|

The Electric Construction Corporation developed the

overhead-wire tram system that began operating in 1893 when the South Staffordshire Tramways

were electrified. |

|

South Staffordshire Tramways.

From The Engineer, 18th November, 1892.

Early in the present year

the South Staffordshire Tramway Company entered

into a contract with the Electric Construction

Corporation, of Wolverhampton, for the equipment

of a section of its lines with plant for

electric traction on what is generally known as

the trolley wire system, the lines having

hitherto been worked by steam locomotives. The

plant is now practically completed, and the

inspection by General Hutchinson and Major

Cardew, on behalf of the Board of Trade, took

place on Saturday, November 12th, so that the

electric cars will very shortly come into

service.

The lines over which the electric cars are to

be run extend from the junction of Holyhead Road

and Bridge Street in Wednesbury, through the

centre of the borough of Walsall, to Bloxwich,

with two branch lines, one running from the

Pleck to Darlaston, and the other from Walsall

to Mellish Road. The length of streets occupied

by the tramways is just over eight miles, six

miles having a single line with turn-outs, the

other two miles having a double line, making a

total length of track, and therefore of trolley

wire, of over ten miles. The route taken by the

lines is shown on the map - Fig. 5 - which also

indicates the position of the generating station

on the line between the Pleck and Darlaston.

Fig. 5. A map of the tramway. |

|

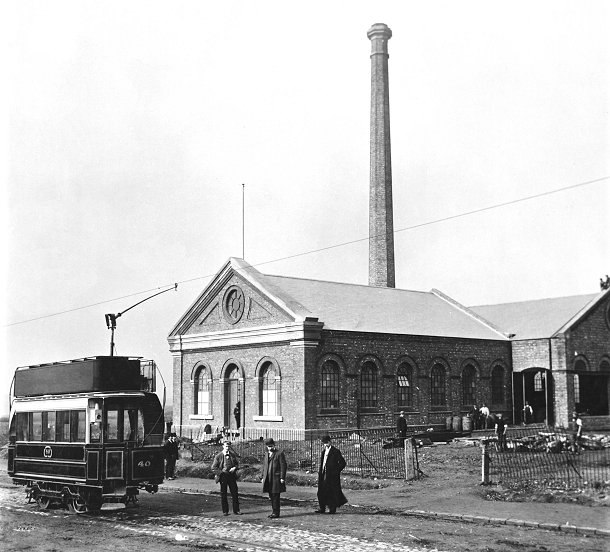

The generating station at Pleck, Walsall. |

|

The generating station is

on the side of the canal, and has a basin for

receiving the barges bringing coal, which

discharge directly into the boiler room. The

canal water is used for condensing.

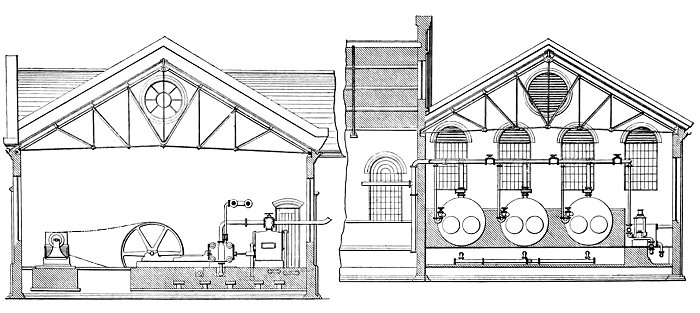

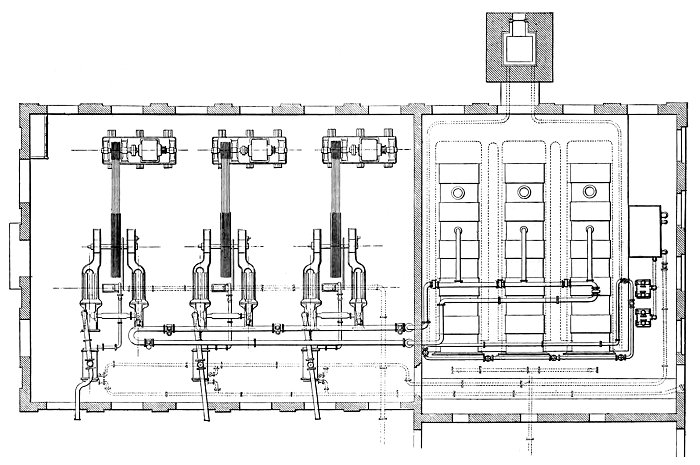

The general arrangement of

the buildings and plant is shown on the plan and

section - Figs. 6 and 7. The three boilers are

of the Lancashire type, 7ft. diameter, 30ft. in

length, designed for a working pressure of 120

lb. per square inch. The three engines, which,

together with the boilers, were made by Messrs.

J. Musgrave and Sons, of Bolton, are of the

horizontal coupled-compound pattern, each easily

capable of indicating 125 horse power with the

above steam pressure, when running at a speed of

100 revolutions per minute. The cylinders are

10½in. and 20in. diameter, 30in. stroke, both

cylinders being fitted with Corliss valve gear;

the flywheels are 10ft. in diameter, and grooved

for seven l¼in. diameter ropes. A surface

condenser is attached to each engine. The steam

and feed pipes are arranged so as to give a

duplicate service between the engines, boilers,

and pumps. |

|

Fig. 6. The generating station. |

|

Fig. 7. A plan of the generating station. |

| Arrangements are also provided so that the

engines can be run non-condensing if required.

The dynamos, one of which is driven from each

engine by means of cotton ropes, are of the

usual Elwell-Parker type, and give an output of

260 amperes at 300 volts, when running 400

revolutions per minute, the field magnets being

shunt wound. The driving pulleys are carried

between two bearings, and there is a coupling

between the pulley and armature shafts, so that

the latter can at any time be removed without

taking off the ropes or dismounting the pulley. |

| Each dynamo is connected by cables carried

under the floor to a patent Elwell-Parker

automatic magnetic contact, which also acts as

the main switch for the machine. These

contacts are adjusted so that, in the event of

an excessive current being demanded from the

machines - due to any accident or short circuit

on the lines - the circuit is opened, and any

damage to the machines prevented.

All three machines feed in parallel on to

common omnibus bars, between which and the

feeders taking current out to the line there is

a simple main switch. Ammeters are provided in

each dynamo circuit, and a voltmeter with large

dial indicates the electromotive force across

the omnibus bars.

Multiple contact switches and resistance

coils are connected in the shunt circuits for

regulating the electromotive force.

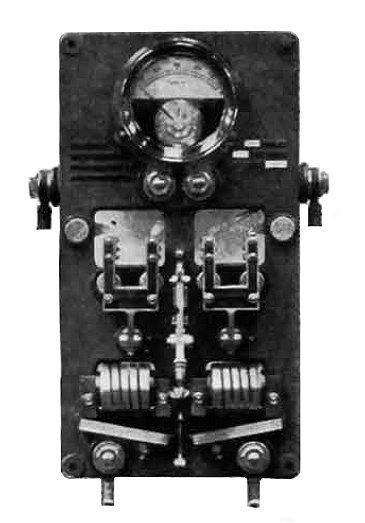

A section of the switchboard showing the

arrangement for each machine is illustrated in

Fig. 4. |

Fig. 4. The switchboard. |

|

From the generating station

the current is supplied to the 0 gauge copper

trolley wire by underground feeders, these being

insulated with vulcanised bitumen, lead

sheathed, and armoured with a double layer of

steel tape, so that they can be laid directly in

the ground without further protection; the

lengths and sections of the feeders are

indicated in the map - Fig. 5.

The return circuit is

completed through the rails and earth. At

distances of approximately half a mile apart

connections are made between the feeders and

trolley wire by means of cables drawn up inside

the posts. Each section of trolley wire is fed

into at both ends, the current passing through

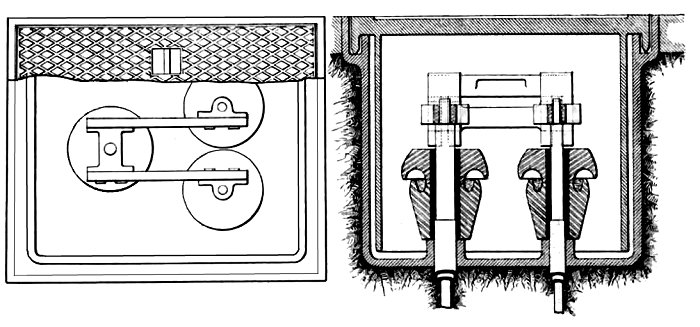

fuses placed in an underground box - Fig. 8 - at

the foot of the feeding posts. These fuse boxes

are made on the diving bell principle, to

prevent any possibility of water accumulating in

them and rising sufficiently high to reach the

connection. The covers are easily drawn up to

allow of examination or insertion of new fuses.

The map - Fig. 5 - shows the position of the

feeding points and fuses. |

|

Fig. 8. Underground fuse boxes. |

|

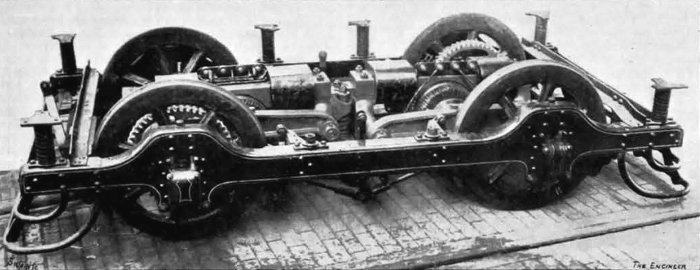

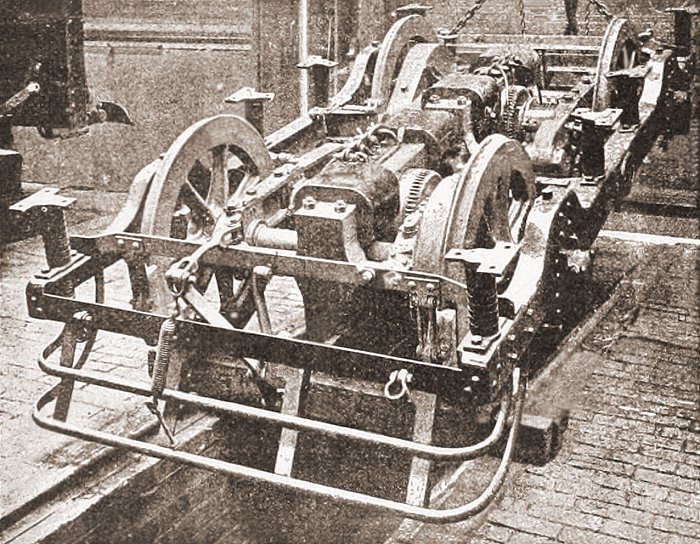

Fig. 2. An under truck with motors. |

| The trolley wire is carried at a height of

20ft. from the surface of the streets by poles

along one side of the road only; arms projecting

from the poles - Fig. 7 - carry the insulators

supporting the wire. A special arrangement,

suggested by Mr. Dickinson, the Tramway

Company's engineer, makes it unnecessary that

the trolley wire should be at a regular distance

from the centre of the rails, the collector

being designed so as to allow a variation of

several feet. Where there is a double line of

rails the pole arm carries two insulators and

two trolley wires, one for the up and one for

the down line. Automatic overhead switches are

fixed at the turn-outs, so as to guide the

collector wheel along the right wire. Fourteen

cars made by Messrs. Brown, Marshall, and Co.,

and the Lancaster Wagon Company, are being

supplied for the equipment of the line, each

carrying forty passengers, eighteen inside and

twenty-two outside. The collector is fixed on

one side of the roof of the car, the arrangement

being clearly shown in Fig. 7. |

|

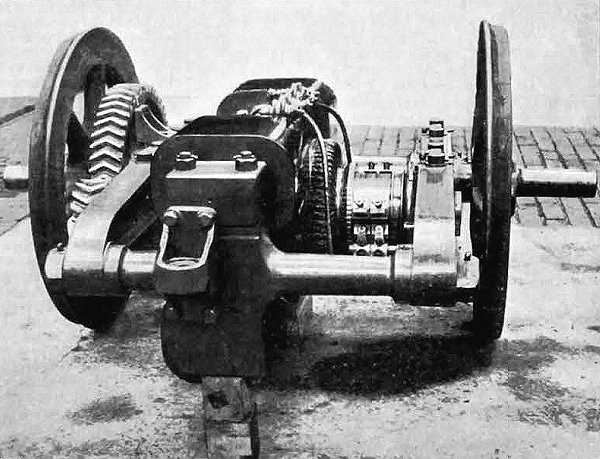

Fig. 3. An Elwell-Parker motor. |

| The under trucks - Fig. 2 - carry two Elwell-Parker

series wound motors - Fig. 3 - each capable of

running continuously with a load of 15

horsepower, the normal speed being 400

revolutions per minute; the armatures are geared

up to the axles by means of cast steel double

helical wheels and pinions, having a ratio of 4

to 1. One motor is considered to be amply

sufficient to take a fully loaded car up the

heaviest gradient of 1 in 28 occurring on the

line. The practice of using two motors on each

car appears to have been brought over from

America, where the lines are not so well laid,

and where, also, they have to contend with snow

and ice throughout the winter. On very few lines

in England do we consider that it will be

necessary to use two motors, although it will be

necessary that the one motor shall be more than

15 horsepower, unless a simple form of gear for

varying the speed with a constant speed of motor

be used. Driving switches are fitted at both

ends of the car, and arranged so that either or

both of the motors can be in use, the regulation

of speed being effected by putting resistance

into the motor circuit. The

whole of the electrical plant has been designed,

manufactured, and installed by the Electric

Construction Corporation, who are also

responsible for the other portion of the plant

supplied to them by various firms as

sub-contractors. The running of the line is also

in the hands of the Electric Construction

Corporation, they having undertaken to work it

at a fixed charge per car mile for a number of

years. Mr. Alfred Dickinson has been appointed

to superintend the working on their behalf. |

|

Another photo of an Elwell-Parker under

truck.

The South Staffordshire Tramways

generating station.

The following description of the tramway is from the Railway

Engineer, volume 14, number 1, January, 1893:

|

The South Staffordshire Tramways have an aggregate

length of about 23 miles. They connect Darlaston,

Wednesbury, West Bromwich, Handsworth, Great Bridge,

Dudley Port, Dudley, Walsall, and Bloxwich with each

other, and last year 4,000,000 passengers were

carried.

About nine miles-viz., from Darlaston and Wednesbury to

the Pleck, thence to Walsall Bridge, where the line

again separates, one branch going to Bloxwich and the

other to Lichfield Road - has been fitted to work by

electricity upon the over-trolley wire system.

The installation has been carried out entirely by the

Electric Construction Corporation of Wolverhampton. The

sub-contractors for the cars were the Lancaster Carriage

and Wagon Co., and Brown, Marshalls & Co., for the

stationary engines and boilers of 150h.p. Messrs.

Musgrave & Son, of Bolton, and the posts to carry the

overhead wire were divided between Messrs. James Russell

& Sons and Messrs. John Russell & Co.

The motors are of the Elwell-Parker type. The posts are

placed at the side of the road, and the bracket arms

carrying the trolley wire stretch out over the road 7 to

10ft., but give a clear height of 21 ft. By a kind of

universal joint the collector is allowed a variation of

several feet, so that it is not necessary for the

trolley wire to be directly over the middle of the line.

|

|

One of the tram trucks from the South Staffordshire Tramways

has survived. It was acquired by the London Science Museum in

1912, and went directly from the Darlaston tram depot to be put

into store. It has recently moved to the National Tramway Museum

at Crich, and must be the oldest tram truck in the world that is

still in its original condition.

|

The truck arrives at Crich.

Courtesy of the National Tramway

Museum. |

| The truck, after being

unloaded from the transporter.

Courtesy of the National Tramway

Museum. |

|

The truck at the Science Museum's store.

Courtesy of

Another view of the truck at the Science

Museum's store. Courtesy of

|

This close-up view of the

truck clearly shows the two electric motors. The gears

can also be seen on the back wheels. The commutators

appear to be in good condition, but unfortunately the

brush gear is missing.

Courtesy of

|

|

Return

to the

previous page |

|