|

Family Background

Geoff was born into a family of

engineers, who originated in the hamlet of Hanbury in

Worcestershire, and moved to Wednesfield in the first

half of the 19th century. His Great Grandfather, Joseph

Stevens and his wife Mary lived in Hickman Street and

Cross Street in Wednesfield and had 7 children, 3 boys

and 4 girls. Their second eldest boy, also called

Joseph, set himself up in business in 1874, at Cross

Street, Wednesfield, as an engineering blacksmith,

trading as J. Stevens & Company.

He was a very skilled man and

turned out a wide range of products from garden tools,

hinges, nuts, bolts, and nails; and would repair

anything from wheelbarrows to bicycles. He also did a

lot of work for the lock trade, and the traditional

blacksmith's work of horse shoeing and bridleware.

The Stevens family tree.

He married Sarah, and they had 9

children, 5 boys and four girls. Their eldest son,

Harry, joined his father in the business. He had a flair

for engineering and was quick to learn. He showed an

early skill at designing and manufacturing special

purpose machines and tools.

In 1894 the business moved to

Tempest Street in Wolverhampton and Harry's younger

brother Joseph began to work there. Joseph Stevens

Senior purchased an American 'Mitchell' single cylinder

4-stroke petrol engine, possibly to provide power for a

blower for the forge hearth, or even just out of

curiosity. It wasn't realised at the time, that the

purchase would greatly change the family's fortunes.

Harry was not impressed with the engine

and decided that he could build something far better. He

bought some rough castings from a firm at Derby, and the

two brothers machined them. The finished engine proved

to be an efficient and reliable design.

Harry and his father were quick to

realise the potential of the engine, which could provide

power for many industrial applications. They further

improved the design and decided to go into production.

Harry also saw the potential of

using an engine for powered road transport. After

reading an article about powered bicycles, he fitted the

'Mitchell' engine into an old B.S.A. bicycle that had

been lying around the works. The motorised bicycle

worked extremely well, apart from the temperamental

engine.

In 1899 Harry and his three eldest

brothers, Joseph, George, and Albert John (known as

Jack) founded the Stevens Motor Manufacturing Company, a

venture that ran alongside the existing family business.

While Harry got the business underway, his three

brothers took outside jobs in order to help to finance

the venture.

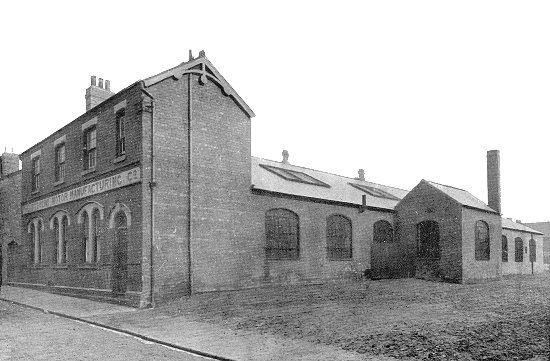

The Stevens Motor Manufacturing

Company in Pelham Street. |