|

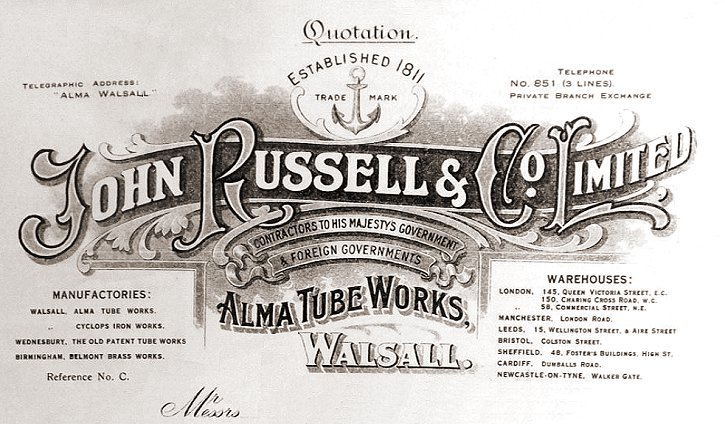

An advert from 1916. |

The largest ironworks in the Pleck area was

Edward Russell's Cyclops Ironworks in Pleck Road, which had

opened by 1873. On the site were 22 puddling furnaces and 3 rolling-mills.

Edward ran John

Russell & Company, an old Wednesbury firm that was

established in 1811. Edward was the son of John Russell and

his wife Mary. After John's death, at the age of 69 in 1853, Edward ran the

business and in 1854 founded the Alma Tube

Works. Edward died in 1875.

The firm still used the Old Patent Tube Works in

Wednesbury, and had three other factories at Pleck; the

Cyclops Tube Works, Alma Tube Works, and Newside Iron Works,

lying side by side between Pleck Road and the canal.

The

company became a Limited company in 1876, and in 1896 Newside Iron Works merged with the adjacent Cormorant

Ironworks.

In 1892 John Russell & Company Limited produced around

half the posts to carry the overhead wire for the

electrification of the South Staffordshire Tramways which

connected Darlaston, Wednesbury, West Bromwich, Handsworth,

Great Bridge, Dudley Port, Dudley, Walsall, and Bloxwich.

The other posts were made by James Russell & Sons.

|

| In 1926 the firm acquired a 100 acre site at Halton, near Runcorn and built a

new tube works there. In 1930 the business was acquired by

Stewarts and Lloyds. The firm took out a patent in 1935

for improvements in water taps and exhibited brass and

gunmetal valves and pipe fittings for steam, water and

gas at the British Industries Fair in 1937. |

John Russell & Company Limited's Walsall

factories.

An advert from 1909.

|

In 1897 the Institution

of Mechanical Engineers visited the tube

works:

Messrs. John Russell &

Company, Alma Tube Works and Cyclops Iron

Works, Walsall

This firm was

established in 1811, and was the first to

manufacture gas tubes by the drawing

process. The Alma Tube Works were commenced

in 1854, and are now divided into the

departments, employing altogether about 800

hands. The oldest department is the butt

weld mill, where butt welded tubes, chiefly

for high-pressure hot water, heating, and

hydraulic purposes, are made by the drawing

process. Here also are made taper telegraph

and tramway poles; railway point and signal

rods; glass blowers' tubes, etc. The

ordinary butt welded steam, water, and gas

tubes are made at the Wednesbury works, and

the process is similar to that employed in

this department. There are also fitting and

socket makers' shops and a stamping shop,

for making large sockets and flanges.

Attached to this

department also is the coil shop, where

coils of all sorts are made for heating and

refrigerating, and tuyere coils for blast

furnaces. In the lap weld department, the

mill consists of five welding and two

skelping furnaces, five out of the seven

being Siemens regenerative furnaces,

supplied with gas from a range of Wilson

producers; from these furnaces, tubes from

inch to 18 inches diameter can be welded.

The finishing shops are

fitted up with tools for cutting off,

screwing, staving, bulging, flanging, and

other methods of making joints, either for

fixing in boilers or for coupling together.

Large quantities of oil line pipe, well

boring and casing tubes, both for oil and

water wells, are manufactured here, as well

as high pressure steam mains, iron and steel

boiler and stay tubes, etc. Storage heaters

for railway carriages and tramcars are also

made, and sent out ready for fixing. The

weldless tube department, which has been

recently added, is equipped with seven

double draw benches, five for cold drawing

tubes up to 2 inches diameter, and two

powerful benches for drawing Belleville

boiler tubes and tubes up to 6 inches

diameter for hydraulic purposes. The rolling

mill consists of four pairs of rolls, driven

by a tandem compound surface condensing

engine.

The Cyclops Iron Works

employ about 400 hands, and can turn out 400

to 500 tons of finished iron per week,

consisting chiefly of tube strip iron for

consumption in the tube works. There are

thirty two puddling furnaces, two of them

working with forced draught, and the others

of the ordinary kind. Three steam-hammers

and a forge train with three pairs of rolls

deal with the product of these furnaces. On

the mill side are a 16 inch and 9 inch mill,

both three high. The 16 inch mill is engaged

almost exclusively on rolling tube strip

from 4¾ to 15⅛ inches wide. The 9 inch mill

rolls 4¾ inches and narrower strip iron, as

well as bar iron. The heating furnace for

the 16 inch mill is one of the new form of

Siemens furnaces, and a second of the same

kind is in course of construction. |

|

|

Factories and sites in 1916. |

|

An advert from 1918. |

|

Some products from the 1916 catalogue |

Standard gas fittings.

Screwed inserted casing tubes with a 5 inch to

12 inch bore.

|

A loop type expansion bend with a

7 inch bore suitable for 180 psi steam pressure. |

| 12 inch horseshoe type expansion

beds for 165 psi steam pressure. |

|

|

Seamless superheaters with special

welded ends for locomotives and boilers. |

| Locomotive superheater elements. |

|

|

Locomotive superheater model. |

| Schmidt type locomotive

superheaters and draught retarders. |

|

| Boiler flue and stay tubes,

lapweld quality. Made from iron, steel, or charcoal iron as

requested. |

|

|

|

|

| Coils were

available in round, square, or rectangular tube,

galvanised or black. They were suitable for

condensing, heating or cooling, in high or low

pressure heating plants. |

|

Seamless superheater coils.

|

Joints for steel steam mains. |

|

Expansion pipes for gas,

water, or steam. |

|

Standard sockets, screwed to

order. |

|

Steam drum for superheated steam at 300 psi.

12 inch steam pipe with 8 inch outlet, and the

companion 8 inch bend.

12 inch steam main, 160 psi.

Steel tubes with welded outlets and welded-on

steel flanges.

| Flanged tubes with

outlets welded-on. |

|

|

Special solid forged

sweep tees. |

| Flanged fittings for 180 psi steam

pressure. |

|

Driving heads and shoes for socketed well

casing tubes.

|

Return to

the

previous page |

|