|

Archibald Kenrick &

Sons Limited

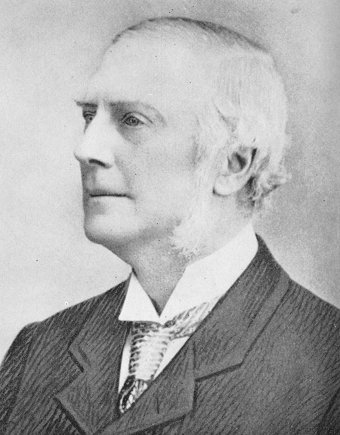

Archibald Kenrick

was born at Wrexham on the 12th November, 1760. In

1780 he moved to Birmingham, where he went into

business with a distant relation, Henry Witton,

making buckles. After acquiring some knowledge of

plating, he went into partnership in 1787 with

another buckle maker, Thomas Boulton, thanks to

financial support from his father. In 1790 Archibald

married Rebecca Smith.

|

|

Archibald Kenrick. |

With the increasing use of shoe laces, it was

time to turn to other products. A year later, he

opened an iron foundry in West Bromwich, producing

cast ironmongery, including coffee mills, door

furniture, cast nails, and mole traps. The foundry

was built on a piece of land, covering over 4,000

square yards, which he leased from John Houghton, for

an annual rent of ten guineas. It was just to the

east of Spon Lane, stretching from Union Street to

the canal. The firm still occupies the same site

today.

Archibald and Rebecca moved into the Springfields,

a large mansion house at the top of Roebuck Lane.

Being quite close to the foundry, Archibald would

ride to and from the works on a mule.

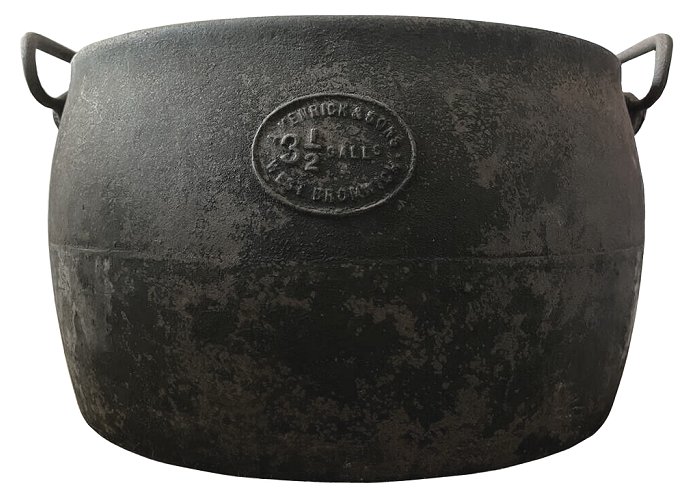

In 1805, the firm began to produce cast-iron

hollowware, particularly for culinary use, and

Archibald developed and patented a new annealing

process. In 1812, steam powered machinery was

installed in the factory, which became the first

factory to manufacture saucepans with rims. |

|

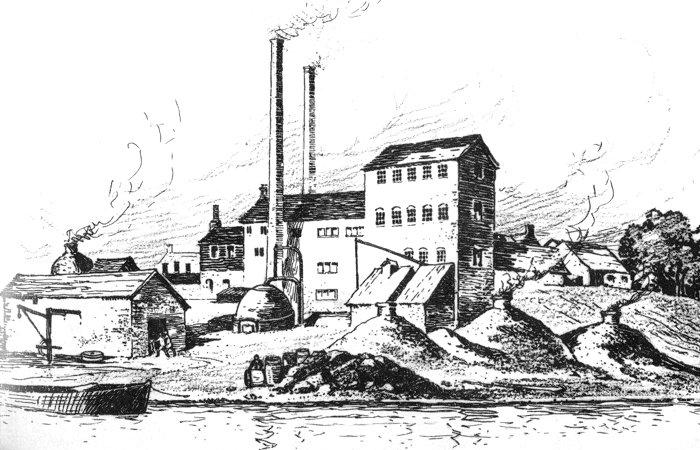

The factory in about 1800. |

|

At this time, Archibald’s nephew, Samuel Kenrick joined him

as a partner in the business, which became known as

Archibald Kenrick & Company. In 1807, Rebecca

Kenrick gave birth to a third son, Timothy Kenrick,

but sadly she died in 1809. Her other children were

Archibald, born in 1798 and George, born in 1803.

In 1812 Archibald married his second wife, Mary

Eddowes, who was 48 at the time. There were four

sons and three daughters from Archibald’s two

marriages.

|

The location of the factory, as it was

in 1902.

The location of the factory, as it was

in 1902.

| In 1818 and 1823, the company purchased land

adjacent to Spon Lane works and the factory was

enlarged. A tramway was built into the ovens which

saved time and heat, and the firm rapidly expanded.

Archibald built houses to rent to a few key workmen

and the area was known locally as Kenrick village. Samuel Kenrick

initially had one fifth of the profits, which

rose to one quarter in 1814 and one third in

1820. The relationship between the partners

deteriorated and Samuel left the business in

1827 to establish Summit Foundry nearby, taking some

of the workmen with him.

Archibald was then joined in the business by his

eldest son, Archibald junior. He

had been educated at a private academy and studied

mechanics in Birmingham. On the 20th October, 1826

he married Anne Paget at Loughborough.

In 1827 Archibald Kenrick, Junior, became a

partner with his father Archibald Kenrick, in the

business, which became Archibald Kenrick and Sons. |

|

|

|

|

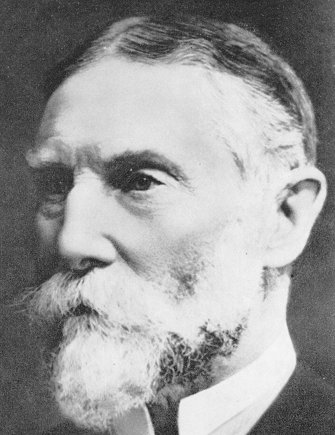

Archibald

Kenrick junior. |

|

Timothy

Kenrick. |

|

| Timothy Kenrick, Archibald senior’s other

son, joined the firm in 1830. Archibald senior died in

1835. At that time there were several hundred

employees at the factory. When Archibald senior

died, his sons, Archibald and Timothy had equal

shares in the partnership. Timothy also served as

Chairman of Lloyds Bank and founded the Nurses'

Training Institution in Birmingham, for which he

purchased a home. Archibald junior began to

suffer from ill health, and so in 1847, his son John

Arthur Kenrick, left university to assist in the

family firm. John Arthur took responsibility for

production. In 1850, John Arthur's brother, William

Kenrick, joined the company and became responsible

for commercial management.

The company’s 1840 catalogue includes door

furniture, saucepans, a waffle iron and a humane man

trap. In 1844 the firm began casting hinges.

|

|

|

|

|

William

Kenrick. |

|

John Arthur

Kenrick. |

|

| In 1846, Timothy had taken out a patent for

glazing and enamelling the metal surfaces of cast

iron, which led to the growth of sales, both at home

and abroad, and also a lot of investment in the company. In

1852 a new foundry was built next to the canal wharf

and in 1857 William became a full partner. In 1868, production management was

in the hands of Frederick Ryland, a professional engineer who was

also the first non-family manager employed in the

firm. Kenrick’s first travelling salesman was

appointed in 1872 and in 1873, George Hamilton

Kenrick, cousin of the two senior partners, John

Arthur Kenrick and William Kenrick, entered the

firm. He became responsible for the day-to-day

commercial management.

By 1878 Kenricks employed over 700 people and so

new offices and warehouses were built. At that time,

more than 30 percent of products were sold

overseas. In 1883 the firm became a limited company,

with John Arthur Kenrick in charge. On the 23rd

February,1885, Timothy Kenrick died, at Maple Bank,

Birmingham.

|

Kenricks' factory.

Kenricks' factory.

| 1886 was a momentous year. The firm acquired the

Birmingham Hollow-ware Company and Kenricks

amalgamated with a principal competitor, A & E

Baldwins, to become the largest supplier of cast

iron butt hinges in Britain. In 1889 Kenricks acquired the bedstead castor

business of Parry & Wythes of Birmingham and in the

following year, new offices were opened in Glasgow,

Dublin and Leeds. Expansion continued in 1898 when

Kenricks acquired brassfounders, Thomas Pemberton,

and increased the workforce by a further 400 people.

A cooking pot.

In 1895,

19 acres of land was given to the town by

John Arthur Kenrick and William Kenrick as the site

for Kenrick Park.

In 1898, John Arthur Kenrick JP., resigned as

company chairman and in 1904, Kenricks began to

manufacture cylinder door locks. By this time, the

company controlled several steel hinge businesses

which were amalgamated in 1910 to form United Hinges

Limited, with premises adjacent to Kenricks’

factory. |

|

A cast-iron door knocker. |

By 1911 there were over 1,200

employees and John Archibald Kenrick had taken over

as managing director. The firm was listed as

ironfounders, enamellers and lock manufacturers,

specialising in cast iron hollowware, household and

builders' ironwork, malleable ironwork and castings. In 1912, during his time as Mayor of West

Bromwich, John Archibald Kenrick presented the

Kenrick Clock in Dartmouth Square, to the Borough.

It still stands there today.

At the outbreak of the First World War, civilian

production ceased and the business relied on

government contracts for work as part of the war

effort. Products included grenades and shells and

fulfilling a

large number of military contracts.

By 1930, George Hamilton Kenrick

(1850–1939), was chairman of the company. The 1930s

were a bad time for the cast-iron hollowware and

hardware trade, which had been in permanent decline

for a decade or so. Most of the holloware produced

at that time was made from aluminium and so Kenricks

had started to produce different cast-iron products

including electric and gas irons, but without

success. Their best selling cast-iron products were

baths and so the firm concentrated on their

production. Bath sales accounted for 39 percent of

turnover by 1935.

Around this time, Wilfred Byng

Kenrick became chairman and he appointed his son

William, as head of the sales department.

In 1939 at the beginning of the

Second World War, the firm had to rely again on

government contracts for war work. The manufacture

of hollowware ended and the many highly profitable

government contracts, rescued the company from its

decline. The firm began moving from iron-casting to

die-casting. During the war, the company

manufactured seven million hand grenades and 1.5

million, 2-inch mortar bombs.

|

| At the end of the war, in 1945,

Wilfred Byng Kenrick’s, son, William, was promoted

to managing director. In 1949, G. F. Shepherd, a retired engineer

living in Australia, agreed to license the company

to manufacture and sell his patented furniture

castor, which led Kendricks into a new area.

The first set of Shepherd castors were produced in

1950 at the time when the bath department closed and

pressure die casting replaced traditional sand die

casting in the factory. Wilfred Byng retired in 1953 and Arthur Wynn

Kenrick, a distant relative, formerly joint managing

director of Kenrick and Jefferson, was appointed

Chairman, and John Donkin, an engineer, who formerly

worked for GEC, was appointed as joint general manager to work with William.

At the same

time, an Australian inventor offered William the

option of using a patent for producing Shepherd's

furniture castor, by die-casting. William

recommended this to the board and production soon

began.

Thanks to the great success of the castors and

William's insistence that from then-on, the

number of sales, and

what the consumer wanted, would determine product

policy and investment, rather than the plant's

capacity to produce items, enabled the firm to

survive.

|

A cast iron door stop. |

|

A Kenrick potato

masher. |

|

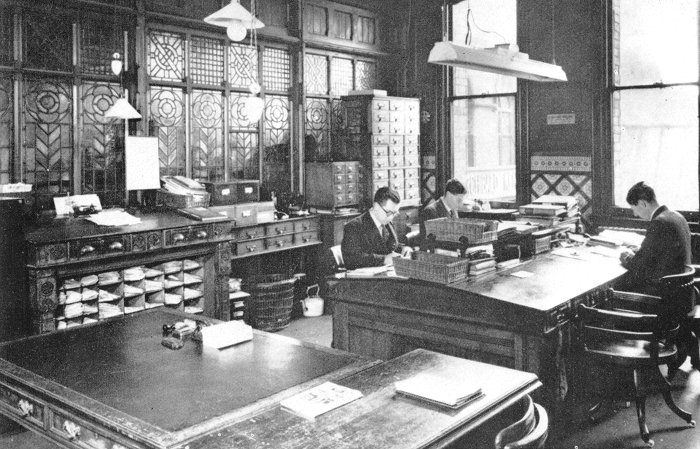

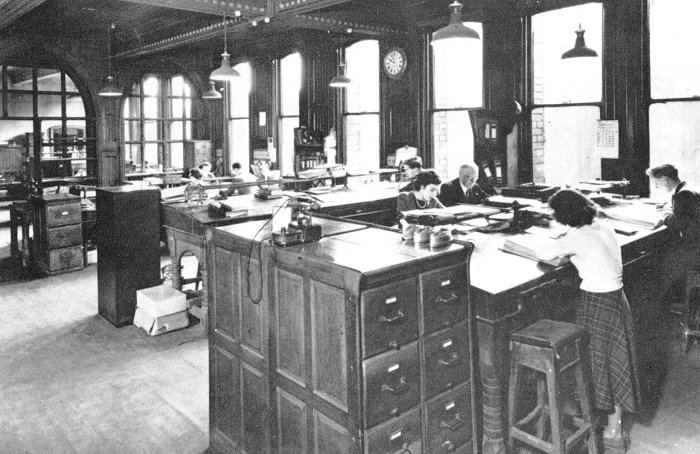

The private office

in 1952. |

|

The public

office in 1952. |

|

Locks and keys have

been important products. |

In

1956, the Kenrick tinning department closed and

thanks to a successful promotional campaign, the

1,000,000th set of Shepherd castors was made in Feb

1958. Castor sales then amounted to 64 percent of

total sales and so the inventor was presented with a

gold plated set of castors. In 1959, the land that had been used for the

Kenrick recreation ground was sold to West Bromwich

Albion Football Club. Two years later the Shepherd

Minicastor was introduced, and the firm had 420

employees.

In 1962, Kenrick’s first plastic castor,

the Meteor, was manufactured under license, then in

the following year, William became chairman as well

as Managing Director.

In 1964, his son Martin,

joined the company and in 1965 the iron foundry

closed. At that time, die cast products accounted

for 80 percent of total output, and Kenrick’s were

described as zinc alloy die-casters and hardware

manufacturers.

|

|

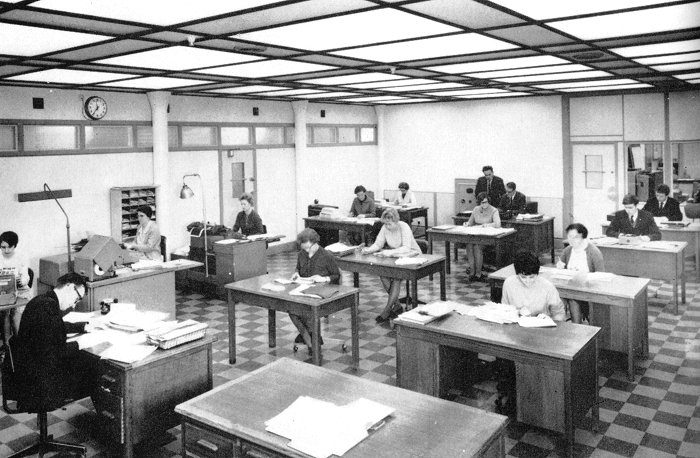

The accounts

office in 1968. |

|

The chairman's

office in 1968. |

|

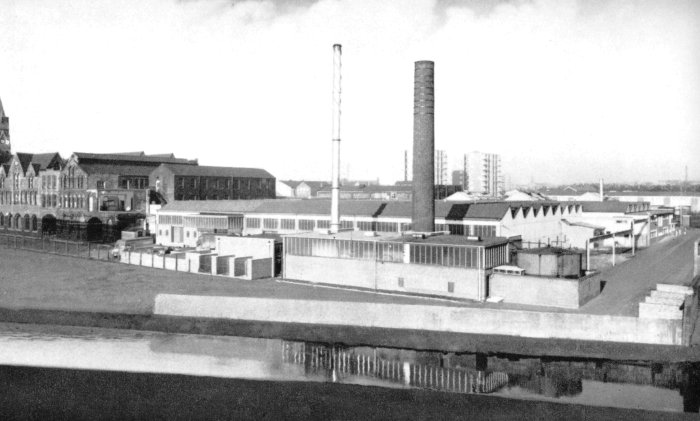

The factory in

1968. |

| In 1978, William retired as Managing Director and

Chairman, and Martin Kenrick became chairman. The

firm introduced more new products including

aluminium extruded hardware, such as window handles

and letter plates, aluminium racking systems and

aluminium twin wheel castors. A new range of

bathroom accessories was introduced in 1984. By

1986 the workforce had been reduced to 120 and the

company was trading profitably. In 1988, new die-cast products included phone box

casings, socket covers and engine mountings. More

castors were introduced in the form of the Suroy

industrial castor in 1990 and the Textile castor in

1991, along with the Sabre Lock shootbolt for

windows.

In 1993 the popular Sentri Lock

system was launched and Kenrick’s Window Test Centre

opened. Since then, Kenricks have continued to

develop new and innovative products and the firm has

celebrated its 230th anniversary. Which is quite an

achievement. |

A Shepherd castor. |

|

|

Return to the

previous page |

|

|