|

Iron Foundries

Vast numbers of iron castings were

produced in the Black Country by the many foundries that

were a familiar sight in the area. Cupola furnaces formed an

important part of the local landscape, and Walsall had its

fair share of them.

An advert from 1861.

An advert from 1861.

Pigot & Company’s National Commercial

Directory published in 1828 lists six iron founders:

|

James Glover, Ablewell Street

John

Glover, Birmingham Road

John James, Ablewell Street |

Parks & Ottway, Goscote

Samuel Perks, Hall Lane

James Thornhill, Church Street |

|

| By 1851 there were 25 foundries, many of which were producing items for the local buckle, saddle, bridle, and

horse furniture industries, but by the later part of the

19th century the items were more diverse. In the 20th

century the industry supplied castings to car, motorcycle,

and bicycle manufacturers; to electrical engineering

companies; to shipbuilders, and to industries of all kinds. |

An advert from 1896. |

|

One of the longest surviving foundries

in Walsall was Chamberlin & Hill in Chuckery Road. The company was established in 1890, and like

most of the local foundries must have produced a wide range

of castings to order. The earliest known products are black

money boxes.

Mr. Chamberlin and Mr. Hill's

factory originally specialised in thin-section

castings used for toy making, electrical switchgear

and domestic hardware. A further foundry was set up

in Lichfield in 1902 making larger castings for

machine tools, mainly used in the textile trade.

Mr. Chamberlin and Mr. Hill had

retired by 1912. During the First World War the

factory produced munitions.

About this time the Bather

family took an increasing stake in the business and

completely took over in the 1920's, running the

business until 1946 when it became a limited

company.

Products then became food

mincers and cast iron idlers for the coal and

quarrying industries. |

The offices at the heritage open day in

September 2014.

|

In 1967 Chamberlin & Hill

bought a foundry that made malleable castings in

Bloxwich. In 1999 Russell Ductile Castings Limited

of Scunthorpe was acquired, followed by Chamberlin &

Hill Castings Limited of Leicester in 2004.

In 2005 the Bather family

sold their share in the company, which in 2007 became Chamberlin plc.

The Walsall foundry then concentrated

on precision

castings up to 5kg in grey iron, to an extremely high

specification, mainly for German car manufacturers. One of

the specialities was housings for turbochargers used in

diesel engines.

In its first 100 years,

Chamberlin & Hill's turnover grew from £1,840 in

1890 to £20 million in 1990. In 2004/05 turnover was

£42 million. Success continued until recent times

when orders were few and far between. |

The original office block and front

entrance to the site in Chuckery Road.

|

The business was forced to pay over £1

million to five nearby residents who had decided to take

legal action against the business for dust pollution.

Chamberlain and Hill ceased trading in

May 2024 with the loss of 78 jobs in Walsall and 51 jobs in

Scunthorpe.

The iron casting and machining firm, Castings PLC, based in

Brownhills, bought the fixed assets and stock of Russell

Ductile Castings Limited and demolition at the Walsall site began in

April 2025. Little is now left of what was one of Walsall's most important foundries.

|

Scrap metal ready for the furnace.

The furnace building.

The cupola.

Filling a ladle in the factory.

Another view of a ladle being filled in the

factory.

Part of the factory.

Part of the factory.

Part of the factory.

Part of the factory.

Roughly cleaning up new moulds.

Roughly cleaning up new moulds.

Another part of the factory.

Moulds were accurately machined by caged

robots.

Part of the line of robots.

Part of the line of robots.

Retrieving machined components from the

robots' cages.

Retrieving machined components from the

robots' cages.

| After machining, each finished component was

extremely accurately measured using a computerised laser

measuring machine. |

The derelict office building in 2025.

| It had been an unforgettable day visiting Chamberlin

and Hill's Foundry at the heritage open day in September

2014. On that occasion it was impossible to imagine that

in just under ten years it would all come to an end. In

May 2024 Walsall lost an extremely important industrial

asset. |

Luckily other foundries still operate in the town,

including

H. Goodwin (Castings) Limited of Stafford Street, founded by

Mr. Goodwin in 1919.

The malleable and grey iron foundry produces engineering

castings in malleable, ductile, aluminium and grey iron for

a wide range of industries. |

An advert from 1935.

|

| The foundry has two 350kg and one 200kg Inductatherm medium frequency induction melting

furnaces, and offers pattern design, and prototype

manufacturing facilities. |

|

A relatively recent company is Majorfax

Limited, in Charles Street. It was established in 1984 and

supplies castings in grey and ductile iron, carbon and

stainless steel, aluminium, and brass.

Another foundry is J.

W. Bonser (Walsall) Limited in Albert Street. The firm

manufactures high pressure zinc die-castings, and has

comprehensive machining, finishing, polishing, chrome

plating, gold plating and powder coating facilities.

Finished products include bathroom fittings. |

An advert from 1974. |

An advert from 1935.

| Castings Limited in Selborne Street, Walsall

were a long-established business, which opened around 1850.

The firm produced high quality castings in whiteheart and

blackheart malleable iron. Customers included car

manufacturers, motorcycle manufacturers, trailer

manufacturers, agricultural machinery manufacturers, and

general engineering companies.

The firm also produced iron castings with special

properties such as high strength and good shock resistance

that were suitable for flame hardening or arc welding. |

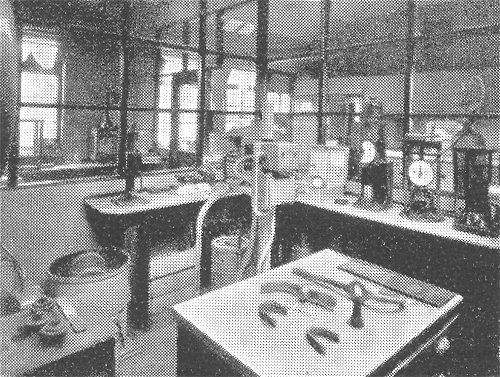

A corner of the laboratory at Castings

Limited. |

|

A corner of Castings Limited's

foundry. |

The firm specialised in the latest types of annealing to

ensure consistent physical properties of castings.

During the process the temperature was controlled by a

continuous temperature recorder, and test samples were

examined under a microscope.

All raw materials had to meet an exacting specification,

and were checked in the laboratory.

The latest rotary furnaces were used to produce the iron.

which was cast in power moulding machines. |

| After annealing, the castings were shot-blasted using

airless centrifugal machines, so that they were absolutely

free from sand, and suitable for enamelling. The Selborne

Street factory is now occupied by Presco Components Limited. |

Another view of Castings Limited's

foundry. |

An advert from 1954.

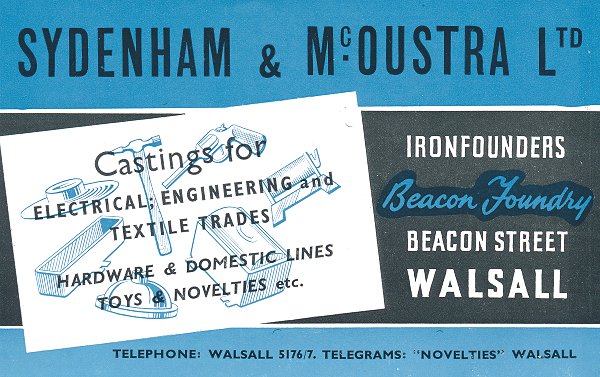

| Another well-known Walsall ironfounder was Sydenham &

McOustra Limited which started at Beacon Foundry, Beacon

Street, Walsall in about 1900. The firm specialised in light

castings for electrical engineering companies, and the

textile trade. The foundry was slightly unusual in that as

well as producing a range of castings for its customers, it

also produced a range of finished goods including small

carpenter's tools, adhesive and tape dispensers, toys, and

money boxes. The up-to-date factory included a rest room,

and shower baths for the employees. |

An advert from 1954.

| Non-Ferrous foundries Many of the

non-ferrous foundries in the town produced horse furniture,

particularly after the introduction of nickel casting. They

supplied the local bit makers, stirrup makers, harness

furniture makers, and horse brass makers.

|

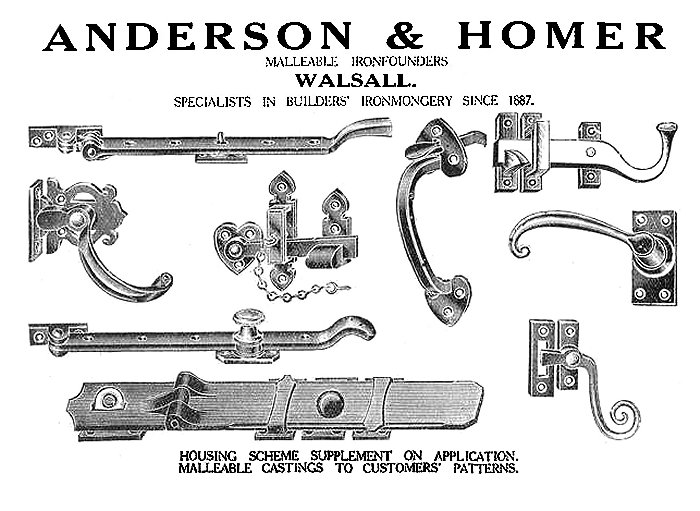

An advert from 1896.

An advert from 1865.

An advert from 1896.

An advert from 1896.

An advert from 1904.

An advert from 1926.

An advert from 1953.

|

An advert from 1953. |

Pigot’s Staffordshire Directory of 1842

lists 23 brass foundries, and 16 brass and iron casters,

many supplying the 41 stirrup makers, 22 spur makers, 5

spur rowel makers, and 122 bridle bit makers that were in the town

at the time. By

1935 (Walsall Red Book and Directory) the numbers had

reduced. There were 18 brass and nickel silver foundries,

and 11 bridle bit makers, 11 stirrup makers, 10 spur makers,

and 1 spur rowel maker. |

| Some of the horse furniture makers

diversified into other areas, eventually abandoning

horse-based products. Joseph Withers & Sons Limited

originally made harnesses, but in the 1930s began to produce

non-ferrous castings and fittings for holloware, bathrooms,

and cars. J. & J. Wiggin Limited began making bridle bits in

Bloxwich, and later turned to stainless steel tableware.

|

An advert from 1935. |

| Another foundry is Lowe Brass, based in

Clarendon Street, Bloxwich.

The firm was established in 1965

and produces brass name plates, rally plaques, vintage car

plaques, canal and boat makers plaques, horse brasses, paper

weights, door knockers

etc.

|

An advert from 1935.

An advert from 1974.

An advert from 1974.

|

Return to

the

previous page |

|