|

When the E.C.C.'s construction work was almost

complete, a running trial and inspection of the whole line was

undertaken on 13th January, 1893. This was reported in the

Manchester Weekly Times as follows:

|

On Saturday a running trial and inspection was

made along the whole length of the new line. The railway took over

three years to construct and cost £85,000 per mile. Lord Salisbury

will visit Liverpool on the 4th February to officially

open the line which runs from Herculaneum Dock to Rimrose Wall,

Seaforth, a distance of six miles. It uses standard gauge track and

there are thirteen stations with another due to be erected at

Seaforth.

Mr. Thomas Parker of Wolverhampton has designed

and carried out all of the electrical work in the electricity

department for the Electric Construction Corporation Limited. That

Corporation is under an agreement to put-down and maintain engines,

boilers, electric lights, conductors, signals, carriages, switches,

and indeed all appliances, and takes the responsibility of the

successful running of the concern for two years, guaranteeing the

proprietary company to the extent of 3.5 pence per train mile run.

The agreement covers depreciation, repairs and several expenses, and

indeed amounts to a bond to take over everything but the actual

management and collecting of fares. Mr. Parker estimates that at a

cost of 2 pounds of coal, a train of two carriages weighing 40 tons,

when each filled with 56 passengers, can be carried one mile.

At the Bramley-Moore Dock Depot there are four horizontal

compound engines by Messrs. Musgrave, of Bolton, each

driving a separate Elwell-Parker dynamo of powerful energy,

and capable of jointly working up to 2,000 horse power. The

boilers are fitted with mechanical stokers, and there is an

arrangement of mechanical coal brokers by which all handling

is entirely obviated, the coal being dropped into them from

the high-level coal railway. From the dynamos the

electricity generated is by means of copper conductors

carried through switch arrangements into the railroad,

instruments in the shed indicating the electrical pressure

upon the road and passing thereto.

The copper conductors are connected to the outside rail

and with a central conductor between the rails in each set,

the positive and negative sides of the circuit being thus

formed. Hinged conductors of cast iron, sliding upon this

conductor make the connection between the motors upon the

train and the dynamos at the generating station. The motors

are carried by the passenger carriages, and the quantity of

electrical energy picked up can be regulated by the man in

charge of the train. The same principal is seen in the case

of the Blackpool tramway, only for obvious reasons the

conductor at Blackpool is below ground, whilst in the

present instance it is on the permanent way, and has the

appearance of a third rail. The conductor is made of mild

steel and its dimensions are about four inches square.

Although two carriages form a train, these vehicles are so made that

any number can be coupled together. They are so coupled as to give a

motor at each end of the train, and the motors are connected so as

to be controlled from either end by the driver, who will always

travel in front, changing ends upon arrival at the terminus, and

carrying with him a key, without which the motors cannot be

operated. Students of electrical science will understand by which

law it is impossible for these trains to travel more than 35 miles

an hour. Mr. Parker says that the moment that very respectable speed

is reached, the motors, instead of picking up electrical power from

the conductors, would at once begin to return power back to the

dynamos. The trains make the journey in 29 minutes including the

stopping times at the stations.

The inspecting party left Water Street Station

shortly after half past one and completed their task in a couple of

hours. During the run the train reached a speed of 30 miles an hour.

The weather that day was awful and the party were pleased to see

that the trains could operate normally under such conditions.

The party included Mr. T. Snape, M.P., Sir W. B.

Forwood, Mr. George Melly, Mr. J. Barrow, Mr. D. Meldrum (Cheshire

Lines Committee), MR. C. A. Rowlandson, Mr. Reginald Todd, Mr. Evanson, Mr. H. J. Brodie, Mr. A. Bare, Mr. P. Higginson, Mr. Thomas

Parker, Mr. S. B. Cottrell (General Manager and Resident Engineer),

Captain Wilkinson, and Alderman Miles and Broughton, of Bolton. In

the evening Mr. Parker entertained the party at the Adelphi Hotel.

|

|

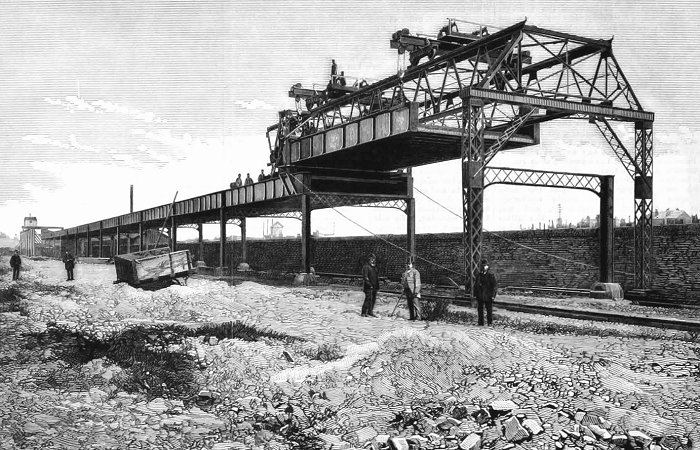

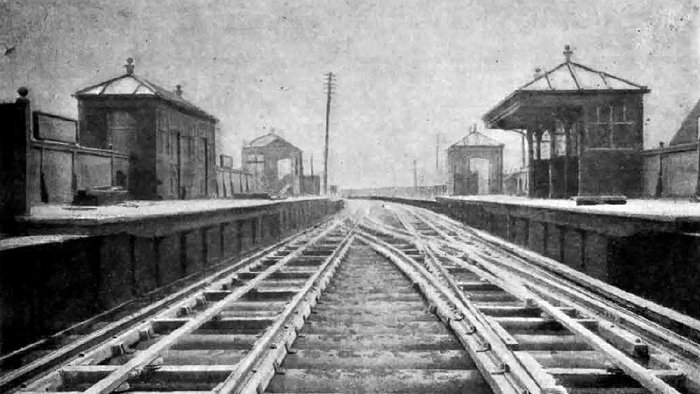

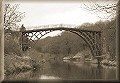

The railway during construction. From The

Engineer.

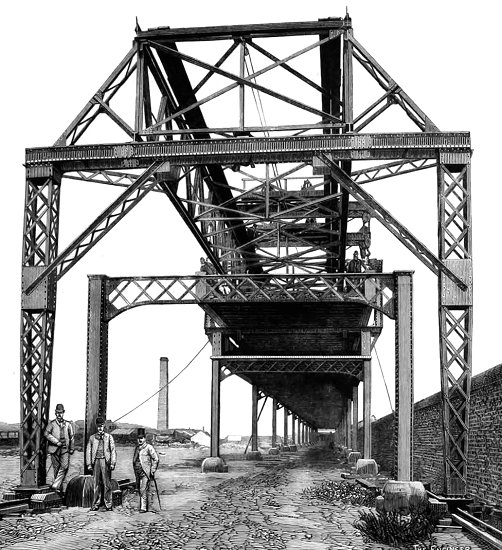

Another view of the construction. From The

Engineer.

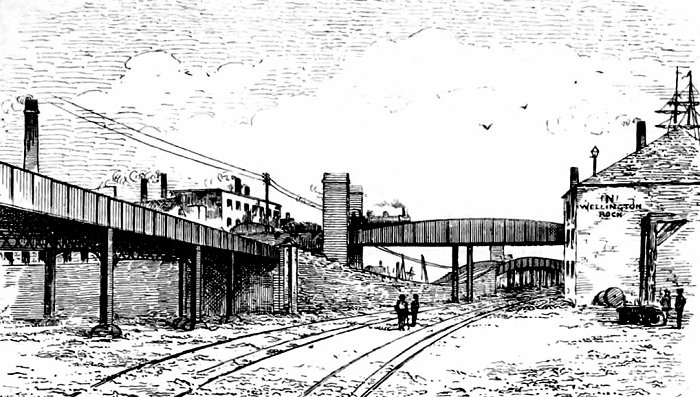

The dip under the Lancashire & Yorkshire

Railway. From The Engineer.

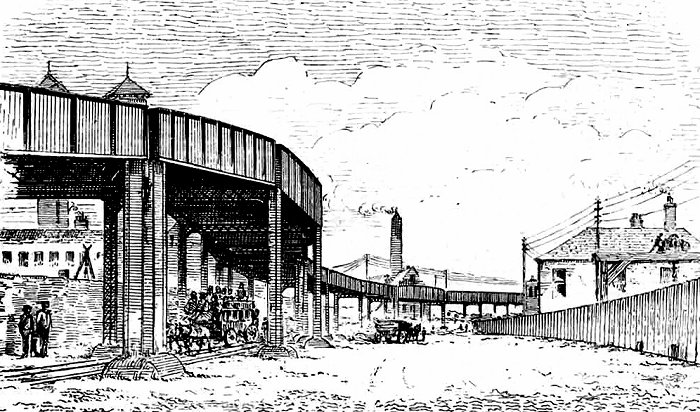

The double curve near the Alexandra Dock. From

The Engineer.

The overhead railway, as seen from the pier

head. From The Engineer.

The preserved third class motor coach in the

Museum of Liverpool.

The interior of the preserved motor coach.

|

|

|

|

The driver's

compartment in the preserved motor coach. |

The railway was formally opened by the Marquis of

Salisbury on Saturday, 4th February, 1893. This was recorded in the

following Monday's edition of the Liverpool Mercury, as follows:

|

Opening of the Liverpool Overhead Railway

Liverpool is the first city in England to build

an overhead railway, and the first city in the world to adopt

electricity as a means of working such a railway, and on Saturday

last, the formality of opening this unique undertaking was performed

by the Marquis of Salisbury. It could hardly be possible to imagine

a fitter person than the ex-premier for performing such a ceremony,

as he has the reputation of being an enthusiastic student of

electricity, and, in addition to that, is one of the two

distinguished men to whom for the last twelve years the country has

alternately trusted its government.

The party arrived at Bramley-Moore Dock and

entered the generating station, which is built in the arches that

support the Lancashire and Yorkshire Railway. All of the vessels in

the dock and the surrounding streets were bedecked with bunting, the

weather was bright, and the scene was of the gayest description, as

equipages and cabs, the picturesque uniforms of the mounted police,

the general animation, the large bodies of police under their

inspectors, lent no small affect to the ensemble.

The Marquis was accompanied into the generating

station by Sir. W. B. Forwood, the Chairman of the Overhead Railway

Company, the Mayor, Mr. R. D. Holt, Lord Lathom, Mr. A. B. Forwood,

M.P., Mr. Brancker, Chairman of the Dock Board, Sir Daniel Cooper,

Chairman of the Electric Construction Corporation, the Rev. Canon

Armour, Mr. J. B. Smith, Mr. E. Laurence, Chairman of the Gas

Company, and others. Also present at the inaugural ceremony where J. A. F. Aspinall (Lancashire and Yorkshire Railway), and Thomas

Parker. The station had been arranged for the accommodation of a

large number of visitors, and that, although there was no

overcrowding, the available space was filled.

The party ascended a platform, speeches were made

and the presentation of a small silver inkstand was made to Lord

Salisbury, who started the electric current of 2,000 horse power

which magically draws the trains over the lines. When the ceremony

was over the party accompanied Lord Salisbury to Sandon Station

where a specially decorated train was waiting to convey them on the

first official trip on the line. The remainder of the party

travelled to Clarence Dock Station where two trains were waiting to

take them over the same route.

With regard to comfort of the new style of

locomotion, it may be said that it is delightful travelling. A

handle is turned, and without any visible means of propulsion or

attraction, off go the carriages with a smooth and even motion,

which can be regulated at the will of the engineer. The carriages

are built on the American principle, with a central passage open end

to end, with seats back to back transversely. The sides are nearly

all window, thus affording an excellent view of the long stretch of

docks. The sensation going down the “switch-back”, necessitated by

the fact that the overhead railway has to go beneath the high level

railway bridge at the Bramley-Moore Dock, is strongly remindful of

the form of amusement which was so popular a year or two ago, though

in a very much more modified degree, the speed of the train

retaining almost uniform regularity. Just beyond the Sandon Station

the marquis’s train was seen coming from the Alexandra Dock,

preceded by flashes of electricity, thus showing the actual power

which moves the carriages.

The train arrived at the Alexandra Dock Station,

with admirable celerity the carriages were moved over the points to

the down line and a swift journey was made to the Water Street

Station, where the passengers disembarked after a most enjoyable

trip. His lordship, however, was taken on to the Custom House

Station, whence he was driven to the Town Hall where a luncheon was

given by the Mayor.

|

|

The railway company were obviously delighted with

the E.C.C.'s contribution to the railway, as can be seen from the

following letter, in which the company is relieved of its obligation

to oversee the running of the line. It also is proof of Thomas

Parker's undoubted skills as a first class engineer and his great

skill in project management

|

|

The letter received

from the railway company. |

The letter reads as follows:

|

The Liverpool Overhead Railway Company

31 James Street

Liverpool

6th January, 1894

To the secretary of the Electric Construction

Company.

Dear Sir,

I am desired by my colleagues to express to you

their satisfaction with the manner in which your company has

fulfilled its contract for the electrical equipment of this railway.

The machinery has been well and substantially

made, it is economical in working, and its efficiency may be gauged

by the fact that during the ten months the line has been opened we

have run a five minutes’ service of trains, and 96 percent have been

on time.

We are now able to relieve you of the charge of

our generating station, which we consider has proved its capacity

and reliability.

We feel that these excellent results are very

largely due to the scientific skill, thought, and untiring industry

of your works director, Mr. Parker, to whom we ask you to kindly

convey our thanks.

I am faithfully yours, William B. Forwood,

Chairman.

|

|

The overhead railway. From an old

postcard.

Another view of the railway, also from an old

postcard.

The railway in 1893. From The Engineer.

|

The Liverpool

Overhead Railway. Part of an article from The

Engineer.

The railway is designed for the

use of any of the well-known systems of mechanical

haulage, but the electrical was ultimately selected,

and that which relates to the working of the line by

electricity has been designed and carried out by Mr.

T. Parker, M.I.E.E., as engineer and manager for the

Electric Construction Corporation. On the line,

which, as we have already said, is six miles in

length, double track, there are fourteen stations,

with crossover roads at each intermediate station,

and double crossovers at the terminal stations. It

is eventually intended to run a three minutes'

service, and generating plant bas been provided for

this. There are some moderately sharp curves on the

line; the maximum being six chains radius. The

maximum distance between any two stations is 1200

yards, and the minimum distance 300 yards. The

journey from one end of the line to the other will

be completed in about thirty minutes, including half

a minute stop at all stations. In the first instance

rolling stock is only being provided for a five

minutes' service. It is hoped that the traffic will

be carried with the expenditure of about 7 lb. of

coal per train mile.

The generating station and

plant occupies a position close to the structure and

approximately in the centre of its length. The

arches under the existing coal railway have been

utilised for the generating station. It is intended

that the line shall eventually be extended at each

end by a length of 1½ miles, this bringing up the

total when completed to nine miles.

The boilers are six in number

and of the Lancashire type, 30 ft. by 8 ft.,

constructed for a working pressure of 120 lbs. per

square inch, fired by Vicars' mechanical stokers,

the coal supply being drawn from hoppers overhead,

into which the trucks on the existing coal railway

are emptied. Coal supplied to the various boilers by

means of a conveyor, and the feed passes through a

Green's fuel economiser, consisting of 384 pipes.

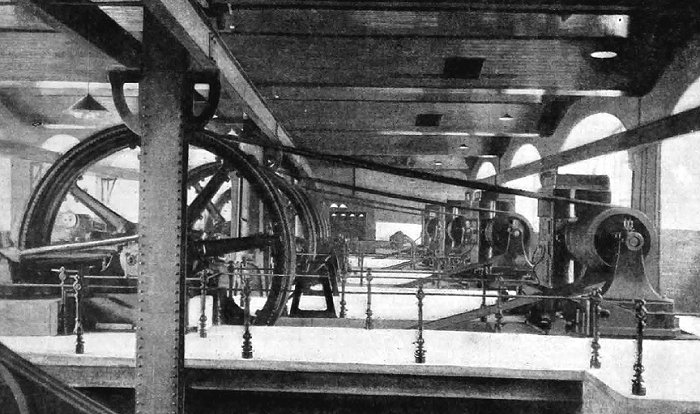

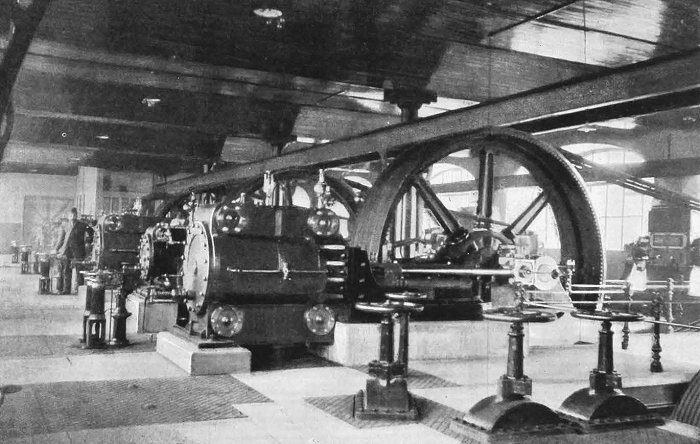

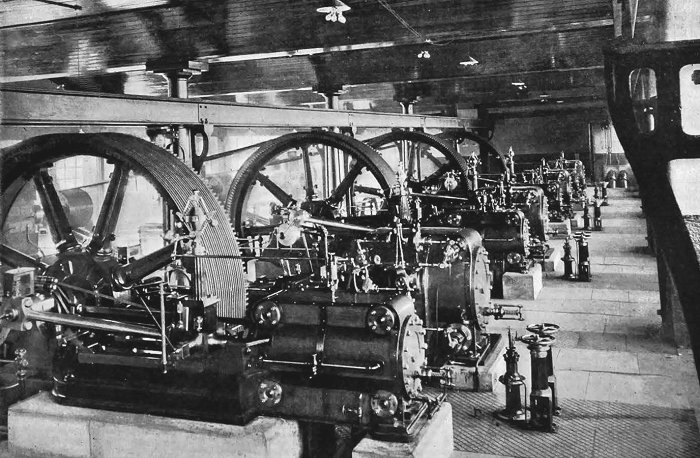

The generating station.

The boilers and steam pipes are

covered with Leroy's none conducting composition.

The dynamos are driven by four horizontal coupled

compound engines, with Corliss valve gear and each

capable of indicating 400 horsepower, with 120 lb.

steam pressure, at 100 revolutions per minute. The

cylinders, 15½ in. and 31 in. diameter, 36 in.

stroke. Valves fitted to all cylinders. The

flywheels are 14 ft. diameter, grooved for nineteen

l¼ in. diameter ropes. Independent surface

condensing plant is used, divided into two units,

each capable of condensing steam from three of the

main. engines, running under full load. The

condensing water is taken from the dock adjoining

the generating station, and passed through brass

tubes. The air and circulating centrifugal pumps are

driven by small compound vertical engines, having

Ferguson’s patent triangular connecting rods. The

cylinders, 7½ in. and 15 in. diameter,12 in. stroke.

As auxiliary machinery there are two pumping engines

for boiler feed, each capable of supplying four

boilers. One engine for driving stoker and conveyor,

10 indicated horsepower, and two small engines for

working the scrapers on the economiser. All steam

and feed pipes are arranged to give a duplicate

service between boilers, engines, and pumps.

Arrangements are also made so that the engines may

exhaust into the atmosphere in case of water not

being obtainable at any time for condensing.

The four Elwell-Parker type dynamos.

Four Elwell-Parker shunt-wound

dynamos, each giving an output of 400 volts and 475

amperes, at 400 revolutions per minute, are used.

The magnets are of the double horseshoe type, fixed

vertically, divided on the horizontal centre line,

so that the top half can be readily lifted off to

allow of examination or removal of the armatures.

The pulley is carried between two bearings, and a

coupling being inserted between the pulley and

armature shafts, allows the latter being taken out

without taking off ropes, dismounting pulley, or

interfering with the set of the bearings. Each

dynamo is coupled up through an ammeter to a double

pole automatic magnetic cut-out, which also answers

the purpose of main switch. All the machines couple

in parallel on to omnibus bars, from which the

current is taken by underground "armoured" cables to

the conductors on the line, a larger automatic

magnetic cut-out being inserted, carrying the whole

of the current. Multiple contact switches and

resistance coils in the shunt circuit arc employed

for regulating the electromotive force of the

machines.

The conductor, consisting of a

steel channel, is carried the whole length of both

the up and down lines between the ordinary rails,

the latter forming the return circuit. The steel

channel is carried upon pot insulators, supported by

cross timbers between the longitudinal sleepers. The

surface of the steel channel, forming the centre

conductor, is ⅞ in. higher than the top of the

ordinary rails. At the crossover roads the conductor

is bent so as to run parallel for a short distance

on each side of the ordinary rails, but leaving

ample clearance to prevent arcing across. The

current is collected from the surface of the steel

channel by means of cast iron shoes loosely hinged

to insulated iron strips carried by the bogies. The

shoes are made much wider than the conductor, so as

to stretch across at the crossover roads from the

conductor on the one side to the conductor on the

other side of the ordinary rails. A collector is

fitted to each motor bogie.

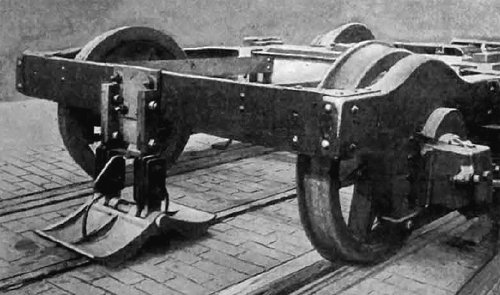

The conductor and the collector.

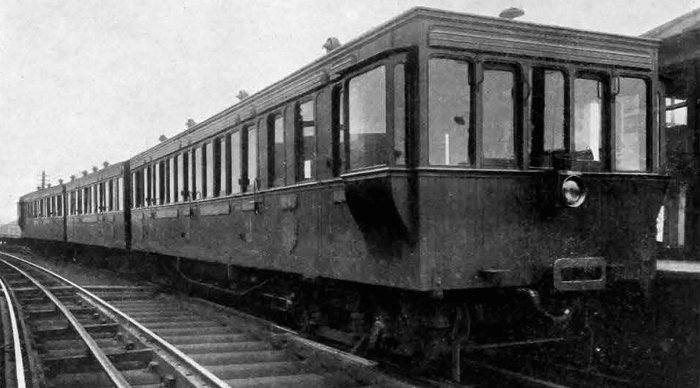

The carriages, two of which

form a train, are in length over end pillars 45 ft.;

the width over side pillars, 8 ft. 6 in. The

carriages are mounted on two four-wheeled bogies,

one of which carries a motor as shown. The centres

of the bogies are 32 ft. apart. The wheelbase of the

bogies is 7 ft., and the wheels are 2 ft. 9 in.

diameter. They carry 57 passengers; 16 first class

and 41 second class.

As each carriage is fitted at

one end with a driver box and necessary switch and

brake gear for controlling the work, there is no

shunting at the terminal stations, the driver

changing ends. The gangway between the two cars

gives a clear passage through for the guard.

The motors on each train are on

the leading and trailing bogies. Six incandescent

lamps light each carriage, supplied with current

from the centre conductor, the same as the motors.

The carriages are fitted with

Westinghouse brakes, with compressed air stored in

receivers carried under the carriages, and these

being charged by an air compressing plant fixed at

the generating station at the north end of the line.

Hand screw brakes are also provided.

The armatures of the motors are

mounted direct upon the axles. Ten revolutions of

the axle per minute gives a speed to the car of one

mile per hour. The maximum speed necessary to do the

journey in the time specified is approximately 26

miles per hour, or 260 revolutions of the motor per

minute. The motors are series wound. |

|

The steam engines in the generating station.

From The Engineer.

Another view of the steam engines in the

generating station. From The Engineer.

Thomas Parker presented a paper on the Liverpool

Overhead Railway to the Institute of Civil Engineers on Tuesday 2nd

March, 1894. The paper was called “The Electrical Equipment of the

Liverpool Overhead Railway”:

|

The

Electrical Equipment of the Liverpool Overhead Railway

by Mr. T. Parker, M.. Inst., C.E.

The plant was required to run a three-minute service on six

miles of double track. In designing it, curves were drawn of the

energy required at any point along the line of one loaded train

with various accelerations. etc., to meet the timetable service.

From these curves the power required at the generating station

was calculated, and four dynamos were arranged, yielding 475

amperes at 500 volts and 420 revolutions, or 1,200 E.H.P. in

all. The dynamos were of the double-line type, rope driven, with

pulley between two bearings, so that the armature could be taken

out without disturbing the ropes.

The electrical efficiency of the dynamos was 97.77. The

switchboard, specially designed for safety and simplicity in

working, was fully described. The main current passed to the

line through a main magnetic cut-out, to break circuit at 3,606

to 4,000 amperes. The conductor was of steel, 4 square inches in

section, supported on porcelain insulators. There were no

feeders, and the return circuit was through the rails, which

were bonded. At each station there was a crossover road. The

conductor was broken at these points, and the collector bridged

across over the main rails without breaking circuit.

It was necessary that the cars should be of the double-bogie

type; it was, therefore, difficult to design motors to give the

power necessary on standard bogie frames. Finally a type was

adopted, as patented by Mr. Eickemeyer, which gave complete

satisfaction. The motor occupied the front half of the

bogie-truck. The weight of the magnets was taken off of the

axles by adjustable springs, and the magnets were kept in

horizontal position by a lever arm fixed to the bogie-frame.

Each car was complete with motor and switchgear to run

independently. Two cars were coupled together to form a train.

Either the driving or trailing motor could be plugged out of

circuit at will. A Westinghouse air-brake was attached to the

car, also the usual hand-brake. The stations were lighted by

50-volt glow-lamps, run off accumulators fixed at the station

and charged from the main dynamos.

The efficiency of I.H.P. to E.H.P. on the line was taken with

carefully calibrated instruments in the presence of the

Engineers. The tests extended over 3½ hours. The mean value of

seven tests of No. 1 Engine gave 88 per cent. I.H.P. to E.H.P.

Curves were given of the power consumed during an experimental

run of one train completing 51 miles in 24 minutes, 57 seconds,

and 23 minutes, 47 seconds, with stops of 25 seconds at each

station. The power required was 44.4 I.H.P. and 46 E.H.P.

respectively. To compare this with actual running, curves were

given from daily log-sheets showing the effects on the

generating station of the alteration to the train service. The

advantage of a large number of trains in pulling down the

maximum current per train was apparent. With seven trains this

was twice, and with twelve trains only 1½ times the average

current per train. With twelve trains running, the average

demand for power continuously was 37 E.H.P. per train.

A comparison of coal used when the train service varied was

given. During April and part of May seven trains were running at

one time, and the coal used was 22.5 lbs. per train mile. From

June to October there had been a 5 minute service from 9 a.m. to

5-30 p.m. The coal used per train mile for the four months of

June, July, August and September, was 17.8 lbs., or making

allowance for charging batteries, say I7 lbs. per train mile.

The price of the Lancashire slack, which was used till the

latter part of August, was 5s. 10d. per ton, but since that

date, owing to the strike, the price for coal from various

sources had varied up to 17s. 6d. per ton. Under the agreement

the contractors had to run the service of trains for 3½d. per

train mile, on a full service of 2,400 miles per day, but as

only five and one eighths miles of line were open, they received

4d. per train mile, and for current to charge lighting

batteries, 7d. per Board of Trade Unit. Figures were given of

the actual working costs for July, August and September, 1893,

which were 3.44, 3.70, and 4.07 pence per mile respectively. The

increased cost of running for August and September was fully

accounted for in the item of coal, and as the railway company

had not employed as frequent a service as at first anticipated

(this being only 1,350 miles per day) the figures showed most

favourably, it being evident that, with coal at an average

value, the line could be run at a cost well within that

guaranteed by the contractors.

|

|

The paper was a great success, and Thomas was

awarded a George Stephenson Medal and a Telford Premium for his

efforts. This can be seen in the following transcript of the letter

that he received from the institution:

|

Sir, I am instructed to inform you that the

Council of the Institution of Civil Engineers has awarded you a

George Stephenson Medal and a Telford Premium for your paper

entitled “The Electrical Equipment of the Liverpool Overhead

Railway”. The formal presentation will take place at the first

ordinary meeting of next session on the second Tuesday in November,

when it is hoped that you will be present to receive the premium

awarded to you.

I am, Sir, your obedient servant, James Forrest,

secretary.

To Thomas Parker, Esq., M. Inst. C.E.

Manor House

Tettenhall

Wolverhampton

|

|

Thomas received a letter of congratulation on the

award, from his friend Thomas Bantock, J.P.

|

Merridale House,

Wolverhampton

5th June, 1894

My Dear Mr. Parker,

Allow me to congratulate you on the award

of the Stephenson Medal by the Society of Engineers.

I hope you may long be spared to receive

the Honours you will be sure to earn in the future and may

your wife and family share in the joy that awaits success.

Yours Truly

Thomas Bantock, J.P.

Tho. Parker Esq., J.P.

Manor House

Tettenhall |

|

Thomas's Stephenson Medal.

Courtesy of

the library and archives of the Ironbridge Gorge Museum, at

Coalbrookdale. |

|

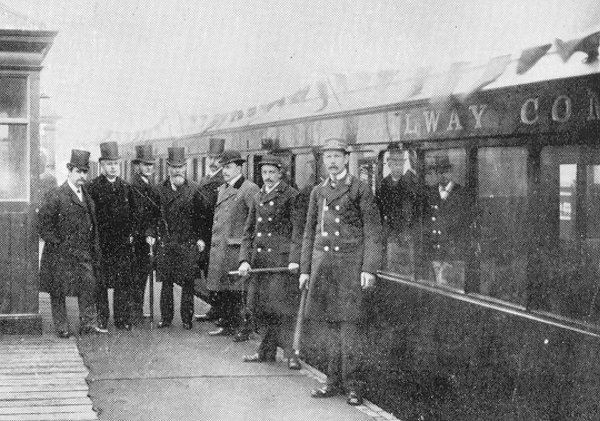

The opening ceremony of

the Liverpool Overhead Railway.

The group L. to R. is as follows:

Thomas Parker; Sir Douglas Fox, joint

engineer; Francis Fox, younger brother and partner of

Douglas; James Henry Greathead, civil engineer. |

|

One of the locomotives in operation.

From 'The Engineer' 24th November, 1911. |

|

A train passes between Canning

Dock and Strand Street. From an old postcard. |

|

A train pulls into James Street

Station. |

|

Return to the

previous page |

|