| Photographs of the inside of Chubb's Wednesfield

Road Works are very few, and far between. Luckily for

us, ex-Chubb employee, the Reverend Bill Enoch, has

kindly passed-on the following photographs that were

mainly taken in the 1950s. He has also written about his

memories of the company, and these are included below.

The factory, now demolished, covered about 10 acres, and

several hundred people were employed there. The

following photographs show some of the highly skilled

workforce, at a time when Wolverhampton could be

justifiably proud if it's world-leading manufacturer of

safes and strong rooms.

The Reverend Bill

Enoch's Memories of the Company

My earliest

memory of the factory would be during the war years when

I passed it each day, either on my bike or on the

single-decker trolley bus, on the way to school. The

drive was full of newly-completed Bren gun carriers,

which were obviously part of Chubb's war-time effort.

In February

1952, not long after completing National Service in the

R.A.F. I joined the company as a clerk in the Programme

Control Dept. I was put to work with Charlie Grainger

who taught me a great deal about the company, its

products, its history, and its place in the lock and

safe industry. |

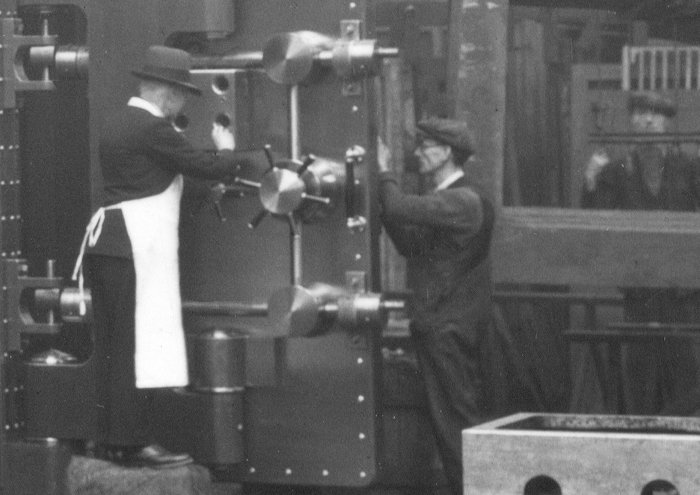

Strong room doors under

construction in the early 1950s. The small doors are emergency exit

doors, built to the same specification as the main

doors. They were used in an emergency when there was a

"lock-out" on the main door. |

An enlarged view from the

photograph above, showing part of the complex locking

mechanism on a strong room door. |

|

I soon

discovered that there was great pride in the company and

its reputation, and as my job involved spending a lot of

time on the shop-floor, I came to realise that this

pride existed at all levels. The reason wasn't hard to

find. Chubb had held the Royal Appointment since the

1830's, and also supplied locks and safes to government

departments and major banks, both here and abroad. They

were probably the best-known lock and safe maker in the

world, as well as being one of the oldest. They had

factories in all the old Commonwealth countries, and

agents all over the world.

The fact that

Chubb was still very much a family business probably

contributed to this sense of pride, especially as "Mr

George", (more properly the Honourable George Chubb) was

frequently to be seen at the factory, and was respected

there. In fact it was generally felt that the company

was run by gentlemen. |

|

Another strong room door, a

little nearer completion. |

|

One of the emergency exit

doors nearing completion. |

|

When

particularly impressive strong room doors or safe

deposits were made, usually for overseas banks, the

families of employees would be invited to inspect them

on the shop floor before they were crated up and sent to

the docks. It was common to find Chubb workers who

started straight from school and stayed until they

retired half-a-century or more later. Many of them lived

within walking distance of the factory.

In the early

1950's one would see only two motor cars in the drive.

These belonged to the Works Director, Mr Rushton, and

the Works Manager Mr Long. For the rest there would be a

couple of dozen motor-bikes and about 500 cycles in the

bike-shed. Everyone else walked home or made for the bus

stops outside the main gates. By the mid 1980s when I

finally left the company there were probably 500

employees’ cars.

Beneath the

factory there was a rifle range, built for the Home

Guard during the war. After the war they formed the

Chubb Rifle Club, which I joined and eventually became

secretary. We competed very successfully in various

Wolverhampton and Black Country Rifle Leagues. |

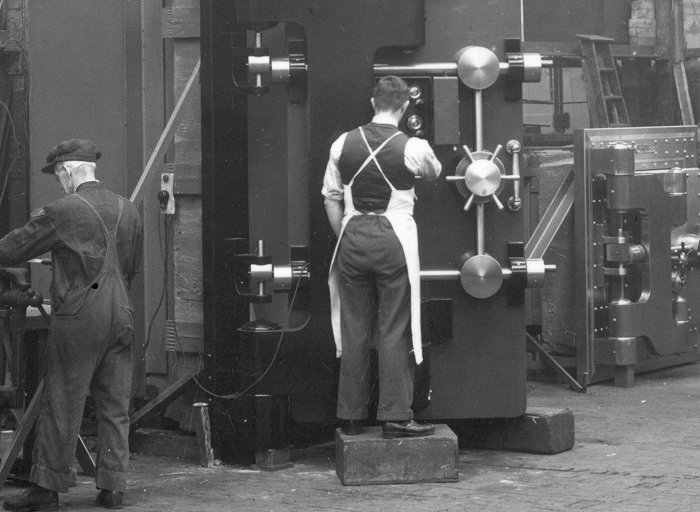

More strong room doors under

construction in the early 1950s. The gentlemen in the foreground

are George Palmer and Albert Booth. |

|

Chubb office quality safes

being painted in the early 1950s. |

|

Another view of painting in

progress. |

|

Names come to

mind from my early days:- Bert Tooby the Chief

Draughtsman, and David Tate who took over when Mr. Tooby

retired. Leslie Tinkler, and Jimmy McGee who were the

estimators. There was George Dean the time study chap,

Reg Milne the chief accountant and Les James who worked

for him, John Jeavons, my boss, and Stan Reese who ran

the shipping department.

Gerry Cox was

the Safe Works foreman, and later Arthur Gandy. George

Prior was in charge of Progress, and Bob Kilvert who

could get a bet on for you in those puritan days. Jack

Walker was in charge of the paint shop and his two sons

worked with him, and Jack Beech was the light Shop

foreman, and two of my many brothers-in-law, Ray Wilkes

the works union convenor and Saiah Wilkes a painter.

Ivor Jennings;

always known as “Bubble" for reasons I never discovered,

and Les Minshall, Albie Booth, George Palmer, Frank

Morris who shot with me in the Rifle Club. Characters,

every one of them. |

Filling a ladle with A.B.P.

alloy (anti-blowpipe alloy) from a furnace in around

1950. The man in the

light suite on the left, with his hands in his pockets

is G.C.H. Chubb, later Lord Hayter. |

|

A close-up view of the ladle

being filled from the furnace. |

|

Casting A.B.P.

alloy (anti-blowpipe alloy) in the early

1950s. |

|

Another view showing the

casting of A.B.P. alloy (anti-blowpipe alloy) in the

early 1950s. |

|

A final view of

A.B.P. alloy casting. |

|

Before the

1950's were out Chubb began to expand. New designs and

materials were always necessary in the constant battle

to keep safes one step ahead of the villains. Better

fire resisting cabinets were developed to meet the need

to protect vital records including computer media. Chubb

Research came into being with highly sophisticated

design and testing facilities. Some demonstrations of

their testing were done before select audiences invited

from police, military and insurance bodies.

Many high

security locks were redesigned so that they could be

mass-produced rather than hand-made by locksmiths,

although these highly-skilled men remained in demand for

the really specialist locks. The Wednesfield Road site

must have doubled in size during the 60's and 70's. |

A special case made for

exhibiting the crown jewels. Chubb held the Royal

warrant from around 1840. The photograph was taken in the

late 19th century. |

|

Chubb certified

fire-resisting cabinets, sizes 1 to 6. From

the 1930s. |

|

The eventual

decline of safe-making seems linked to changes in

society itself. For more than a century Chubb had made

ever stronger and more sophisticated safes in answer to

increasingly skilled and resourceful safe-breakers.

Sometimes it seemed that the villains got ahead, in

which case Chubb had to come up with something better,

until the next legitimate advance in cutting or boring

techniques which might give the criminal the edge. And

so on.

But there came a

time when money began to go out of fashion as we all

swapped our cash for bits of plastic. The need for the

big Chubb safes and strong-room doors began to dry up,

especially as the safe-makers at that moment in time

were well ahead of the safe-breakers. The villains

changed tack, finding it preferable to attack cash in

transit rather than knock themselves out on safes they

weren’t going to get into. The rest, alas, is history. |

Chubb strongroom reinforcement

"Tangbar" and other items about to be transported from

the works. Possibly in the 1920s or 1930s. |

The following photographs were

kindly sent in by Adam Morris who worked at the

Wednesfield Road site from 1979 when he started as

an apprentice, until 2001 when it closed. He trained

in the Quality Department, before moving on to

CNC machines in 1987, at a time when there were over

1,000 employees at the works.

The official staff

photograph taken after the manufacture of a

pair of doors for the King of Brunei, around

1995. Courtesy of Adam Morris. |

|

Left to right: |

|

|

Back row: |

? , Mick Beeston, Norman Stevens,

Mac Gardiner, Adam Morris. |

|

Middle row: |

George Fones, Terry Pallant, Geoff

Dunn, Steve Lloyd, Den Deg, Roger Green,

Andy Burgiss, Pete Swan, Brian Jones,

Sid Hobbs, Albert Rhodes, Roy Stanley,

Terry Bloomer. |

|

Front row: |

Bill Hickman, Alan Kimber, Mac

Evans, Ron Alcock, Alan Jones |

The following two photographs show the front and back

page of Adam's Apprenticeship Indentures, signed by Mr

Charles Barton, the MD at the time. Chubb used to take

on around 20 craft apprentice's each year, at

Wednesfield Road, up until about 1982. They also had

Technical Apprentices and Commercial Apprentices. The

in-house training centre had its own Fitting and Bench

Shop, a separate Machine shop, and a staff of four. In

the early to mid 1980s the training school moved to the

Josiah Parkes site.

I must thank Michael Stevens for kindly sending the

following photos, and Will Morgan for some of the names. The first two are of the Chubb rifle

team, who won the Bird Trophy in 1964. They were

gathered together to celebrate their success, and were

photographed at Chubb's Rifle Range which was under the

factory floor.

|

|

| Left to right:

Front row - Bill Heritage, Ken Bould, Bill Enoch (club

secretary).

Back row - Michael Stevens, Harry Saich,

Councillor Alan Beste |

The same people as on the previous photo

except that first left on the front row is Les

James.

In the rifle range the targets were attached to a

trolley that ran on rails. It was positioned by a rope

and pulley system, similar to that seen in the film "The

Great Escape". It was done this way because of the lack

of roof space. If the trolley de-railed, as it would if

the operator was impatient, it was quite an ordeal to

crouch down and waddle along in order to put matters

right. The rifles used were BSA Martini, lever action,

single shot .22 calibre.

On one occasion, a club member brought a pistol

to try out, and without checking, fired a couple

of rounds down the range. Unfortunately, the

trolley with the targets had de-railed and

another member was some distance down range and

not clearly in view. The ensuing altercation was

quite amusing, to say the least.

|

The Bird Trophy. |

The range was unique. The outer door

lead directly into a small room, where

the guns and ammunition were secured.

The roof was just above head height.

The shooting positions, of which there

were two, were on a raised level at

about waist height, which was constant

from that point onwards down the range.

It was quite common to be lying in the

prone shooting position and hear the

large and very heavy safes being

trundled about in the workshops directly

above.

Having a fertile imagination was not

an asset, and it was no wonder some

members developed a certain reluctance

to shoot when the floor above started

creaking. |

Michael also sent the following two photos of a

version of a Chubb safe that was produced by Wedgwood.

|

If anyone can add to the story,

or has any photographs of the works, please contact

Bev Parker.

|

Return to the

Chubb menu |

|

|