|

Beginnings

The family business was founded in 1910

by Thomas Partridge and two of his sons, Arthur and Joseph.

Thomas, who was born in Brierley Hill in 1858, had moved to

Darlaston by the turn of the century, working as a foreman

carpenter in an engineering factory, with a wife, four sons,

and a daughter. He became a Methodist preacher, and often

walked many miles each Sunday to preach at various churches.

He held strict religious opinions, had a well-developed

sense of humour, but had little patience with slow workers,

and contempt for sickness of any kind. |

|

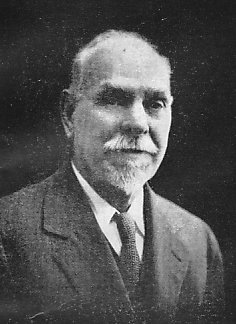

Thomas Partridge. |

By 1910 Arthur and Joseph had finished their

apprenticeships as carpenters and joiners, and were working

in Darlaston, constructing wooden buildings under their

father, who was the foreman. They often talked about, and

planned to start their own business.

The opportunity came through a new member of the family.

In 1910 Thomas’s widowed sister Maria Kelly married Richard

Delves Evanson, a carpenter and property repairer who had a

small business in Walsall. He got on well with Thomas,

Arthur and Joseph, and so it seemed to be a good idea to

form a partnership.

This led to the formation of Evanson, Partridge & Company

which came into existence on 7th March, 1910 with a capital

of £200. Unfortunately the venture was not a success. A few

months later Richard Evanson retired, and the partnership

was dissolved on 31st July, 1910. On that day the

partnership of Thomas, Arthur, and Joseph Partridge was

born. |

|

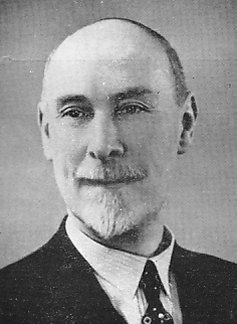

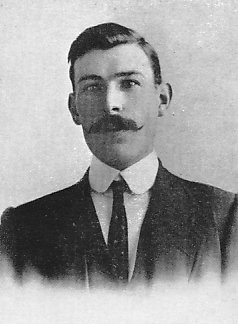

Arthur Partridge. |

Joseph A. Partridge. |

Bert Partridge. |

|

The New

Business

They purchased a small factory on the

corner of Darlaston Road and Pleck Road, Walsall, and set up

a joinery works. To begin with there were two or three

woodworking machines, powered by a gas engine. They employed

a young boy, A. Clement Kelly (known as Clement), who was

Thomas Partridge’s nephew, the son of his sister Maria, and

stepson of Richard Evanson. He would eventually become a

director of the company.

The business grew so rapidly that soon

a larger factory with more machinery became a necessity. In

1912 the firm purchased a piece of land in nearby Wallows

Lane, off Bescot Road, where a new factory was built. The

company built a wide range of timber-framed buildings

including bungalows, churches, boat houses, hospital

buildings, garages, and sports pavilions. The firm

specialised in the making of wide-span Belfast roofs for

industrial purposes including factories, aeroplane hangars,

warehouses, and dock sheds. All of the joinery was produced

in the factory by a team of experienced craftsmen. |

|

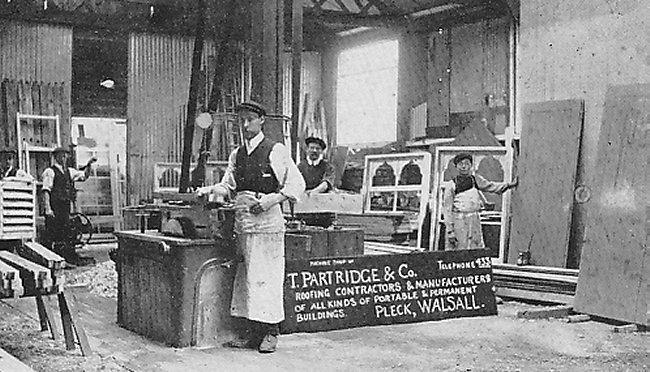

The woodworking machine shop in the

original factory on the corner of Darlaston Road and Pleck

Road. |

|

Around this time the firm developed,

and patented a putty-less roof glazing bar which was sold as

‘Elite’ leaded roof glazing. It became widely used in

factories, warehouses, and aerodromes throughout the

country.

By the First World War the industry was

changing fast. More buildings were built with a steel frame,

and it became obvious that the firm had to move in that

direction. With this mind, Bert Partridge, Joseph and

Arthur’s younger brother, trained as a steel structural

engineer, and joined the firm in 1914 at the age of 21.

During the war the firm received many

government contracts for the making and fixing of ‘Elite’

roof glazing. Many millions of feet of glazing were fitted

to buildings of all kinds, which proved to be difficult

because of the shortage of skilled labour.

In 1917 Thomas, who had reached the age

of 59, decided to retire, and leave the business in the

capable hands of his three sons. |

|

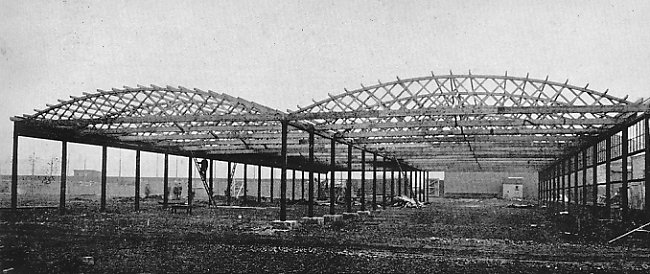

A Partridge two-bay Belfast roof. |

|

Inter-War Years

In January 1919 the company opened a

new office at Chamber of Commerce Buildings in New Street,

Birmingham, with S. H. Barrett, a 23 year old structural

engineer, in charge. In April of that year, Norman

Partridge, Thomas’s youngest son, joined the firm. He had

been trained as an accountant and so took over the

commercial side of the business.

The firm continued to be successful,

and became a private limited company on 27th January, 1920

with Arthur, Joseph, and Bert Partridge as directors. The

three brothers also started a new venture. They founded the

Walsall Wholesale Cabinet Company Limited, to manufacture

furniture. The new venture was so successful that Joseph

needed to devote all of his time to look after it. He

resigned from T. Partridge & Company Limited, leaving it in

the hands of Arthur and Bert.

In the early 1920s the demand for

steel-framed buildings rapidly grew. Up until this time the

company had been using steelwork that had been supplied by

outside contractors. For some time the directors had

considered the possibility of extending the company’s

operations to include the manufacture of structural

steelwork. The opportunity came in 1923 with the closure of

the Pleck Foundry Company Limited in Darlaston Road, and the

selling-off of the factory.

Arthur and Bert acquired the old

factory, and T. Partridge & Company Limited moved to the new

site. The much larger premises allowed the business to

expand, and with the installation of new plant, produce

structural steelwork. By 1927 a new company office had

opened at 8 Newall Street, Birmingham, and the business

continued to grow, receiving orders from many large and well

known British companies including the Austin Motor Company

Limited and I.C.I. |

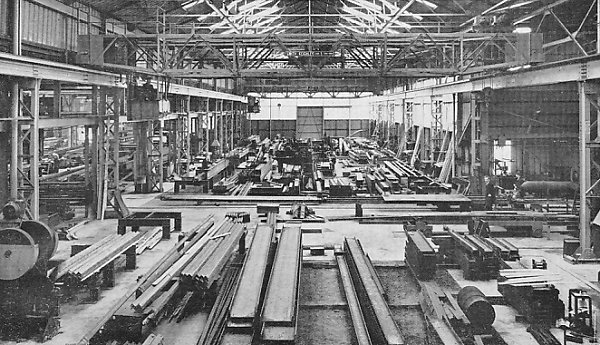

|

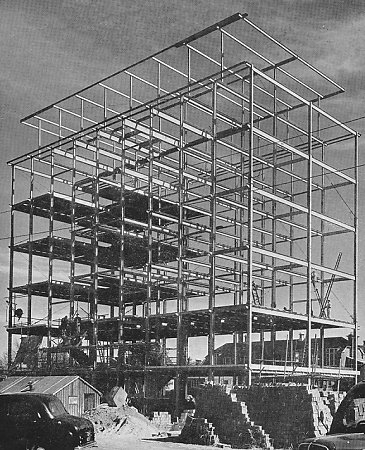

The new factory in about 1960. |

|

In 1927 the firm got its largest order

to date, a warehouse building for Austin, which covered two

and a half acres. The contract was completed in record time,

less than seven weeks after receiving the order. All of the

structural steelwork had been fabricated in the new

Darlaston Road factory.

In 1930 another generation of the

family entered the business in the form of Raymond

Partridge, Arthur’s seventeen year old son, who started his

career in the drawing office at Birmingham. He then spent

some time in the Template Shop at Walsall, and later moved

to the Walsall drawing office where he gaining experience in

detailing. After his training he returned to the Birmingham

Office where he worked on detailing and estimating. In 1938

he became a company director.

By 1934 the firm had outgrown its

Birmingham office and so new and more spacious premises were

found in the newly completed Lombard House in Great Charles

Street.

There were several important changes in

1935. Arthur’s doctor advised him to retire on medical

grounds, which he reluctantly did. This resulted in a

reorganisation in which Bert Partridge became both Chairman,

and Managing Director. Two new directors were appointed,

Norman Partridge and S. H. Barratt. Around the same time

Clement Kelly became Site Manager.

In 1936 a new profit-sharing scheme was

launched, which was far ahead of its time. Initially it

applied to technical and commercial staff only, but would

soon be extended to manual workers, so that all members of

staff could benefit from the firm’s success.

In the late 1930s with war being almost

inevitable, the company worked on a large number of

contracts for the new factories that would be needed as part

of the war effort. While this work was in progress, steel

framework was deigned and built for four new Danilo cinemas,

at Cannock, Quinton, Stoke, and Stourbridge. |

|

The

Second World War

At the beginning of the war the threat

of aerial bombardment was paramount in many people’s minds.

Many local authorities were concerned about the effects of

the blast from high explosives on their air raid shelters.

This resulted in the introduction of a scheme to strengthen

existing underground shelters with structural steelwork.

Orders for suitable steelwork arrived

from municipal authorities in thirteen counties, which

involved the production and installation of over 1,300 tons

of structural steel.

Another form of air raid shelter was

introduced, called the Morrison Shelter, named after Herbert

Morrison the Home Secretary. It was a heavy steel box with

an opening side made of strong wire. Two or three people

could crawl inside for protection. It would stand in the

living room and double-up as a table. During the early years

of the war the company built over 2,000 of them. |

The structural steelwork for Slough

College. |

|

During the blitz the fire services in London increased

in size. A lot of extra garage space was needed for new

appliances. The company received orders for the building of

a large number of fire service garages in the London area,

and also carried out rapid repairs to factories that were

damaged during the bombing campaign.

Because of wartime shortages, every construction job

required a building license, and any purchase of steel had

to be authorised by a government department. The shortage of

timber led to the end of production of Belfast trusses, and

the patent ‘Elite’ glazing bar.

Birmingham was seen as a likely target

for the German bombers, and so most of the staff in the

Birmingham office moved to the Walsall site. The building

was sub-let to the Ministry of Works, apart from a small

room used by members of the design staff.

|

|

Other war work included the manufacture

of gun shields, machine gun brackets, gun pedestals, winch

casings for ships, davit frames, fulcrum brackets for tanks,

flail arms for mine destroying Scorpion tanks, and parts for

Bailey bridges. Over 1,000 tons of steelwork for power

stations was fabricated and shipped to Russia.

Towards the end of the war the company

made parts for the two top secret Mulberry artificial

harbours that were taken across the English Channel to

offload cargo on the beaches during the Allied invasion of

Normandy. |

|

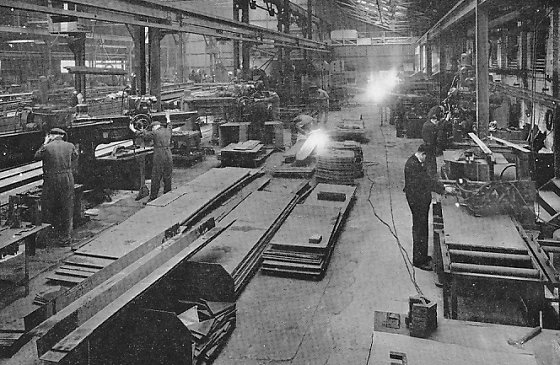

Structural steel in the main stockyard

bay at the factory. |

|

After

the War

In the late 1940s large numbers of new

schools were built. The company supplied and usually erected

the structural steelwork for over one hundred and thirty of

them. On 16th January, 1947 one of the company’s founders,

Thomas Partridge died, after a long and enjoyable

retirement. He was greatly missed because he had always been

on hand to offer advice whenever needed. In the same year,

Bert’s only son Malcolm, joined the business after spending

five years in the army. He trained in the factory and the

drawing office, and went-on to become a company director in

1952. |

|

One of the company's mobile cranes

working on a building site. |

|

The mid 1950s was a sad time for the

family. Arthur died in September 1954 at the age of seventy

two, and Joseph died in March 1956 at the age of sixty nine.

In 1955 Bert resigned as Managing Director due to ill

health, and died in November 1956 at the age of sixty three.

After Bert’s death the management consisted of:

Norman Partridge – Chairman and Company

Secretary

S. H. Barrett – Contracts Director

Clement Kelly – Site Director

Raymond Partridge – Sales Director and Joint

Managing Director

Malcolm Partridge – Works Director and Joint

Managing Director |

|

|

Some of the factory staff in the late

1950s. |

| Part of the welding shop which

covered around 14,000 square feet. |

|

|

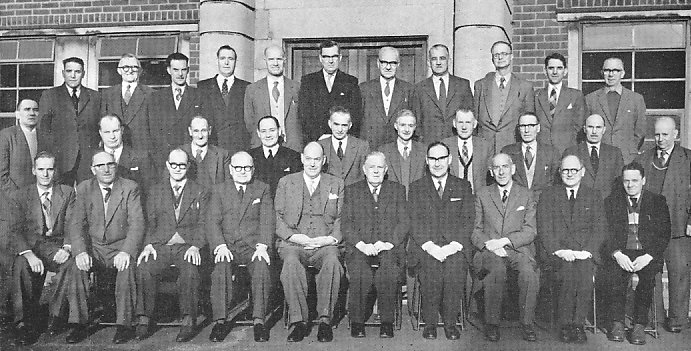

A group of employees, all with

over 25 years service.

Back Row left

to right: J. Bissell, H. Gwinnett, C. A. Troman, J.

T. Finney, E. T. Hayward, L. J. Martin,

W. H. Smith, C. Griffiths, H. J. Troman, W. A. Raybould,

and A. J. Lovatt.

Middle Row left

to right: W. E. Worrallo, J. T. Whitehouse, R.

Poynton, E. Maull, W. Booker, A. O. Troman,

C. Stackhouse, G. Dabbs, G. Manning, and G. W. S. Dixon.

Front Row left

to right: W. Coyne, G. W. James, D. Salt, S. H.

Barrett, N. Partridge, A. C. Kelly,

R. A. Partridge, G. E. Hallam, H. Smart, and F. H.

Phillips. |

|

Building techniques were rapidly

changing. Structural steelwork had always been held together

by rivets, but with improved methods, welding was rapidly

taking over. Portal frame construction was also becoming

standard, especially for wide span buildings.

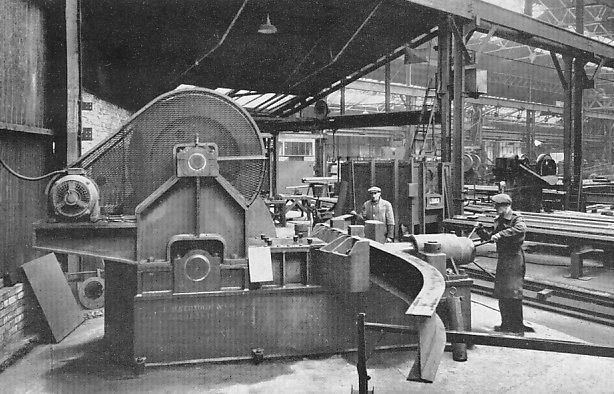

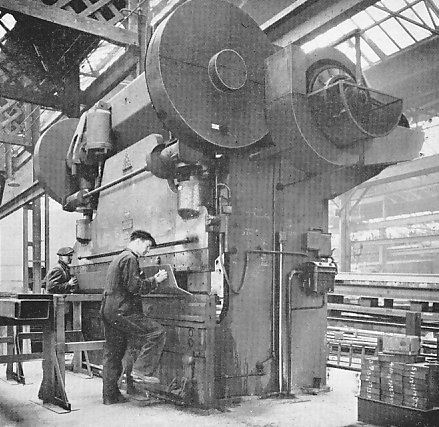

In order to keep abreast of the times,

new machinery had to be installed in the factory, including

a large brake press, large guillotines, plate rolls, and a

massive bending machine. Over £100,000 was spent on new

machinery and plant.

Some of the company’s largest orders

included extensive building projects for I.C.I., a new power

house for Courtaulds at Grimsby, Equipment for Stewarts &

Lloyds Minerals Limited at Wirksworth, and buildings and

extensions for the John Thompson (Wolverhampton) Limited

group of companies.

T. Partridge & Company Limited closed

some years ago. The Pleck site is now occupied by Whittalls

Wines Limited. |

|

The new fabricating bay built in

1956. |

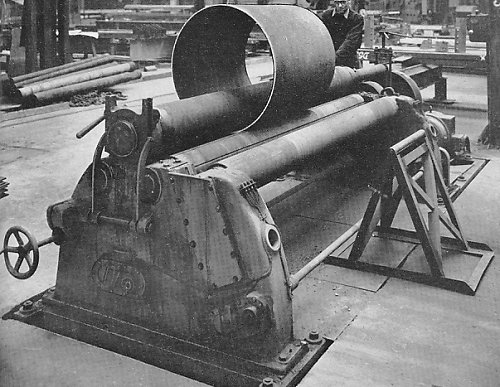

| A bending and straightening

machine. |

|

|

A 240 ton brake press for

flanging plates up to 10 feet in length. |

| One of the plate rolls. |

|

|

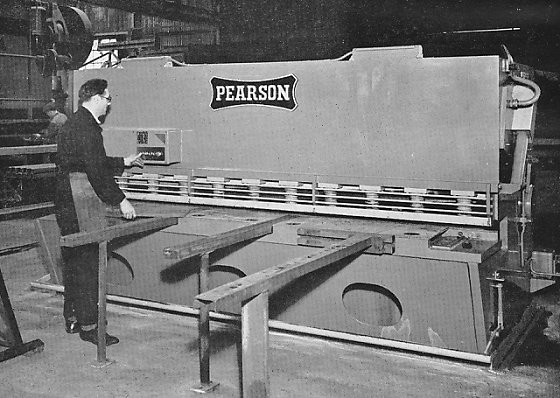

A large guillotine, capable of

shearing steel plate up to 10 feet long and

½ inch thick. |

|

The company directors.

Left to right: Malcolm

H. Partridge (Works Director), S. H. Barrett (Contracts

Director), Norman Partridge (Chairman and Secretary), A.

C. Kelly (Site Director), and A. Partridge (Sales

Director). |

| Members of the drawing office

staff. |

|

|

Members of the commercial

staff. |

| Members of the works staff. |

|

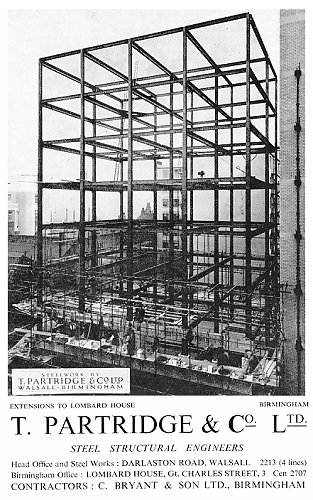

An advert from 1953.

| The information and factory photographs are taken from 'The

Partridge Story 1910 - 1960' which was published by the

company. |

|

Return to

the

previous page |

|