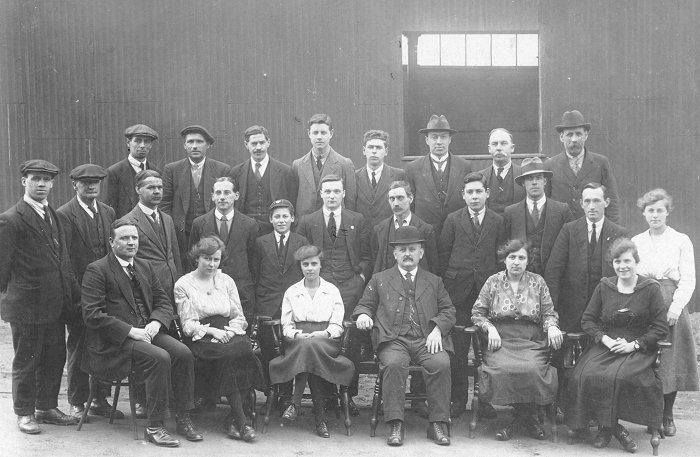

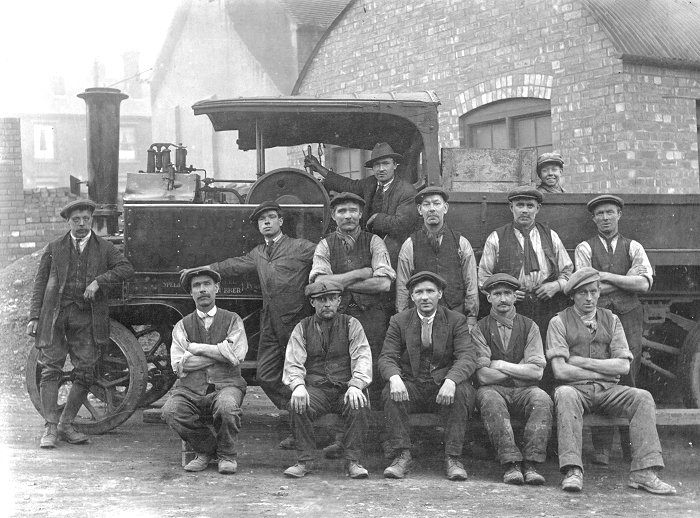

Some of the staff

during World War One: back row left to

right: number 3- Billy Fisher, number 4-

M. H. Dale, number 6- Joe Davies, number

8- Jack Chorley. Middle row left to

right: number 1- Arthur Crawford,

number 2- ? Blakesly, number 3-

Billy Dudley, number 6- Teddy Walker,

number 7- Harry Sanders, number

10-Walter Clifford. Front row left to

right: number 1- ? Griffith, number 4-

Mr. Clifford senior, number 5- Lizzie

Long (Horace Morgan's wife). Courtesy of

Wendy Marston. |

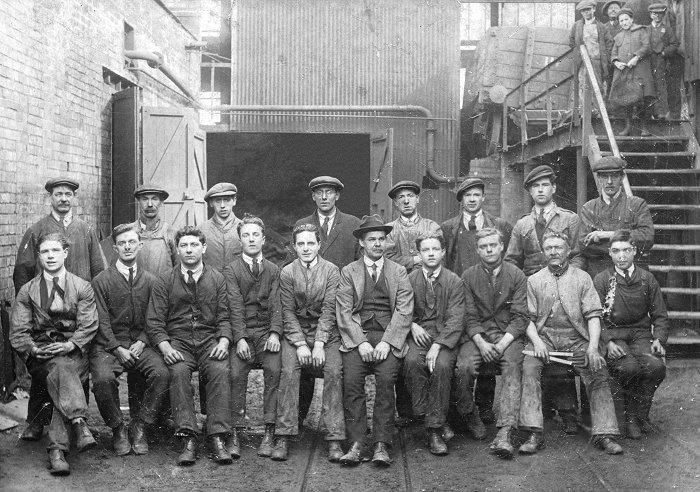

Another group of

staff from around World War One. Front

row left to right: number 2- Jack

Davies, number 3- Harry Parsons, number

6- Billy Dudley. Courtesy of Wendy Marston.

|

Another photo from World War

One. The building in the background on the right is

the old canteen. Wilf Brown is at the controls of

the steam lorry. Courtesy of Wendy Marston.

|

Another group from around the

same time. Middle row left to right: Billy Dudley,

Jack Davies, Harry Parsons. Courtesy of Wendy Marston.

|

|

An advert from 1913. |

Francis

Henry Lloyd (born in 1844) died after a railway accident

in 1916 and was replaced by his son, Daniel Charles

Lloyd, who lived at Tettenhall, Wolverhampton. He would leave home at a

quarter to eight each morning and catch the

tram to Wolverhampton, the train to Wednesbury,

and presumably the tram to James Bridge via

Darlaston. After the return trip each

afternoon, he arrived back

home around 6 p.m.

The senior partner,

John Hemming, died in the early 1920s. After

his death, Daniel Charles Lloyd became

Chairman and Managing Director. Daniel's wife

Hilda was convinced that Francis Henry Lloyd

got leukaemia from standing too close to the new X-ray machine,

bought to detect faults in castings.

Francis

Henry Lloyd also founded the Weldless Steel

Tube Company at Wednesfield, which was taken

over by Tube Investments in about 1927. |

|

An advert from 1916. |

| In 1919 a new heavy foundry was built and output

increased to about 6,000 tons of castings a year. At the

time there were nearly 600 employees. After the

depression of the late 1920s production greatly

increased with over 13,000 tons of steel products being

produced annually.

Their success was no doubt helped by

the excellent management-employee relations that always

prevailed at the works. A training scheme for young men

began at the factory, and by the time the recession had

ended, the firm had a large number of skilled workers. |

Tapping a furnace to produce pig

iron. |

|

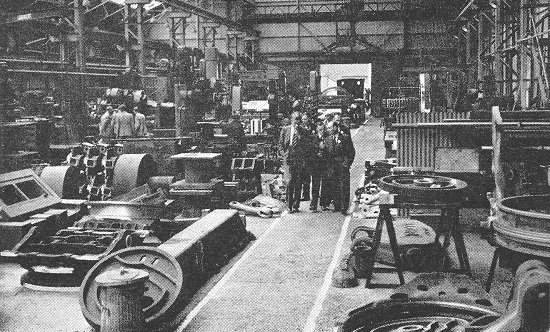

The factory in 1919. From 'The

Steel Casting'. Courtesy of Wendy Marston. |

|

|

|

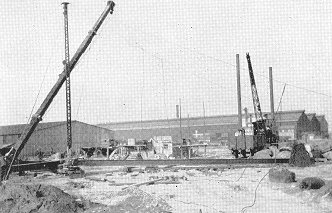

| In 1933

the breaking area where scrap steel and steel

castings could be broken up, was moved to a less

restricted area. The derrick on the left is

being dismantled before being rebuilt at the new

location on the right. |

|

|

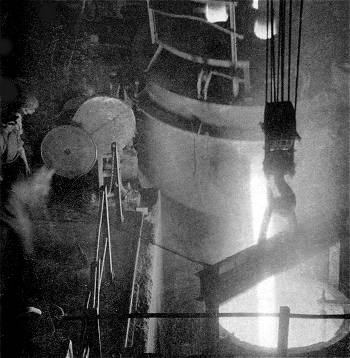

Tapping an electric arc furnace at

F. H. Lloyd.

|

In the early 1930s the company

started to produce heavy castings for mechanical

excavators and earth-moving machines for an engineering

firm in Lincoln.

The company's staff magazine "The

Steel Casting" appeared in 1938, around the same time as

many operations in the factory were reorganised.

Mr. A. B. Lloyd made an exploratory

visit to America to discover how large American

engineering companies were organised. He visited Bucyrus

Erie Company, manufacturers of surface, and underground

mining equipment, including steam shovels, draglines,

hydraulic excavators, and mining trucks. He also talked

to engineering consultants.

|

| On his return to Wednesbury he

carried out a preliminary survey of operations at the

works, and appointed a firm of engineering consultants

to produce a plan to make the factory operate more

efficiently. The consultants began their investigation on April

1st, 1938, which resulted in the formation of a central

production department to take responsibility for the

coordination of production throughout the works.

A

standards department was also created to oversee and

standardise production times. Internal order forms were

redesigned, and a printing machine was installed to

print them.

Before the reorganisation, productive effort was

measured by tonnage produced, which was misleading, due

to the increased use of intricate steel castings with

lighter sections.

Under the new scheme, man hours were taken into

account when considering the efficiency and output of

each department.

The reorganisation ensured that every department was

kept fully employed without congestion, and an improved

standard of service was given to customers. |

The staff magazine. |

|

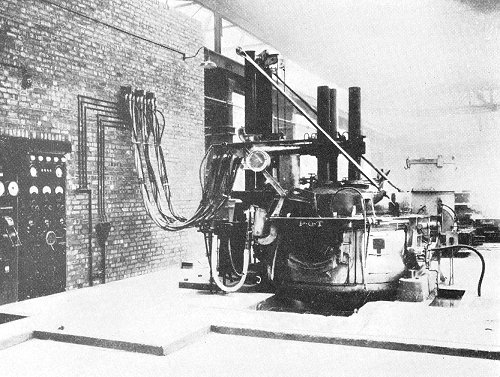

The electric furnace, charging

bucket and control board. |

In 1938 a new electric arc furnace was installed

to increase the steel-making capacity at the works.

In 1914 Mr. D. C. Lloyd acquired the company's

first electric furnace, for experimental purposes. The 5 cwt. furnace proved to be

uneconomical due to high running costs.

By the late 1930s, the advent of the national grid

and cheaper electricity, together with improvements

in furnace design and operation, made an electric furnace a

practicality, and led to the purchase of a direct

arc furnace. |

| The direct arc furnace had a capacity of 4 to 5 tons

and was supplied by Birmingham Electric Furnaces

Limited, which had the manufacturing rights for the

Moore Rapid Lectromelt Furnace, made by the Pittsburgh

Lectromelt Furnace Corporation of America. The

installation went well. Within 14 weeks of the initial

order the furnace was in operation. The furnace was

charged by a swing roof, actuated by a hydraulic ram,

which also swung the electrode gear. The steel scrap

used to charge the furnace was loaded into a bucket

with drop-bottom doors, secured with a hemp rope. |

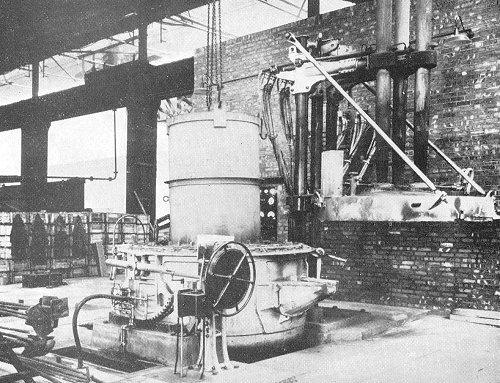

The bucket is swung into position

in readiness for charging. |

|

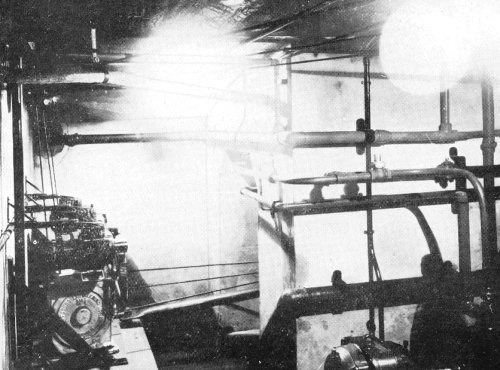

The winch motors controlling the

electrodes. |

After lowering the bucket into the furnace, the rope

quickly burnt away, allowing the scrap to fall. The

whole charging operation only took a few minutes. The

roof, the body of the furnace, the electrode holders,

the doors, and all metal parts exposed to heat were

water-cooled.

The hearth was lined with refractory material to

remove as much sulphur and phosphorus from the charge as

possible. |

| The 7,000 volt supply that fed the furnace sub-station

was stepped down by an oil-filled transformer with a

tapped secondary winding supplying up to 215 volts to

the furnace. The charge was heated by the current

flowing through the graphite electrodes, arcing across

the gap between the electrodes and the charge.

The gap had to be precisely maintained to supply the

correct amount of heat. |

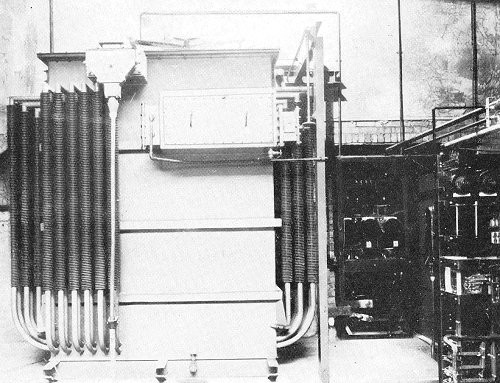

The transformer and automatic

electrode control. |

| This was accomplished by a Westinghouse automatic

regulator which operated each electrode independently

through a winch and motor to lower or raise the

electrodes and maintain a steady operating current. |

|

The machine shop. |

The average time taken from

charging to tapping was about three hours, giving an

output of one ton per hour.

The furnace was mainly used for the

production of carbon steels, but also for the alloy

steels which were being developed at the factory.

|

| In 1938 the company opened Lloyds

(Burton) Limited at Burton on Trent, which would

eventually be the last part of the business to survive. |

|

|

|

Return to

the contents |

|

Proceed to the

early 1930s |

|