|

Thomas Parker, Limited

After leaving the E.C.C., Thomas decided to form

his own electrical manufacturing company and Thomas Parker,

Limited was the result. The idea to start the company came from

a number of enthusiastic ex-Elwell Parker employees, who greatly

respected Thomas, both as an employer and an engineer. They

formed the engineering backbone of the company and also invested

in the company.

The first directors appointed on 10th May

1894, were:

Charles Tertius

Mander, Mayor of Wolverhampton.

Thomas Graham, proprietor of the Express & Star newspaper.

William Thomas, manufacturer.

Thomas Parker.

The Express & Star of Wednesday, 23rd May,

1894 reported that a prospectus for Thomas Parker, Limited had

appeared in the advertising columns and that the company was

formed to carry on the business of manufacturing plant for

electric lighting, electric transmission of power, electric

railways, electric tramways, electro-chemical, electro-

metallurgical, and such other purposes as are incidental or

conducive to any of the above objects, and new developments and

improvements in electrical and general engineering. |

|

The location of the works.

|

The article stated that the

vendor and promoter is Mr. Thomas Parker, F.R.S.E., M.I.C.E.,

M.I.M.E., M.I.E.E., J.P. of the Manor House, Tettenhall, founder and

managing director of Elwell-Parker, Limited and for five years works

manager and chief engineer of the Electric Construction Company,

Limited.

Thomas Parker acquired the freehold of about seven acres of

land on which to build the works. It was on Wednesfield Road,

Wolverhampton, within a few yards of the Great Western, London

and North Western and Midland Railway stations. |

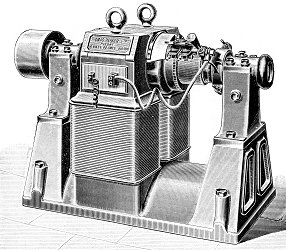

| The Thomas Parker dynamo that was

installed at Cragside in Northumberland by Drake and Gorham,

electrical contractors, based at Victoria Street, London.

This is an early example of

one of the company's products, dating from 1895.

Courtesy of Robin Wright,

Engineering Warden, Cragside. |

|

|

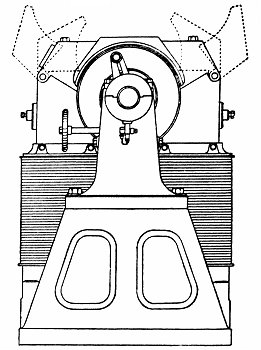

Another view of the dynamo at

Cragside. Courtesy of Robin

Wright, Engineering Warden, Cragside. |

|

Railway connections were sanctioned by

Wolverhampton Corporation, for a level crossing from the site of the

works towards the Midland and Great Western Railway stations. The

offices and works were within three minutes walk of the three

railway stations.

Thomas entered into a contract with the company,

dated 11th May, 1894, to act as managing director for a

period of ten years. A capital of £75,000, in 7,500 shares of £10

each, was required, of which 4,500 were quickly taken up, and the

balance of 3,000 shares were offered for subscription. The Mayor of

Wolverhampton, Alderman C.T. Mander, J.P., was chairman of the board

of directors. The temporary registered offices of the company were

at Albany Chambers, Lichfield Street, Wolverhampton.

|

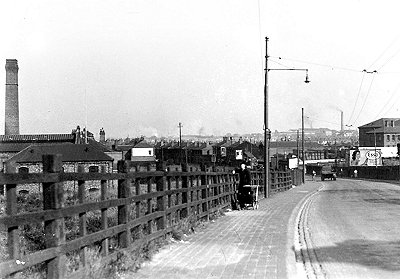

The company's factory can be seen

on the extreme left.

At the time the photograph was

taken the works were occupied by Joshua Bigwood & Sons

Limited.

Courtesy of Bill Howe. |

|

|

At the beginning of June tenders for the erection

of the works were allotted and sent out, and building work commenced

on 26th June. The buildings were erected by Mr. H. Lovatt, builder of Wolverhampton.

The first statutory meeting of the shareholders

was held on 17th August, 1894. The minutes book, records, that in

answer to a shareholder's question, Mr. Charles Mander, the

Chairman, said The purchase of the Eickemeyer Dynamo Winding

Patents had been completed, and the legal proceedings commenced by

the Electric Construction Company remained as they were, but this

board was considering the question of granting the E.C.C. the use of

these patents on terms to be agreed. The Chairman also reported

that the erection of the works was rapidly approaching completion

and that there was every prospect of the company at once entering

upon a large and remunerative business.

|

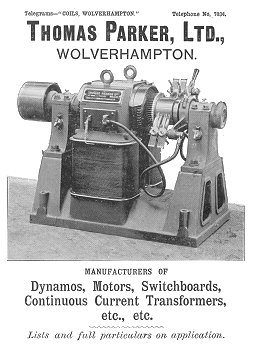

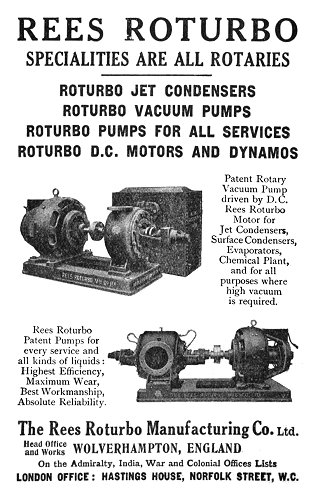

An advert from 1898.

|

|

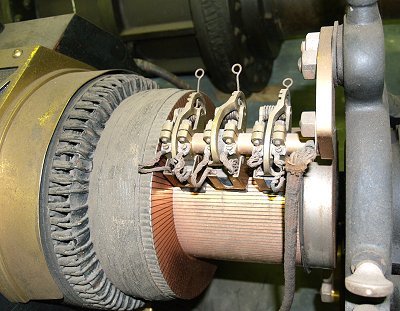

The Eickemeyer Patents mentioned by the Chairman

were extremely important in the manufacture of armatures for dynamos

and motors, and permission to use them was essential to the E.C.C.,

who hotly disputed Thomas Parker, Limited's right to the patents.

An old drum armature dynamo showing the

maze of wires at each end of the armature. |

The old style of drum armature dynamo had a

great bundle of wires crossing and re-crossing at both ends,

forming a complex maze, which was difficult and time consuming

to wire-up, and difficult to sort out under fault conditions.

This problem was resolved by Eickemeyer in about 1890. He developed an assembly

technique in which the windings were initially made on a former

and then neatly slotted into the armature. He patented the

process, but it was not generally adopted until about 1898. |

On 28th May, the Express

& Star reported that the Eickemeyer patents must be considered a

valuable property in the electrical world, judging by the struggle

to possess them. The proprietors, through their agents and power of

attorney, say that they are disposing them to Thomas Parker Limited,

and nobody else. The Electric Construction Company Limited, are

taking the means to establish their right to a license to use the

patents.

The E.C.C. published a letter regarding the

patents, in the Midland Evening News, on 22nd May , 1894

(some of the wording is a little strange):

|

The attention of my Board has been

directed to the prospectus of this company, which was

advertised on Saturday. One of the chief inducements which

is held out to subscribers is the acquisition of the

Eickemeyer Patents for winding dynamos; but the prospectus

makes no mention of the fact that these patents are in Mr.

Parker’s hands – subject to a general license in favour of

my company for the whole of the United Kingdom. The

statement in the prospectus that “Mr. Parker and his staff

designed and superintended” certain works is misleading, as

only a portion of our staff employed upon the works in

question has joined Mr. Parker since the Board of my company

dispensed with his services. We have reason to believe that

we shall have to claim certain of the other patents which it

is represented on the prospectus will be transferred to the

proposed company, as having been taken out by our employees.

The whole matter has been placed in the hands of our

solicitors, Messrs. Linklater and Co.

Your obedient servant,

By order of the Board

James Grey

The Electric Construction Company Limited, Queen Street

Chambers, Queen Street, London, E.C.

21st May 1894 |

|

The Eickemeyer Company published their reply in

the Express & Star on Friday, May 25th, 1894:

|

To publisher Express & Star,

Wolverhampton.

Sir, - Re Thomas Parker Limited. Please

insert in tomorrow’s issue a copy of the wire just received

by me,

Robert Willcock, Solicitor, 49 Queen

Street, Wolverhampton.

Thomas Parker Limited

The Electric Construction Company Limited

hold no general or any license whatever to USE the

Eickemeyer patents, or any of them. The only persons

entitled to use such patents, so far as winding is

concerned, are the Eickemeyer Company, who have agreed to

assign same to Thomas Parker.

A. Macdonald Blair, 5 St. James’s Square,

Manchester.

Solicitor for

the Eickemeyer Company and Mr. Giles Atherton, their

Attorney. |

|

The E.C.C. responded with a letter in

the Midland Evening News:

|

To the Editor of the Midland Evening News

Sir, - Re Thomas Parker, Limited. My

Boards have taken note of the wire from Mr. A. McDonald

Blair and Mr. Giles Atherton, which appears in your paper on

the subject of the Eickemeyer patents. I am instructed by my

Boards to say that they have directed Messrs. Linklater &

Co. to issue a writ against Mr. Thomas Parker and Thomas

Parker, Limited, to establish our rights. – By order of the

Board, I am, Sir, your obedient servant,

The Electric Construction Company, Limited.

James Gray, Secretary

|

|

The following day a further letter appeared

in the Express & Star:

|

Re Thomas Parker, Limited.

My Board have taken note of the wire from

Mr. A. McDonald Blair and Mr. Giles Atherton, which appears

in your paper on the subject of the Eickemeyer patents.

I am instructed by my Board to say that

they have directed Messrs. Linklater & Co. to issue a writ

against Mr. Thomas Parker and Thomas Parker, Limited, to

establish our rights.

By order of the Board.

I am Sir, Your obedient servant, James Gray, Secretary. The

Electric Construction Company Limited. Queen Street

Chambers, Queen Street, London, E.C. |

|

The dispute was eventually resolved and the

E.C.C. paid £2,000 to Thomas Parker, Limited, for the right to use

the patents.

|

|

Registration of the New

Company

The company was registered with a capital of

£75,000 divided into 7,500 shares of £10 each, on Tuesday, 13th

November, 1894.

Its object was to carry on business as electrical

and mechanical engineers, and electricians, and as manufacturers of

electrical appliances and apparatus of all descriptions.

There were

to be not less than three, nor more than seven directors;

qualification, £1,000.

|

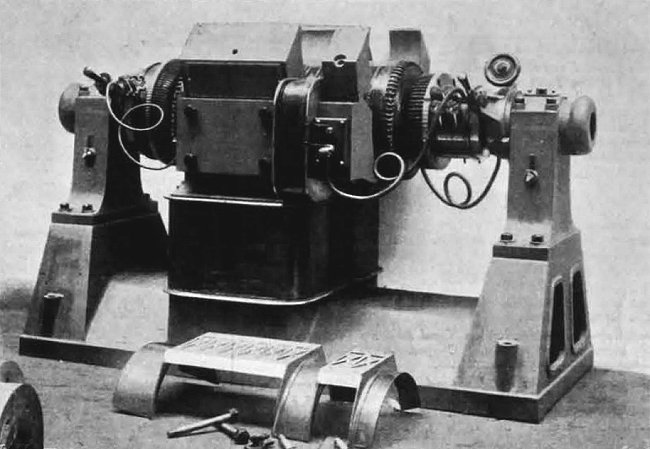

One of the company's dynamos.

|

| The Express & Star reported on the progress of

the new works, on 13th November. The article stated that the

erection of the new premises belonging to this company was

nearing completion and that the works will soon be in full

operation. Building work has gone on without interruption,

though the work of laying the floors of concrete and wood blocks

has taken some considerable time. The huge machinery was fixed

on the bed plates, and Mr. Parker, the managing director, was

well pleased with the progress generally of the works. Already a

sufficient number of orders had been secured to start the works

and employ a considerable number of hands. A range of offices

was also to be built to replace the temporary office in

Lichfield Street. |

The side view of a Thomas Parker dynamo

showing the folding pole pieces, which allowed the armature to

be lifted out for maintenance. |

The new works

The new works were

officially opened on Monday, 10th December, 1894. There were

erecting, fitting, pattern, and machine shops, and a foundry for

brass and ironwork.

The building at the left of the entrance was set

apart for the erecting, fitting and machine departments. It had four

150ft. long bays, two with a span of 32ft., and two with a span of

42ft. 6 inches, all complete with travelling cranes. The iron

columns which carried the roof also supported the rails for the

travelling cranes.

In the first bay were the main engines for

driving the whole of the works, and for testing the machinery before

it was sent out. The steam for the engines was supplied by two large

Babcock & Wilcox boilers.

In the second bay were the larger tools,

general erecting and testing machinery. The third bay was the

machine shop, with lathes, milling machines, drilling machines, and

general tools used for carrying out work of any size. The fourth bay

was for light brass work, winding armatures, and other portions of

machinery.

|

|

The building had a concrete floor with wood blocks and a railway track

connected with the Midland Railway Company’s sidings. The machinery

was of an exceptionally fine description, with the latest

improvements and every arrangement to secure accuracy and rapidity

in working. The building was heated with steam from the main boilers

and radiators. The travelling cranes and machinery were driven by

motors supplied with electric current from one main dynamo, which

also supplied the electric light for the building. |

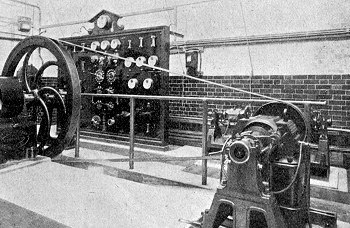

The 12 Kilowatt Thomas Parker, Limited dynamo,

that was installed at the National Physical Laboratory. |

|

The foundry building was 120ft. by 40ft., and was

complete with a ten ton, electrically fitted, travelling crane.

There was a large cupola placed in a convenient position, with a

covered stage, and a hoist for taking up pig iron, coke etc.

The pattern shop was 80ft. by 40ft. with a

concrete floor, over which wood blocks were laid. It was heated by

steam radiators. Mr. A.P. Brevitt, of Wolverhampton, was the

architect, and Mr. Henry Lovatt, the builder. Messrs. Heenan and

Froude, of Manchester, have supplied the iron work, and Messrs.

McTear & Co. of Belfast, the roofs.

Official Opening

The ceremony of setting the machinery in motion

was performed by the Mayoress, Mrs. C. T. Mander, in the presence of

a large and representative gathering. Amongst those present were the

Mayor, Alderman C.T. Mander, Mr. T. Parker, Mr. T. Graham, Mr. W.

Thomas, directors, Mr. T. Bantock; Aldermen Saunders, F. D. Gibbons,

S. T. Mander, J. Annan; Councillors Craddock, Lewis, Williams, Jenks,

McBean; Messrs. J. Evans, G. Armstrong, R. Shaw, T. Holcroft, H.

Holcroft, B. Bantock, S. Watkins, T. Wilson, L.T. Smith, W. Lees,

J.T. Homer, W. Bradford, A. P. Brevitt (architect), H. Lovatt

(builder), H. G. Powell, M. Wilkie (secretary), W. W. Walker,

J. Brotherton, J. Mould, H. Lea (Messrs. Lea and Thornbury). J. E.

Underhill, J. W. Sankey, J. H. Woodward,

E. S. G. Rees, C. H. Iles, W.

Armistead (the last 4 named gentlemen are members of staff); Dr.

Totherick, the Revs. Dr. C. A. Berry, C. Pockney, T. G. Haughton, Mrs.

Graham, Mrs. Burnup, and Mrs. Parker.

After an inspection of the machinery by most

of those present, Mr. Parker called upon the Mayoress to set the

machinery in motion, which she did amid loud cheering from

spectators and work people.

|

|

Thomas Parker

|

Mr. Parker presented the Mayoress with a

deerskin blotter, inscribed by the four directors; C. T. Mander,

T. Graham, T. Parker, and W. Thomas. The company then adjourned

to the pattern shop. Speeches were given by Mr. T. Bantock, Mr.

C. T. Mander, Mr. T. Graham and Mr. Brevitt.

Mr. Parker said that he was glad to see Mr.

Bantock present and to know that the Mayor was by his side, upon

whom he looked as a tower of strength in connection with that

undertaking.

The site upon which those buildings had been

erected was a field in July last. The idea of starting those

works was fixed upon by the gentlemen who formed his staff, who

about nine years ago came to Wolverhampton as pupils to him at

the works of Elwell-Parker, Limited, and had grown with and

taken a large part in carrying out the works that made the name

of Elwell-Parker known throughout the world. |

| They had been his staff through the term of his

agreement and of service with the Electric Construction

Company, Limited, as their engineer and works manager.

They made the term of further union to be the initiation

of a new concern. They now gave Thomas Parker, Limited,

their united services and experience, and had each

subscribed largely to its capital. He wished them to

receive from the friends of the firm credit for this.

|

| The Thomas Parker

rotary converter at the Museum Collections

Centre, Duddeston, Birmingham. |

|

|

Another view of the rotary

converter. |

By inviting the Mayoress and their friends there

that day, to see their progress, they wished them to see

they were in real earnest. Of their buildings they

would be able to judge, and they had plenty of ground

for development. They were now able to take in hand the

largest work which was likely to be required.

They intended to do the higher class of work at the

lowest cost. They had plenty of orders in hand. |

| He had the greatest faith in the greatness of the

future of electrical engineering, where the object was

sound and legitimate business. This, he was sure, was

the one object of the directors. They had been working

upon designs and patterns the last five months, and

hoped to be able to offer the public a better class than

they had bought hitherto, and improved designs. They were

far more advanced than those present were able to judge,

and if they visited the works a month or two hence, they

would see a great change. |

A close-up view of one of the commutators on the above rotary

converter. |

|

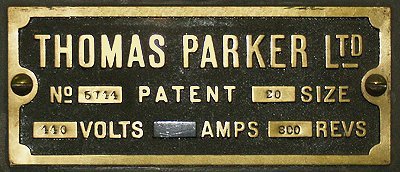

The manufacturer's plate on

the rotary converter. |

|

They could see they were making great

strides. They had obtained some important patent rights, and he

thought the works would be a standing monument to their

chairman, the Mayor, during his Mayoralty.

Electric Lighting at Wightwick Manor

Thomas was friendly with the Mander family and on a visit to

Wightwick Manor in 1895, he suggested that electric lighting

should be installed in the house. The family agreed and the work

was carried out by Thomas Parker, Limited, in 1895 / 96. The

installation consisted of a steam driven generator, which

supplied 100 volts D.C. for the lamps. A set of lead-acid

batteries was added at a later date.

Read a

contemporary account of Thomas

Parker, Limited |

|

| |

|

|

|

The following article appeared in the January 11th, 1895 edition

of 'The Engineer':

Continuous

Current Hinged Pole Piece Dynamo.

Messrs. Thomas Parker, Limited, Wolverhampton, Engineers.

In the dynamo illustrated above one of the

special features is the cutting through of the pole pieces, and

hinging these so that they can be turned back to allow of the

examination, or taking out of the armature by a direct vertical

lift, and without upsetting the bearings. The hinge is placed at

the angle of the pole piece, so that when turned back halfway,

the magnet ferrule can be lifted off, after the armature has

been removed, without uncoupling the hinged piece. This

arrangement allows of machines being fixed in confined spaces,

which would not be suitable with the ordinary type of machine,

where the armature has to be threaded in to or out of the

magnets. There is also considerably less risk of damage in

withdrawing or replacing the armature.

There is an oil well in the pedestal

underneath the bottom of the bearing, the bottom bearing being

continuous; a ring runs in this well and over the top of the

shaft, giving continuous lubrication. Where machines are coupled

direct to high speed engines, the armatures are at the bottom,

the pole pieces in this case also being cut through, so that the

upper portion of the magnets can be lifted away, and the

armature then lifted out.

With these new arrangements, the putting in

or taking out of an armature is much more simple, and occupies

far less time than is required by the old method. All armatures

are coil wound under the Eickemeyer patents. |

|

|

Second Annual

Meeting

The annual meeting of the directors and

shareholders for 1895 was held at the works on Wednesday, 31st

July, 1895. The Mayor, Mr. C. T. Mander, presided and amongst those present

were Mr. T. Parker, Managing Director, W. Thomas, Richard

Armistead, Giles Atherton, representing Rudolf Eickemeyer,

Armistead jnr., Woodward, Iles, J. E. Underhill, Rees, M. Wilkie,

and H. P. Smith. |

This excellent example of a Thomas Parker

dynamo can be seen at the Black Country Living Museum, Dudley. |

The Chairman said that the company was only formed

in April 1894 and they had only commenced work at the end of

January, and not much had much happened before the middle of

March. The balance sheet practically referred to only five or

six week’s trade and their invoices for the month of July were

50 percent more in value than the whole of the trading up to

April last.

In June 1894 they started with a workforce of just 3 men and

now they were employing 268.

They should be able to wipe off their debt at the bank and spend

more money on buildings, machinery and tools. |

| At present they had most admirable machinery,

capable of turning out the largest dynamos etc., but they wanted

offices, another smith’s shop, another bay to their main works,

and they would then be able to turn out double the present

amount of work. They had orders on the books amounting to over

£24,000, so that they would be turning out a lot of work and had

every prospect of doing a sound and prosperous business. |

| Mr. Parker, in seconding, expressed the pleasure

it gave him to see the shareholders inspecting the works and

noting how they were going on. They did not start a business;

they had had to start to build up a business, and that, they had

been successful in achieving. Their turnover at the present time

would make them a profit on the capital, and if they got further

money, which they hoped to do, they would with a very slight

outlay in buildings be able to double the output of the place,

and so double, in his opinion, the value of the share capital.

They could readily have any amount of orders; their difficulty

was in being able to execute them. |

A close up view of the commutator and

armature on the Thomas Parker dynamo at the Black Country Living

Museum, Dudley. It shows the high standard of workmanship and

quality of construction, that is typical of a Thomas Parker

product. |

|

The works might look a trifle straggling,

but they had been so laid out as to bring in a siding from

either the Great Western or the Midland. The balance sheet was a

small one, but it showed a good beginning. Today they were

making a dividend, and he thought the shareholders would agree

with him that they had established a good business, they were an

accepted fact in the electrical world, their goods were selling,

and that altogether they had done even better than anticipated

under the circumstances. A year hence, and he expected they

would go away from the annual meeting thoroughly well satisfied.

The Order Book

Thomas Parker, Limited, like most other

similar concerns at the time relied on orders from municipal

authorities. The £24,000 mentioned in the 1895 Chairman's report

included an order from Wolverhampton Council for dynamos etc.

for their new power station and electrical distribution system.

| Read about

Wolverhampton's first power station. |

|

A Disappointing

Future

The annual meetings always took place at

the registered offices in Wednesfield Road. Although the

directors looked forward to a successful future, it was not to

be, as can be seen from the dividend records:

| 1895 |

No dividend mentioned |

| 1896 |

5% dividend |

| 1897 |

7% dividend |

| 1898 |

8% dividend |

| 1899 |

10% dividend |

| 1900 |

10% dividend |

| 1901 |

10% dividend. The directors say that they

are trying to get a quotation from the London Stock

Exchange. |

| 1902 |

10% dividend |

| 1903 |

6% dividend. |

| 1904 |

No dividend mentioned |

| 1905 |

No dividend mentioned |

| 1906 |

No dividend mentioned |

| 1907 |

No dividend mentioned |

| 1908 |

No dividend mentioned |

| 1909 |

Company wound-up |

At the 7th annual meeting, on Monday, 8th

July, 1901, the Chairman said that there was no need for much

comment on his part and they proposed to pay a dividend of 10

percent, to which he did not think the shareholders would

object. Mr. Elton, a shareholder, observed that the company had

made £3,000 less profit than last year, and £3,000 less than the

year before, making it £6,000 in two years. In the same period,

some thousands more debentures had been borrowed. If that was a

small company, and they went on at the same rate, they would

soon be in the hands of the debenture owners alone.

Thomas Parker was a benevolent employer as

can be seen from the following article that appeared in 'The

Engineer' on the 4th September, 1896.

| At the works of Thomas Parker, Limited,

electrical engineers, of Wolverhampton a

re-arrangement of hours has just come into

operation. Instead of starting each morning at 8

a.m. and leaving at 6 p.m., with an interval for

dinner, the works will in future be open from 6

a.m. till 5 p.m., and an hour and a half will be

allowed for meals, whilst the closing hour on

Saturdays will be noon instead of 1 p.m. |

|

Unfortunately the reduced hours did not

have the desired result, as can be seen from a letter that

Thomas sent to Mr. Hulse, of Messrs. Hulse and Sons, Manchester.

|

Thomas explained that the

reason which influenced the firm in trying a

forty nine hours week when they started the

works, towards the end of 1894, was a wish to

fall-in with the general desire which seemed to

exist that shorter hours should be conceded to

mechanics if possible, and the circumstance that

the Government had conceded the eight hours in

certain of their engineering departments was

also not without its efforts. As time went on,

however, the firm was disappointed with the

results. The men showed no desire to assist the

firm in anyway out of regard for the great

concession which bad been made them, and there

was just as much time wasted as under a fifty

three or fifty four hours week.

Further, the men, especially as their number

grew with the extension of the firm's business,

showed a distinct dislike to continue working to

six o'clock, and would have preferred to stop an

hour earlier, as is the rule under the present

changed condition of things. At the present time

the men begin work at six o'clock a.m. and leave

at five in the evening, taking out half an hour

for breakfast and an hour for dinner for five

days in the week, and on Saturday stop at noon,

thus making a fifty three hours week. |

|

The short week was abandoned after the

failed experiment, and the union instantly made a demand for

increased wages, which the company refused to pay. The outcome

of the dispute is not known, but it resulted in Thomas Parker

having a great dislike of the extremes of trades unionism. At

the time of the dispute the number of employees had increased to

over 400.

In 1897 / 98 the company made the

generators for the Folkstone Electricity works, which opened in

1898. They produced 3,000 volts D.C., which was stepped-down at

sub-stations, using rotary converters. The system operated until

1923.

|

A

visit by members of the Institution of

Mechanical Engineers in 1897 to Thomas

Parker Limited

These works are situated on the

Wednesfield Road, within five hundred

yards of the railway stations. They were

built in the latter part of 1894, and

some extensions have recently been made.

They comprise in independent buildings;

iron and brass foundries; pattern

makers' and smiths' shops; and the main

shop, 250 feet long by 150 feet wide, in

which are the machine tool, erecting,

winding, and testing departments; and

stores. The offices adjoin the main

shop. The whole of the works including

the power cranes are driven

electrically; and the lighting by arc

and incandescent lamps is also supplied

from the same generating plant. Most of

the machine tools are driven from line

shafting; but some lately added, have

their own motor. The works are employed

solely in the manufacture of dynamos,

motors, and switch gear, etc. and

furnish complete equipment for electric

lighting, electric railways, tramways,

and power transmission. The number of

workpeople at present employed is about

400. |

|

On 2nd August, 1899, the Express

& Star reported that Mr. T. Parker, the founder of the business,

had relinquished the position of managing director, but retained

his seat on the Board of Directors. In addition the company had

retained his special services in the way of advice, by

appointing him consulting electrical engineer. Also in 1899

Thomas developed a method of manufacturing Chlorate of Soda

using a version of his "Wednesfield Furnace".

|

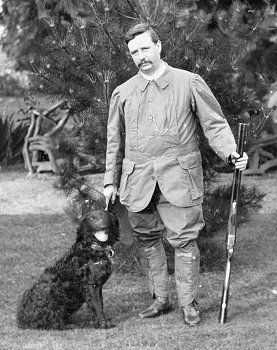

Thomas Parker and his favourite dog,

Bruce. Courtesy of Gail Tudor. |

Large scale electricity distribution became

a reality in South Staffordshire with the formation of the

Midland Electric Corporation in June 1897. Thomas Parker was the

creative genius behind the venture and the Corporation’s

chairman was Wolverhampton engineer, J. F. Allbright. In 1898 it

was granted Provisional Orders to supply a number of the local

towns, including Bilston, Brierley Hill, Cradley Heath,

Darlaston, Kingswinford, Old Hill, Tipton, Wednesbury and

Willenhall.

The M.E.C. was the first company to get Statutory

powers to distribute electricity over such a large and varied

area. A power station was built on 14 acres of land at Ocker

Hill to supply the power. It was near to a coal mine and by the

side of the Birmingham Canal Navigation. Sub stations were built

at Bilston, Brierley Hill, Darlaston, Old Hill, Tipton and

Wednesbury. Some local councils including Tipton and Wednesbury

decided to distribute the power themselves, whereas others left

it to the Corporation.

|

| An article from 'The Engineer', 17th

February, 1899:

Enclosed Type Motors

The enclosed type of motor is

gaining ground, especially for use in confined

situations, or in places such as

engineers' and other shops, where bits of iron,

steel, or like substances, might fall on the

armature, and for

crane work. The original difficulty with enclosed

motors was undue heating, but this, with improved

designs, has been entirely overcome.

Our illustrations show two motors made by Messrs.

Thomas Parker, Limited, of Wolverhampton. Figs. 1

and 2 show the motor generally used by this firm for

driving cranes or for machinery where floor space is

a consideration, the motor in this case being either

hung to the machine it is driving or placed upon a

bracket on the wall, if shafting is being driven.

It will be seen that the motor used is of the

horizontal two pole type, arranged so as to

economise space to the utmost. The pole pieces are

of a somewhat peculiar shape, and are bolted to the

side of the motor box. In the interior view, Fig.

2., a liberty has been taken with the drawing, the

brushes being shown as they are when at work,

although,

as a fact, they are fixed to the end cover, and

would have been taken away when this was removed.

This end cover is provided with a lid which can be

lifted for the inspection of the commutator and

brushes. The brushes are of the carbon block type,

the carbon being kept against the commutator by

means of springs and levers as shown. The weight of

the motor complete in its case is 11½

cwt., and its normal consumption is about 220 volts

and 30 amperes at 500 revolutions per minute.

Fig. 3 shows a torque curve of this motor. It

will be seen that at its normal rated point, 30

amperes, the torque is equal to 83lb. at a radius of

1ft. At 60 amperes the torque is no less than 197

lb. at 1ft. The armature,

as is the case with all Messrs. Parker's machines,

is wound with the patent Eickemeyer coils. For

ordinary shop work, such as the driving of shafting

by belts, or for coupling direct, another class of

enclosed motor is used. Figs. 4 and 5 show Messrs.

Parker's iron-clad motor.

|

In this machine no moving part, with the

exception of the pulley, is uncovered. This

is a useful point when it is desired to have

the motor running in such a position

that small tools or bits of metal might fly

into it.

The motor is provided with a hinged top,

part of this top forming one of the pole

pieces. When this is laid open it is easy to

remove the armature, and the bearings can be

got at for oiling by means of the smaller

covers at either end. The coolness with

which this motor runs is remarkable.

The temperature inside the box is but

little in excess of what it would have been

had the machine been running without its

covering. No doubt this is due to the design

and winding of the motor, and the ribs on

the outside assist in the dissipation of the

heat. This type of machine is used by

Messrs. Parker in their own shops for

driving shafting, machine tools, etc., and

they appear to give great satisfaction. The

brushes are of the same type as in the crane

motors, and seem to run with practically no

attention. |

|

|

|

An article from 'The Engineer',

17th March, 1899:

The Electric "Buff"

The Electric "Buff" or bob motor, shown in the

accompanying illustration, has been designed and

patented by

Messrs. Thomas Parker, Limited, of Wolverhampton,

for polishing silver plate for hotels and ships.

Larger sizes

made in the same way are intended for buffing

brasswork during construction. The small two pole

motor, and the

starting and regulating switch, are fitted inside

the pillar, as also is the regulating resistance, so

that the whole thing is

self contained, and only requires the two main wires

bringing to it. The bearings and commutator are dust

proof, so that none of the material used in

polishing can get into, and damage them. |

|

| An article from 'The Engineer', 5th May,

1899:

A New Variable Ratio Transformer

Fig.1. Variable ratio transformer.

Our illustrations show a new

form of variable ratio direct current transformer,

three of which have recently been made

by Thomas Parker, Limited, of Wolverhampton, for the

lighting of Bromley and Chiselhurst. These are the

first of

this type which have been built, and we understand

that the tests have come out very well. The

transformer in Fig. l is shown with its hinged pole

pieces opened so that the armature is easily lifted,

which is extremely useful for such things as

transformers, which frequently have to be placed in

confined situations with none too much head room.

The novelty about this particular type is the

arrangement of the auxiliary or regulating pole

piece, which, instead of springing from the

bed-plate, as has hitherto been customary, is made

by an extension of the main pole piece.

The main field, or a portion of

it, is therefore diverted into the auxiliary pole

pieces, thus minimising the reaction of these

independent pole pieces. The armature is wound as

shown in Fig. 2, and has two cores. In the ordinary

transformer, with two sets of coils wound on one

core, any alteration to the field acts on both

windings equally, so that if it is required to

compensate for a drop of electromotive force in long

lengths of feeders, it is necessary to insert a

resistance in series with either the high tension or

the low-tension winding. In the transformer in

question the larger core has one winding complete,

the evolutes or cross connections coming between the

two cores. This is the high-tension winding. The

low-tension winding comes outside this, and extends,

in addition, over the smaller core. By thus

extending one set of the armature coils over the

auxiliary core it is possible to add to or diminish

the electromotive force in this particular set of

coils by means of the auxiliary field, without

affecting the other winding, and thus get the

variable ratio.

Naturally it is not always that

the conditions warrant the use of such a machine.

These particular transformers have been built for

Messrs. Edmundson and Co., and the conditions which

have had to be conformed to are as follows:- One of

the machines will either be supplied with

high-tension current at from 2000 to 2100 volts, in

which case it would have to give 420 to 450 volts

and 105 amperes, or with current at 420 to 450

volts, in which case it would give 2000 to 2100

volts and 22 amperes. Thus, when 2100 volts are

applied to the high-tension side, 450 volts are

available at the secondary, and vice versa. This

particular machine, therefore, is either for a

"step-up" or "step-down" transformer.

The other two machines are

intended simply to be supplied with high-tension

current, and are required to give 150 amperes from

420 to 450 volts. The primary electromotive force is

to vary from 1900 to 2000 volts, but the machines

are required to give their full output at 450 volts

with only 1900 volts at the primary when running at

600 revolutions per minute. |

|

|

In some parts of the area, problems arose

due to subsidence from mining. To prevent the cables being

broken, "loop pits" were built every 200 yards, each containing

6 yards of slack cable and the cable in between the pits was

enclosed in pipework.

Thomas left Thomas Parker, Limited, in

1904, at the end of his ten year contract, and moved to London

to work for the Metropolitan Railway.

He was a keen advocate of smoke

abatement in industrial areas, and in the same year he

invented 'Coalite', a smokeless fuel obtained by the

low-temperature carbonisation of coal. The retorts for the

production of 'Coalite' were designed by Thomas and produced

at a company that he established near Wolverhampton.

|

| The Thomas Parker

Alternator at the Museum Collections Centre,

Duddeston, Birmingham. |

|

| A close-up view of

the above alternator showing the revolving

field coils and the slip rings. |

|

Things continued to get worse for the company as can

be seen in the Chairman's report of 24th July 19057.

The accounts showed an adverse balance caused by lack of

orders. The report concluded that this state of

affairs was general throughout the electrical trade in

England and was brought about by the general bad trade

of the country, combined with the large amount of

capital which had been sunk into the industry during the

last few years, and large new works which had been

built, leading to new extensions in the old works, to

meet the competition.

In 1896 the total capital invested in electrical

works in England was about £2,000,000, whereas at the

present time it was nearly £12,000,000, and it had

doubled even since 1900.

During the previous year they had reduced the

workforce and had gone on short time; however during the

previous two months they had returned to full time. |

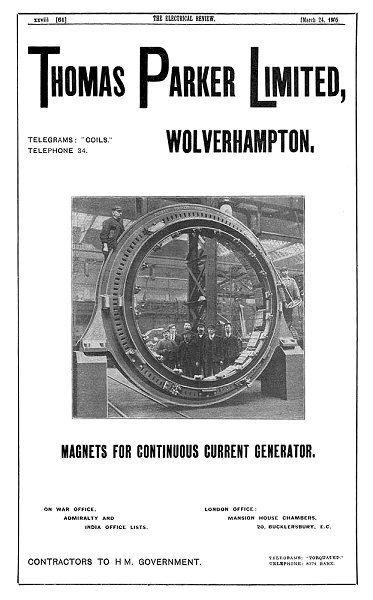

| An advert from the 'Electrical

Review', March 1905. |

|

|

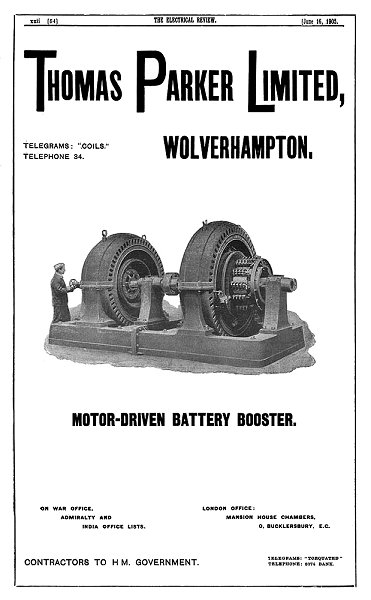

An advert from the 'Electrical

Review', June 1905. |

An example of what appears to be one of the

company's later products, a

¾hp. 100volt DC motor. Courtesy of Simon Bosworth. |

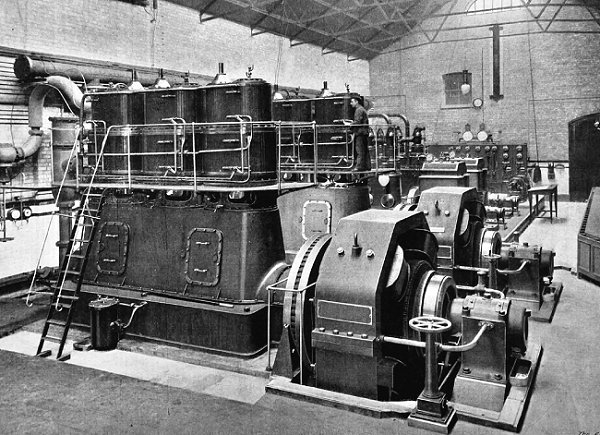

Two high tension, DC dynamos made

by Thomas Parker Limited and installed in Hull

Corporation's electric lighting station in 1900. The

dynamos are directly coupled to compound steam engines

made by W. H. Allen, Son & Company of Bedford. From 'The

Engineer'.

|

|

Wolverhampton Journal, November 1906

A company has just been registered with a

capital of £30,000 in £1 shares, to acquire from E. S. G. Rees

and Thomas Parker, Limited, the benefit of certain existing

inventions relating to centrifugal turbine and similar pumps.

To

adopt an agreement with the said vendors, and to carry on the

business of pump manufacturers, iron workers, founders,

smelters, smiths, engineers, ironmasters, etc. The subscribers

are C. T. Mander, J. E. Underhill, C. H. Iles, W. Armistead, C.

F. Bekenn, P. B. Down, and E. S. G. Rees. |

|

On 14th June, 1908 at

a special meeting, it was decided that the

company would be reconstructed as the Rees

Roturbo Manufacturing Company Limited. |

|

In 1909 the company was wound up after the

directors put it into voluntary liquidation, and transferred all

the assets to the Rees Roturbo Manufacturing Company Limited,

which survived until about 1936.

An advert from 1909.

An advert from 1909.

|

Edmund Scott Gustave Rees

(1861-1930) was born in Ghent, but soon afterwards

the family returned to England and lived in

Manchester. He worked for Thomas Parker Limited, and

invented the 'Roturbo' pump.

Around 1936 Rees Roturbo went out of business,

and the factory was acquired by machinery

manufacturer, Joshua Bigwood & Sons Limited.

The factory continued

in use until Bigwoods closed in the early 1980s, when the the

buildings were demolished to make way for an industrial estate. |

|

|

|

|

|

|

Return to the

General Election |

|

Return to the beginning |

|

Proceed to the

Metropolitan Rlwy |

|

|