|

Coalite, a School, and a Plaque

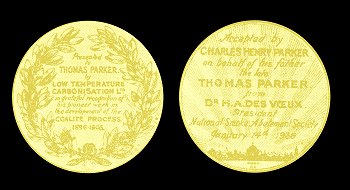

Thomas invented the smokeless fuel 'Coalite' in 1904,

it was one of his most important inventions. Large quantities were

sold, and the Low Temperature Carbonisation Company, which produced

'Coalite', was run by Thomas's son, Charles. On 14th January, 1936

Thomas was posthumously awarded a gold medal by the Smoke Abatement

Society for his invention. The medal was presented to Charles, on

his father's behalf, by Dr. H.A. des Voeux, president of the

society, at a luncheon in London.

|

Thomas's posthumous medal.

|

The medal has now been lost, it was stolen from

Thomas's daughter, Jessie, many years ago.

Although Thomas never made a penny from his invention,

because it was ahead of its time, the Low Temperature Carbonisation

Company was extremely successful after his death.

In 1906 production started at Wednesfield,

and in 1908 patent rights were granted in a number of other

countries. Thomas Parker had found a way around the problem of

casting the retorts which had been experienced by other

foundries.

In 1936 the company built a large factory at Bolsover,

Derbyshire, which employed 1,000 men in the production of 'Coalite'.

The plant occupied 17 acres, had two miles of railway sidings and

288 retorts. The company signed a contract for 1,000,000 tons of

coal for the new plant. Each ton of coal produced four gallons of

petrol, 18 gallons of oil and 14cwt. of smokeless fuel. 12 squadrons

of the Royal Air Force exclusively used petrol that was produced by

the company and the Royal Navy purchased large quantities of oil.

The company also produced a wide range of speciality chemicals and

recycling solutions for waste.

Unfortunately in 2004 the company was in receivership

and the production of Coalite ceased on June 10th. Its virtues were

listed in a long article in The Times newspaper on 4th May, 1907,

from which the following extracts were taken:

| The career of Mr. Thomas Parker, J.P., M.

Inst C.E., M. Inst. M.E., M. Inst. E.E, of

Wolverhampton, the inventor of Coalite, is one

of those of commercial and scientific activity

which are rarely recorded until the subject of

them has passed from out of our midst. It would

be no excessive compliment to speak of Mr.

Parker as an English Edison. Nearly a generation

ago he invented a steam pump which took a medal

at the Inventions Exhibition. About 1878 he was

the first to design and build a dynamo for the

deposition of metal from solutions to take the

place of the huge cells then in vogue. In

partnership with Mr. Bedford Elwell, the firm of

Elwell-Parker, Limited became famous throughout

the world, and one of its most notable

performances was to design and construct the

electrical plant for the first electrically

driven tram system of any considerable size in

this country. In 1888 the firm was absorbed into

the Electric Construction Corporation, Limited,

and many very noteworthy enterprises were

successfully carried out by this Company under

Mr. Parker's direct management, such, for

instance, as the design and construction of the

Liverpool Overhead Railway. In the field of

chemistry Mr. Parker's achievements are also

remarkable. He it was who solved the problem of

the successful pyro-electric extraction of

phosphorus, and his patented processes are at

present used in all the great phosphorus works.

In 1900, Mr. Parker was called in by the

Directors of the Metropolitan Railway to take

charge of the contemplated electrification of

the line, and from the results of his

experiments the Directors caused specifications

to be drawn up by Mr. Parker, and ultimately not

only the Metropolitan but also the District

Railway was electrified on almost identically

the same principle as that employed in his

construction of the Liverpool Overhead Railway.

Something over 50 specifications stand to his

credit in the Patent Office.

Mr. Parker has also written and spoken much

upon the subject of the reform of Units of

Measurement, and is one or the most active

members of the British Weights and Measures

Association, formed to oppose the introduction

of the Metre and its derivatives into this

country. He has pointed out, with all the weight

of his long engineering experience behind him,

that the inch forms in every way a more

advantageous and practical unit than the metre.

Quite apart from the hygienic aspect of the

smoke evil, Mr. Parker was deeply impressed by

the enormous economic waste of which coal-smoke

is merely the outward and visible sign. Before

ever the Royal Commission on our coal supplies

reported that, of the 150 millions of tons of

coal annually used in this country, 60 millions

are burnt to waste, Mr. Parker had recognized

the facts and had realised the import of this

gigantic loss and the consequences that are

bound to ensue if the national resources

continue to be squandered with this reckless and

senseless prodigality. As early as 1881 a Gold

Medal was awarded to Mr. Parker at the Smoke

Abatement Exhibition for his invention of the "Kyrle"

grate for the consumption of anthracite and

other fuels. He soon realised, however, that

what was needed was the production of a

smokeless fuel, and not merely the provision of

mechanical contrivances for economical

consumption.

The fuel must be absolutely smokeless, and

must be of such a nature that it cannot emit

smoke. Unlike coke, the fuel must be capable of

being readily lighted. It must be adapted for

satisfactory consumption in any existing grate,

stove, or kitchen range, and must provide the

cheerful ore insisted upon by popular choice,

and must emit neither unpleasant nor unhealthy

fumes. It must be in other respects as

convenient and relatively as cheap as the

present alternative fuels.

In the midst of his busy life, Mr. Parker

tried many extensive experiments with a view to

eliminating the smoky gases from bituminous

coal. In the end he discovered a process of

treating coal of any size or quality in such a

manner as to extract completely the whole of the

smoke-producing elements, and at the same time

to increase the calorific value of the resulting

product.

Coalite is much more bulky, by reason of its

porosity, than an equal weight of coal, and

since it lasts much longer, radiates more heat,

and burns more steadily than a coal fire, and is

converted entirely into carbon dioxide (no loss

occurring in the shape of smoke or of carbon

monoxide), and since also, even at its present

price, it is cheaper than coal, it may

reasonably be expected before long to prove

itself so very economical that its use will

become universal, not perhaps so much from any

urgent desire to assist in the promotion of

smokeless London, as simply on the ground of the

actual money - saving effected through its use.

Coalite has triumphantly passed the ordeal of

independent and searching tests made under the

direction of the Coal Smoke Abatement Society,

and has amply demonstrated its ability to meet

the points already referred to as being

essential in a perfect fuel.

Tests were conducted in rooms forming part of

the large block of buildings situated at the

corner of Great George Street, Westminster, now

being constructed under the superintendence of

Sir Henry Tanner, Chief Architect to H.M.

Government. The trials, which extended over 13

days, were performed under conditions and

regulations precisely similar to those issued

for the grate tests held under the auspices of

the same Society in July, 1905 (the Lancet of

19th May, 1906).

The tests of the sample submitted for

examination have demonstrated that Coalite is

easily lighted, and that it remains most of the

day glowing and cheerful, with a yellow flame

varying in size, while it emits no smoke. It

further requires little or no attention, as it

has no tendency to cake. No carbon monoxide was

detected in the flue gases, indicating that

practically perfect combustion had been secured.

As with with good coal, Coalite maintains a more

uniform fire and keeps the temperature of the

room more steady. It does not die down into an

inert looking mass, and deposits no soot.

The founders of the Coalite industry have no

doubts about its successful future, and they are

laying their plans upon a scale commensurate

with the expected demand for a fuel which

combines within itself all the qualities which

have so long been vainly desiderated. A long

frontage to the Thames, over a mile in length,

together with some hundreds of acres of

hinterland, have been secured, and works are

being put down of a size sufficient to deal with

from three to four millions of tons of coal

annually. The plant used in the preparation of

Coalite is entirely different from that used at

present in the gas and coke manufacture. The

stills are automatic and continuous in their

action, and the coal fed in at the top emerges

as Coalite at the bottom. As the apparatus

undergoes no destructive high temperatures, the

wear and tear is small, and the perpetual

renewals common in gas making practice are

rendered unnecessary.

Last, but not least, Coalite will bring to

fruition the hopes of those who have written,

preached, and striven for a cleaner life in a

purer atmosphere. At last it will be possible

for Londoners to breathe a wholesome air,

uncontaminated with the smoke fumes and fogs

they have so long endured. Every one will

rejoice if the lives of our cathedrals and other

national buildings may be lengthened, and if the

beauty of our priceless treasures of art may be

preserved. The flowers and trees in our parks

and gardens will at last be able to grow with

natural vigour; and, most important of all, we

may rejoice in the thought that our children

will not be handicapped by those abnormal and

unhealthy conditions which the black smoke

nuisance has too long imposed. They at least

will see and enjoy the fulfilment of the long -

cherished dream of A SMOKELESS LONDON. |

|

|

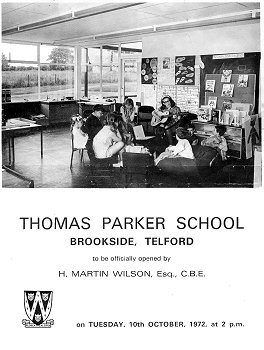

On 10th October, 1972 a new school opened at

Telford. It was called the Thomas Parker school in honour of

Thomas. When opened, the school catered for 40 children with

special needs.

Members of the Parker family attended the opening ceremony

and a large framed photograph of Thomas Parker, complete

with a list of his achievements, was presented to the

school.

The school still exists today and is now called the Bridge

School. |

| At long last Thomas is getting some well-deserved

recognition in Wolverhampton. On 26th February, 2007 a

new exhibition opened at Bantock House, featuring a

number of important historical figures from the City's

past. One of them is Thomas Parker. In May 2007 a new

artwork, in several parts, has been erected in Riches

Street, celebrating Thomas and his works. |

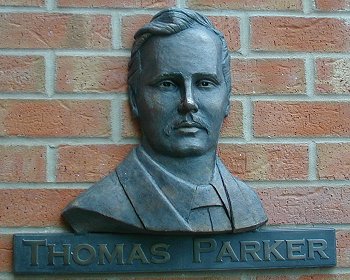

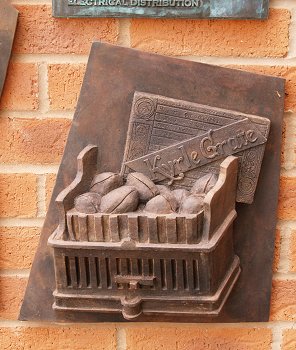

Part of the new plaque. Courtesy

of John McKenna. |

| The reliefs were designed and cast in bronze

by John McKenna, who has several other sculptures in

the area. His works are designed and manufactured in

his studio at Turnberry, Ayrshire, Scotland. |

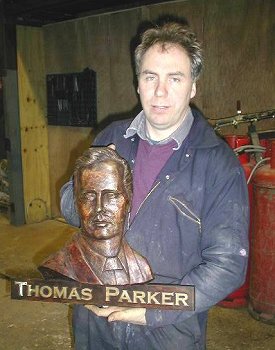

John McKenna and the

reliefs that depict many of Thomas's

achievements. Courtesy of John McKenna. |

John was involved in the plaques at St.

John's Retail Park in Wolverhampton that

celebrate car makers Sunbeam and Star, and the

Boulton Paul Defiant relief sculpture at

Pendeford. John's many local works include the

'Child At Play' steel railings features at

Wednesbury, the Green Man Sculpture relief for

the Green Man Passage in Dudley, way markers for

the Midland Metro tram line along the length of

a cycle path at West Bromwich, the 'Lucas Lion'

stainless steel relief sculpture on the former

Lucas Car parts production site at Newtown in

Aston, Birmingham, the 'Genie of Industry'

stainless steel artwork at Longbridge,

Birmingham, the Colossus of Brownhills, the 12

metre high stainless steel statue of a coal

miner that stands at Brownhills to celebrate the

areas' former coal mining industry, the

'Needles' Canopy at Butlers Passage, Walsall,

and the Palfrey Horse, which stands in Palfrey

Park, Walsall. Visit John's

website: www.a4a.co.uk |

| The top relief shows an early tram, similar

to the ones used on the Blackpool Tramway and

the South Staffordshire Tramway. The text reads

as follows: 1843 - 1915

Engineer & Scientist

Lived close to this site and worked on

many of his inventions here in Wolverhampton,

some of which are described on this plaque.

1881

Responsible for the first electric tramway

in the world at Portrush, Northern Ireland,

powered by the first hydro electric generator.

1882

Founded the first company in the Midlands

to manufacture electrical equipment such as

dynamos, motors, switchboards and transformers. |

Another view of the

reliefs. Courtesy of John McKenna. |

| The middle relief on the left shows the

Wednesfield furnace and the text reads as

follows: 1887

Wednesfield Furnace. Invented the method

of producing phosphorus and chlorate of soda by

electricity.

The middle relief on the right shows a Parker

dynamo and one of his early cars. The text is as

follows:

Thomas Parker designed and built cars.

Possibly the first motorist in Wolverhampton as

he had an electrically operated vehicle as early

as 1884.

The bottom but one relief on the left shows a

Parker alternator and the text reads as follows:

Designed and built multi-phase alternators

with stationary armatures and revolving fields,

a very successful design for many years. He used

the principal in alternating current furnaces

for purifying metals and establishing a more

efficient method of electrical distribution.

The bottom relief on the right shows a Kyrle

grate and the text is as follows:

Awarded two gold medals by the smoke

abatement society for perhaps his most important

work against air pollution. One for his

invention of the Kyrle fire grate and one for

his invention of distillation of coal by low

temperature method to produce a smokeless fuel -

"Coalite".

|

John McKenna holding

"Tom".

Courtesy of John McKenna. |

|

An Elwell-Parker dynamo

and a Parker car from about 1895. |

|

The Kyrle grate produced

by the Coalbrookdale Company from about 1880. |

|

A Wednesfield furnace. |

|

An early Parker tram. |

A final view of the plaques. Courtesy

of John McKenna.

|

|

|

|

|

Return to

the Funeral |

|

Return to the beginning |

|

Proceed to

Commemoration |

|