|

Some New Features

in Moto-Vehicle Design by Thomas Hugh Parker

From the March 1899 edition

of The Automotor and Horseless Vehicle Journal

An Excerpt from a

paper read before the Liverpool Self-Propelled Traffic

Association

by Mr. Thomas Hugh Parker, on 28th February 1899

Some two and a half years ago, I was spending my time

supervising the erection of electrical and general plant in the

Transvaal goldfields. and the necessity for an efficient motor

controller often presented itself to me. After giving some

considerable time and thought to the problem, I obtained a

satisfactory result, and communicated the idea, by means of

drawings, to my father, Mr. Thomas Parker, at Wolverhampton, for use

in the factory. Soon after this, I heard the pleasing news that a

Bill was to be presented to Parliament to allow of mechanical road

locomotion in England, and was not long in grasping the fact that

the controller would also adapt itself to controlling electrical

road vehicles. Fired with this idea, and wishing to be in the first

swim of a new industry, I started for England, and immediately after

my arrival in Wolverhampton set to work designing an electric car.

I selected a section of road over which it was obvious the car

would have to run, viz., between my father's house at Tettenhall

and the town of Wolverhampton, a distance of 2.5 miles without a

single yard of level ground in its length, the gradients varying

from 1 in 120 to 1 in 15. The first difficulty that presented

itself was to obtain data to work upon. My idea was that 12 cwt.

would be more than a reasonable. weight to allow for an unloaded

electric car for six passengers, and the nearest article I could

find of this weight was my father's brougham. I procured a large

spring balance, and set out at daybreak to map out a curve of

the force required to draw the brougham over the track. We took

the shafts off and attached the horse with the spring balance

inserted between the animal and the vehicle, and not until that

December morning had I fully realised the power of a horse,

although I have had to deal with them nearly all my life. My

dream of 12 cwt. was at an end, for, after carefully working out

all points, the weight totaled up to a minimum of 25 cwt. for a

three hours' run at eight miles per hour.

Having determined the approximate power required, the next most

important problem was the design of the motor and gearing.

|

|

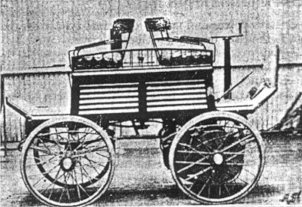

Figure 1. A small electric dog-cart with

double bogie steering. Courtesy of the late Jim Boulton. |

After a great deal of discussion amongst the members

of the family, it was decided that it would be preferable to use two

motors coupled by means of single or double reduction gear, running

in oil, ever required, to the hind wheels, in preference to using a

single motor and differential gear. Double spur gearing did not work

in well with the design, the result of which decision was that

chains had to be used on the second reduction, necessitating the use

of eccentrics for taking up the slack or stretch of the chains, and

two frames to support the motors separately. |

| These first motors were series wound, and designed

to run at 950 revs. per minute, and give a torque effort of 30 lbs.

on the periphery of each armature with a current of 25 amperes.

Forty was chosen as the number of cells, to permit of their being

charged in series on the usual 110 volt circuit. The controlling of

the car came next. To do this without the use of resistance coils

was a difficult matter at first, but eventually turned out to

be one of the simplest. Three speeds forward and one backward were

found to meet all requirements, and these variations were obtained

by dividing the cells into two groups of 20 each. The three forward

movements were obtained as follows: First, by putting batteries in

parallel, motors in series, giving two miles per hour;

second, batteries series, motors

series, four miles per hour; and third, batteries series,

motors parallel, eight miles per hour. The one backward movement,

batteries parallel, motors series, with current in the armatures

reversed, two miles per hour. The whole of the operations were

carried out, by means of the controller mentioned at the beginning

of this paper with less than one single turn of the handle.

The steering gear presented itself next. I had heard a great

deal of what had been done, and had seen a car with Ackermann

gear, but was dissatisfied with it, and also the double cycle

head arrangement. I wanted a steering gear that would admit of a

car running round a small circle with as little resistance as

going straight ahead, and, after a great deal of scheming

devised the idea of moving both front and hind wheels in

opposite directions at the same time and through the same angle,

which, both in model and practical form, worked splendidly. It

enabled the car to be turned in its own length without turning

the wheels under the body, and is naturally doubly as sensitive

as a single bogie or broken axle gear. Another great advantage

is that it admits of all four wheels being driven, and the load

being equally divided on all four wheels. It gives a good

support to the bottom of the vehicle, which in most cases is

made quite flat. Each wheel can be provided with a brake.

A careful examination was made of the various types of

batteries, and it was decided to give the Blot Company the order

for the first set. Having overcome the various points of

difficulty on paper, some premises were rented in which it was

just possible to build and put the car together, and as the

weight of the car grew we had to shore the floor up from

beneath. Six weeks from the day we commenced, the car was ready

to be launched. I say launched, because it had to be lowered 18

inches into the square, down some planks. |

| Somehow the news leaked out that a trial was to take

place, and we found a large crowd of people waiting outside when the

doors were taken down, as there was not sufficient room to open them

when the car was inside. You may judge from this how much chance we

had to make a private trial. However, she was launched and ran a 10

mile trip, with nine people aboard, without a hitch. During the

journey we had occasion to descend some very stiff gradients, and I

found, although I bad some powerful brakes upon the car, it was with

great difficulty I could restrain it from getting the better of me. |

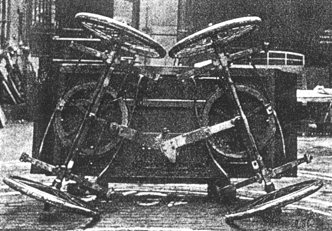

Figure 2. A view of the bottom of the small

double bogie car with axles turned to their extreme angle. Courtesy

of the late Jim Boulton. |

| Although I did not say anything to the passengers,

I decided before the journey was finished not to attempt another

trip with series motors. I had the motors dismounted and had them

shunt wound, and, needless to say, had to stand a good deal of chaff

for such a thing, as running shunt motors in conjunction with

storage batteries on tramways had years ago been given up as

impracticable. The motors were hung on the third day, the

connections were made, and the car ran down into the street, the

result being beyond expectation. Instead of the sudden rush of

current as at starting with the series motors, viz., 50 amperes, the

car moved steadily away with less than 10 amperes, although the

current was about the same when the rate of travelling accelerated.

We then proceeded to take some tests on an incline. To do this we

ran the double journey to Tettenhall and back. The work of

manipulating the car was very much reduced, it only being necessary

to set it to the required speed and look out for obstacles. On

descending the stiffest hill the speed did not increase 5 per cent.,

and it was very gratifying to see the ampere meter reading 20

amperes to the good, charging the batteries instead of wearing the

brake blocks away. In case of need it was found possible to bring

the car to a stand from full speed ahead in 3 feet on a 10 per cent.

gradient, without the use of the brake or reversing the motors. This

original car has been running almost daily for the past 18 months

exactly as it was made, without a single breakdown, and has carried

some of the most eminent men of the century upon it.

I will now proceed to describe a few lantern slides I have had

prepared under difficulties for you, showing the various stages

of progress. |

| The original controller is adapted for use with

shunt motors working on ordinary high tension circuits, to enable

three movements to be made consecutively with one handle, locking

and interlocking each movement. There are two rollers or discs fixed

to the centre spindle, actuating two levers connected to the two

switches, top and bottom. In starting from zero, the one disc, which

is slightly in advance of the other, first puts on the shunt switch

and locks it on, leaving the handle free to turn a full revolution

in the same direction. |

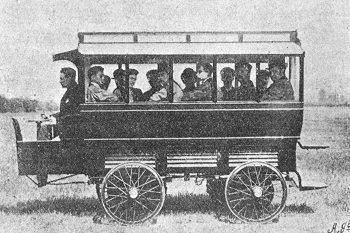

Figure 3. A 14-seater omnibus. Courtesy of

the late Jim Boulton. |

| The next portion of the revolution puts on the main

switch and locks it on, allowing the main current to flow through

the armature with resistance in the circuit. This resistance is

determined by the switch arm carried on the centre spindle below the

discs working on an ordinary divided resistance ring, and, in this

case, admits 24 points of regulation in a single turn of the handle.

When stopping the motor, it follows that the maximum resistance must

be put into the circuit ready for starting. Again, the main current

must be broken before it is possible to break the shunt, thereby

avoiding all danger of burning out the armature, which would be the

case if the shunt were broken first. Further, if the motor has to be

stopped and started often, as in the case of hauling machinery or

hoists, cranes, and the like, the shunts can be left on, as shown,

by which arrangement, no damage is done to the insulation by the

high voltage, due to induction on breaking shunt circuits.

In the controller, as adapted to the electric cars, the spindle

carries five discs connected to levers projecting from discs.

From each of these discs project eight teeth, which connect with

eight bars, which are connected to the batteries and motors. The

whole of the five movements are obtained in about three-quarters

of a revolution of the handle, and each movement is locked and

interlocked in its proper order. Figure 1 is a small electric

dog-cart with double bogie steering, driven by the front wheels,

and double reduction through differential gear. |

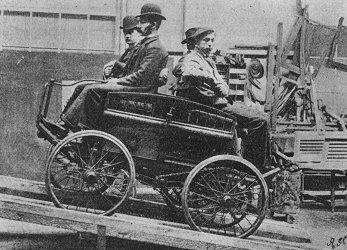

Figure 4. An oil-car climbing a gradient of

1 in 6. Courtesy of the late Jim Boulton. |

Figure 2 shows a view of the bottom of the small

double bogie car with axles turned to their extreme angle. We were

asked by the. London Electric Omnibus Company (Limited) to design

and build them an electric omnibus. They had made three or four

attempts, under Mr. Ward's direction, but had not been rewarded with

much success. I had already had some experience with the car

carrying nine passengers, and I went to London to see Ward's omnibus

run. The car that had run so successfully with us weighed 30 cwt.

unloaded, and carried nine people. |

|

Ward's omnibus weighed, with 24 passengers on, something like 7.5

tons. I saw that their difficulty was in the enormous weight, and

decided to build one not to exceed 3.5 tons, loaded with 14 passengers,

driver, and conductor (Figure 3). This was constructed on the

double-bogie principle having the batteries under the seats. It has two

motors, one on each bogie, driving all four wheels. To each of the four

wheels has been attached a powerful hydraulic brake, worked by means of

a force pump near the driver's seat. The vehicle has three speeds

forward and one backward, it will turn in its own length, has only two

handles to manipulate it, and will run over ordinary roads 25 miles with

one charge at a mean speed of eight miles an hour.

Figure 4 shows an oil-car climbing a gradient of 1 in 6, upon which

it is just as easily manipulated as upon the level, stopping,

starting, backing, and going forward at the will of the driver, and

without the aid of a brake.

|

Return to the

previous page |

|

|