The Mechanical and

Electrical Engineering Company (Walsall) Limited

|

|

The company was founded in about 1907 by Henry J. Webb,

an experienced and practical engineer. The premises were

at 62 and 63 Bradford Street, Walsall, and consisted of

a retail shop on the ground floor, with an office,

stockroom, and workshops above. In the shop, all kinds of

electrical items were for sale, ranging from electric

light fittings, electric lamp holders and shades, lamps,

wires, switches, telephones, electric bells, electric

novelties, hand lamps, torches, carbons for arc lamps,

etc. The firm specialised in lighting and power

installations, and stocked all components for the

lighting of country houses. The firm carried out

electrical installations in large or small factories,

and fitted electric lighting to cars and other vehicles.

In later years, all kinds of repairs were made to

electrically powered industrial machines, and power

installations were carried out. Other services included

the rewinding of electric motors, and the building to

order of transformers, geared motors, and variable speed

motors.

By the 1950s the firm had a factory in Rollingmill

Street, Walsall called Robust Works, while still

retaining the Bradford Street premises.

An advert from 1954. |

|

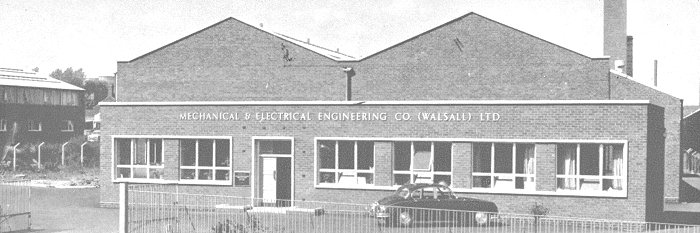

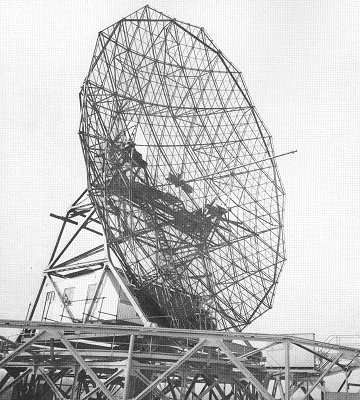

The factory in Rollingmill

Street. From 'The Steel Casting', courtesy of Wendy Marston. |

| The Managing Director Mr.

Francis Webb. From

'The Steel Casting', courtesy of Wendy Marston. |

|

|

General Manager Mr. W. T.

Williams who joined the company in 1913 after

leaving school. From

'The Steel Casting', courtesy of Wendy Marston. |

|

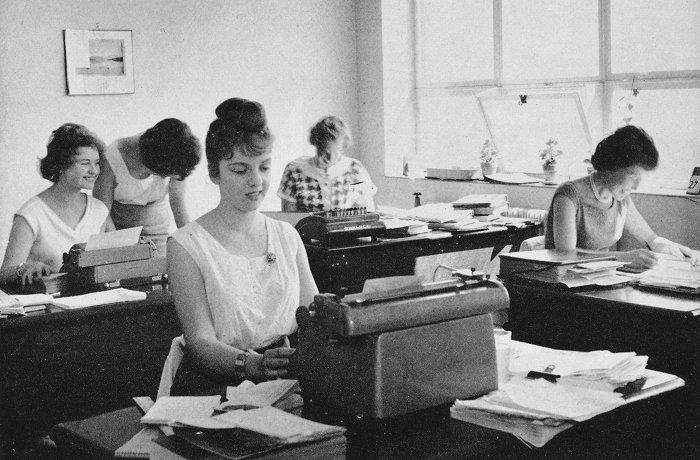

Some of the secretarial staff

in the office. From 'The Steel Casting', courtesy of

Wendy Marston. |

|

An advert from 1976. |

In about 1960 the firm became part of the Lloyd Group

and a new up-to-date factory was built in Rollingmill Street

which included a wide range of equipment to improve the

efficiency of the electrical repair department, and to

speed-up repairs. The new equipment included an

electrically-heated stove with a loading capacity of 400

cubic feet. It had two powerful fans to circulate hot air,

ensuring an even temperature throughout, and accurate

temperature control. It was mainly used to dry windings that

had been impregnated with insulating varnish.

The installation included heavy duty coil winding

machines which had been designed and built in-house, and

could handle the large high frequency coils used for the

melting and heat treatment of metals.

Metal spraying equipment was also installed along with a

heavy duty hydraulic press to deal with the extraction and

fitting of rotor shafts.

|

| The works department had the facilities to repair all

kinds of electrical tools, and a large stockroom for

replacement parts, enabling an almost 'repair while you wait

service' to be carried out. By 1961 the firm employed

over 100 skilled men, some of whom started as apprentices in

the company's training scheme in the Bradford Street

workshops.

There were also contracting and maintenance departments,

and a subsidiary company EMCO Limited that provided a 24

hour maintenance service for all kinds of electrical and

electronic plant throughout the Midlands.

In the early 1960s EMCO carried out the installation and

wiring of the controls for the radar dishes (including the

one in the photograph opposite) at the Royal Radar

Establishment at Defford near Malvern. |

|

|

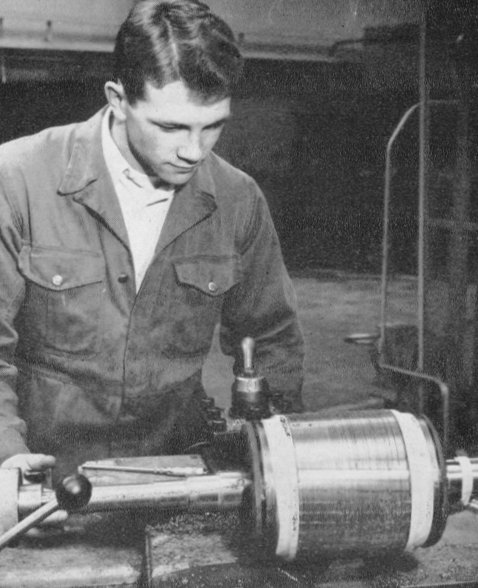

Mr. J. Morrell at work, machining a rotor core in

1961. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

Pat Clift and Alan Rose winding

and connecting rotors. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

Mr. J. Davies, winding an armature

for a small electric motor in 1961. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

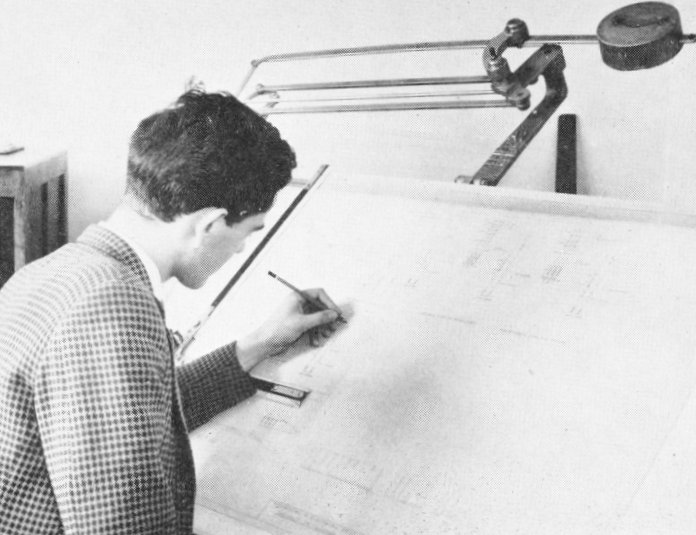

Colin Webb, son of the Managing

Director at work on a drawing board. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

|

|

|

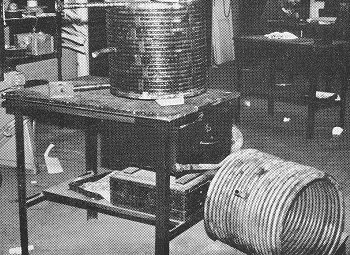

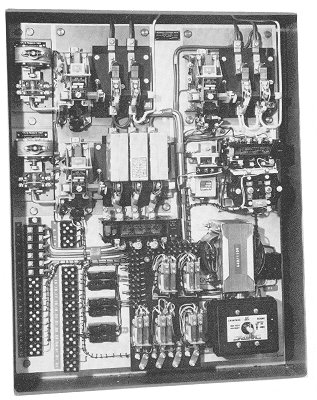

A newly

wound replacement high frequency coil, and the

control panel on one of the automatic machines. |

|

|

|

|

|

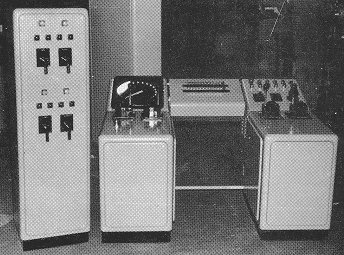

The

maintenance department, and a partly completed motor

rewind. |

|

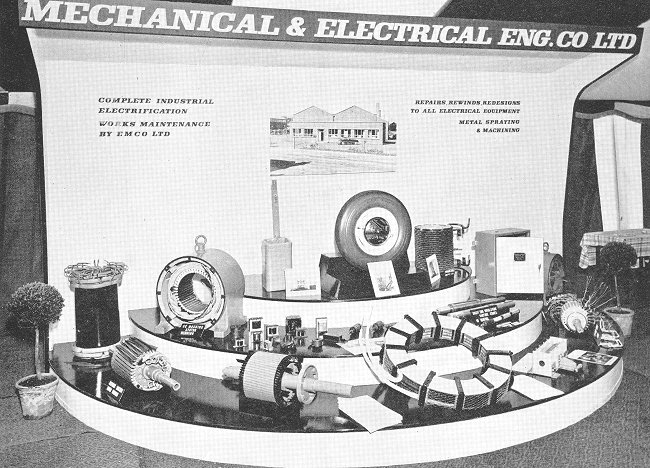

The company's stand at the

exhibition at James Bridge Steelworks to celebrate the

British Steel Foundry Year, in 1962. |

| Some typical motor rewind

jobs: |

|

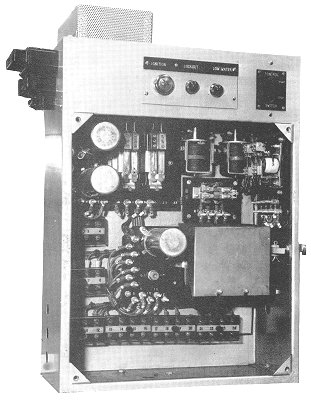

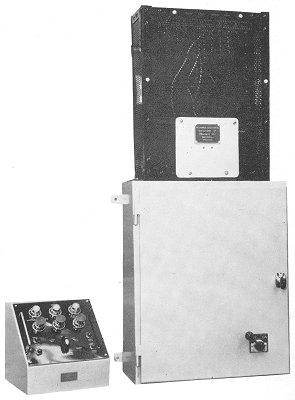

In 1963 the company opened an electronics section to

produce control equipment for a wide range of industrial

applications. The photograph opposite shows a control

panel for train heating boilers which provided

fully-automatic control from the driver's cab. The panels

were fitted to diesel locomotives by Spanner Boilers

Limited.

Other products manufactured by the section included an

electronic timer unit, timing from 0 to 100 seconds, and

temperature control units. |

|

|

|

|

Producing

wiring looms, and wiring small control units. |

|

| All kinds of electrical equipment

was overhauled in the company's workshops, including the

200hp. Sulzer-Haywood Tyler 150,000 gallons per hour

submersible pump opposite. It was used to lift water into a

canal from an underground reservoir, via 170 ft. of 12

inch diameter steel pipes. |

|

|

|

|

|

Examples of

the company's electronic control units. |

|

|

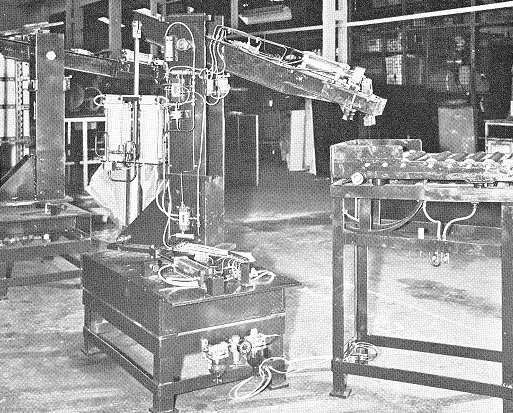

In 1971 the firm completed its

first export order to Yugoslavia.

It was for the 2-billet

pneumatically operated handling arm shown opposite. |

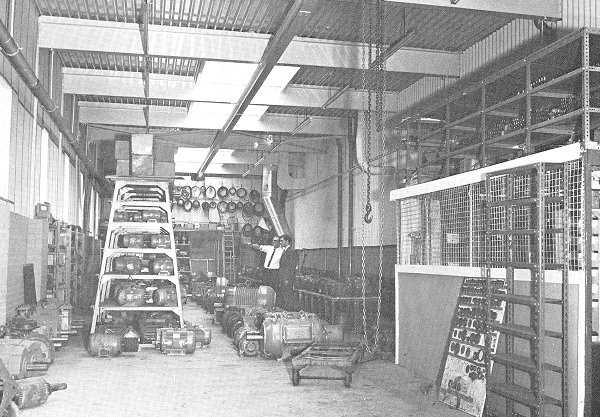

The new 3,600 square feet storage

bay, designed and installed by E. C. & J. Keay in 1971.

Keays also built a new works canteen with vending

facilities. |

|

Return to the

previous page |

|