| Thanks to Arthur Lockwood, the Crown Nail Company

of Wolverhampton will never be forgotten. During the last months

of manufacturing he was a familiar figure in the works,

faithfully recording the disappearing scene. Arthur has kindly

allowed me to include some

of the many paintings and sketches that he did there, which are

now one of the few records of tack manufacturing in the U.K. |

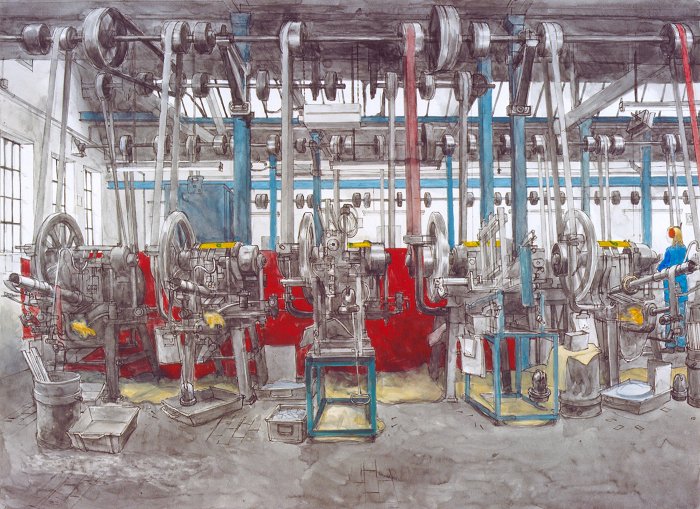

This fine view of the tack shop was painted in

November 2004, about a month before the factory closed. On the

left are two hand-fed large Lloyd tack machines and to

their right are two Lloyd tack machines with autofeeds. The

machine on the far right is another large Lloyd tack machine.

When all of the machines were in operation the noise was

overpowering and the rotating line-shafting, pulleys and belts that

drove the machines was an impressive sight indeed. |

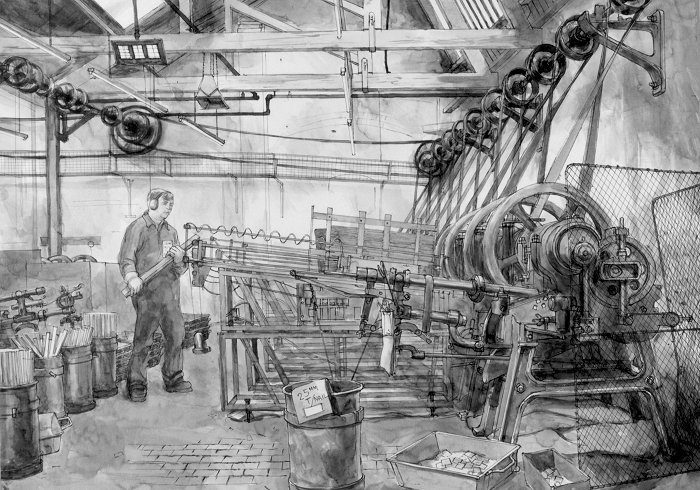

Another view of the tack shop, also from November

2004. The feeder is holding a bundle of steel strips which are

about to be dropped into the magazine on one of the autofeeds.

They are automatically fed into the machines, and tacks and

small nails are cut from them. The two machines on the far right

are large Lloyd tack machines in which the steel strips are

hand-fed, one at a time into the feeding tubes that can be seen

protruding from the front of the machines. |

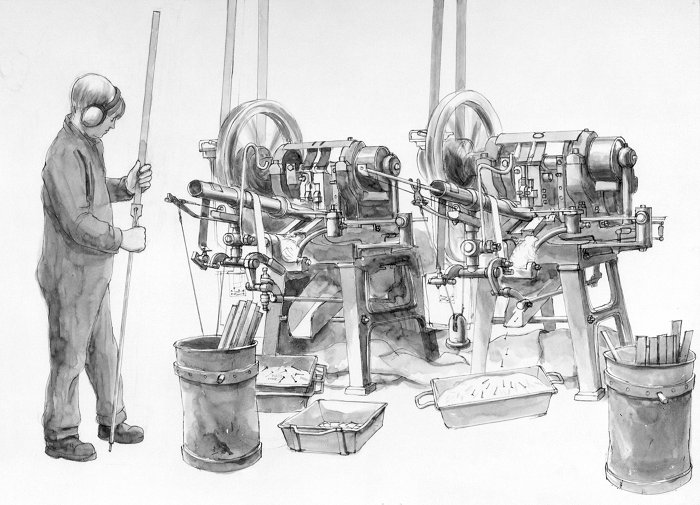

This view, also from November 2004 shows a feeder

loading a steel strip into a feed rod. This is inserted into the

feeding tube where it is rotated through 180 degrees between

each cut. The feeder is about to insert the strip into the

machine on the left. The machine on the right already has a

feed rod inserted, the end of which can be seen

protruding from the feeding tube. The hanging weight below the

tube is attached to the end of the feed rod by a leather and

slowly pulls the steel strip into the machine. |

|

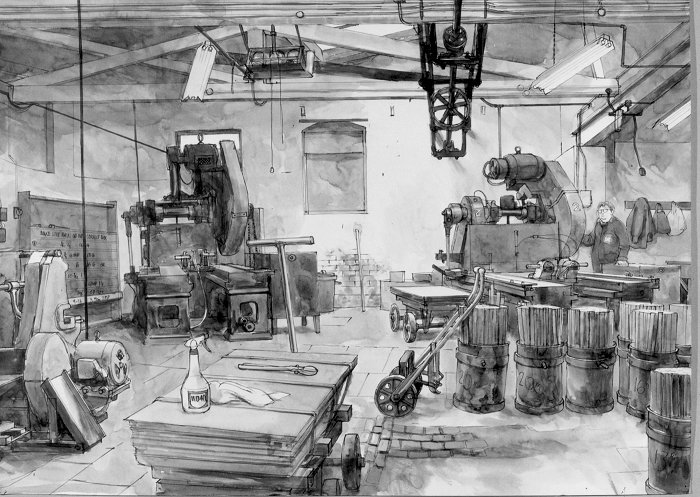

This is a view of the shearing shop, again from

November 2004. Kevin Farrington can be seen operating one of the

Rhodes shearing machines that cut the steel strips from a large

piece of sheet steel. Each time a strip was cut, the room

vibrated and a deep thumping noise came from the machine that

could be heard throughout the surrounding area. This was

followed by a tinkling sound as the freshly cut strip fell into

a steel collecting box.

When cut, the steel strips were loaded into kegs to be taken

into the tack shop as required. Some of the loaded kegs can be

seen in the foreground. |

Another view of the shearing shop showing both of

the Rhodes shearing machines. The trolley in the foreground is

loaded with the sheets of steel that are about to be cut into

strips. Loaded kegs can be seen on the right and Kevin

Farrington is standing in the background by the side of a

shearing machine. |

This is a view of the strip store that was drawn

in January 2005 after the end of production. The piles of empty

kegs are awaiting their fate. Within a few days everything was

cleared and most of it was sold for scrap. The overhead

line-shafting was cut down and the building quickly emptied to

become a silent and eerie place. A great contrast to what it was

like a few months before. |

|

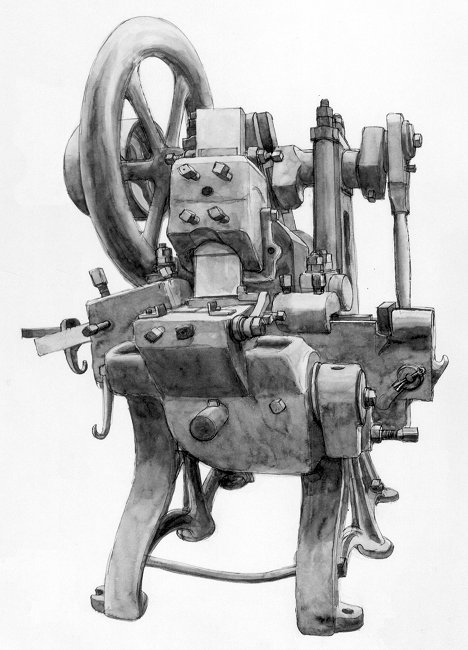

This lovely sketch from January 2005 shows an old

nail machine from the 1870s. Thankfully the machine has survived

thanks to the Black Country Living Museum where it is at present

in store. |

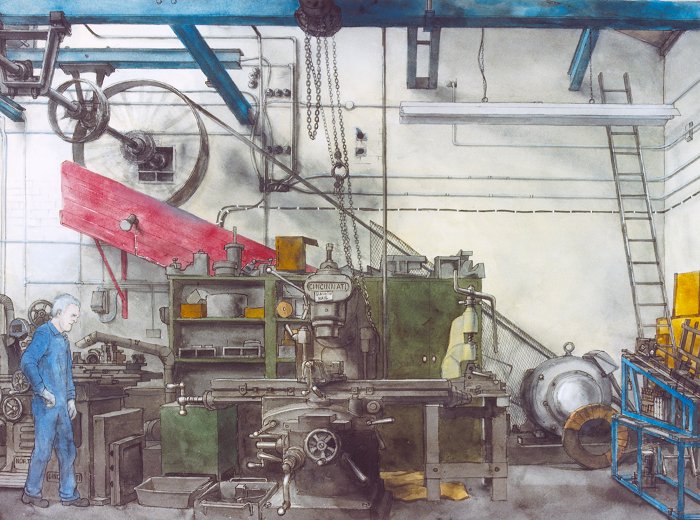

This view shows a corner of the fitting shop in

December 2004 just before the works closed. On the right is the

50hp. electric motor that drives the overhead line shafting.

It's amazing to think that the whole of the tack shop was driven

from just this motor.

On the left is Jim Hughes and in the centre is a Cincinnati

milling machine which luckily has survived. |

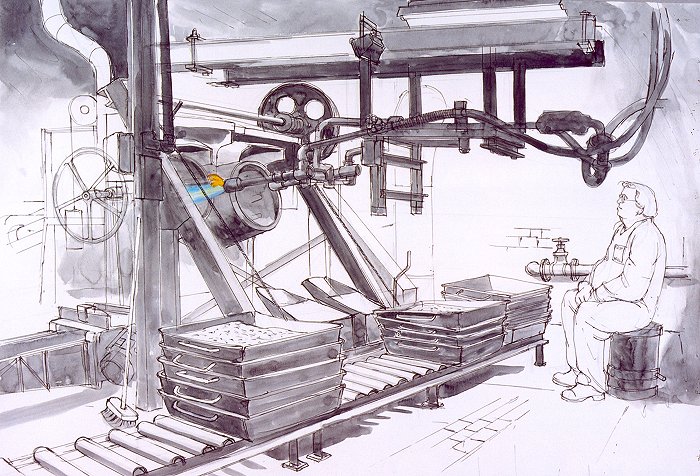

The bluing machine in operation in November 2004.

Kevin Farrington is seen in charge of the bluing machine that

blued the tacks after manufacture.This was the last tack bluing

machine in the country and was designed in-house. When in

operation it was a very impressive sight with long bright flames

licking the rotating drums containing the tacks. It was very sad

to see such an impressive machine being cut-up for scrap. |

|

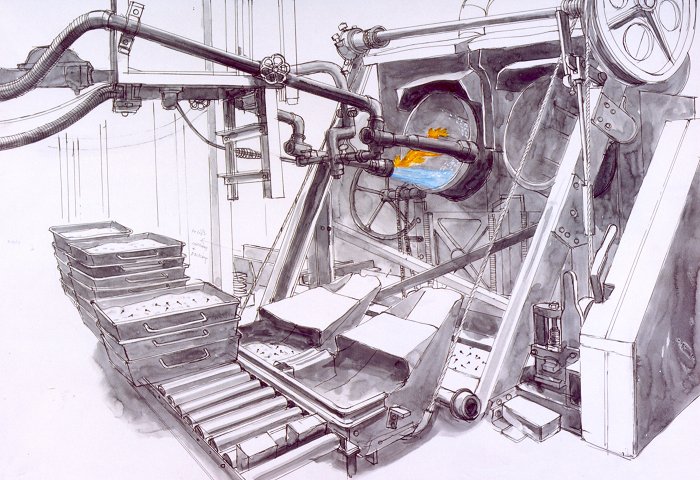

Another view of the bluing machine. |

Last but not least is a view of the steel shop

from December 2004, just before production ended. The machine on

the right is the gauging machine that accurately measured the

thickness of the sheet steel before shearing. The steel strips

had to be the correct thickness in order to ensure that the

finished products were of the correct size, quality and

specification. The painting shows one of the last bundles of

steel that was gauged before being used. |

|

Return to

the

previous page |

|