|

Sadly I have had to update this article

because in April 2020 the business went into administration.

Yet another victim of foreign competition and the coronavirus

outbreak.

Bev Parker

Walsall’s longest surviving foundry

was Kirkpatrick’s, in Frederick Street, and across the

road in Charles Street. It had been in operation since 1855.

In the 1820s, brothers John and Thomas

Kirkpatrick moved from their home in Kirkcudbrightshire and

settled in Walsall. In 1832 they were joined by their

younger brother William, born in 1817. He became an

ironfounder, and in 1855 set himself up in business. The

foundry was originally part of the Frederick Street site,

but re-located across the road in Charles Street, where it

has been since the 1930s or 40s. The foundry's modern

electric induction furnace, has

produced large amounts of high quality black iron door and

window furniture. The firm employed around 70 people and

exported products throughout the world. |

|

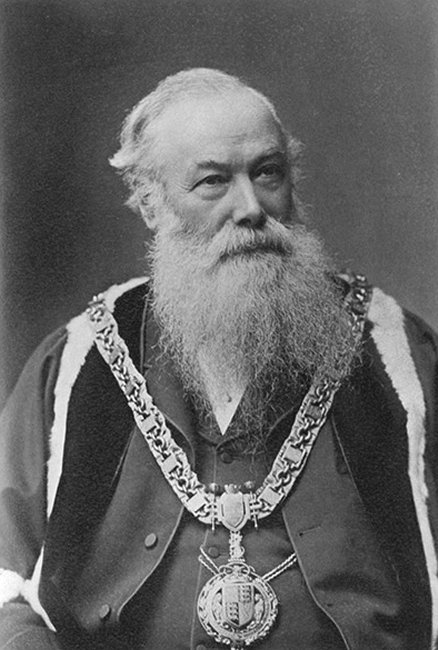

William Kirkpatrick, Mayor of

Walsall. |

William Kirkpatrick began producing Gothic and Medieval

style iron work and door furniture, which was very popular at

the time. He had a strict Covenanting upbringing and became

involved in the church, and later joined the Walsall School

Board.

In 1877 he was elected to Walsall Council, and became

a Justice of the Peace. In 1886 he became Mayor, a post he

held until his death in 1887.

After his death, William was succeeded

in the business by his son Vincent who oversaw the

incorporation of the firm in 1901. Kirkpatrick Limited

became well known as a manufacturer of a vast range of high

quality builders’ ironmongery, much of which was in

production until recent times. During both world wars the firm concentrated on items

for the war effort, including thousands of fittings for

ammunition and storage boxes. |

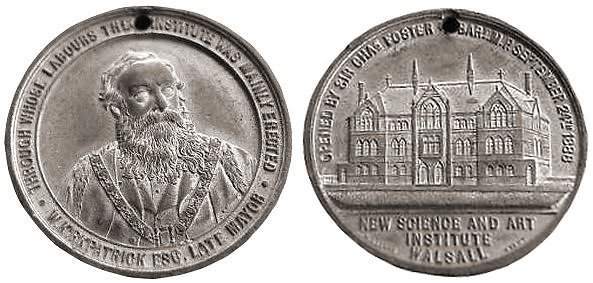

One of William Kirkpatrick's many achievements

during his time as Mayor of Walsall was the building

of the Science and Art Institute in Bradford Place.

This medallion commemorates the opening of the

institute on the 24th September, 1888. |

|

An early photograph of some of the

staff. Courtesy of Stephen Preston.

Back row left to

right: C. Skett, I. Evans, A. Oakley, J. Carter,

T. Cooper, T. Kelly, and J. Foxley.

Middle row left to right: J. Leadbeater, T.

Edge, W. Edginton, C. A. Bickley, A. Dunam, J.

Steadman, and

J. Bridgewater.

Front row left to right: G. E. Moss, E. Booker,

M. Kirk, G. Walker, A. Dkins, W. Thornton and A.

J. Philpot. |

|

|

An aerial view of the factory

from the 1930s. |

|

An old view of the Frederick

Street factory. Courtesy of Stephen Preston. |

The factory in the mid 1940s.

|

A busy day in the warehouse.

Courtesy of Stephen Preston. |

An old company letterhead bearing the firm's

motto - I mac siccar - I make certain.

| Over the years the firm has produced almost every kind

of builders' ironmongery. The vast range of products has

included Gothic handles and latch furniture, lever handles,

door pulls, bolts, chains, letter plates, postal handles,

door knobs, sash handles, lifts and pivots, thumb screws,

cupboard knobs and buttons, hasps and staples, locking bars,

hinges, cleat hooks, refrigerator fittings, casement stays

and fasteners, quadrant stays, hat and coat hooks, handrail

brackets, wire strainers, trestle hinges, pipe clips, stair

treads, pulleys, bucket brackets, ventilators, spanners,

rowlocks, blind fittings, manger rings, stable fittings,

latches, and much more. Many of the items were still in

production at the beginning of 2020. For many years the foundry would cast almost any

small item for a customer, but as the demand for the firm’s

high quality builders’ ironmongery grew, production was

concentrated in this area.

The firm has been a good

employer, the skilled workforce included members of families

who have worked there for several generations. The

products were in great demand and Kirkpatrick was

the only manufacturer in the country of traditional

black ironmongery. Their handmade products were British

from start to finish. |

Filling ladles. Courtesy of

Stephen Preston. |

| We now live in a throw-away society, and are used to

buying products that all too soon reach the end of their

useful life. Kirkpatrick's products are different, they

really do last a lifetime. The company sometimes

received items for repair, which turned out to be cheap

inferior foreign copies, not made to Kirkpatrick's high

standard. The company even received a foreign copy of

its own catalogue in the post, advertising what were in

fact, second-rate copies of the firm's products. There

was a time, not that long ago, when we were proud of our

home-made products, carrying the 'Made in Britain'

label. Kirkpatrick's products were something that we can

still be justifiably proud of today. We not only made

the best ironmongery, but made it here in Walsall, in

the heart of the Black Country. |

| The following

photographs were taken on a visit to the factory in

2015, kindly arranged by Stephen Preston: |

|

The company's offices in Frederick

Street. |

|

Filling a ladle with molten metal

from the furnace. |

|

Another view of the furnace as two

of the moulders fill their ladles. |

|

|

|

|

Casting,

a busy time in the foundry. |

|

|

Filling some of the moulds with

molten metal. |

|

Another view of one of the

moulders at work. |

|

Casting is always a spectacular

sight. |

|

The castings begin to cool. |

|

The end of the morning's casting. |

|

Finishing off, and assembling some

of the many products. |

|

Another view of the assembly area. |

|

A corner of the packing department

from where products were sent all over the world. |

| |

|

View some of the products

from

the company's 1925 catalogue |

|

| |

|

|

A few of the company's vast

range of products from the 1950s: |

|

Fittings for doors, cupboards,

gates, and drawers etc.

|

|

|

Fittings for casements, sashes,

skylights, fanlights, etc.

|

|

|

Miscellaneous articles for

trade and domestic purposes:

|

|

|

Cast-iron goods:

|

|

| A few of the vast range

of products, recently in production: |

| Sadly, in recent times, the company has suffered

from increased foreign competition that resulted in a

loss of orders. The company had an annual turnover of

around £1.65m, but the recent long-term closure of many

markets due to the coronavirus outbreak, resulted in the

business going into administration. This led to a loss

of 50 jobs. Administrators were appointed on the 16th

April, 2020 and a meeting of the creditors was planned

for the 9th June.

From The Gazette.

The empty building, now facing an

uncertain future.

We are now in a time of great

depression, when manufacturing would help with our

much-needed recovery. It is sad that British

manufacturers don't receive a suitable helping hand.

Their contribution would greatly benefit our ailing

economy.

The closure was a terrible blow for everyone at the

company, who had worked so hard to ensure that it would

have a long-term future. Foundries in the Black Country

are now few and far between. Walsall can be justifiably

proud of Kirkpatrick's wonderful record. |

|

Return to

the

previous page |

|