This article is a building history the Dixon's Building

in Cleveland Road and Dixon's site in the triangle bounded by Cleveland

Road, Bilston Street and Hospital Street . It also contains information

about Forder's, the cab makers, and about Reade Brothers, the

manufacturing chemists.

References in square brackets can be found at the end of

the article. Click on "notes" for further information about the topic under

discussion. All "photos" are by the author.

The building and its site

This building, owned by S J Dixon & Son Limited, was erected in 1885 on

Cleveland Road by a local firm of builders, Bradney & Co, as an extension to

Forder & Co's extension to their 1880/2 factory. Bradney's workmen are said

to have used the newly available electric light to extend their working day

in order to complete the work.

The building was reported to have been, at the time of its completion,

the tallest building in Wolverhampton; but whether or not that included

church spires or purely secular buildings was not stated [Oldham].

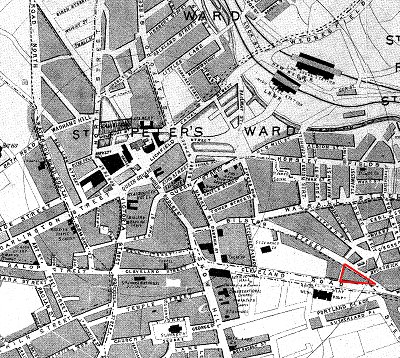

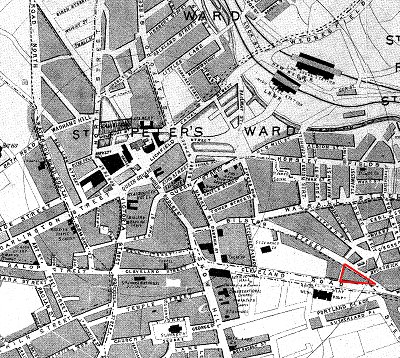

It was set in a landscape of mixed industrial, residential and public

buildings (Maps 1 & 2).

Map 1: part of John Steen's Map of Wolverhampton

1884. The site discussed here is shown outlined in red. |

Along Cleveland Road, on the way into town, stood the

Staffordshire Hospital, the Baker building, the cattle market and St.

George's church. At the back of the Hospital, the beginning of the All

Saint's housing development could be seen and Cleveland House stood in

its' own grounds.

On the road to Bilston was the workhouse and there

were wharves and factories along the canal which, along with the

railway, bisected the road, whilst there was extensive housing arranged

around courts on the far side of Bilston Street. |

| It is known through the Town Commissioners' records that

the cattle market was built on land purchased from the Duke of Cleveland

at his own suggestion. The land on which Cleveland Road stands had of

course once belonged to the Duke's estate but was sold by him to the

Town Commissioners for their 1828/30 town road improvement scheme. The

former Lord Darlington, granted the title of the Duke of Cleveland of

the second creation, as a reward for backing the right side in the

quarrel over the Reform Bill, thus had a road and two streets named

after him (Cleveland Street connected Cleveland Road to town. |

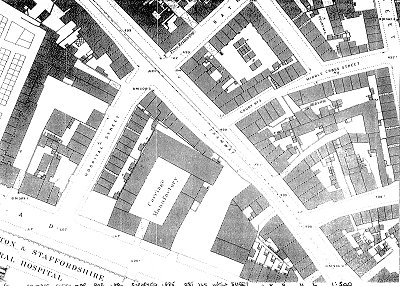

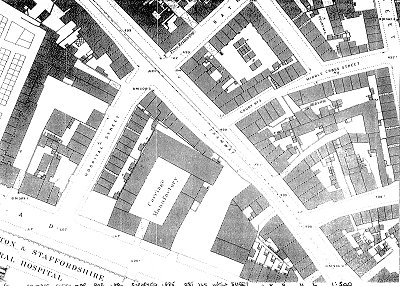

Map 2: part of Ordnance Survey Map, 1886. Note the

open courtyard plan of the "carriage works"; the Royal Hospital in the

bottom left corner; the grid pattern of the cattle market on the left

edge; and the courtyard housing to the right. |

Darlington Street had been constructed on land purchased

from the Earl for the Holyhead Road).

The schedule of deeds to the Cleveland Road houses

[note a], which stood in the part of the space now occupied by Dixon's'

customer car park, shows that in 1848 the land or the houses were partly

owned by the second or third Duke of Cleveland (the first having died in

1842). It has not however been possible to establish yet who owned the

remainder of the triangular site owned by Dixon's today, including the

original owner of the land on which both the first carriage manufactory and

the extension were built.

Forder & Co

The success of Forder & Co's carriage making business

[note b] had put pressure on their premises in town on the corner of

Garrick Street and Bilston Street. In 1873, they had won joint first prize

in a competition run by the Society of Arts to find an improved design for a

London cab or two-wheeled public conveyance [Walrond, but sources vary. For

another account of Forder's contribution to hansom cab design, see

[note c]. The Prince of Wales, one of the patrons of the Society,

granted Forder's his Royal Warrant, Queen Victoria's followed and the

company also built for the Duke of York. They continued to win medals for

their carriage designs.

The Hansom Cab, designed and patented by Joseph Hansom, first appeared

for use as a public conveyance in 1834 and was not a success. By the 1870's

however it had been improved and the finest version is said to have been

made by Forder's [Walrond]. By using better materials and lighter wheels

they had reduced the weight and made it more comfortable, even being the

first to manufacture cabs with doors which could be opened and closed by the

driver.

They traded throughout the UK, especially in London cabs, and abroad.

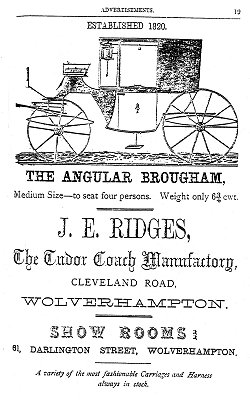

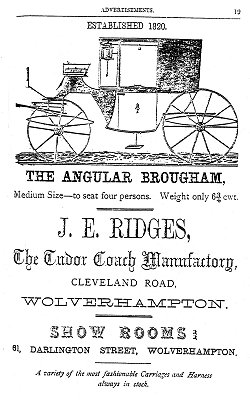

Figure 1: Advertisement from the South

Staffordshire Fine and Industrial Arts Exhibition Catalogue, 1869. |

In 1880, they acquired the Tudor works in Cleveland Road

and had a purpose-built manufactory constructed on the site to provide

much needed increased floor-space. For over forty years the Tudor Works

had seen the production of coach and railway carriages (William Tudor,

later joined by G S Tudor) and coaches and harness, included the

part-exchange of carriages and renting them out (J Ridges, Tudor's

former Manager) (figure 1). Later on, probably in the 1870s, Alfred

Tudor, independently of the family firm, carried on the same line of

work in the collection of buildings known as the Tudor Works. Alfred's

presence there is said to have drawn Forder's' attention to the site

when they needed to move. [R M Forder]

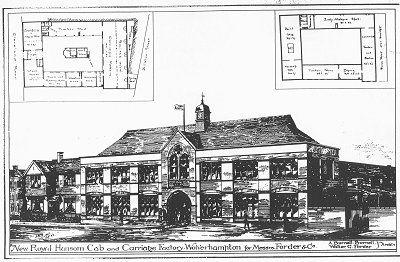

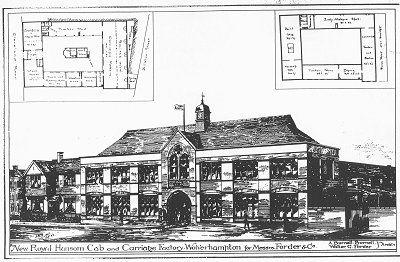

The names of the architects on the 1883 drawing (fig 2) of the new

carriage manufactory are Walter G Forder (of whom nothing is known) and

A Burnell Burnell who, according to his entry in the Directory of

British Architects: 1834-1914, seems to have been only 19 or 20

years old when the site was purchased [note d]. |

| Behind the two-storey brick showrooms and workshop

fronting onto Cleveland Road, a two storey factory, which it is said had

a glass roof although its extent and exact position has not been

established [Oldham], ran back nearly to Bilston Street. Great pains

seem to have been taken siting the different processes that went into

carriage building. According to Richard Forder, Alfred's great grandson,

the successful company's factory was run as a production line. |

Figure 2: Forder's "New Royal Hansom Cab and

Carriage Factory", 1883. From a framed print presented to Dixon's by

Richard Forder. By courtesy of S.J.Dixon & Son Ltd. |

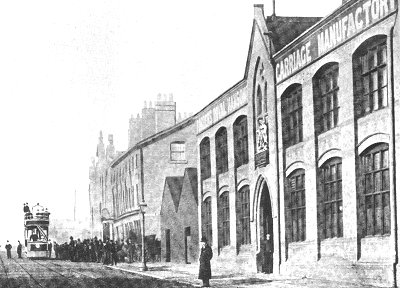

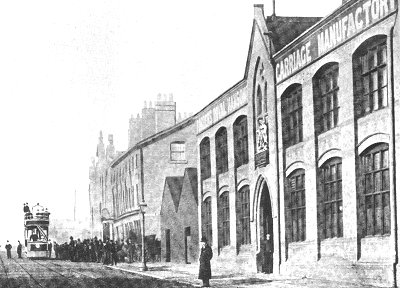

Figure 10: Cleveland Road in 1902, showing

Forder's carriage works on the right. (Detail of photo from S. Dewey and

N. Williams, Wolverhampton on Wheels, crediting Bert Bradford's

collection). |

Only three years after the 1882 opening, plans were

drawn up for further expansion. In the event only the right hand side

was built and forms the present Dixon's building. The old two storey

building was left in place. (photo 1). It is not known why such a

building was proposed in the first place instead of another two storey

factory, nor why is was subsequently decided only to build half of it.

The 'extension', as it is known, has its frontage on Cleveland Road

(photos 1, 2, 3 & 4) and occupies the adjoining site to the east of the

first factor |

| Photo 1: Dixon's Cleveland Road

frontage, with the former MFI premises and the 'site' of Forder's to the

left. |

|

|

Photo 2: the roof line of Dixon's

Cleveland Road frontage. |

| The building is 80 feet high, 117 feet wide and 45 feet

deep (figs 4 & 5). The floor line, window design, and the use of brick

would have integrated the "extension'' into the first factory.

Photo 3: Dixon's Cleveland Road frontage: the

central section. |

|

|

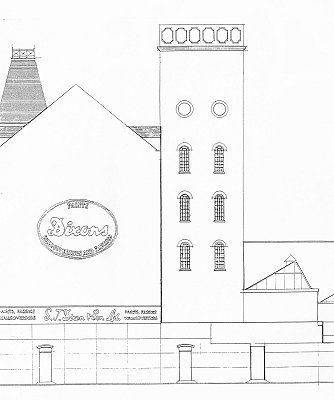

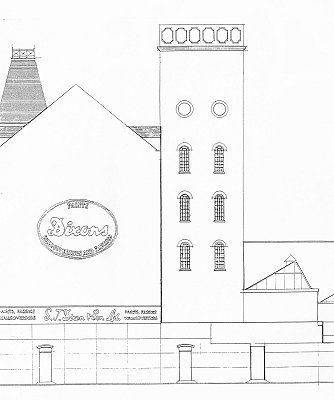

Figure 4: rear elevation, 1999, by

Richard Deer, BA (Hons) (Arch). By courtesy of Reade Associates. |

| The gable and rear walls are of stock brick but it is

the facade that fulfills the Victorian ideal of having a building that

is both useful and beautiful, a celebration of Victorian commerce. The

polychromatic effect is achieved by contrasting cream stone, as well as

horizontal bands of blue bricks, against the high quality orange

terra-cotta bricks laid in Flemish bond. Across the top of the third

storey are decorated panels in terra-cotta that was prized for its

qualities of durability and demonstration of decorative relief work (fig

15 & photo 2). Terra-cotta was used extensively on new commercial

buildings, especially in Manchester and Birmingham' [Gorst, p.35]. This

building predates the terra-cotta decorated Victorian Law Courts in

Birmingham by two years. Eight brick pilasters frame the ground and

first floor windows and have stone pediments and carving. Stone is also

used in bands over some of the window arches and for most of the two

central bay windows (photo 3). |

Figure 5: east elevation, 1999, by Richard Deer,

BA (Hons) (Arch). By courtesy of Reade Associates. |

Photo 4: the east gable wall. The arches are not

visible in this photograph but you can make out an old adjoining gable

end and the shadows of a painted sign. |

There are six floors including a basement;

dormer windows afford enough light to use the loft as a working area. A

steeply pitched roof with decorative ironwork railings rises from the

square tower above the central dormer, perhaps echoing the cupola of the

first building (photo 2). Drainage pipes run inside the front wall so as

not to spoil the facade. The brick arches visible on both gable walls

may suggest the removal and infill of windows, although the same stock

brick has been used and the infill is so skillful as to render it

virtually undetectable (photo 4). It was perhaps decided not to install

the windows and only the arches remain as anomalies.

Although by now internal lifts were being installed elsewhere, e.g.

the Granary in Bristol, 1869 [Gorst, p.39] this building's hydraulic

lift was external and made best use of the designed roof space (Photos

5, 6 & 7).

|

| Photo 5: the interior of the lift

shaft, showing original pulleys. |

|

Photo 6: a bricked in roundel, inside the top of

the lift shaft. |

Built at the back, raw materials and finished goods

could be therefore transported in the lift and added to the processes

undertaken in the original building [Forder]. There is however, evidence

of brick infill to some rear windows that may suggest the installation

of hoists or pulleys was necessary later on (photo 7) [Deer]. Perhaps

the vertical 'extension'' did not meld into the horizontal factory as

well as it had been anticipated. Five metal-framed windows light the

lift floors. |

| Pedestrian access to each floor was inside the building

by utilitarian wooden staircases and these may be the ones still in use

today [Aston].

The rise of the steps is not of a uniform height and the

outside edge of the tread seems at times to be following the grain of

and knots in the wood rather than to have been planed or sawed to a

common width. |

Photo 7: rear elevation of Dixon's, from the

Bilston Road. |

It has not been established when the new

building was first used but Forder's occupation of the "extension'' did not

last long. In 1893 a notice in the London Gazette, reported in the

Wolverhampton Chronicle of the 6th December indicated financial problems.

The 'extension' had already been sold to Thomas Reade on the 1st December

(fig 16)) and then passed by conveyance in 1908 to Reade Brothers. The

basement had been leased to the Staffordshire Brewery in 1890 on a five year

lease

[note e].

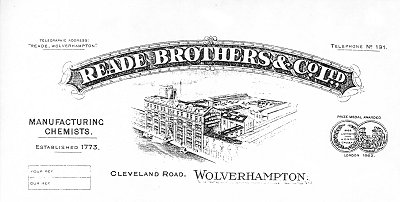

Reade Brothers

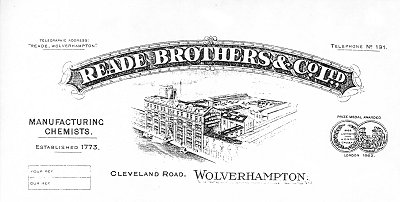

Figure 4: an old letterhead of Reade Brothers,

showing the building. By courtesy of Alan Reade. |

Reade Brothers, a local firm of Manufacturing Chemists,

making patent medicines both for people and animals, as well as paints

and varnishes, (figs 4, 5 & map 3 ) occupied the building until 1959

when it was put up for sale. |

| The introduction of the National Health Service in 1948

with free doctors' examinations and prescriptions had dramatically

affected the patent medicine industry (fig 20) [Reade]. Reade Brothers

moved to nearby premises to carry on diversified manufacturing until

more recent times. When their last chemist retired, the premises were

cleared for rental and the company's hand written recipe books for the

patent medicines, as well as some of the containers of the products,

were rescued for private safe keeping. Others were donated to

Shugborough Hall, the Black Country Museum and Blist's Hill in

Ironbridge; but the majority were destroyed [Reade]. Carriage

manufacture under Forder's name carried on in the old building into the

twentieth century. Thereafter the building had a chequered history.

According to one source [CA] Attwoods bought the building but never

actually used it as their car showroom although a lift was installed to

take cars from the ground floor to the first floor. |

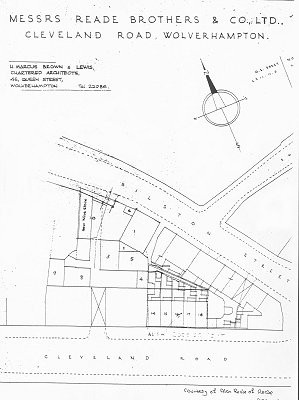

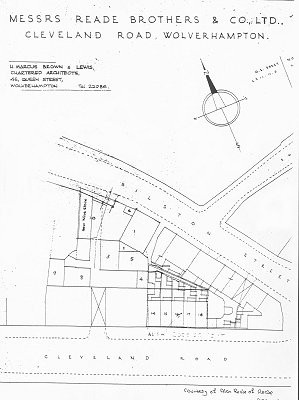

Map 3: Block plan of the site, 1949, for Reade

Brothers, by H. Marcus Browne & Lewis, architects of 46 Queen Street. By

courtesy of Alan Reade of Reade Associates. |

In years preceding its purchase by Dixon's in 1974, it was

owned by MFI, as their Wolverhampton retail furniture outlet.

Figure 5: a 1928 photograph of part of the

building with Reade Brothers' fleet of vans. Note the old building to

the right. Photo by courtesy of S J Dixon & Sons Ltd and Reade

Associates. |

By then the central archway had become a door, the

windows blocked up or replaced, and the central gable and cupola removed

from the roof. The brickwork now seems to have been replaced by block

facing which has been painted (photo 1). Reade Brothers' original 1959

sale price for the 30,000 sq ft 'extension' premises, (also known as the

Tudor Works), and including adjoining houses on Cleveland Road (map 3),

was £40,000 [D. Swingwood, p.59]. |

S. J. Dixon and Son Ltd.

| By September 1960, S. J. Dixon & Son Ltd, already looking

to expand from premises in Princess Street, agreed to pay £21,000 for

the by-then dilapidated factory and the houses (figs 6a, b, c & map 4).

An application for planning permission for a change of use was put to

Wolverhampton Council. Architects, Butler Wones, drew up plans for a

ground-floor showroom and trade counter, modern offices and, at the top,

storage space, all floors reached by a new concrete staircase attached

to the inside of the east gable wall [CA]. |

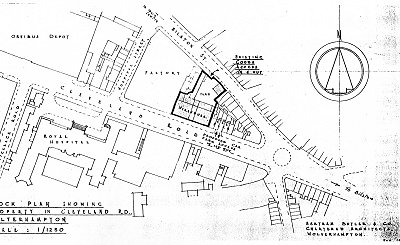

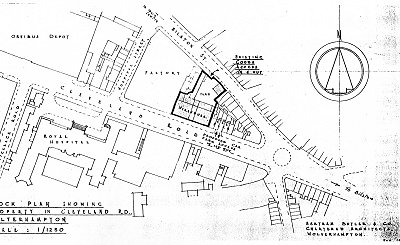

Map 4: Block plan, 1960, by Bertram Butler & Co,

Architects, Wolverhampton; for S. J. Dixon & Son Ltd.. By courtesy of

S. J. Dixon & Son Ltd. |

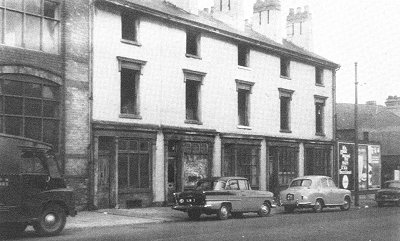

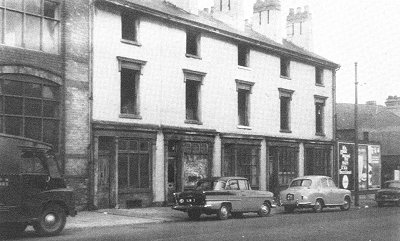

Figure 6a, a view of the building just before its

acquisition by S. J. Dixon and Son Ltd. Figure 21c shows the five cottages

with shops which were later demolished for the present customer car

park. All photos from: S. J. Dixon and Son Ltd: the History of a Family

Firm. |

Biddulph & Thrift's alteration work, somewhat curtailed,

was unveiled in the grand opening of December 1961 and covered by a six

page spread in the Express & Star. A window replaced the central archway

and a canopy was erected from there to the new door where the right hand

window had been. The revolving door inside the new entrance was later

added to cut down on the cold draughts of air coming from the front

entrance straight to the trade counter directly behind it at the rear of

the building (photo 1) Single rectangular panes of glass replaced the

two windows that it covered and their arches were in-filled at the top.

The replacement of windows to the left was undertaken some years later.

The brickwork was also cleaned. Later works by Dixon's include access

by roller-shutter doors (photo 7) out to the newly designed rear

delivery yard with its own new buildings, those of Reade Brothers being

demolished, and installing an electric lift. Dixon's' ownership of the

entire triangular site was completed when they acquired the plastics and

resins factory, which occupied the entire length of Hospital Street. |

| Demolition of neighbouring houses to the east

in 1978, both on Cleveland Road and Bilston Street, created a much-

needed customer car park and eased traffic congestion on Cleveland Road

[Swingwood, p.99] (map 4). Dixon's then created two new customer

entrances in the east gable wall, one to the trade counter at the back

and the other to the public showrooms at the front of the building

(photo 4).

Inside the loft walls are visible today the metal bands installed to

prevent further bowing. A leaking roof has caused the complete

replacement of roof tiles and battens, leaving what are thought to be

the original beams in place [Deer] and the rain-damaged wood has been

replaced on the inside of some dormer windows. |

Figure 6b, another view of the building just

before its acquisition by S J Dixon and Son Ltd. |

Figure 6c, a final view of the building just

before its acquisition by S J Dixon and Son Ltd. |

The building now finds itself virtually marooned in a

run-down, albeit protected, area (photo 9) and Dixon's face the

challenge of attracting the public (CA) from the busy major road at the

rear, as Cleveland Road is now a cul-de-sac and is cut off from the town

centre by the ring road. Plans are before Wolverhampton Council in

spring 2000 to 'turn the building around' [Deer], including the addition

of ceramic tiles to the east gable wall and a sculpture on the top of

the lift shaft, thus establishing this as a landmark building for our

own time [Deer]. |

| Photo 9: Dixon's building from the

car park of the former Royal Hospital. |

|

SOURCES

[anon]1869 South Staffs Industrial & Fine Arts Exhibition, Official

Catalogue

[anon]Wolverhampton & Staffordshire Illustrated Biographical &

Commercial Sketches, 1898

Bridgen's Directory of Wolverhampton 1833

Gorst T. , The Buildings Around Us, 1995

Mason F., The Book of Wolverhampton, Barracuda Books, 1979

Oldham D. S., A brief history of the changing life and face of one of

Wolverhampton's oldest buildings, 1985

Swingwood D., S. J. Dixon and Son Ltd: the History of a Family Business,

privately published, 1985

Upton C., A History of Wolverhampton, Phillimore, 1998

Walrond S., Looking at Carriages, 1980

Wolverhampton Chronicle 1893 Wolverhampton Archives & Local Study

Centre

Express & Star 1961 Wolverhampton Archives & Local Study Centre

Schedule of Title Deeds & Documents relating to Factory at Cleveland Road

1959 and houses nos l4 to 18 Cleveland Road. Courtesy of Alan Reade

Public Health in Wolverhampton, a collection of archive sources,

Wolverhampton Archives

ACKNOWLEDGMENTS

Grateful thanks to the following who gave generously of their time and

information:

C. Aston, S. J. Dixon & Son Ltd for the tour of the building,

photographs, company history and oral information

Richard M. Forder, great grandson of Alfred Forder, oral information.

Alan Reade of Reade Associates & Reade Brothers family for stationery,

copies of deeds schedules, newspaper cutting, sight of recipe books and

medicine containers as well as oral information

Richard Deer, architect, Reade Associates for oral explanation of his

present plans for the building and for copy plans and photographs

|