|

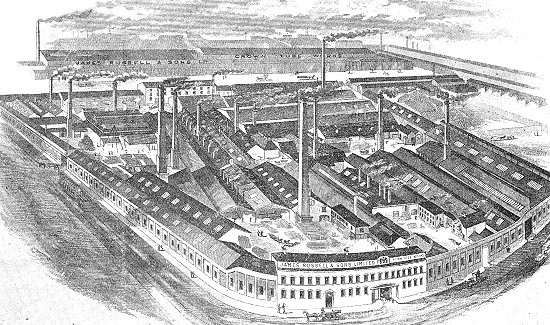

James Russell & Sons, Limited, inventors and first

manufacturers of tubing.

Crown Tube Works, Wednesbury |

|

|

The name of Wednesbury is inseparably associated with

one of the most important branches of industrial activity

carried on in the Midlands, namely, that of tube

manufacturing, for it is here that it can be said to have

had Its birth. |

| The firm who Justly claim the honour of being first

manufacturers is that of Messrs. James Russell & Sons

Limited, of the Crown Tube Works, who have been established

from the commencement of this branch of industry, and, who

by reason of their many inventions and improvements are now

justly regarded as the oldest and most celebrated firm in

the United Kingdom. The premises occupied cover about ten

acres of ground surface, and consist of extensive mills for

butt and lap welded tubes, also iron, malleable iron, brass

and gun metal foundries, large fitting and turning shops,

for general purposes. In addition to which the firm has extensive brass finishing

shops, and a separate coil and fitting manufactory.

They also possess a branch works at Darlaston, for

galvanising purposes, in order to meet the heavy

demand for goods of this description. The

arrangement and equipment throughout is on a most

comprehensive and complete scale, the works being

supplied with all the most improved machinery and

appliances known to the trade. About 1,300 hands are

employed.

Unsurpassed facilities exist for executing

the largest orders in the promptest and most

satisfactory manner. Messrs. James Russell & Sons

are manufacturers of tubes in iron and steel from an

eighth of an inch to six feet in diameter for gas,

steam, water, and oil mains, also of plain, spiral,

and tapered tubes for shipbuilding, architectural,

and other purposes, such as bedstead and boiler

making and artesian well boring, also coils, core

bars, regulating valves, roller tubes for looms and

machinery, tramway, telegraph, and electric light

poles to forty feet long in one piece; brass and gun

metal fittings of every description for gas, steam,

water, and hydraulic purposes; also stocks, dies,

and taps of Whitworth's standard thread, for gas

tubes, bolts, nuts, etc., and all kinds of tools for

engineers', gas fitters', and smiths' use.

In all

these manufactures the firm have undoubtedly reached

the highest point of excellence, as they are found

to combine in an eminent degree all the most

desirable qualities of best material, superior

workmanship, finish, and durability. They have long

maintained a high reputation, and have a widespread

and influential connection both at home and abroad.

They have established four branch depots, namely, at

108, Southwark Street, London; 6, Mark Lane, New Briggate, Leeds; 114, Colmore Row, Birmingham; and

33, King Street West, Manchester. The directors of

the firm are gentlemen of well-known influence and

standing in the district. |

|

Wednesbury coal mines are

nearly exhausted after centuries of working; first,

as open works (where the measures were readily got

near the surface) with the aid of inclined plane or

ladders; secondly, as bell-pits, and lastly as deep

shafts with winding gear, once worked by gin horses,

now by steam engines. Here the men have just come up

the shaft in a cage. This open cage is steadied in

the slides, and "catches" in the chain would prevent

it falling to the bottom in case of a breakage.

The coal getting here has

recently moved eastwards, towards West Bromwich and Hamstead, where the piercing of the Permians has

discovered coal over 400 yards below. The rural aspect of the

country, as is shown on the "road home" of the

colliers, soon gives way to the desolation of pit

mounds and colliery wastes.

|

|

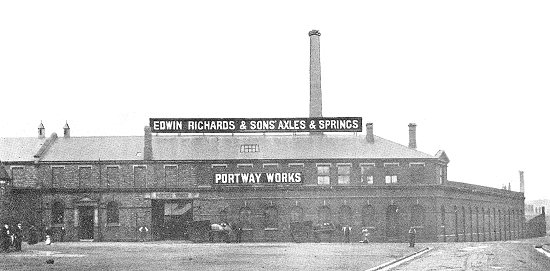

Edwin Richards & Sons, established

1810, manufacturers of high

class axles for every description of' vehicles;

best quality coach and carriage

springs, special hand made coach bolts.

Dog cart ironwork, self-acting carriage steps,

and stampers of step treads, etc.

Brass and Ironfounders.

Carriage hardware of every

variety

Makers of Weatherill's patent

springs.

Portway Works, Wednesbury.

|

|

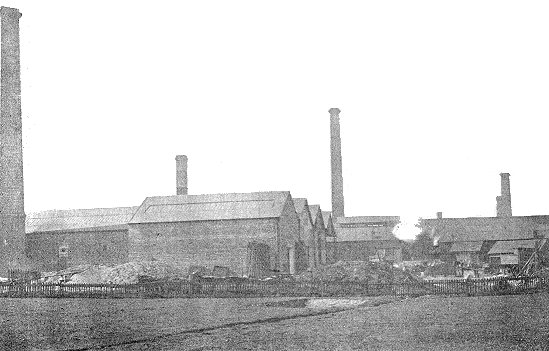

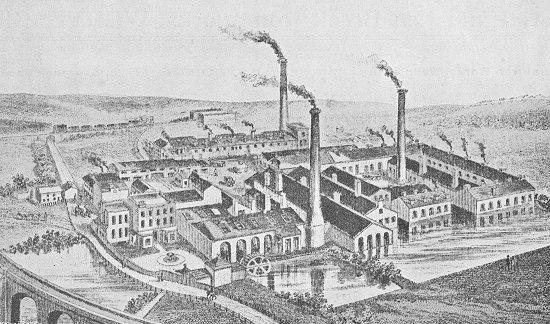

The business carried on under

the above style and title is one of the oldest of

its kind in Wednesbury, the home of the tube

trade, and it is also one of the largest and most

flourishing. Founded in the year 1869 the "Hope"

Tube Works have always enjoyed the advantage of able management, to which no doubt

is largely due the wide patronage and the high

reputation which have been earned. The firm's

products are known in almost all parts of the

civilized world, and are appreciated wherever they

have found their way. The works, of which an

excellent exterior view is given below, combine ample space with a convenient

arrangement of the different departments. Every

facility necessary for the efficient carrying-on of

the trade is possessed, and the machinery and all

appliances in use being of the most approved modern

designs.

The employees are picked men, a

large proportion having been in the service of the

firm for some years, and all work is turned out not

only capably but expeditiously. Tube making in very

nearly all its branches is carried on here.

Bedstead, blind, and fencing tubes, with ferrules

for same; oval, flat, and section tubes of all

descriptions; special light tubing; extra strong

tubing for handrails, etc.; gas, steam, and water

tubes and fittings; cold drawn weldless steel tubes,

for cycles, boilers, etc., are all included in the

every day work of the firm.

They enjoy the

distinction of having been the first firm in

Wednesbury to make weldless tubes; and the

enterprise of the conductors has recently had a

striking exemplification in the enlargement of the

works for the purpose of dealing on a large scale

with the special branch of the trade which has to do

with the manufacture of cycles. McDougall's tubes,

of whatever kind, have for their chief

characteristics, strength, lightness, and tenacity.

The two gentlemen whose photographs are given above

are the working heads of the concern.

|

|

John Knowles, Walsall Street Works,

Wednesbury.

Tubes and Fittings.

Wrought-iron tubes for gas, steam, and

water.

Speciality: All descriptions of

wrought-iron fittings for gas, steam, and water.

Galvanised tubes and fittings.

Locomotive and marine boiler tubes, brass fittings, stocks

and dies, gas fitters' tools, gas burners, etc.

|

Walsall Street Works.

|

The manufacture of wrought iron tubes

and fittings, of all kinds, for gas, steam, and water

purposes, constitutes a highly important branch of

industrial activity in the town of Wednesbury, and a name

very prominent in this connection is that of Mr John

Knowles, proprietor of the Walsall Street Works. The

Walsall Street Works were founded in 1850, and the trade

done has been of an eminently successful and progressive

character. At the present time the premises utilised cover a

considerable area of ground; they possess a capital office

and warehouse frontage to Walsall Street, and are

substantially constructed as well as very conveniently

arranged. They are fully and modernly equipped for all

operations carried on, and afford steady employment to about

one hundred and sixty hands. Every description of tubes and

fittings are produced for both home and foreign markets, and

it is generally admitted throughout the trade that these

manufactures are unsurpassed for thorough reliability and

superior finish. It may be mentioned that every tube is

tested before leaving the works. A considerable reserve

stock is kept on hand to meet pressing demands, and special

tubes can be made to order on short notice. The continued

success of this business, under the management of Mr.

Knowles and his sons, is fully assured. |

|

This establishment dates back to

the year 1840, earning a world-wide reputation for

its wheels and axles. In 1864 it was registered as a

limited liability company,

and reconstructed in 1889. The present

directors are: John Pierce Lacy, J.P. (Chairman),

John Brooks, William McLaren, and Simon Leitner,

J.P. The Secretary is J. F. Cay.

The registered capital of the

company is £437,500. It consists of 30,000 ordinary shares, £7 each,

and 35,000

preference shares, £6.10s each. The capital called up and

payments in advance is £348,594 consisting of ordinary shares, £4 per share,

paid; and preference shares,

£6.10s. per share, paid.

The Works of the Company cover

an area of 500 acres, and 3,000 men are employed.

The Works are

situated at Wednesbury, Staffordshire, about seven

miles north-west of Birmingham, and have railway

approaches from the Great Western Railway, the North

Western Railway, and the Midland Railway; also the

Birmingham Canal Navigation runs into the principal

Works.

The work turned out is of the

greatest variety, consisting of:

| Railway wheels and axles of

all types; weldless steel tyres; iron and steel

axles; steel, wrought iron, and cast iron bridges;

roofs, girders, turntables, switches, and crossings;

rolled iron and open hearth basic and acid steel

plates; bars, also sections of every class; castings;

rolls; all kinds of cast iron and wrought iron and

steel tanks; and gasworks and water plant. |

Some of the largest bridges in

India and Japan have been supplied by this company. Blackfriars Bridge, London, also was made here.

The works comprise :

1. Brunswick Iron and Steel

Works.

These have been re-organised, and the

steel-cogging, bar and plate mills, for basic and

acid steel, are of the most recent

design, and are fitted with the latest types of

labour saving appliances.

The specially mild basic steel

turned out here has a wide reputation for

reliability; some being made as low as 22 tons

tensile, for water tube boiler work of torpedo

boats; various grades of basic steel are produced up

to 32 tons tensile, all very ductile. Angles, bars,

and channels of an immense variety of sections are

rolled, in steel and iron, as well as sheets; also

steel plates to 7ft. 6in. wide by 30ft. long. The

total capacity of finished products is about 600

tons of iron and 600 tons of steel per week.

2. Brunswick Wheel

Works.

These works have manufactured and supplied

every known type of wheel, and lately have been

thoroughly re-organised; a large addition of modern

machinery has been made, notably-two hydraulic wheel

forging presses of 1,200 and 2,000 tons for the

manufacture of cold spoke and hot spoke wheels,

disc wheels, and wrought iron washers and bosses for

wood wheels.

The machine shop is replete

with all classes of lathes and tools for finishing

the wheels, and is one of the most complete in the

country. Capacity about 700 to 800 pairs of wheels

per week.

3. Monway Iron and Steel

Works.

In this department are manufactured the weldless steel

tyres, iron and steel axles, and iron

plates. There are here four open hearth, acid-lined,

steel melting furnaces (two of 25 ton and two of 15

ton capacity); also two basic open hearth furnaces.

The output is 100 tons of plates, 100 tons of axles,

and 250 tons of tyres per week, besides a large

amount of basic ingots and blooms.

4. Old Park Bridge

Yard.

Boiler yard and foundry. This department is

well laid out for bridge, roof, and similar work,

and has most powerful cranes, capable of dealing

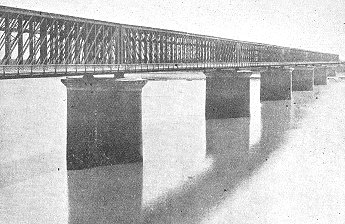

with the largest bridges made. The Benares Bridge,

consisting of seven main spans of 356 feet by 25

feet by 35 feet, nine spans of 114

feet, and weighing 6,500 tons, was built here; it

was made entirely of Steel.

|

The Benares Bridge. |

There is also a large foundry

and machine shop; in the latter there is a very

large faceplate lathe capable of turning 40 feet

diameter. All kinds of machine tools and

hydraulic pressing and riveting plant are found

here. The principal work consists of bridge and roof

work, girder work, engine turntables,

water tanks, water cranes, points, switches, and

crossings; all kinds of gas works apparatus, general

engineering work, castings, and steel tubbing for

mines; the capacity being 10,000 tons per annum. An

enormous variety of patterns on hand, to be used

or converted at short notice for almost any casting.

5. Collieries.

The company

owns a number of collieries, the principal output

being from Millfields. It will be seen from the

foregoing that, with a central position, ample

railway and canal accommodation, and having control of the operations from

the raw to the finished material, and a most

efficient plant, the company is in an excellent

position to supply the highest class of finished

products. |

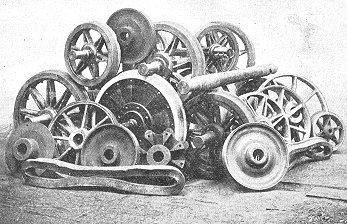

| A group of wheels manufactured

by the company. |

|

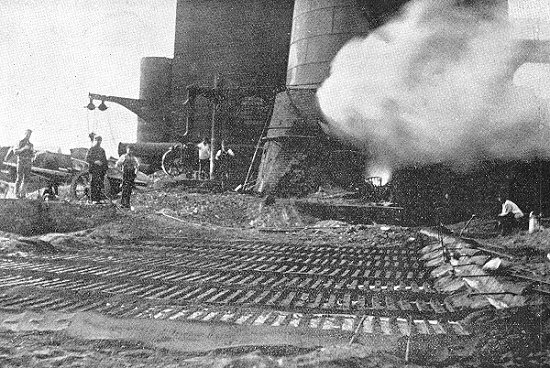

| Willingsworth Blast

Furnaces |

|

Willingsworth Furnaces stand near the site of

Willingsworth Hall (once the seat of the Parkes family,

ancestors of Lord Dudley), a Tudor building demolished 30 or

40 years ago.

Only one of the two furnaces is now in blast, but that is

quite up-to-date in all modern improvements. On the picture,

smoke may be seen rising from the slag which is escaping

from the tap hole. |

Presently the molten iron will be tapped, allowed to

flow through the "runner" which is seen on the right hand,

and thence to the trenches of the "big sow and little pigs". Wednesbury's last remnant of plant for producing pig iron.

|

|

Charles’ Wednesbury Bridge New

Coal Wharf. |

| The Forge Pool Colliery belongs to Alderman Wilson

Lloyd, J.P., and is now being worked by him.

It is part of the Wednesbury Hall Estate, and was once

called the Great Park Farm.

The mineral part of the estate, since the year 1699, has

belonged to Richard Parkes (died 1729) and his descendants.

|

|

|

Richard Parkes lived at Oakeswell Hall.

His daughter Sarah married, 1727, Sampson Lloyd, banker, of

Birmingham, who died 1807, leaving his share of the estate

of Richard Parkes, which he inherited, to his descendants,

of whom Mr. Wilson Lloyd is one, and is the only

representative of the Heirs of Parkes now living in

Wednesbury. The Great Park before mentioned contained

formerly two large pools, one near the Old Park Road, now

nearly filled up, the other, partly shown in the picture,

called Forge Pool. These two pools gave water power to the

Tilting Forge which adjoined Park Lane House. This was

before the introduction of steam power, when all ironworks

were driven by water.

|

| Edward Elwell, Wednesbury

Forge |

| Elwell’s Pool and Viaduct |

|

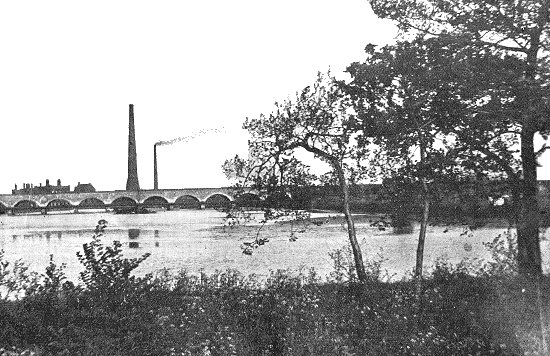

This is part of the old South Staffordshire

Railway opened in 1847. Here is a viaduct crossing Elwell's Pool,

which was formerly a timber structure, into which a goods train fell

in June, 1859. The former family residence of Elwell's is seen in

the distance by the side of the Forge. This large sheet of water,

being contiguous to the main road, might be made available for

boating and other aquatic sports.

|

| John Bagnall & Sons

Limited |

|

|

|

|

|

|

Return to

Places part 2 |

|

Return to

the contents |

|

Proceed to

Industries part 2 |

|