|

William Mills Limited

A once familiar sight in Friar Park Road, for over fifty

years, was the factory of William Mills Limited,

aluminium founders.

William Mills started the business

in the 1890s at Sunderland, making ships’ gear of all

kinds, including iron castings produced in the firm’s

foundry. By 1898 an aluminium foundry had been added to

the site, which must have been one of the first in the

country. Amongst other things the foundry produced

castings for the Mills putter, considered an essential

buy for enthusiastic golfers.

The firm soon started to produce

castings for the up and coming car industry, and had a

stand at the 1903 Automobile Show at Crystal Palace. In

the same year the firm became a limited company. At the

time, the motor car industry in the West Midlands was

rapidly developing, and possibly because of this,

William Mills decided to relocate the business to the

Midlands, and opened a foundry in Grove Street, on the

border of Birmingham and Smethwick. |

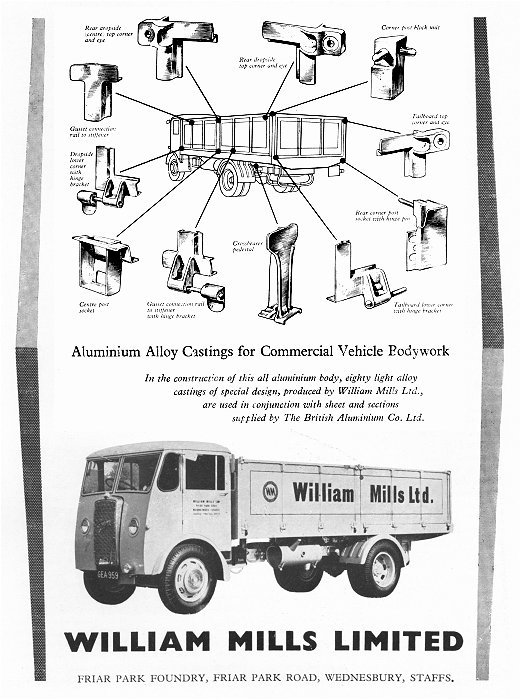

An advert from 1923.

|

The new foundry began turning out a

large number of castings both in iron and aluminium alloy,

mainly for the motor industry. The firm also made cooking

utensils, and a popular type of roller skate which had

aluminium wheels. By 1914 there were around three hundred

employees.

In the First World War the foundry

produced lightweight castings for the newly formed aircraft

industry which rapidly grew as part of the war effort. At

this time, William Mills invented a terrible weapon, the

Mills hand grenade, which was not produced at the foundry,

but by the Mills Munitions Factory in Birmingham and by a

host of contractors. William Mills opened the munitions

factory in 1915, and around 75,000,000 grenades were

produced. Due to his contribution to the nation’s armoury,

William Mills received a knighthood in 1922.

In the early 1920s, William Mills

Limited was acquired by The British Aluminium Company

Limited in order to extend their range of cast aluminium

products. The production of iron castings ceased, and from

then-on the firm concentrated on the production of aluminium

castings. |

Friar Park Works.

| New laboratories and an up-to-date heat treatment plant

were built and the firm became one of the leading producers

of aluminium castings. Initially traditional sand casting

continued to be used, in which a fresh sand mould had to be

produced for every casting. In order to streamline

production, die casting was introduced in which an

accurately machined cast-iron mould could be used many

thousands of times before replacement. It was one of the

first die casting foundries in the country. Products

included aluminium alloy wheels, and castings for internal

combustion engines. |

An advert from the mid 1950s.

|

An advert from 1968. |

Sir William Mills also invented a

patent instantaneous engaging and disengaging gear for

ships, and a telescopic walking stick seat. He died in 1932

and the business continued to thrive. At the start of World

War 2 the firm came under government control and was

required to produce medium and large aero engine castings. A

new foundry opened in Friar Park Road, Wednesbury which was

designed and managed by the firm. Products included the

aluminium blocks for the Merlin engine used in the Spitfire.

After the war the company took over

Friar Park Foundry from the government and sold-off the old

works in Grove Street. The new factory had been designed for

the production of sand castings of a particular type, but

changes had to be made to permit the production of a much

wider range of castings of different types and sizes, and

also die castings which would form a large proportion of the

output. |

|

As well as the traditional gravity die

castings, high-pressure die castings were introduced, using

new machines which could produce castings of up to 10lbs in

weight, in great rapidity, with thinner sections and of

great accuracy. Some of the castings were so accurate that

the need for subsequent machining was eliminated.

The process was again improved so that

precision castings of up to a hundredweight or more could be

produced, including engine blocks, and even parts for guided

missiles.

Sadly the factory closed some years

ago, and all traces have now disappeared. |

|

|

Return to the

previous page |

|