|

Neptune Forge, Chain, Anchor, and Engine Works |

|

The business was founded in 1862 by

Joseph Wright and Thomas

Tinsley, a well known Dudley nail factor. Joseph Wright

was born in Dudley on the 7th October, 1826. His father,

James Wright, was a blacksmith in Dudley. Joseph began

his working life helping his father in his business and

as an apprentice at Woodside Iron Works at Dudley. After

his apprenticeship he became an erector for Woodside

Iron Works and was involved in many projects including

the erection of a large factory in India and the

erection of Ormesby Iron Works, Middlesbrough.

He then became a partner in the

firm of Head, Wrightson and Company at Stockton-on-Tees.

During his time there he designed and built several

large blast-furnaces, developed a method of making

railway chairs cheaply, designed and improved plant for

use in foundries, and designed plant for use with blast

furnaces. In 1860 Joseph became a member of the

Institution of Mechanical Engineers. When the

partnership came to an end in 1862, Joseph returned to

Dudley and founded the chain and anchor making business

at Neptune Works, Tipton, with his future father-in-law,

Thomas Tinsley. Neptune Works stood alongside the

canal at the southern end of Sedgley Road West. In 1864

he married Thomas’s daughter, Grace Elizabeth Tinsley.

|

|

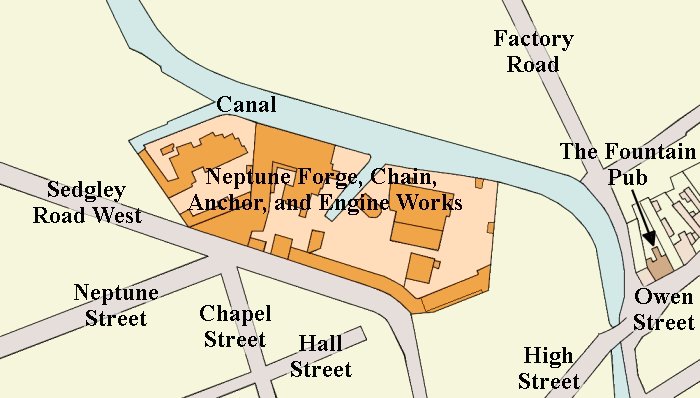

The location of Neptune Works,

based on the 1884 Ordnance Survey map. |

|

Neptune Works was a great success,

becoming one of the largest chain and anchor works in

the country. Its products were sold throughout the UK

and abroad, to countries including Germany, Russia, and

Turkey, where they were well appreciated. Only the

finest iron was used. It came from Bloomfield Iron Works

(B.B.H. iron) and from the Earl of Dudley’s ironworks.

Products included Martin’s self-canting anchor, which

was patented by Claude Martin, and sold in large

quantities.

The firm became Joseph Wright and

Company and the order books continued to fill. In 1881

Joseph and Grace were living at 45 Islington Row,

Edgbaston, with their four children.

|

|

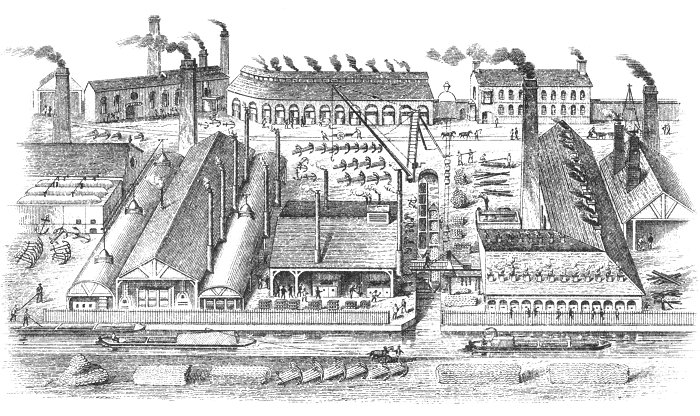

Neptune Forge, Chain, Anchor, and Engine Works. |

|

Samuel Griffiths includes the

following description in his Guide to the Iron Trade of

Great Britain, published in 1873:

When in the Black Country the

other day, we were particular in our enquiries in

respect to Wright's chains and cables at the Government

testing and proof establishment at Tipton, and were

there informed that the testing and proving of the

cables and chains turned out at the Neptune Forge

completely justified the celebrity for quality which Mr.

Wright's chains have in Germany, Russia, the Levant, and

other foreign markets.

The anchors made here are well

known throughout the world, the Neptune Forge having

turned out from time to time the best and largest made.

We understand the excellency of the quality of the

chains and cables is owing in a great measure to the use

of B.B.H. and the Earl of Dudley’s bars which are

unsparingly consumed at this great factory, although the

price paid is £1 per ton to £1.12s.6d. per ton more than

any other iron of this class made in Staffordshire.

Messrs. Wright & Company are now engaged on large orders

for the Russian and Turkish Governments.

|

|

|

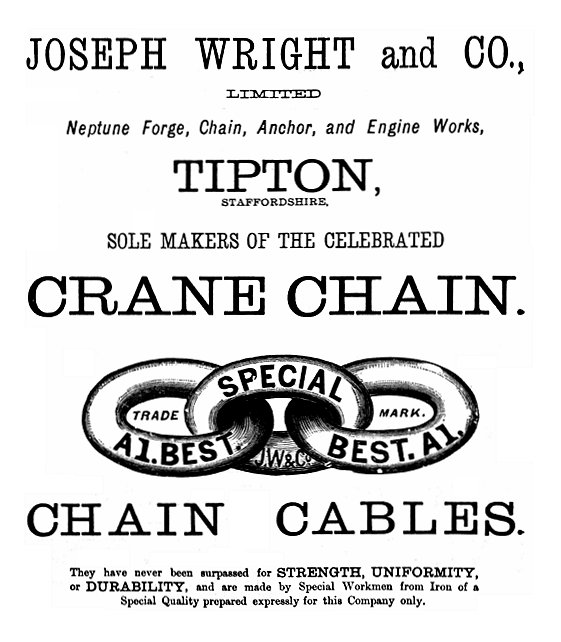

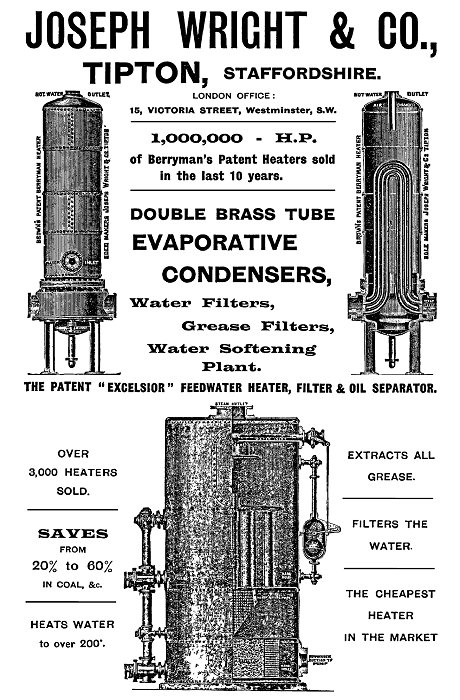

An advert from 1880. |

By 1880 Joseph Wright and Company

were sole makers and patentees of the Berryman improved

coal-saving feed-water heater that saved between 15 to

60% of coal, water and labour.

This resulted in Joseph

forming the Patent Heater Condenser Company.

In 1882 the

company manufactured anchors, chains, chain cables and

the Berryman feed-water heater and interheater. |

| Other

products included all kinds of forgings in iron and

steel, housing pins and boxes, chain cables, crane

chain, lashing, sling, and coupling chains, draw bars,

hooks, rings, swivels, shackles, smith’s work of every

kind, boilers, colliery tubs, and tanks. Also Martin's

Patent Anchors. |

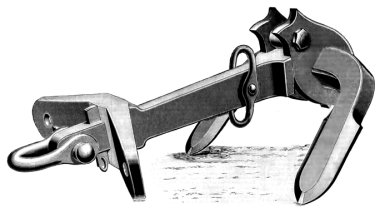

A patent anchor. |

An advert from 1896.

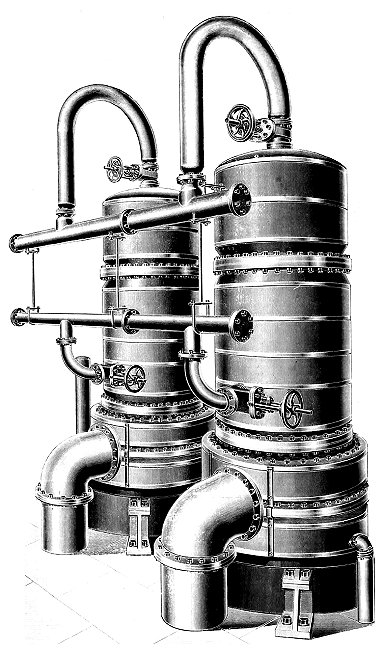

Berryman improved

coal-saving feed-water heaters. From 'The

Engineer', 1898. |

In 1887 he retired from the firm,

and practised as a consulting engineer in Westminster,

at the same time carrying on the manufacture of heaters,

evaporators, condensers, water softeners, and other

appliances connected with the purification of water.

His

last invention, completed only a few days before his

death, was a high-speed engine for electric lighting

installations.

During the last eight years of his

life, Joseph suffered from terminal throat cancer and

died on 20th October 1893, at the age of sixty-seven.

In 1903 the company received an order from the

Wath-upon-Dearne Main Colliery Company for a heater

detarteriser, to heat and soften about 18,000 gallons of

water per hour. The device was the largest of its kind

ever made, being around 35ft. high, 8ft. diameter and

weighing around 40 tons.

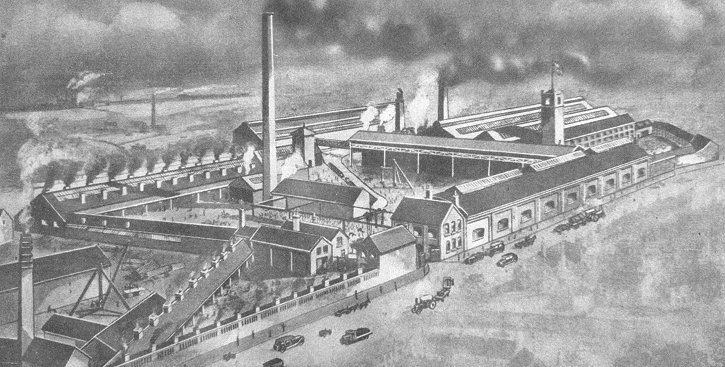

The firm founded Wright's Forge and Engineering

Company in 1913 and in 1922 - 1923 the business was

acquired by N. Hingley and Sons of Netherton. In the

1960s, N. Hingley and Sons became part of F. H. Lloyd &

Company of Wednesbury.

|

|

Wright's factory. From

a 1920s advertising brochure. |

|

Testing chains at

Wright's works. From a 1920s advertising

brochure. |

|

F. H. Lloyd's

Tipton Factory

On 4th November, 1963 a team of men from James Bridge

works moved into the two empty bays of Wright's Forge in

Tipton. Lloyds acquired the site in order

to fettle large turbine castings which were occupying

valuable space at James Bridge. Heading the team of ten

was George Wilkinson who had the task of setting up the

operation there. Initially there was no shotblast or

heat treatment facilities, just hard work.

Within twelve months, a shotblast plant and a heat

treatment furnace had been installed, and by the end of

1964 there were 13 welders, 17 finishers, 3 burners, 3

shotblasters, 2 heat treatment furnace men, 2 crane

drivers, and 1 labourer. By the 1970s the building had

grown to four bays covering 100,000 square feet. Around

3,000 tons of fabrications were produced annually under

the control of George Roberts, Production

Superintendent.

|

|

A view inside F. H. Lloyd's

Tipton factory. Courtesy of Wendy Marston. |

| Machinery in the factory included a 700 ton twin 'C'

frame hydraulic press, designed and built at the James

Bridge factory. It could handle steel plate up to 16

feet wide and ¾ inch thick. There were 4 automatic gas

profile cutters and fully automatic welding machines. The Fabrications Section moved to Tipton in 1966, and

became a separate division of F. H. Lloyd and Company

Limited in 1967. Lloyds Steel Fabrications became one of

the country’s leading manufacturers of welded steel

fabrications. It was a great success.

Dick Howett was general manager, in

charge of sales, estimating and process planning,

costing, buying and production. The production

superintendent was George Roberts who was responsible

for all production and work schedules. He maintained

liaison with customers on delivery and ensured that the

right materials were in stock for the job.

|

|

A large fabrication nears

completion in the Tipton factory. Courtesy of Wendy

Marston. |

|

Colin Hammond was chief planning

engineer at Tipton. His department prepared estimates

against enquiries, from which quotations were submitted.

The department also translated orders and drawings into

detailed working instructions for manufacture. George

Arnold oversaw quality control, which included checks on

raw materials, work in progress, and completed

fabrications, using special test equipment.

Muriel Simmons was secretary to Mr.

Howett, and the young lady, known as the voice of the

division, Barbara Potter, was the telephonist.

|

|

In the autumn of 1965 a new

canteen opened on the Tipton site. It became known

as the 'Wilkeyville' canteen, named after the boss,

George Wilkinson. Courtesy of Wendy Marston. |

|

Plate preparation equipment in the

factory included four automatic gas profile cutters, a

Hancoline HL.3 and HL.4, a Hanco-ordinate c.90 and BOC

Bison, which were giant pantographs to exactly reproduce

on a sheet of steel a design or profile which was read

from a specially prepared drawing by an optical sensor.

There were also a number of straight-line cutting

machines, and twin C-frame hydraulic presses, designed

and built by Lloyds.

Four welding processes were used:

manual arc, cored wire CO2, submerged arc and electra-slag,

the last two being fully automatic. The electroslag

machine is a prototype and the only one of its kind in

this country, manufact:ured by ESAB of Sweden. It could

butt weld plates up to 15 inches thick.

There was a North Sea gas fired heat treatment furnace with a

capacity of 24 ft. x 16 ft. x 11 ft. where fabrications were heated

to a temperature of 650°C to relieve any stresses set up by welding.

The shot blast plant was in a heavily shielded room measuring 27 ft.

x 24 ft. x 18 ft. high with an opening top to permit the craning in

and out of fabrications. Steel pellets were 'shot' from a nozzle by

compressed air at high speed to scour the surface scale from the

fabrication and reveal the pristine grey metal that is steel.

On 12th August 1969 F. H. Lloyds became part of F. H. Lloyd Holdings

Limited which was created to oversee the various companies in the

Lloyd group. The Tipton factory closed in the late 1980s and the

site is now occupied by Neptune Park apartments and Neptune Health

Park medical practice.

|

|

A large fabrication leaves the

Tipton factory. Courtesy of Wendy Marston.

|

|

Return to

the

previous page |

|