| C. & L. Hill Limited Iron foundries and brass foundries were

once a common sight in the Black Country, where cupola

furnaces could be seen in every town. Some foundries

produced finished products that were sold under their own

name, but the majority supplied the essential castings that

formed some of the major parts of locally made items.

One such foundry was C. & L. Hill

Limited, which started life in Doctor’s Piece, Willenhall.

The business was founded by Charles and Lemuel Hill, on 13th

December, 1899, to manufacture small brass castings for the

trade. Early products ranged from stair rod eyes to six inch

diameter door knobs. Around thirty moulders were employed in

the foundry, and business was good. The company soon outgrew

the small factory and looked around for a new site on which

to expand.

In 1913 a new factory was built in

Stringes Lane, which consisted of a brass foundry, and an iron

foundry. During the First World War considerable numbers of

cast iron annealing pans, cast brass shell adaptors, brass

shell hoses, and petrol can caps were produced.

In 1920, the two company founders died within a

few weeks of each other. On 29th June, 1921 a limited

company was formed under the chairmanship of Mr. Maurice

Slater. The board of directors (of which there were four) included Mr. A. E. Owen,

Managing Director of Rubery Owen in Darlaston. The new

company operated from the premises in Stringes Lane, and

owned houses in Victoria Street and John Harper Street. |

|

In the early 1920s there were large

numbers of brass foundries in the area, and so competition

in the production of small brass castings for the trade was

rife.

The directors decided that the best way forward was

diversification, and so the foundry was extended to produce

non ferrous castings for the engineering and electrical

trades, and annealing pans. An aluminium foundry was added

in 1922.

On 30th December, 1929 Mr. A. E. Owen

died. He was replaced on the board by his son Mr. A. G. B.

Owen, who was appointed Managing Director in March 1930. |

| Mr. Maurice Slater.

From 'Goodwill' staff magazine, spring 1948. |

|

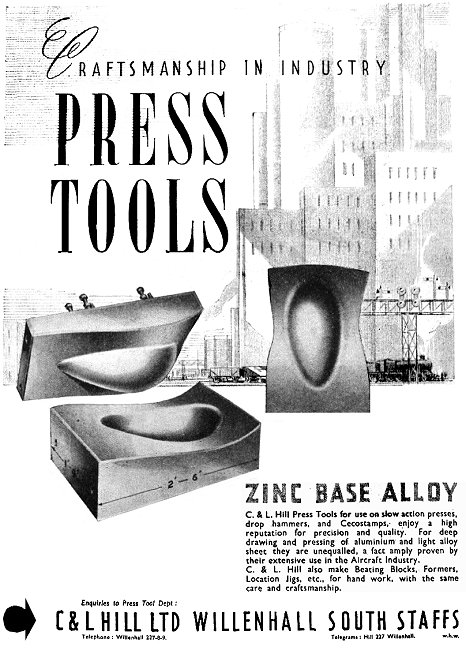

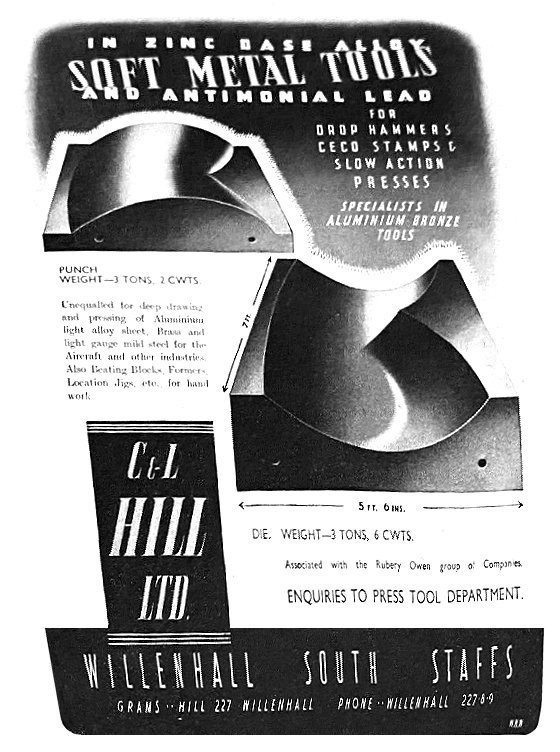

An advert from 1943.

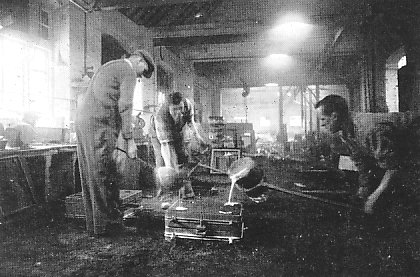

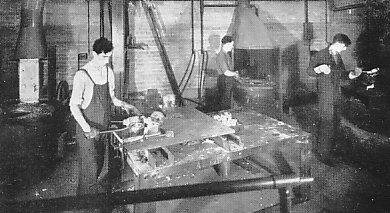

Hand casting in the foundry. From

'Goodwill' staff magazine, spring 1947. |

In 1930 the foundry was extended again, this time to

produce chill cast phosphor bronze bars for the engineering

trade. In 1934 the annealing pan business was sold, and in

early 1935 the decision was taken to reduce the company's

capital. This resulted in the business being put into

voluntary liquidation, and reconstructed by the formation of

a new company with the same name (C. & L. Hill Limited) to

take over the business and part of the assets.

The new company was incorporated on 10th April 1934. |

| With the sale of the iron foundry, the firm specialised

in non-ferrous sand castings and non-ferrous alloys. Chill

cast phosphor bronze bars known as "Hilchil Phosphor Bronze

Bars" were also produced.

Admiralty contracts were secured for the

production of bronze castings for electric switch boxes, and

cores, which in 1937, as part of the rearmament programme,

led to large Admiralty orders. Products for the Admiralty

included torpedo parts, switch

boxes, and electrical equipment for navy vessels. This led

to the enlargement of the foundry, and the installation of

new plant. |

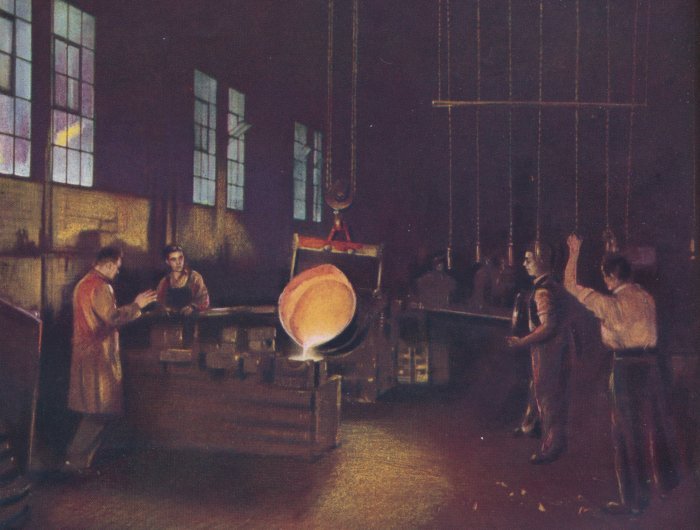

Casting a large mould. From 'Goodwill'

staff magazine, spring 1948. |

A corner of the aluminium gravity die

casting department. From 'Goodwill' staff magazine, spring

1948. |

During December 1939 a branch works

opened in Wednesfield Road, Willenhall.

At the outbreak

of war, both foundries began producing war work for the

Admiralty, the Ministry of Supply, and the Ministry of

Aircraft Production.

The two foundries worked flat-out to

complete the orders and new plant was installed at

Wednesfield Road. One important product was bronze compass

coil corrector cases to combat German magnetic mines.

|

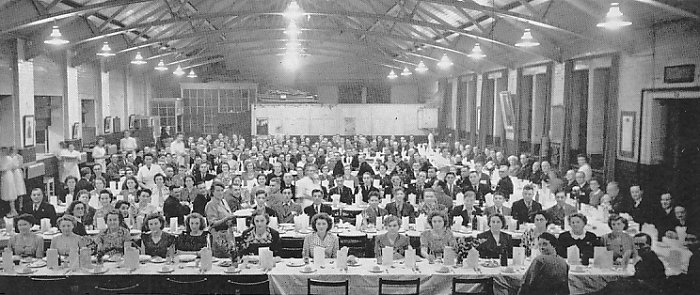

Hill's jubilee dinner at the

Rubery Owen Concert Hall, on October 13th, 1949. From

'Goodwill' staff magazine, Christmas 1949. |

|

An advert from 1954. |

During the Battle of Britain, the

company began to manufacture press tools for the aircraft

industry, and developed a range of zinc base tools for the

production of air intakes, and fuel tanks etc. Hill’s

produced the oil fuel tanks for De-Havilland Mosquitos,

petrol tanks for Supermarine Spitfires, and tools for the

Short Brothers’ Sunderland flying boats. In 1944 the company became part of the

extensive Owen Organisation, after Rubery Owen & Company

Limited began to invest in the business. Hill’s war work for the aircraft industry led to the

development of zinc alloy tools for the production of items

made from Perspex, and also tools for the production of

rubber handle bar grips. In order to ensure that demand

could be met, a number of centrifugal machines were

installed at the factory.

The two foundries were organised into

six departments, which included a laboratory and research

department. Castings were made in brass,

gunmetal, phosphor bronze, copper, aluminium alloy, light

alloy, zinc, and lead. Chill cast bars, and gravity die

castings were also produced. One of the departments

specialised in metal refining.

|

|

Castings were produced to 44

specifications, in weights of 1 oz. to 1 ton. Zinc tool

castings were made up to 4 tons. Customers included the

motor, and aircraft manufacturers, atomic energy companies,

and the general engineering trade.

|

|

New offices were opened at Stringes

Lane in June 1949, followed by a new canteen in September

1951.

Staff members fully participated in the various social

activities that took place within the Owen Organisation.

Hills had an active horticultural society, a rifle club, and

an angling club, which regularly competed with similar clubs

run by the other factories in the organisation.

Staff members also competed at sports events, often held locally at Rubery Owen’s sports ground at Bentley. There were also day

outings, and social events in the canteen, organised by the

canteen committee.

In the canteen, workers could play darts, and snooker

etc.

|

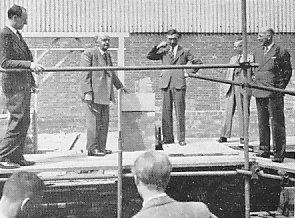

The stone laying ceremony at the new

offices. Left to right: Mr. A. G. B. Owen, Mr. Maurice

Slater, Mr. W. Bradley (builder), Mr. A. Griffiths (Rubery

Owen), and Colonel Lindop (director). From 'Goodwill' staff

magazine, autumn 1949. |

|

An advert from 1943. |

Mr. A. G. B. Owen making a speech

at the opening of the new canteen. From 'Goodwill' staff

magazine, Christmas, 1951. |

|

|

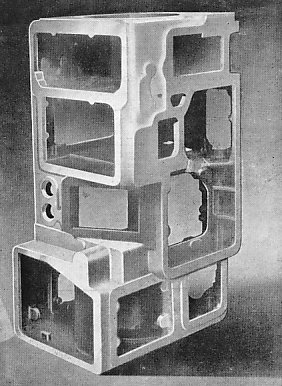

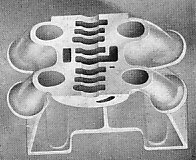

Examples of some of the

intricate, high quality castings that were produced in

the foundry. On the left is a gun metal sand casting,

and above are aluminium gravity die castings.

From 'Goodwill' staff magazine,

spring 1948. |

|

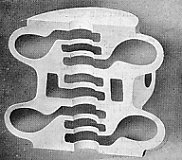

Two gun metal sand castings,

sectioned to show the cored ports.

From 'Goodwill' staff magazine,

spring 1948. |

|

|

In 1971 Rubery Owen & Company Limited

bought the last remaining 33.3% preference shares. Sadly the

factory closed in 1972 and the property was sold. C. & L.

Hill Limited had the following subsidiaries: Central

Patternmaking Company Limited; Hill, Alzen Sales Limited;

and C. & L. Hill (Die Castings) Limited. In 1981 the dormant

company changed its name to Rubery Owen (Pressings &

Fabrications) Limited.

Based on articles and reports from

editions of ‘Goodwill’, the Owen Organisation’s magazine;

and the Owen Group records.

|

|

Return to

the

previous page |

|