| Jensen Motors Limited Jensen was founded by two brothers,

Alan and Richard Jensen, who were born in 1906 and 1909.

They became interested in cars at an early age, and so

in 1930 their father set them up in their first

business, Patrick Jensen Motors, based at Edgbaston.

They ran the business with Joe Patrick, but moved on the

following year after a disagreement.

In 1931 they started work at W. J.

Smith & Sons, an old established firm of motor body

builders, located in High Street, Carters Green, West

Bromwich. Smiths specialised in bodywork for lorries and

cars. After William Smith’s death the brothers took over

the business, and in 1934 it became Jensen Motors

Limited.

The business specialised in

custom-built bodies for a range of readily available car

chassis made by a range of manufacturers including

Morris, Singer, Standard, and Wolseley. In 1934 the

brothers received a commission from American actor Clark

Gable to him build a special car, on a Ford V8 chassis.

The brothers very much wanted to

manufacture their own cars and so work soon began on the

first model called the “White Lady”. The large open

tourer was powered by a 3.5litre Ford V8 engine and

appeared on the market in 1936. They also produced a

saloon version. Quite a few cars were built, but many

orders were also received for commercial vehicle bodies

for lorries, vans, and buses. In 1939 the first Jensen

lorry, the Jensen lightweight truck was launched. Built

for Reynolds Tubes, it used aluminium alloys, and was

powered by a 4.7 litre Perkins diesel engine. It had a

5-speed Moss gearbox.

After the war Jensen launched another lightweight

lorry, the JNSN, which was easily recognisable by the

radiator grille, shaped to the JNSN letters. It was available in a range of forms including

lorries, trucks, pantechnicons, and even as a luxury

coach. The vehicles sold well and remained in production

until 1956.

Ray Horton's JNSN Jensen lorry from 1951. At

the Black Country Living Museum in 2008.

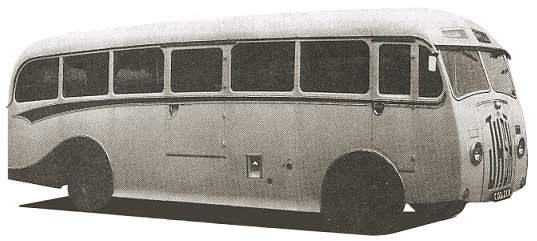

A JNSN luxury coach.

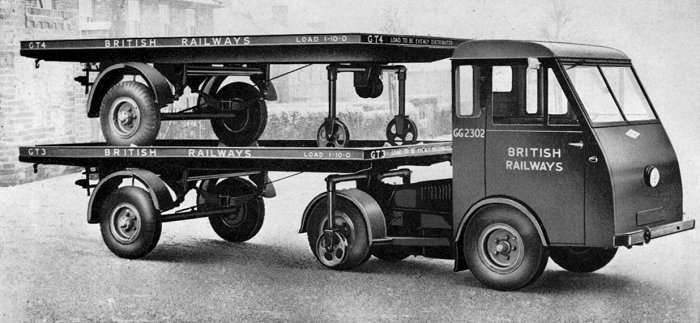

In the late 1940s, production of another commercial

vehicle, the 'Jen-Tug' began. It was a 3 ton articulated

vehicle, available with a wide range of trailers,

including a flat trailer, a wire-sided trailer, a box

trailer, a tipping trailer, a shallow tipping trailer, a

high-sided trailer, a swan-neck trailer with winch, and

a container.

The cab had an Austin A.50 four-cylinder,

overhead valve petrol engine, with a capacity of 1.5

litres, and an output of 50 bhp. at 4,400 rpm. It

had a built-in four-speed synchromesh gearbox, a Borg &

Beck, single dry-plate 8 inch hydraulically operated

clutch, and was mounted on an easily removable

sub-frame. It also had powerful Girling hydraulic brakes

with 11 inch diameter drums on both the tractor and

trailer, a Jensen patent tractor coupling, operated from

the cab, and a turning circle of 22 feet.

A 'Jen-Tug' with a flat bed trailer. From

the Jensen sales literature.

|

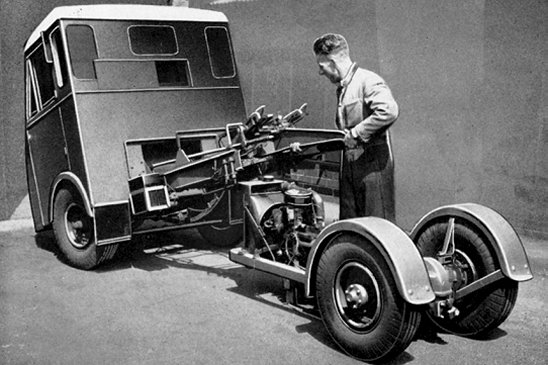

The lightweight 'Jen-Tug' cab with the

engine sub-assembly removed for servicing. From the

Jensen sales literature. |

Another view of Ray Horton's JNSN lorry at the

Black Country Living Museum.

| The 'Jen-Tug' became quite popular, and was

supplemented by an electrically-powered version, the

'Jen-Helec'. The vehicles were made at West Bromwich,

and also in Jensen's factory at Stoke.

Jensen also built a number of German 'Tempo' 26 cwt.

front-drive trucks under licence, and bodies for the

four-wheel drive Austin Gipsy. |

A front view of Ray Horton's

lorry. |

A final view of Ray Horton's lorry.

During World War 2 the firm

concentrated on war work, building components for

military vehicles, including turrets for tanks.

Conversions were also carried out on American Sherman

tanks to turn them into amphibious vehicles.

After the war, car production

resumed with the launch of the Jensen ‘PW’ luxury

saloon, powered by a 3.86litre, 8 cylinder Meadows

engine. Unfortunately the engine suffered from excessive

vibration and so a replacement was essential.

The car didn’t go unnoticed. Soon

after making its appearance at the London motor show, a

remarkably similar design called the ‘Sheerline’ was

launched by Austin, much to the annoyance of Jensen.

Austin had been so impressed with the ‘PW’ that they

quickly produced an almost identical design. Heated

discussions followed between the two companies, and in

order to placate Jensen, Austin agreed to supply them

with ‘Sheerline’ engines, which could be used in the

‘PW’ as a replacement for the unsuitable Meadows unit.

This was to be the start of a long and successful

relationship between Austin and Jensen. |

|

An early Interceptor. From sales

literature. |

Although the ‘PW’ remained in

production until 1952, only a small number were built,

partly due to the shortage of materials after the war.

In 1950 the Jensen ‘Interceptor’ name appeared for the

first time in the form of a modern coupé with a

lightweight body. The car, partly designed by Eric Neale,

an ex-Wolseley body designer who joined Jensen in 1946,

remained in production until 1958. |

| In 1953 Jensen launched a new model, the ‘541’ which

had a fibreglass body designed by Eric Neale, and sold

for £2,346. The car had many Austin components,

including the engine, to keep the price to a minimum.

The car continued in production until 1962 when it

was replaced by the ‘CV8’, a lightweight design, powered

by a Chrysler V8 engine. |

Another early Interceptor. From

sales literature. |

|

The combination of the lightweight design and the

powerful engine meant that the car had a top speed of

130m.p.h. A number of different versions were available

including the ‘F.F.’ four wheel drive that sold for

£5,249. The initials F.F. stood for Ferguson Formula,

named after Harry Ferguson the tractor designer who

invented the four wheel drive used in the car. Something

like 350 ‘CV8’s were built.

Denzil Partridge's Jensen bodied

Austin A40 Sports from 1952.

|

| In 1956 Jensen moved to a

new purpose built factory in Kelvin Way, West Bromwich

where they not only made cars but also continued to make

car bodies for other manufacturers, including Sunbeam

‘Tiger’ bodies for Rootes, and carried out finishing

work on ‘1800’ bodies for Volvo. They also made several

different bodies for Austin including the A40 Sports

model, the Austin Healey 100, and the ‘Gipsy’. Over

1,000 people were employed in the Kelvin

Way works. |

The new factory in Kelvin Way. |

Another view of the new factory.

|

M. Webb's 4litre Jensen from 1956. |

In the late 1950s Jensen was taken

over by the Norcross Group which led to an awkward

relationship between Norcross and the Jensen brothers.

In 1965 the ‘CV8’ was replaced by

what would be Jensen’s most well known model, the

‘Interceptor’, a totally different car to the original

model bearing that name. The modern-styled body was

designed by the Italian coachbuilder Touring, and

initially built in Italy by Vignale, and later at Kelvin

Way. Several versions were available including a

convertible, a coupé, and a saloon. |

An advert from 1956.

|

In 1966 the ‘Interceptor’ was voted

‘Car of the Year’. Around 4,500 would be built.

Unfortunately the Jensen brothers,

now getting on in years, and not happy with the

direction the company was taking, especially with the

use of Italian bodies, decided to call it a day, and

retired from the business in 1966. |

Jason Taylor's MK3 Interceptor

from 1971. |

|

A MK3 Interceptor saloon. From

sales literature. |

In the late 1960s things started to go wrong. The

Austin Healey was discontinued and so Jensen lost a most

lucrative contract, the main source of income for the

company.

At the time body building work was in short supply,

and the business found itself in deep trouble. |

|

An interior view of the factory.

After the demise of the Austin Healey, Donald Healey

planned to build a new sports car as a replacement,

built by Jensen and aimed at the American Market.

Jensen’s dealer in California, Kjell Qvale, an extremely

successful American businessman, was greatly impressed

with Healey’s plans for the new car. As a result he

became Jensen’s major shareholder, and employed Donald

Healey as company chairman. The plans for the new car,

called the Jensen Healey rapidly got underway and the

car went into production in 1972. Unfortunately there

were faults in the design, and the build quality left a

lot to be desired. An improved version appeared the

following year, but Donald Healey disapproved, and

resigned. |

| Desperate efforts were made to improve the

situation, including cost-cutting which resulted in a

large number of redundancies. New up-market versions

of the ‘Intereceptor’ were launched including a

convertible and a coupé, but all to no avail.

Jensen’s financial situation worsened and a Receiver

was appointed in September 1975. Production continued

until Jensen Motors Limited went into liquidation in May

1976. |

John Meredith's Jensen Healey from

1973. |

|

Another view of John Meredith's

Jensen Healey from 1973. |

The company was sold in two parts

to a holding company, Britcar Holdings. The two parts

were Jensen Special Products Limited, and Jensen Parts

and Service Limited.

Jensen Special Products Limited was

a specialised engineering and design company, mainly

formed from Jensen’s development department.

Unfortunately the venture failed after an unsuccessful

management buy-out. |

|

Jensen Parts and Service Limited

had been formed to service and renovate Jensen cars. It

became quite profitable and began to import Subaru, and

later Hyundai cars. Company employee Ian Orford, who had

purchased the right to the Jensen brand name, took the

business over in 1982 and it became Jensen Cars Limited.

He decided to restart production of the ‘Interceptor’

using the original jigs and readily available

components. The new Series 4 ‘Interceptor’ made its

first appearance at the 1983 Birmingham Motor Fair. The

car was almost identical the previous model, except that

it now had a Chrysler 5.9litre engine. The car sold for

around £45,000, but production never really got underway

and only a few were built.

In 1988 Ian Orford sold the

business to Unicorn Holdings of Stockport. Although

development work then started on a new model, the Series

5, it never came to fruition. After a round of

cost-cutting, a Receiver was appointed in 1992 which

resulted in the closure, and sale of the Kelvin Way

Site. In April 1993 Martin Robey, a manufacturer of

Jaguar body spares in Nuneaton purchased the design

rights, copyrights, tooling, stock of parts, and almost

the entire contents of the works. Some of the remaining

Jensen staff joined the Nuneaton workforce and the

business became Martin Robey Sales Limited. Their Jensen

and Jensen Healey works Parts Department still offers

parts from the original Jensen stock, and also

manufactures parts using the original tooling and

specifications.

In 1998 Creative Design Limited of

Redditch developed a new Jensen car, the ‘S-V8’.

Although a few were built, the project was unsuccessful

and ended in 2002. |

P. D. Bryan's immaculate Jensen Healey GT from

1975.

|

|

Return to the

previous page |

|

|