Final Expansion

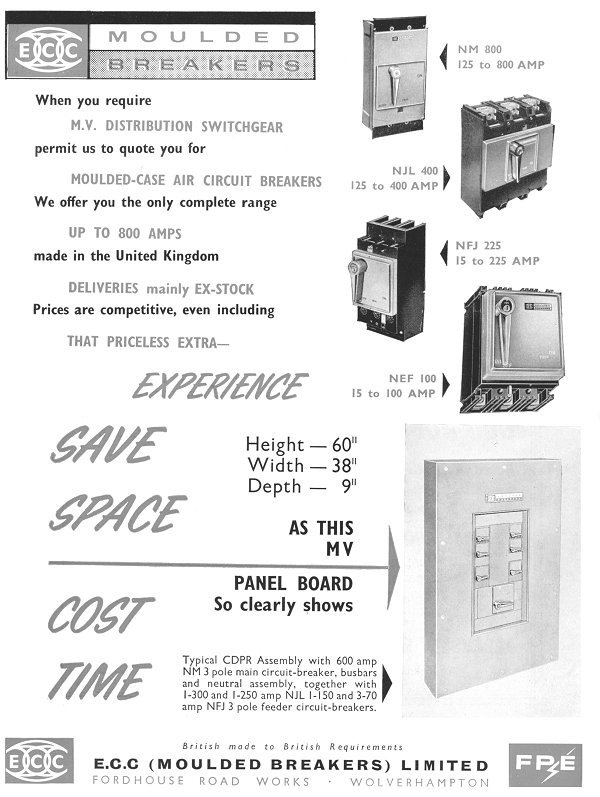

An advert from 1965.

By the late 1960's the E.C.C. had several other factories,

both in Wolverhampton and abroad.

The factory in Shaw Road. |

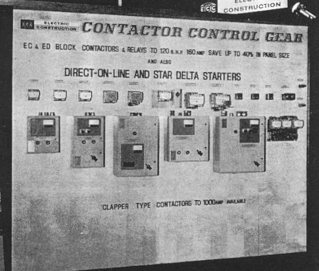

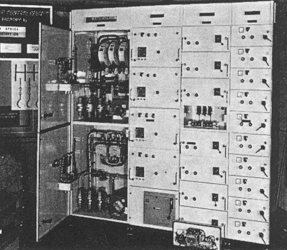

A control gear factory was built at Shaw Road, which

was only about 400 yards from the main works. The factory was laid out

for the flow production of contactor type control gear, to cope with the

heavy demand for power station equipment and specialised automated

process equipment. |

| Examples of some of the products

produced at Shaw Road. The display includes the range of EC/ED

contactors and star delta motor starters. |

|

|

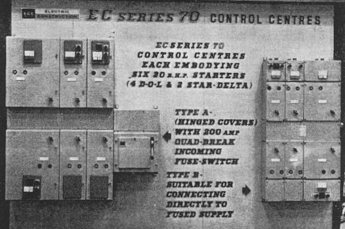

A display showing some of the EC

series of contactors, built into control centres. |

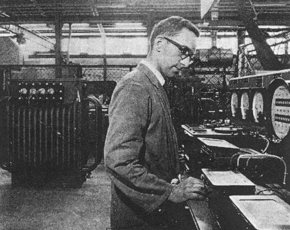

Another view of

the factory. |

|

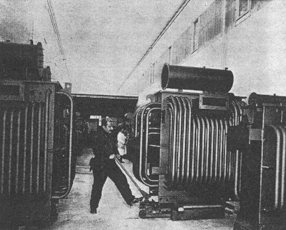

The factory at Fordhouse Road. |

Two associate companies were set up in a

new factory in Fordhouse Road Bushbury. The companies were E.C.C.

Moulded Breakers Limited and Federal Electric Limited. The factory

was about 1 mile from the main works and produced a complete range of

medium voltage switchgear for use in electrical distribution in

industry, hospitals, shops and houses etc. |

| Production started in 1959. The products also included

fuse switches and moulded-case air circuit breakers.

Another view of the factory. |

|

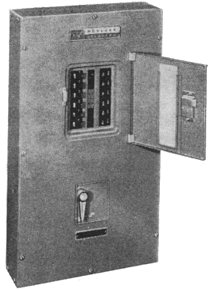

| A Stablok distribution board. |

|

|

A Quadbreak

panel-board. |

|

|

|

A CDPR 600Amp, 3 pole

circuit-breaker. |

|

|

A plug-in circuit- breaker. |

|

| 15 to 100Amp moulded-case air

circuit breaker. |

|

|

| 15 to 225Amp moulded-case air

circuit breaker. |

|

|

|

125 to 400Amp moulded-case air

circuit breaker. |

|

|

125 to 800Amp moulded-case air

circuit breaker. |

|

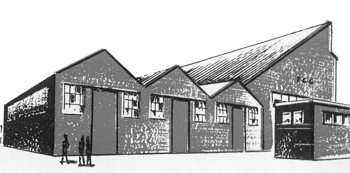

A drawing of the South African factory. |

E.C.C. also had a factory in South Africa. The South

African company was appropriately called E.C.C. South Africa,

Proprietary Limited. A wide range of E.C.C. products were produced

there. |

This piece of

switchgear is one of the many E.C.C. products that were made in South

Africa. |

|

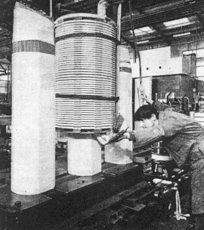

The New Plymouth Works. |

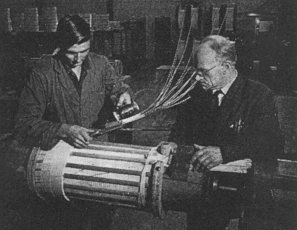

E.C.C. Transformers & Controls Limited was set up at New

Plymouth, in New Zealand. Many types of transformer were produced there,

the key staff being trained at the Wolverhampton works. |

Arthur Gill, leading hand - L.T. winding. |

Peter Langley, Test Department. |

Jack Webster, painter. |

Lindy Vango - H.T. connecting. |

David Wright, transformer assembly. |

The transformer core building team. |

The E.C.C. also had overseas offices at

Toronto in Canada and Melbourne in Australia.

|

|

|

Return to the

Later Products |

|

Proceed to the

Final Years |

|