| Electric tramcars on the

South Staffordshire and Birmingham District Tramways Company

Limited, Later South Staffordshire Tramways Company Limited. |

|

Plans for

Electrification

The company decided that electric

traction was the way forward as early as 1888. The seventh

annual meeting took place in the company's offices at

Darlaston depot on 29th March, 1888. At the meeting the directors

agreed to promote a Bill to incorporate the company in order to extend the company’s

operating powers, and to use electric traction on the

network. This resulted in the passing of the South

Staffordshire Tramways Act, 1889 which allowed the company

to be incorporated as the South Staffordshire Tramways

Company. The Act also allowed the company to borrow a

maximum of £50,000.

The following officials were present at

the meeting:

Chairman - W. J. Carruthers Wain

Directors - W. Busby, C. E. Davison, C. James, and the newly

appointed F. H. Lloyd

Company Solicitor - Joseph Smith

General Manager - Alfred Dickinson

Company Secretary - H. Hatchett

Mr. W. J. Carruthers was also Managing

Director of the Birmingham Tramways Company.

Mr. Alfred Dickinson was also

consulting engineer to the Birmingham Tramways Company, and

the Birmingham Cable Tramway Company.

Mr. Joseph Smith, who had previously

been Town Clerk of Wednesbury was also Chairman of the

Birmingham Tramways Company, and Managing Director of the

Electric Construction Corporation Limited of Wolverhampton. In October 1890

he went on a fact finding tour of the United States of

America to look at electric tramway systems in the country,

and while there gave a talk to the American Street Railway

Association about English tramways. Around this time he

changed his name to Joseph Ebbsmith.

Mr. W. J. Carruthers Wain and Mr Joseph

Smith were two of the key founders of the Tramways Institute

of Great Britain and Ireland. Mr. W. J. Carruthers Wain

became President of the Institute.

On 4th March, 1891 at the company's

annual meeting, the chairman stated that running costs had

increased to 12.71 pence per mile, in spite of rigorous

economies. The directors felt that the only sensible way to

reduce running costs was to use an overhead electric wire

system. The company had already contacted a number of

electrical firms who had sent representatives to see what

was possible, and were expecting to receive proposals and

quotations. The company produced an elaborate

booklet entitled "Electric Traction for Ordinary Tramways,

Descriptive Pamphlet, 1891". It extolled the virtues of

electric traction and stated that the company was ready to

recommend that shareholders should agree to electrifying the

tramway from Bloxwich to Wednesbury via Walsall using an

overhead wire.

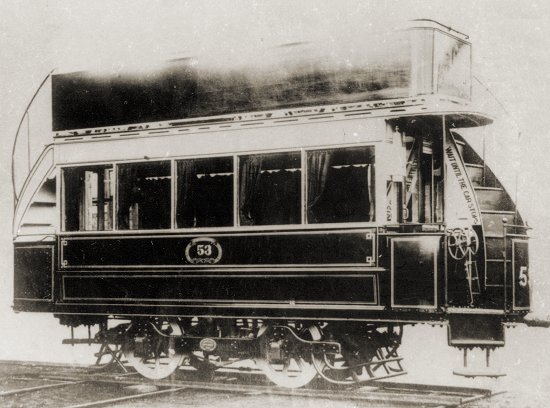

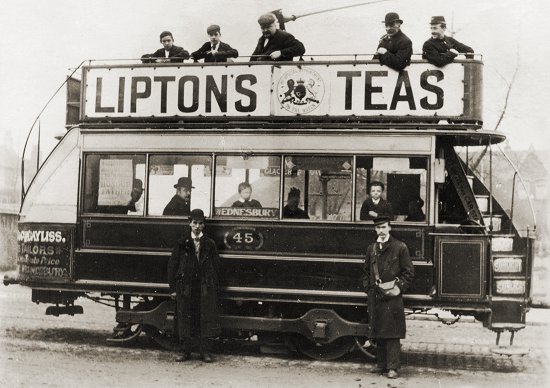

A South Staffs electrically-powered

tramcar.

In April 1891 the company approached

both Walsall and Wednesbury councils to ask permission to

electrify the tramway from Walsall to Wednesbury, and

Walsall to Bloxwich, using a system of overhead wires.

Wednesbury Council immediately agreed to the proposal, but

Walsall insisted that the company should pay the expenses of

Walsall Corporation's adviser on electric traction, Mr.

Frederick Brown, for a fact-finding trip to the USA to investigate the

various systems in operation there. The company agreed and

also sent Alfred Dickinson along to gather information.

During three weeks in May and June 1891 the pair travelled

about 4,000 miles around the country and visited all of the

main networks.

On his return, Alfred Dickinson stated

that he preferred either the Thompson-Houston or the

Edison-Sprague system, and applied to the Darlaston Local

Board for permission to electrify the line from Darlaston to Mellish

Road, Walsall. Mr. Brown submitted a report to Walsall

Corporation in which he stated that the overhead system of

electrical traction called the trolley system, would be the cheapest, safest, and most efficient

means of running street cars. He thought that the side pole

and span wire system would be the most suitable for use in

Walsall.

Alfred Dickinson presented a paper to

the Tramways Institute of Great Britain and Ireland, on 30th

December, 1892, in which he stated that the only methods of

electric traction to consider were the accumulator, conduit,

and overhead wire systems, only the latter of which had so

far proved to be perfectly satisfactory.

On 17th September, 1891 an

extraordinary company meeting was held to decide upon the

methods to be used to raise the required capital needed to

electrify the network. It was decided that the required

amount would be borrowed by taking out a mortgage on the

company's undertaking.

At that time the only overhead wire

system in operation in the country was at Leeds on the

Roundhay Line. The town councils sent a deputation to Leeds

to inspect the line. After the inspection, it was felt that

the overhead wires in use at Leeds were unsightly and so

unsuitable for use. Alfred Dickinson however, had already

been considering this problem, and on 28th March, and

21st December, 1891 he submitted patent applications for

"Improvements in masts and trolleys for the Overhead

System". On 13th February, 1892 a patent was granted for a

mast or arm fitted to the tramcar by a ball and socket

joint, and controlled by springs, so that it could swing in

any direction. The trolley would be kept in position under

the wire by guides extending above the wire, which were

sprung on hinges so as to pass obstructions. His successful

design became the standard, and fore-runner of the later

swivel-head trolleys used on trolley buses.

Alfred Dickinson's design was submitted

to the local authorities, and unanimously approved. The

company agreed that wherever possible, the poles with the

bracket arms for carrying the trolley wire would be placed on the site of existing gas lamps, and would

carry the gas lamp. This would reduce the number required

and reduce the amount of street clutter. The

routes would also be single track with passing places in

order to reduce the amount of overhead cabling.

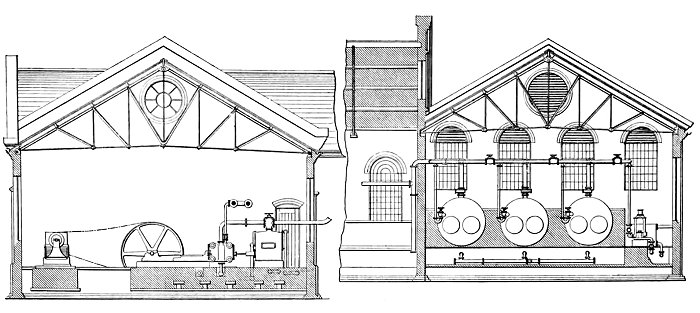

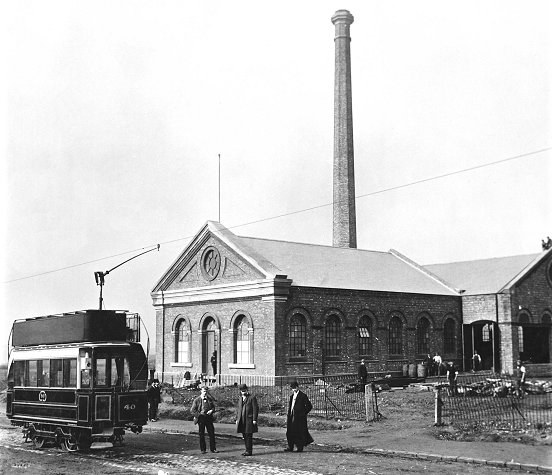

Pleck electricity generating station.

In 1892 the company entered into a

contract with the Electric Construction Corporation Limited,

Wolverhampton for the equipping of the company's lines from

Walsall to Wednesbury, Darlaston, and Bloxwich, and the

building of an electricity generating station at Pleck. E.C.C.

would also supply all of the electrical equipment and

tramcars, maintain the network, and operate the services for

a period of five years. Payment was to be by a fixed charge

per car mile. The company had close links with the E.C.C.

through its secretary, Joseph Ebbsmith who was Managing

Director of E.C.C., and Alfred Dickinson who had worked

closely with the firm during its installation of the the

electrical equipment for the Bristol Road accumulator

tramway in Birmingham. The work would be personally supervised

by the E.C.C.'s Manager and electrical engineer, Mr. Thomas

Parker.

Work in Progress

By April 1892 the E.C.C. were

manufacturing equipment for the line, and by August, poles

were being erected along the streets. The mild steel poles

were made by James Russell & Sons Limited at Wednesbury,

and John Russell & Company Limited at Wednesbury and Walsall. Part of the

Darlaston depot was equipped for electric traction, as was

part of Birchills Depot.

The generating station was built

alongside Darlaston Road at Pleck, adjacent to the Walsall

branch of the canal from where coal could be delivered

directly to the building, and water used to condense steam. There were three 120psi Lancashire-type boilers and

three 125hp. horizontal-coupled compound steam engines, all

made by Musgrave & Sons of Bolton. The engines had Corliss

valve gear and each drove an Elwell-Parker type shunt-wound

dynamo via multiple cotton ropes. The dynamos each provided

350 volts DC at 260 amps at a speed of 450 rpm. Only two of

the engines and dynamos would be in use at any one time, feeding

350 volts to the line via a switchboard.

The trolley wire was roughly divided

electrically into half mile sections, each fed from a cable

beneath the road, and a fusebox under the pavement, adjacent

to the nearest pole.

The rolling stock consisted of 16

double deck cars, 8 built by Brown, Marshall & Company, and

8 built by the Lancashire Carriage and Wagon Company. They

seated 18 passengers inside, 22 outside, and weighed 6

tons 13 cwt.

The prestigious engineering magazine, 'The Railway

Engineer' was very sceptical about the project. The January

1893 edition carried the three short articles below:

|

|

|

|

All of the electrical equipment was

made by the E.C.C. including two Elwell-Parker type 15hp. series-wound

motors for each car, and all of the control gear. The motor

controls and two sets of brake controls were fitted under

the stairs, and the motor-control resistances were fitted

under the floor. The poles for the overhead wire were

placed at the side of the road, and the bracket arms

carrying the trolley wire stretched out over the

road from 7 to 10 feet, giving a clear height of 21 feet. By a kind of

universal joint, as in Alfred Dickinson's patent, the

trolley was allowed a variation of several feet, so that the

wire didn't have to be directly over the middle of the

track. |

|

South Staffordshire Tramways.

From The Engineer, 18th November, 1892.

Early in the present year

the South Staffordshire Tramway Company entered

into a contract with the Electric Construction

Corporation, of Wolverhampton, for the equipment

of a section of its lines with plant for

electric traction on what is generally known as

the trolley wire system, the lines having

hitherto been worked by steam locomotives. The

plant is now practically completed, and the

inspection by General Hutchinson and Major

Cardew, on behalf of the Board of Trade, took

place on Saturday, November 12th, so that the

electric cars will very shortly come into

service.

The lines over which the electric cars are to

be run extend from the junction of Holyhead Road

and Bridge Street in Wednesbury, through the

centre of the borough of Walsall, to Bloxwich,

with two branch lines, one running from the

Pleck to Darlaston, and the other from Walsall

to Mellish Road. The length of streets occupied

by the tramways is just over eight miles, six

miles having a single line with turn-outs, the

other two miles having a double line, making a

total length of track, and therefore of trolley

wire, of over ten miles. The route taken by the

lines is shown on the map - Fig. 5 - which also

indicates the position of the generating station

on the line between the Pleck and Darlaston.

|

|

Fig. 5. A map of the tramway. |

|

The generating station at Pleck, Walsall. |

|

The generating station is

on the side of the canal, and has a basin for

receiving the barges bringing coal, which

discharge directly into the boiler room. The

canal water is used for condensing.

The general arrangement of

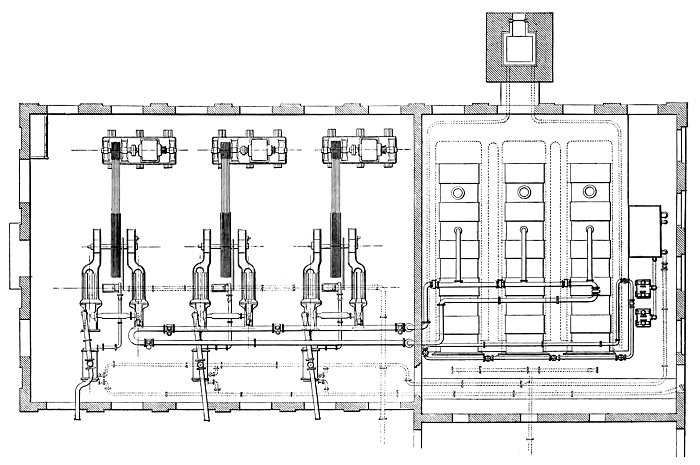

the buildings and plant is shown on the plan and

section - Figs. 6 and 7. The three boilers are

of the Lancashire type, 7ft. diameter, 30ft. in

length, designed for a working pressure of 120

lb. per square inch. The three engines, which,

together with the boilers, were made by Messrs.

J. Musgrave and Sons, of Bolton, are of the

horizontal coupled-compound pattern, each easily

capable of indicating 125 horse power with the

above steam pressure, when running at a speed of

100 revolutions per minute. The cylinders are

10½in. and 20in. diameter, 30in. stroke, both

cylinders being fitted with Corliss valve gear;

the flywheels are 10ft. in diameter, and grooved

for seven l¼in. diameter ropes. A surface

condenser is attached to each engine. The steam

and feed pipes are arranged so as to give a

duplicate service between the engines, boilers,

and pumps. |

|

Fig. 6. The generating station. |

|

Fig. 7. A plan of the generating station. |

| Arrangements are also provided so that the

engines can be run non-condensing if required.

The dynamos, one of which is driven from each

engine by means of cotton ropes, are of the

usual Elwell-Parker type, and give an output of

260 amperes at 300 volts, when running 400

revolutions per minute, the field magnets being

shunt wound. The driving pulleys are carried

between two bearings, and there is a coupling

between the pulley and armature shafts, so that

the latter can at any time be removed without

taking off the ropes or dismounting the pulley. |

| Each dynamo is connected by cables carried

under the floor to a patent Elwell-Parker

automatic magnetic contact, which also acts as

the main switch for the machine. These

contacts are adjusted so that, in the event of

an excessive current being demanded from the

machines - due to any accident or short circuit

on the lines - the circuit is opened, and any

damage to the machines prevented.

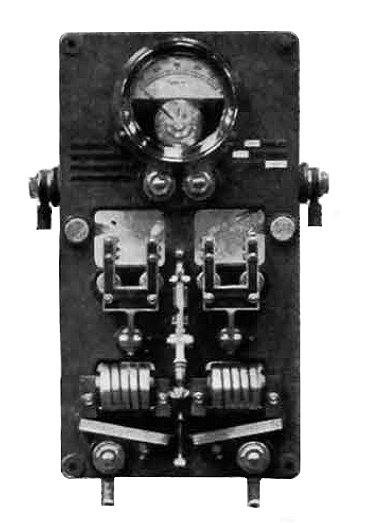

All three machines feed in parallel on to

common omnibus bars, between which and the

feeders taking current out to the line there is

a simple main switch. Ammeters are provided in

each dynamo circuit, and a voltmeter with large

dial indicates the electromotive force across

the omnibus bars.

Multiple contact switches and resistance

coils are connected in the shunt circuits for

regulating the electromotive force.

A section of the switchboard showing the

arrangement for each machine is illustrated in

Fig. 4. |

Fig. 4. The switchboard. |

|

From the generating station

the current is supplied to the 0 gauge copper

trolley wire by underground feeders, these being

insulated with vulcanised bitumen, lead

sheathed, and armoured with a double layer of

steel tape, so that they can be laid directly in

the ground without further protection; the

lengths and sections of the feeders are

indicated in the map - Fig. 5.

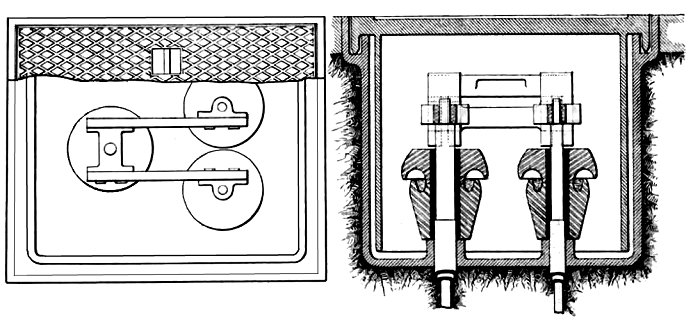

The return circuit is

completed through the rails and earth. At

distances of approximately half a mile apart

connections are made between the feeders and

trolley wire by means of cables drawn up inside

the posts. Each section of trolley wire is fed

into at both ends, the current passing through

fuses placed in an underground box - Fig. 8 - at

the foot of the feeding posts. These fuse boxes

are made on the diving bell principle, to

prevent any possibility of water accumulating in

them and rising sufficiently high to reach the

connection. The covers are easily drawn up to

allow of examination or insertion of new fuses.

The map - Fig. 5 - shows the position of the

feeding points and fuses. |

|

Fig. 8. Underground fuse boxes. |

| The trolley wire is carried at a height of

20ft. from the surface of the streets by poles

along one side of the road only; arms projecting

from the poles - Fig. 7 - carry the insulators

supporting the wire. A special arrangement,

suggested by Mr. Dickinson, the Tramway

Company's engineer, makes it unnecessary that

the trolley wire should be at a regular distance

from the centre of the rails, the collector

being designed so as to allow a variation of

several feet. Where there is a double line of

rails the pole arm carries two insulators and

two trolley wires, one for the up and one for

the down line. Automatic overhead switches are

fixed at the turn-outs, so as to guide the

collector wheel along the right wire. Fourteen

cars made by Messrs. Brown, Marshall, and Co.,

and the Lancaster Wagon Company, are being

supplied for the equipment of the line, each

carrying forty passengers, eighteen inside and

twenty-two outside. The collector is fixed on

one side of the roof of the car, the arrangement

being clearly shown in Fig. 7. |

|

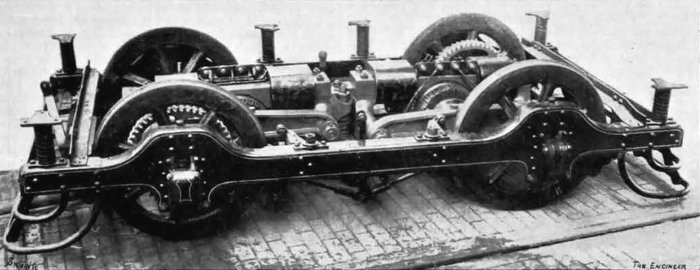

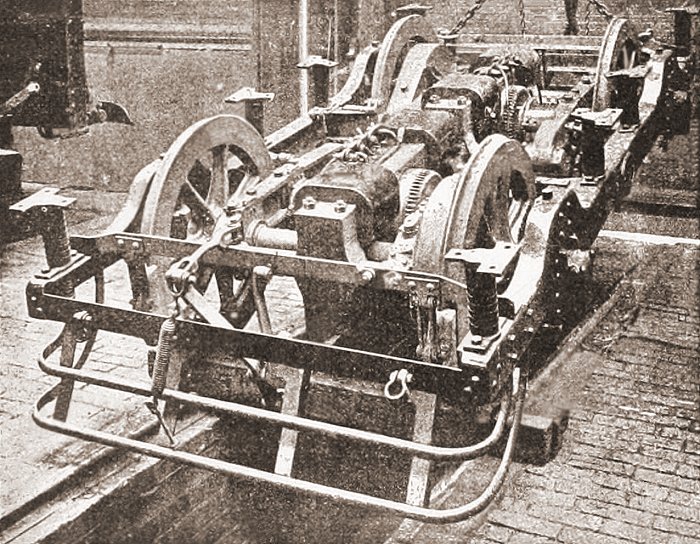

Fig. 2. An under truck with motors. |

|

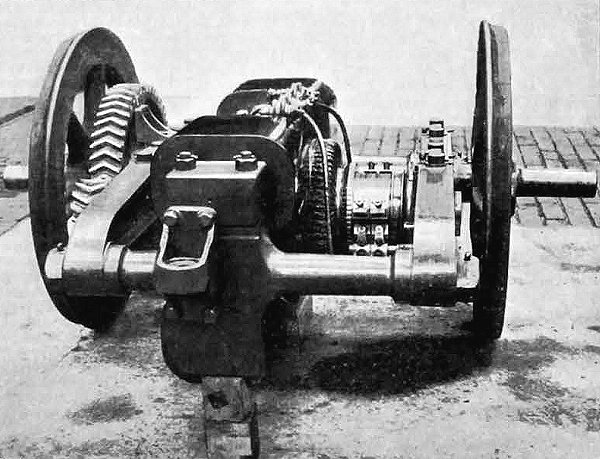

Fig. 3. An Elwell-Parker motor. |

| The under trucks - Fig. 2 - carry two Elwell-Parker

series wound motors - Fig. 3 - each capable of

running continuously with a load of 15

horsepower, the normal speed being 400

revolutions per minute; the armatures are geared

up to the axles by means of cast steel double

helical wheels and pinions, having a ratio of 4

to 1. One motor is considered to be amply

sufficient to take a fully loaded car up the

heaviest gradient of 1 in 28 occurring on the

line. The practice of using two motors on each

car appears to have been brought over from

America, where the lines are not so well laid,

and where, also, they have to contend with snow

and ice throughout the winter. On very few lines

in England do we consider that it will be

necessary to use two motors, although it will be

necessary that the one motor shall be more than

15 horsepower, unless a simple form of gear for

varying the speed with a constant speed of motor

be used. Driving switches are fitted at both

ends of the car, and arranged so that either or

both of the motors can be in use, the regulation

of speed being effected by putting resistance

into the motor circuit. The

whole of the electrical plant has been designed,

manufactured, and installed by the Electric

Construction Corporation, who are also

responsible for the other portion of the plant

supplied to them by various firms as

sub-contractors. The running of the line is also

in the hands of the Electric Construction

Corporation, they having undertaken to work it

at a fixed charge per car mile for a number of

years. Mr. Alfred Dickinson has been appointed

to superintend the working on their behalf. |

|

|

Another photo of an Elwell-Parker

under truck. |

|

The Line in Operation

The electrification work had been completed by November,

and so the Board of Trade inspection was carried out on

Saturday 12th November by Mayor General Hutchinson and Major

Cardew. They arrived by train at James Bridge Station and

were met by a large party including the mayors and officials

from Walsall and Wednesbury, several of the tramway

company's directors, Alfred Dickinson, and Thomas Parker from

the E.C.C. They boarded one of the new trams and travelled

to Darlaston depot, where the motors were inspected. The

party then re-boarded the tram and travelled back along the

same route to Pleck generating station for an inspection of

the mechanical and electrical machinery. Afterwards they

travelled in the tram over all of the electrified lines, which

were duly inspected.

Mayor General Hutchinson's favourable report arrived on

21st November and the official opening ceremony took place

at Pleck generating station on Saturday 31st December.

Guests included the Bishop of Lichfield, the mayors of

Walsall, Wednesbury and West Bromwich, the chairman and

directors of the tram company, and directors of the E.C.C.

The current was turned on by Mrs Carruthers Wain, and the

party proceeded in one of the new trams to the drill hall in

Walsall for lunch.

The new trams began running on 1st January, 1893. The

E.C.C. appointed Alfred Dickinson to oversee the working of

the line. They were operated by the E.C.C. as agreed in the

terms of the contract. The tramway company then paid the

E.C.C. 4½ pence per operational

mile. Eight of the new trams were based at the Darlaston

depot, and eight at Birchills. Each driver and conductor was

responsible for the operation of their tram, which they ran

for six days a week. On the seventh day it was

checked-over at the depot. No uniforms were supplied.

Drivers usually wore a bowler hat, and conductors had an

ordinary flat cap.

The new system worked well,

much to everyone's satisfaction. In the first twelve months

of operation the electric tramcars ran 262,692 miles and carried

1,668,057 passengers, at a cost of just 4.06 pence per mile,

compared with 7.04 pence for the steam trams. Although the

electrification had been a great success, the tram company

faced an uncertain future. Some of the shareholders were

extremely unhappy with the company, and in April and May,

1894 they urged their fellow shareholders to sign a petition

asking for the winding-up of the company. The petition was

presented by Mr. Alfred Dawson and other shareholders to Mr.

Justice Vaughan Williams in the Chancery Division of the

High Court of Justice. It made allegations of fraud, and

stated that the shareholders wanted more say in the running

of the company, and a new chairman. As a result, an

extraordinary meeting of the shareholders was held on 12th

June, and a new Board elected. They were: Chairman - Alftred Dawson,

Directors - William Somers

Schuster, and Samuel Richardson Blundstone.

| The April 1894 timetable for

the electric tramcars includes details of a fifteen minute

service between Bloxwich and Wednesbury via Walsall, and a

half hourly service between Darlaston and Mellish Road,

Walsall, via The Bridge.

The fare from Darlaston to The

Bridge was three pence, as was the fare from The Bridge to

Wednesbury.

Return tickets and season tickets could also be

purchased. |

Another view of Pleck

generating station, possibly taken during an early

inspection. |

Stormy Times

The company remained in a

poor financial state, so much so that the E.C.C. announced

that as from midnight on Friday 14th December, 1894, it

would end its contract with the tramway. The E.C.C. claimed

that it was owed between £7,000 and £8,000 by the tram

company. The sudden stoppage came as a blow to many people.

The electric trams had been very popular, operating a

frequent and punctual service that had become a necessity

for much of the local population. The Mayor and Town Clerk

of Walsall stepped-in to try and resolve the problem in

order to get the trams running again. Agreement was reached

between the two parties, and the trams began running again

on 22nd December, but from the 7th January, 1895 the fifteen

minute service on the Bloxwich, Walsall, and Wednesbury

route became half hourly. The fifteen minute service was reinstated in the

following September.

On 18th August, 1895 Mr.

Alfred Dickinson J.P., C.E. left the company to form his

own business in Birmingham as a tramway consultant. He was

replaced by Mr. J. J. Robins, but remained in overall charge

of the electrified lines on behalf of the E.C.C.

Problems resurfaced towards

the end of 1895 when the E.C.C. informed the local councils

that it could not continue to operate the line after the end

of the year because of the dreadful condition of the track,

which was in bad need of repair. Some work must have been

carried out because the trams continued to run.

In 1896 the tram company

became involved in two court cases. The first in February

was against Joseph Ebbsmith and W. J. Caruthers which

resulted in the company being awarded £12,845 plus costs.

The second involved the E.C.C. which was still asking for

the money it was owed. The case, held in the Chancery Court was

won by the E.C.C. and resulted in long-term negotiations

between the two companies. By June 1897 a provisional

agreement had been reached. The E.C.C. took-up an

interest in the tramway company and received a lease on

the electrical tramways.

Towards the end of 1896 the

newly formed British Electric Traction Company attempted,

but failed, to promote a Bill in Parliament to enable it to

take-over all of the local tramways, including the South

Staffs, and form a unified electrically-powered system.

After the failure of the Bill, B.E.T. began to contact

individual companies, and local authorities with the

intention of taking-over individual lines. On 11th June,

1897 it reached an agreement with the E.C.C. in which the

E.C.C. handed-over its entire interest in the tramway in

exchange for £50,000 in debentures. This was assigned to BET

by an indenture dated 29th July, 1897 which gave BET a

controlling interest in the company.

Another view of one of the electric

tramcars.

The story continues in

the following sections:

|

|

Return to the

electric trams menu |

|