|

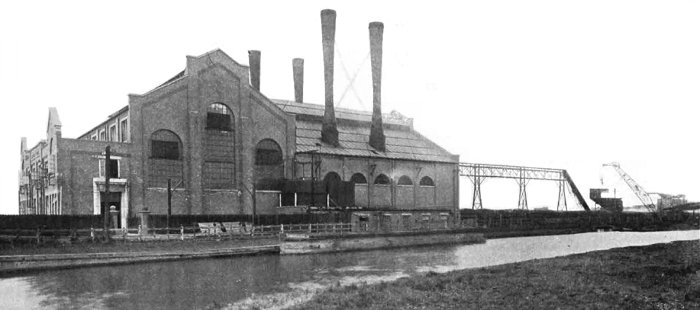

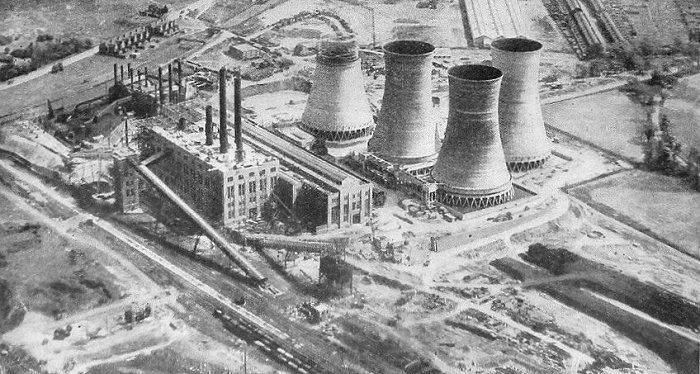

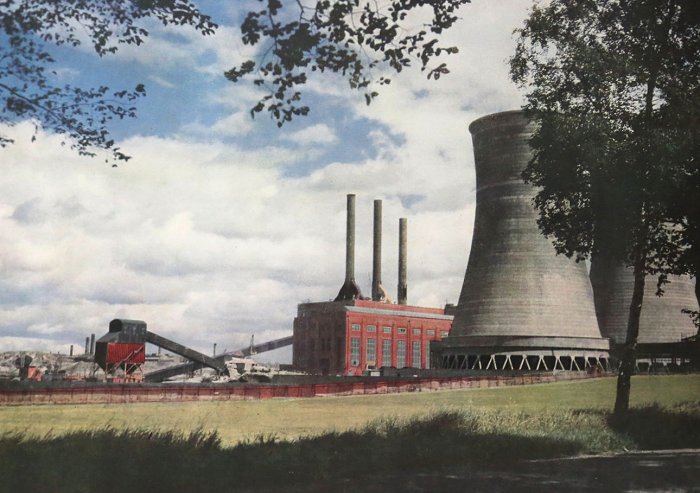

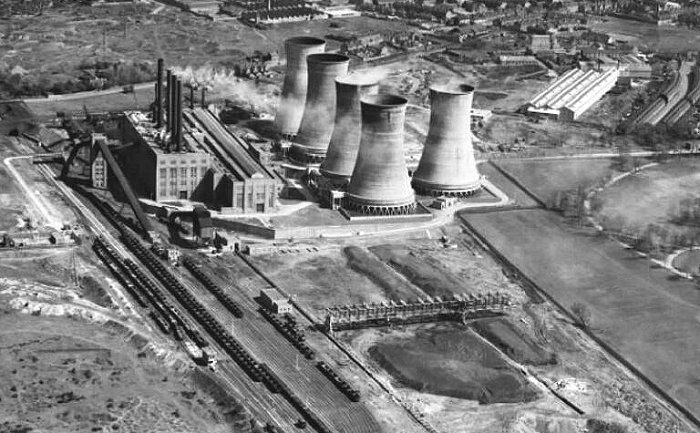

The original Birchills power station.

Walsall Corporation was granted

a Provisional Order by the Board of Trade to supply electricity in 1890,

and work on the project began in 1895. The original

generating station was built in Wolverhampton

Street, by the canal, but soon proved to be uneconomical and

unable to supply sufficient electricity to the area.

The plant consisted of coal-fired boilers supplying

steam to Chandler compound engines that were

directly coupled to Thomas Parker Limited two-pole

dynamos. The initial capacity of the plant was

240kW, with a maximum load of 155kW. New equipment

was soon added to raise the capacity to 2.6MW. The generating station opened in December 1895

and made its largest annual profit of £1,385 in

1915.

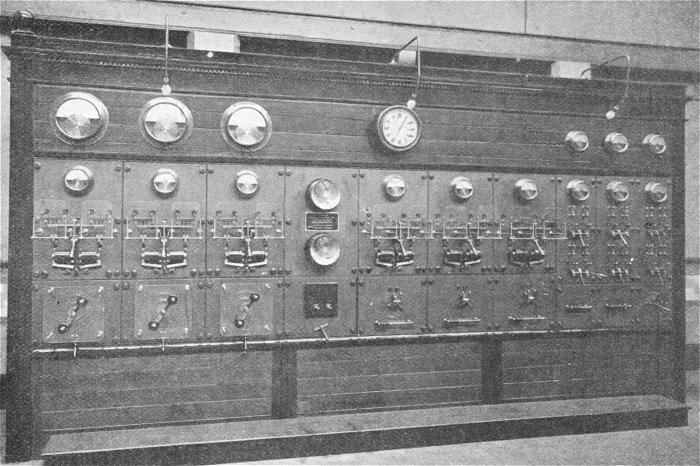

The main switchboard in 1898.

In 1913 Walsall Corporation

decided to build a new generating station at

Birchills, which would feed a 6,600 volt, three phase

network. Mr. M. Lacy, M. Inst. C.E. was employed as

consulting engineer and he realised that a new

generating station was essential. Work began in 1914 when Mr. H. A. Howie was

appointed engineer and manager. Birchills power

station was designed to run as efficiently as

possible, and soon appeared alongside the Birchills

Canal, which would provide the necessary cooling

water for the generating plant. By 1916 electricity

was being generated at Birchills, although the

project was not officially completed until 1922.

The original power station in

Wolverhampton Street, closed in 1917 and was kept

open for a little while for emergencies.

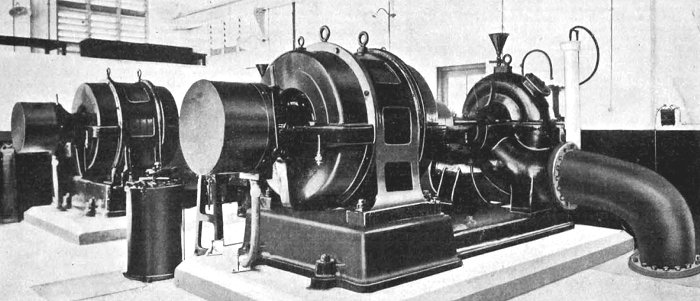

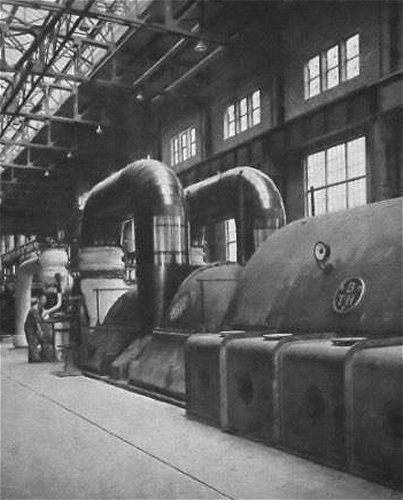

An electrically driven pumping

plant was included to take cooling water from the

Anson Branch of the canal, which after use could be returned either to

the Walsall Canal or the Anson Branch. The pumping

station building initially housed two Mather and

Platt pumps, which are shown below. They were

capable of handling 10.6 million gallons per day.

The electrically driven pumps.

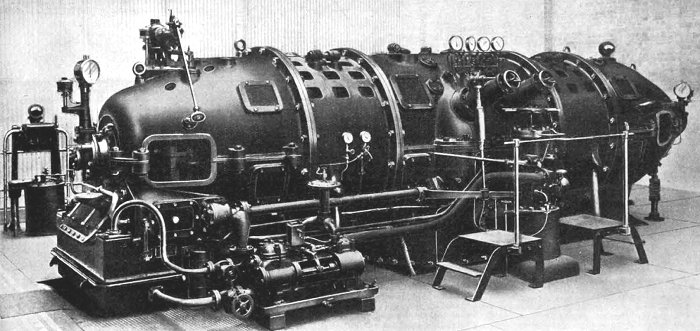

Electricity was generated by a

5,000 kilowatt Brush-Ljungstrom turbo-alternator

working at a steam pressure of 180 lb. per square

inch. This was directly coupled to two Brush

three-phase, 6,600 volt alternators, having a

combined output of 5,000 kilowatts, as shown below.

The Brush-Ljungstrom turbo-alternator set.

The power station began

producing electricity around 1916, but the official trials of the

alternator were not carried out until 23rd May,

1922. They were completely successful, and followed

by further trials on November 22nd. The thermal

efficiency of the station was found to be 17.49

percent. Further extensions of the three-phase

feeders, and four-core distribution cables were soon

carried out by Callenders Cable and Construction

Company Limited, which improved the supply, and greatly benefitted many of

the local factories.

In 1925 the power station came

under the control of the West Midlands Joint

Electricity Authority which supplied power to much

of the West Midlands. In 1944 the Authority decided

to build a new power station on the Walsall site,

alongside the old Birchills Power Station. After

nationalisation of the industry in 1948, Walsall

became part of the Midlands Region of the Central

Electricity Generating Board. The new power station,

called 'Walsall B', officially opened on 30th

September, 1949 and had six cooling towers, and six

tall chimneys above the generating hall. It burned

‘slack’ coal, a mixture of coal and coal dust which

was delivered by road, rail and the canal. As with

the earlier power station, cooling water was taken

from the canal. There were six main

turbo-generators, each producing 34,000 kilowatts.

With the addition of two smaller diesel generators

and three machines in the old power station, it

produced a total of 225,500 kilowatts.

The new power station under construction.

When the new power station

began generating in 1949, one of its 34,000 kilowatt

machines could supply almost the entire electricity

for Walsall and Aldridge. By January 1963, it took

four of the station's six main machines to supply

the area because of a step rise in demand.

|

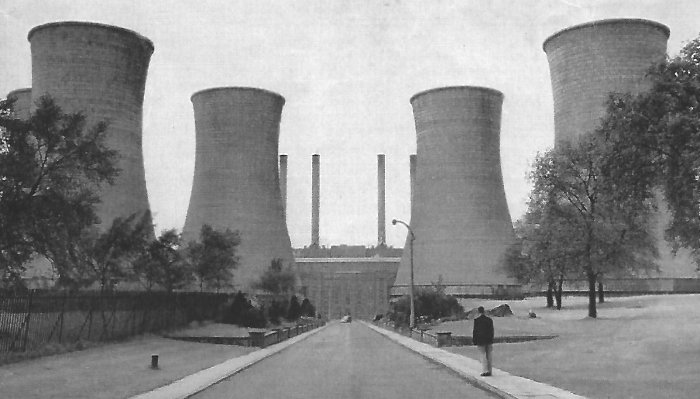

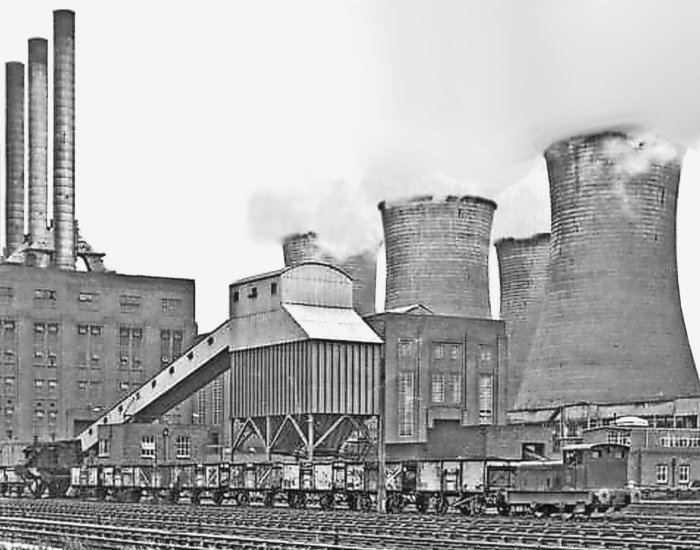

The new power station. Courtesy of John &

Christine Ashmore. |

The new power station cost

£12,000,000, and burned 450,000 tons of coal a year.

The coal store could hold up to 135,000 tons. The

twelve boilers evaporated 2,400,000 pounds of steam

per hour, and were stoker-fired to raise the steam

to 875 degrees Fahrenheit at a pressure of 650 lbs.

per square inch. There were four distillation

plants, capable of purifying 60,000 lbs. of water

per hour, to provide a pure supply of water for the

boilers.

After use, the steam from the

turbines was condensed in the cooling towers so that

it could be reused. The cooling towers were 165 ft.

in diameter at the base, 100 ft. in diameter at the

top, 240 ft. high, and each weighed over 2,700 tons.

There were also water-cooled condensers supplied

with water from the canal. When the power station

ran at full load, the condensers required nearly

10,000,000 gallons of canal water an hour.

Electricity was generated at

33,000 volts, then stepped-up by transformers to

132,000 volts for the National Grid. The power

station employed 366 people. By the early 1980s it

had become less efficient than its modern

counterparts, and so it closed in October 1982.

After standing empty for nearly four and a half

years, it was demolished in March 1987. The first

buildings to go were the cooling towers. Two were

demolished in November 1984, two more in June 1985

and the last two in November 1985.

|

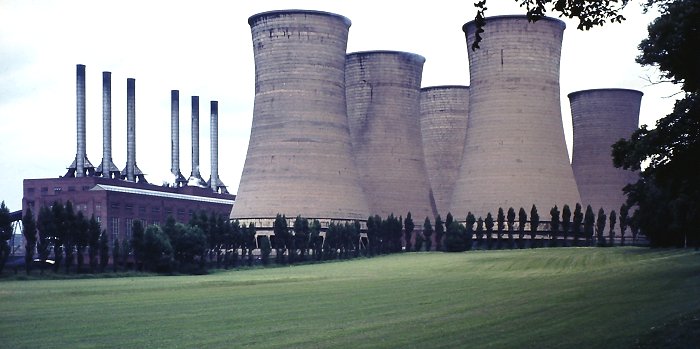

The power station. Photo taken by Richard Ashmore. Courtesy of John & Christine Ashmore. |

|

The power station from Bentley Common.

Photo taken by Richard Ashmore. Courtesy of John & Christine Ashmore. |

Looking past a lovely old cottage

towards Reedswood Park and the power

station. Photo taken by Richard Ashmore. Courtesy of John & Christine Ashmore. |

|

|

| In the distance is the

once-familiar sight of Birchills power

station. The photograph from the 1970s

was taken by Richard Ashmore. Courtesy of John & Christine Ashmore. |

The power station dominated much of

the local landscape. A view from

Edinburgh Avenue, Bentley, looking

towards Kent Road. The photograph was

taken by Richard Ashmore. Courtesy of John & Christine Ashmore. |

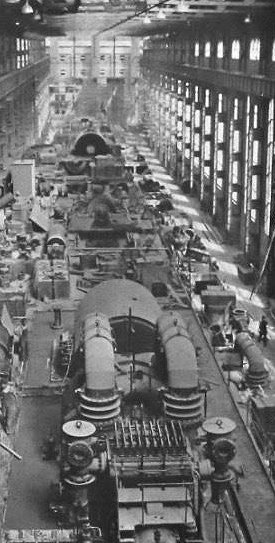

One of the six 30MW turbo-alternators,

which ran at 3,000rpm. at a steam pressure of 600psi. and a

temperature of 850 degrees Farenheit. |

|

The turbine room during construction. |

I must thank John and Christine Ashmore

for their help in producing this

section.

|