| Introduction

Modern towns and cities rapidly grew during the

Victorian period when large numbers of people flocked

there to find work in the many factories and industries

that were appearing at the time. This resulted in

numerous problems including cramped living conditions

that were often unsanitary.

The industrious Victorians found

solutions to the problems and in doing so laid down the

basis of modern town and city life, which is dependant

upon many essential services such as gas and electricity

supplies, refuse and sewage disposal, an adequate

transport infrastructure and street lighting, schools,

hospitals, and last but very far from least, a clean and

reliable water supply.

The serious health problems that

can arise from an unclean and inadequate water supply

caused many deaths in the 19th century. Large

numbers of people died as a result of the cholera

epidemics that occurred in 1831 to 32, 1848 to 49, 1853

to 54, and 1865 to 66. The disease spread from India and

became known as Asiatic Cholera. It spread via trade

routes and reached Europe in 1826, spreading from Turkey

to Russia, Poland, Germany and the Baltic ports, from

where it came to Sunderland in 1831. In January 1832 it

arrived in Newcastle and Gateshead and soon reached

York, Leeds, Manchester, the Black Country, London, and

reached Devon and Cornwall during the autumn.

In Bilston there were 745 deaths

and from 50 to 200 deaths in each of the other Black

Country towns. In London there were 4,218 deaths.

Thankfully by the end of 1832 the epidemic had ended.

The disease returned in 1848 and again lasted for around

two years. This time there twice as many deaths.

When the disease returned in 1853

people began to realise that it had something to do with

the unclean water supply, although the exact cause was

not initially understood. As before there were many

deaths in London, and after the "Great Stink" of 1858

when the River Thames smelled of raw sewage, something

was finally done. During the next 7 years Joseph

Bazalgette and the Metropolitan Board of Works

constructed London’s immense system of sewers, which led

to a clean water supply and the eradication of the

disease. It was then accepted that cholera was spread by

a water-borne bacteria, and the importance of a clean

water supply became apparent.

|

|

Throughout the country local

authorities built water works and these were greatly

improved to provide a plentiful supply of clean water.

Wolverhampton was typical in this respect and greatly

benefited from the work of the local authority's water

committee, whose members worked tirelessly to provide an

essential and adequate supply of clean water. This

greatly improved people's lives and helped to reduce the

amount of disease, and the resulting death rate.

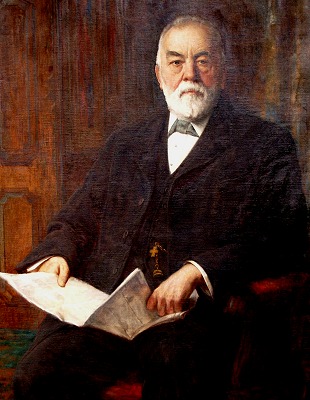

One of the important figures on the

committee was its chairman John Marston, better known as

the manufacturer of Sunbeam bicycles, motorcycles and

cars.

By a strange coincidence, one of

his homes, The Oaks in Merridale Road was purchased by

the water company in the early 1950s and became the

company's office. Partly thanks to his work the town

eventually received the high quality water supply that

it needed. |

| John Marston in

his later years. Courtesy of the Marston

Wolverhampton Heritage Trust. |

|

| To commemorate the committee's achievements a small

booklet was published in 1911 describing the development

of the water works. The booklet, which provides a

detailed description of the works can be read below. |

|

A Brief History of Water

Undertaking and Description of New Works Officially

opened by Alderman John Marston J.P. Chairman of the

Water Committee. 20th July, 1911

|

|

In the year 1845 a small company

was formed under the style or title of "The

Wolverhampton Waterworks Company" which sought and

obtained parliamentary powers to sink wells and

establish works at Tettenhall, for the purpose of

supplying water to the town and suburbs of

Wolverhampton.

The scheme of the company was

strongly opposed in Parliament by the proprietors of the

Staffordshire and Worcestershire Canal, who feared that

if wells were sunk below the level of their Canal and

extensive pumping operations were undertaken, their

waterway would be prejudicially affected, and as the

result of their opposition the depth of the wells was

limited to 18 feet below the level of the Canal at

Newbridge.

The effect of this limitation

practically ruined the scheme, for upon its completion

the company found that they could only obtain about

150,000 gallons of water per day instead of the million

gallons for which works had been constructed.

The Cornish "Bull" engines which

were installed were designed by one of the most

celebrated engineers of the day, Thomas Wickstead, and

their duty was to raise the water from the wells and

force it over a stand pipe fixed inside the structure

which is now used as the smoke stack. |

|

Tettenhall waterworks. |

The comparatively small quantity of water obtained

was inadequate for the needs of the district and the

company decided to apply for further powers and in 1851

powers were obtained to sink wells and establish works

at Goldthorn Hill, but the second scheme of the company

proved more costly and even more disappointing than the

first, for the new wells only yielded an additional

supply of 120,000 gallons per day of very hard water. |

|

Anticipating an abundant yield from

their new wells and headings the company had installed a

large Cornish beam engine and constructed two covered

reservoirs to hold 750,000 gallons each, but the small

yield of the new works was not commensurate with the

expenditure incurred, and it utterly failed to satisfy

the requirements of the district, consequently the

company was again forced to seek additional

parliamentary powers, and in 1855 embarked upon its

third and last venture. In the same year the

Wolverhampton Corporation and a new company styled "The

Wolverhampton New Waterworks Company" promoted bills in

opposition to the original company, and a three-cornered

fight ensued for powers to construct a pumping station

at or near Cosford Bridge, and to impound the upper

waters of the River Worfe.

The bills of the original company

and the Corporation were thrown out and the scheme of

the new waterworks company was sanctioned by Parliament,

and the following year the new company obtained another

Act for the transfer of the properties and rights of the

original company.

With the acquisition of the old

works, the new company appears to have revised its

scheme, for instead of constructing reservoirs to

impound the upper waters of the River Worfe, the river

course was slightly widened and a dam or weir

constructed in conjunction with the authorised pumping

station at Cosford Bridge, and considerable alterations

and extensions were made to the works of the old

company.

At Cosford the works undertaken by

the new company involved the construction and erection

of engine and boiler houses, chimney, two rotative

Cornish engines, boilers, and a pumping main was laid to

Tettenhall, and, in order to supplement the yield of the

River Worfe during dry seasons, a borehole was sunk and

the water therefrom was conveyed into a brick tank where

it mixed with the river water.

At Tettenhall the works were

extended, the erection of a new engine and boiler house

(the old boiler house and smoke stack being demolished

to enable this work to be carried out), a reservoir was

constructed for the storage of the Cosford water; one of

the old well engines was altered into a forcing engine,

and the Goldthorn Hill well engine was taken down,

altered, and re-erected in the new engine house as a

forcing engine to deal with the Cosford water; new

boilers were installed; the stand pipe was taken down

and the brick shaft in which it was encased was

converted into the smoke stack. |

| At Goldthorn Hill a small engine was erected in the

place of the large Cornish well engine; a supply tank

was erected on the top of the engine house the town

mains were extended to the reservoirs and by this means

the reservoirs were converted into balancing tanks to

govern the pressure in the town mains. |

Another view of the works at

Tettenhall. |

The wonderful interior of the

waterworks at Tettenhall. A cathedral to water, and

steam pumping engines. |

These works took several years to carry out, but

sufficiently good progress was made to enable the

company to supply Cosford water into Wolverhampton

during October, 1858. A few years later the

Corporation made provisional arrangements with the

waterworks company for the acquisition of their

undertaking, and in 1861 the undertaking was acquired by

the Corporation under the powers of the "Wolverhampton

Waterworks Transfer Act" and on the 1st January, 1868,

the Corporation entered into possession of the works;

the conditions of transfer being that the Corporation

should, after a certain date, pay in perpetuity 5 per

cent. upon the Preference Shares, and 4 per cent. upon

the Ordinary Shares of the company.

Upon obtaining control of the undertaking it became

necessary for the Corporation to obtain powers to

continue, maintain, alter and improve the existing

waterworks, and the requisite powers were subsequently

obtained by the Wolverhampton Improvement Act, 1869. |

|

The yield of the various works

proved adequate for the demands of the district until

1874, when a very dry summer caused a shortage in the

river supply, and the Corporation then sought advice as

to the possibilities of obtaining an increased yield

from underground sources by carrying out further sinking

operations at Cosford. The late Mr. J. F. Bateman was

consulted and he recommended the Corporation to sink a

deep borehole, and acting upon the advice given, the

Corporation sunk a large diameter borehole 918¾ feet

deep. This work was commenced in May, 1876, and

completed in December, 1877, and upon completion the

borehole yield by artesian force, a very large

additional quantity of water of most satisfactory

character. A few years later, however, the increasing

demands of the district caused the Corporation to again

seek an additional supply, and upon the advice of the

Consulting Engineer,

Mr. H. J. Marten it was decided to

extend the Cosford Works by sinking a well in close

proximity to the deep borehole and to connect the well

and borehole together by a heading so that an increased

yield from the underground sources could be obtained by

pumping down below the normal water level in the

sandstone formation. The well was commenced in 1881 and

the following year it was completed, and the large

Cornish engine which was then erected by the Lilleshall

Company, speedily proved the wisdom of the course

adopted.

It then became necessary to augment

the pumping plant at Tettenhall to deal with the

increased yield of the Cosford Works and to provide for

the growing demands of consumers, and in 1884 another

house was erected, and a large Cornish forcing engine

was installed by Messrs. Hathorn, Davey & Co. of Leeds.

The next step the Corporation

deemed it advisable to take was the duplication of part

of their system to prevent the possibility of shortage

of supply through breakdowns of engines at Cosford, or

the bursting of the pumping main, and in 1888 operations

were commenced which took several years to complete, and

entailed a variety of work being undertaken. |

| An additional pumping main was laid from Cosford to

the summit of Summerhouse Hill; another well was sunk at

Cosford; the buildings were extended and two more

engines were installed by Messrs. Hathorn, Davey & Co.,

one engine as reserve to the Lilleshall well engine, and

the other as a reserve to the original forcing engines.

About the time this work was nearing completion the

Corporation consented to release the Bilston.

Commissioners from their agreement to purchase water in

bulk, although the works were then quite capable of

yielding sufficient water for the needs of the entire

district, but one reason which influenced the decision

was the prospect of largely increasing demands and

consequently the necessity for incurring further capital

expenditure upon entirely new works, and it was pointed

out that the severance of Bilston from the water area

would immediately relieve the Corporation of the demands

of a population estimated to exceed 20,000; the margin

of supply over demand would be largely increased and the

question of providing additional works could be

postponed. |

Another interior view of the old

waterworks. |

|

From a financial point of view the

action of the Corporation in thus disposing of part of

the water area was undoubtedly a mistake, but from the

point of view of conserving the supply, it must be

admitted the anticipations of the advisers of the

Corporation as to the capability of the works to

maintain a constant supply of water to the district for

a number of years, have been fully confirmed, for beyond

improving the general conditions at the Pumping Stations

and extending the distribution mains for the continued

growth of consumers, the auxiliary works officially

opened today represent the only actual additional supply

works since undertaken. It should be mentioned, however,

that an abortive attempt was made in the year 1896 to

obtain an additional supply from the neighbourhood of

Lower Penn; that unsuccessful applications were made to

Parliament in 1901 and 1902, for power to construct

works near Worfield, and that it was not until the

Corporation succeeded in arranging terms with the

proprietors of the Staffordshire and Worcestershire

Canal Company (which Parliament confirmed in 1903), that

the sinking of deep wells or boreholes at the Tettenhall

station was made possible.

The present Waterworks Engineer is

responsible for the scheme of extension at this station

and for the design and construction of the various works

incidental thereto, which have involved the sinking of

three boreholes; the erection of an Engine House; the

construction of a triple expansion rotative pumping

engine; the construction of an additional storage

reservoir, and the laying of a 24-inch pumping main to

Goldthorn Hill. |

The ornate entrance to the old

building at Tettenhall. |

The boreholes were sunk by Messrs.

A. C. Potter & Co., of Lant St., Borough, S.E., in the

most expeditious manner. In the first place a trial

borehole was sunk 1,001.75 feet deep by means of which

the formations were proved and the quality and

approximate quantity of water available was ascertained,

and it is due to the success of this boring that the

other works were then undertaken.

The trial borehole is 16ins.

diameter from the surface to 300 feet deep; 12ins. from

300 to 632 feet; 10½ins. from 632 to 929 feet, and 9ins.

From 929 to 1,001.75 feet.

The permanent or pump boreholes are

1,100 feet deep, and their diameters are as under:-

28ins. from the surface to 300 feet deep; 24ins. from

300 to 450 feet; 20ins. from 450 to 830 feet; 16ins.

from 830 to 930 feet, and 14ins. from 930 to 1,100 feet. |

|

From the surface to 300 feet, each

borehole is lined with steel tubes; those in the trial

borehole being 15ins. internal diameter, and those in

the permanent boreholes 25ins. internal diameter.

Specially designed shoes with lead pipe and india rubber

compression rings, are fitted at the bottom of each set

of tubes by means of which tight joints are made with

the walls of the boreholes, but before proceeding with

other work the effectiveness of the shoes was thoroughly

tested and then the spaces between the tubes and

borehole walls were filled with cement grout to prevent

any possibility of surface water finding its way into

the boreholes. From 830 to 930 feet the boreholes are

lined with perforated tubes to prevent the pebbles and

the faulty sandstone there met with, from falling in and

choking up the holes.

As the work progressed samples of

water were taken and submitted to the Borough Analyst,

Mr. E. W. T. Jones for examination, and the following is

a copy of his report upon a sample he obtained at the

works on the 22nd January last. |

| |

Grains per gallon |

| Total Solid Matter dried at

212 deg. Fah. |

21.0 |

| Free and Saline Ammonia.

|

0.000 |

| Albuminoid Ammonia |

0.000 |

| Nitric Nitrogen |

0.05 |

| Combined Chlorine |

0.98 |

| Oxygen absorbed in 4 hours at

80 deg. Fah. |

0.000 |

| Colour through 2 feet |

very pale bluish-green

tinge |

| Appearance |

Clear |

| Hardness before boiling |

14.28 |

| Ditto after ditto |

5.50 |

| Ditto Temporary |

9.78 |

|

Bacteriological Examination:

No organisms were shown on Gelatine

at 20 deg. C., nor on agar-agar at 37 deg. C. after 4

days incubation.

|

| The Solid

Matter in solution consisted of: |

| Lime |

7.70 |

| Magnesia |

1.71 |

| Soda |

1.11 |

| Potash |

0.51 |

| Sulphuric

Anhydride |

0.38 |

| Nitric Anhydride |

0.19 |

| Chlorine |

0.98 |

| Silica |

0.77 |

| Carbonic Anhydride |

7.87 |

21.22 |

| Less Oxygen for

Chlorine |

|

0.22 |

|

|

Total |

21.00 |

|

From this it will be seen that although the water is

a shade harder than the water hitherto supplied, it

is an excellent water for a town supply, in fact,

organically and bacteriologically it is perfect.

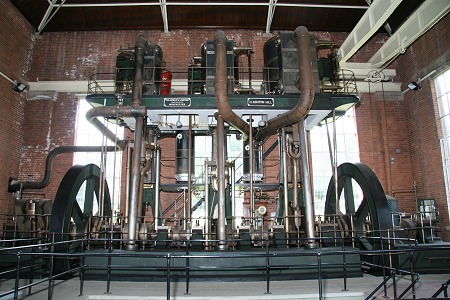

The engine which has been

erected to deal with this water is a vertical triple

expansion rotative condensing engine of the inverted

type with the rams or force pumps placed directly

under the steam cylinders and connected to cranks

set at angles of 120 degrees, and with the borehole

or lifting pumps operated from the ends of the main

shaft.

It is capable of lifting 62,500

gallons per hour with the borehole pump from any

depth not exceeding 260 feet below the floor level

and delivering the same into a suction tank, whilst

the rams are capable of forcing 125,000 gallons per

hour against a head of 180 feet when running at a

piston speed of 160 feet per minute. Steam for the

engine is obtainable from the boilers which replaced

the old ones a few years ago, and the working

pressure will be 160 lbs. on the square inch.

The general arrangement is such

that the engine can be worked either as a ram pump

only, or as a lifting engine only, but in ordinary

work it will perform both duties, and then it will

pump equal proportions of Cosford and Tettenhall

water into the distributing mains.

|

| The leading

dimensions of the engine are as under, viz.:- |

| Stroke 3ft.

6in.: |

|

| High Pressure

Cylinder |

19in. diameter |

| Intermediate

Cylinder |

29½in. diameter |

| Low Pressure

Cylinder |

46in. diameter |

| Ram Pumps |

16in. diameter |

| Stroke 2ft.

9in.: |

|

| Borehole Pumps |

16in. diameter |

The flywheels are 12 feet diameter and weigh about 11

tons each. The valve gearing is of the well known

Corliss type end is operated by eccentrics on the main

shaft. The contract for the engine was placed in the

hands of Messrs. Galloways Ltd., of Manchester.

|

An impression of how the interior

of Tettenhall waterworks must have once looked when its

Galloway's engine was there.

The photograph shows the preserved

Galloway inverted vertical triple expansion pumping

engine at Maple Brook Pumping Station. Courtesy of

Chris Allen. |

|

The engine house is 48 feet long by

22 feet wide and 52 feet high, measured from the

basement floor to the shoes of the roof principals, and

its situation is between the boilers and the engine

house which was erected by the new waterworks company

about the year 1860, sufficient space having been left a

few years ago, when substituting new boilers, for the

purpose thereof.

The foundation portion of the house

had to be carried out by piece work as parts of the

boiler house had to be demolished; boiler and other

foundations had to be taken out; the main flue had to be

diverted and rebuilt, and provision made for safely

continuing pumping operations, and this work was

executed by Mr. H. Holloway, of Bilston Road,

Wolverhampton, but the contract for the superstructure

of the house was placed in the hands of Messrs. Willcock

& Co., of Darlington Street, Wolverhampton.

The additional storage reservoir

has been formed partly by excavation and partly by

embankment. It has been constructed throughout with

cement concrete, in the proportions of four parts by

measure of broken Bentley stone and two of sand to one

of cement, and the whole of the concrete was

mechanically mixed.

| The

principal dimensions of the reservoir are as

under, viz.:- |

| At

coping of walls |

312ft. long by 202ft. wide |

| At

floor level |

299ft. long by 189ft. wide |

|

Thickness of wall at top |

1ft. 6in. |

|

Thickness of wall at floor |

8ft. 0in. |

| Depth

from coping to floor |

19ft. 0in. |

|

Capacity at normal working level (16 feet) |

6,000,000 |

|

Surface area of water at working level |

1.396 acres |

The inlet main is laid along the

embankment, and is controlled by a Venturi meter. The

outlet main is connected to the outlet main of the old

reservoir, so that in ordinary work the water level in

both reservoirs can be uniformly maintained; but a

branch main is laid from the outlet main to the suction

tank of the new engine, and the arrangement of the mains

is such that all the engines at the station can be fed

with water from either or both reservoirs. The

connections to the old mains were all made under

pressure by means of one of Ruscoe's patent machines.

The object of the new reservoir is

not intended for increasing storage accommodation, but

its provision was felt to be necessary to enable the old

reservoir to be emptied, cleaned and repaired. The

contract for this work was placed in the hands of Mr. H.

Holloway, of Bilston Road, Wolverhampton.

The work of laying the 24inch

pumping main from Tettenhall to Goldthorn Hill was also

entrusted to Mr. Holloway, and with the exception of the

portion over the Smestow Brook and the canal at Compton,

it is composed of cast-iron socket and spigot pipes. The

portion over the brook and canal at Compton is of mild

steel with flanges welded on, each length of which has

been specially made to meet the peculiar conditions

which existed.

The pipes generally used are 12

feet in length, and weigh approximately 1 ton 9 cwt.

each. They are jointed together in the following way,

viz.-

| A ring of ⅜in. round lead rod was first

forced to the back of the socket, then lead

wool was inserted and caulked in layer by

layer to within 3¾ inches of each socket

face. Plain hemp was then caulked in to

within 1¾ inches of the socket face, and

finally the remainder of the socket was

filled with lead wool, each skein of which

was thoroughly caulked in. |

The pipes were made by the Stanton

Iron Works Co., and they were all subjected to a test

pressure of 260 lbs. on the square inch before leaving

the works. The main is divided into sections controlled

by stop valves and provided, where necessary, with air,

reflux, bypass and emptying valves, all of which valves

were supplied by the Glenfield Co., of Kilmarnock.

A comparison may now be made of the

conditions existing today with those at the time of the

transfer of the undertaking to the Corporation. In 1868

the works were incapable of distributing more than

2,000,000 gallons per day whilst the demand averaged

1,500,000 gallons; 12,890 houses were connected to the

mains and the income from water sales amounted to

£12,943.

Today the works are capable of

distributing over 5,000,000 gallons per day, whilst the

demand during the year ending March 31st, 1911, averaged

3,474,000 gallons; 35,415 houses were connected to the

mains at the same date, and the income from water sales

amounted to £37,553.

At the transfer the actual

expenditure upon works and plant amounted to £210,327.

10s. 0d., and at March 31st, 1911, the Capital actually

expended amounted to £392,562, of which sum £93,567 had

been paid off.

In concluding this brief account of

the undertaking a reference may be permitted to those

responsible for its present satisfactory position. From

1868 to 1881, Mr. Alderman Fowler (subsequently first

Viscount Wolverhampton) presided over the Water

Committee, and the fact must again be recorded that it

was principally due to his initiative that the

undertaking was acquired by the Corporation; from 1881

to 1891 Mr. Alderman J. G. Wright held the office of

Chairman, and since 1891 to the present date, Mr.

Alderman Marston has presided over its destinies.

From 1868 to 1892 the management of

the works was entrusted to Mr. Lyons Wright, who

formerly held the position of secretary to the

waterworks co., and since July, 1892, the present

Engineer, Mr. E. A. B. Woodward has managed the

undertaking, and been responsible for the design and

carrying out of the various additions and alterations

which have been made to it since his appointment, and

the date hereof, July 20th, 1911. |

|

Return to

the

previous page |

|