E.C.C. Products from

the 1950's and 1960's

This section contains details of some of the company's later

products and notable installations. The E.C.C. installed purpose built

equipment for all kinds of industrial uses, much of which is probably still

in use today. The curators recently visited a Wolverhampton nail

manufacturer and noted that the whole factory was driven from E.C.C. motors.

We were told that one of the motors, which must be about 50 years old, and

is in daily use, was actually cleaned and oiled about 15 years ago, and

hasn't been touched since. This shows how well-made and reliable, the

company's products are.

| The first transatlantic telephone cable between

Clarenville, Newfoundland and Oban was inaugurated on 25 September

1956. It was designed to link both the United States and Canada to

the U.K., with facilities for links to other European countries. It

provided 30 telephone circuits to America and 6 to Canada, as well

as a number of telegraph circuits to Canada.

E.C.C. designed and manufactured the power equipment for the Oban

terminal station, as is mentioned in the advert on the right. |

|

|

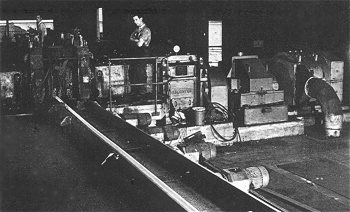

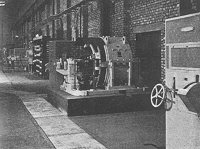

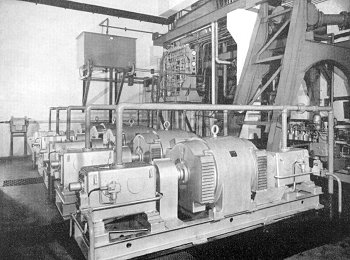

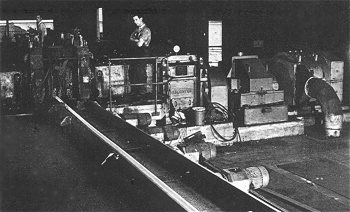

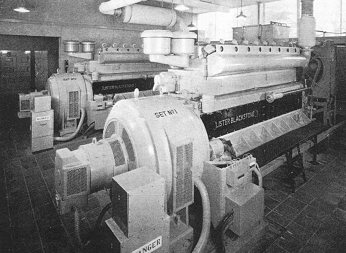

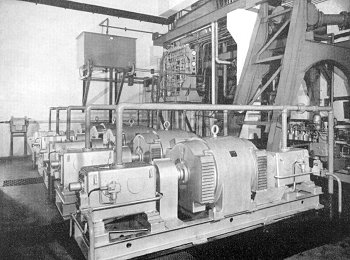

The finishing mill with 750h.p. E.C.C. drive

motors. |

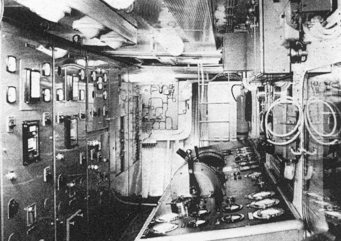

When Bayliss, Jones & Bayliss Ltd., of Cable Street,

Wolverhampton, opened a new rolling mill, it was driven by E.C.C.

motors. More than two hundred motors were used in the system, the

main mill drives producing 3,150 hp. and 4,000 hp. The other four

main motors were housed in the motor room along with the rectifier

and switchboard. These provide the supply to the five variable

speed, 460 volt D.C. motors. |

| The supply equipment consisted of four 580/832 KVA

rectifier transformers, feeding four mercury arc rectifiers, each

with an output of 500 kW, at 1135 amps. The E.C.C. Service

Department and the Electrical and Maintenance Department of Bayliss,

Jones & Bayliss, installed the equipment without substantially

effecting production. This was one of the most modern rolling mills

in the Midlands and specialised in the rolling of alloy steels and

carbon steels. |

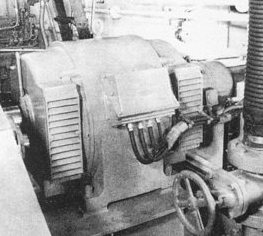

The motor room. |

|

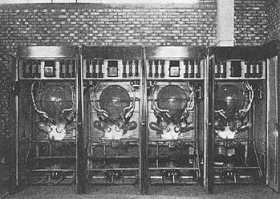

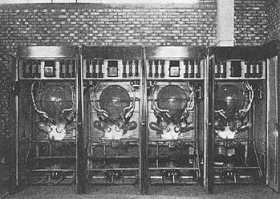

The four mercury arc rectifiers. |

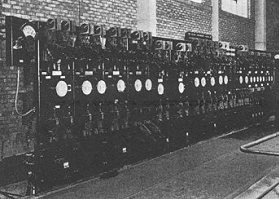

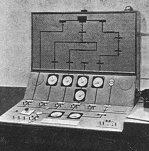

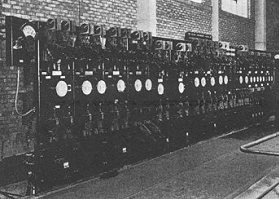

The D.C. Switchboard.

|

|

The Fisheries research vessell "Arni Fridriksson" was

built for the Icelandic Government, and launched on 1st March 1967.

The ship's electrical system was designed and built by the E.C.C. It

supplied 440 volts, 3 phase at 50 Hz. |

|

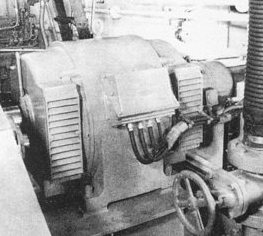

The main generator. |

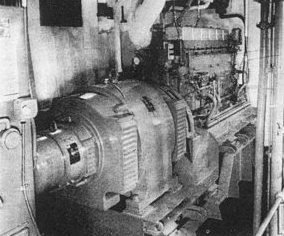

The auxiliary generator. |

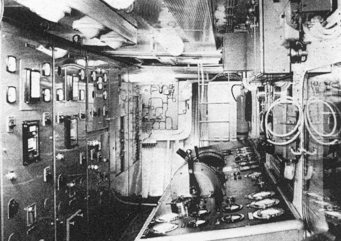

The main control switchboard.

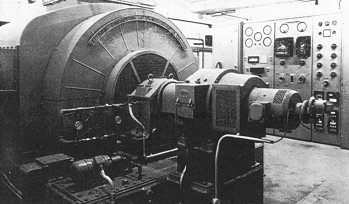

A view of the engine room showing the two main

generators. |

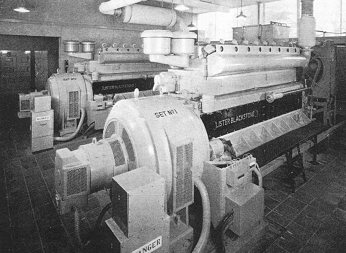

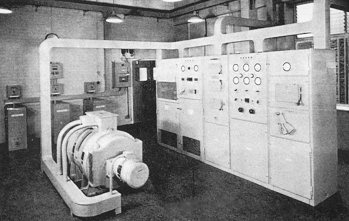

On Friday 9th July 1965 the 2.5 million pound

telephone trunk centre at Woodcroft, Edinburgh, was formally opened

by the Director General of the Post Office. The standby and

continuity power equipment was designed and built by E.C.C. It

consisted of two 300 KVA, 415 volt A.C. generators. They were of the

self-aligning bearing type with overhung exciters. The output

voltage was automatically regulated to within plus or minus 1.5%.

Each generator was driven by a Lister/Blackstone diesel engine at

750 r.p.m. |

| The company also supplied a 35 KVA 415 volt, 3 phase

generator, for the uninterrupted supply for essential services. On

mains failure, a battery automatically provides power for a D.C.

motor, which drives the generator until the main diesel engines and

generators are up and running.

The 35 KVA generator. |

|

|

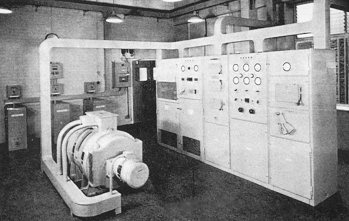

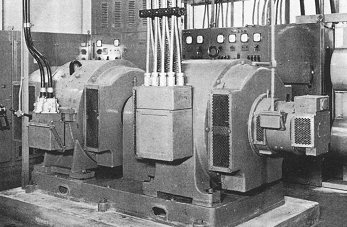

In 1965 a Univac 490 computer system was installed at

the British European Airways West London Air Terminal. The E.C.C.

provided the continuity power equipment and associated control gear. |

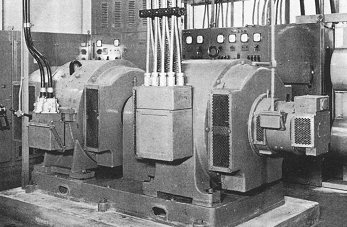

| It consisted of two motor-generator sets, each of

which provided 208 volts, 3-phase, at 60 Hz. Each unit consisted of a

350b.h.p., 400 volt steel yoke D.C. motor which was coupled to a

300 KVA, 240 kW A.C. generator. The output voltage was automatically

controlled to within plus or minus 1% and separate control panels

were provided for each generator. Solenoid operated, air-break

circuit-breakers were included in the output circuitry. |

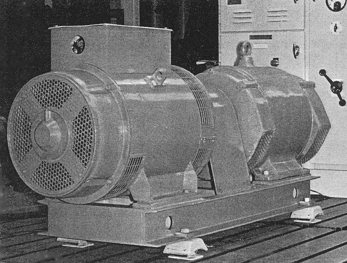

One of the motor-generator sets. |

|

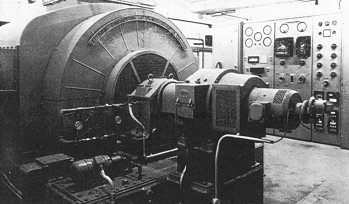

The E.C.C. generator, exciter and

control switchboard. |

English Clays, Lovering, Pochin & Co. Ltd.

commissioned an unmanned, remotely controlled 5 Megawatt

Turbo-Generator, to supplement its existing electricity supply.

The E.C.C. provided the turbo-generator and the associated

control gear. The generating station was located at Bugle in

Cornwall and produced electricity during peak periods and at

times of power failure. |

| The generator was powered by a land version of

the Proteus Turbo-prop aero engine that was built by

Bristol-Siddeley. The engine ran on class 'A' diesel fuel and

full electrical power was available within five minutes, after

the engine started. The station produced 11,000 volts and

storage was provided for 24,000 gallons of diesel fuel, which

was enough to run the generator for 80 hours at maximum power. |

The control desk. |

|

One of the 2,000 hp. diesel hydraulic

locomotives. |

In 1958 the E.C.C. produced a number of

Dynostarters, which were used to start up locomotive

diesel engines. They were used in Type 4, 2,000 hp. diesel

hydraulic locomotives that were built by the North British

Locomotive Company Limited, at Glasgow. The locomotives were

65ft. long and weighed 116 tons. They had a maximum tractive

effort of 50,000 lbs. |

|

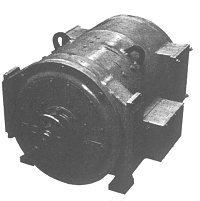

An E.C.C. Dynostarter. |

|

|

In the 1960's the company started to produce

synchronous reluctance motors. These were much smaller and

cheaper to build than traditional A.C. motors. They were simple

to start, requiring no starting gear. Direct on-line starting or

star-delta starting was used.

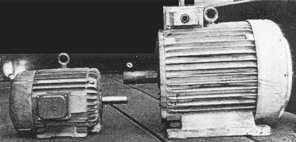

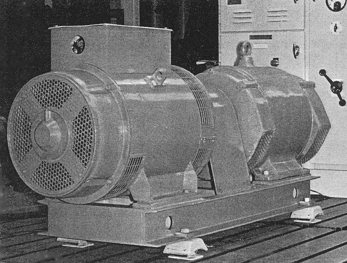

The photograph shows a C350

reluctance motor driving a BRF 250 brushless generator. |

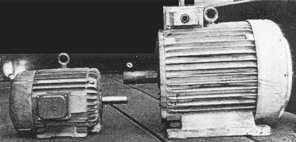

| Comparing one of the new synchronous reluctance

motors, on the left, with the traditional type of A.C. motor on

the right. Both motors deliver the same output power. |

|

|

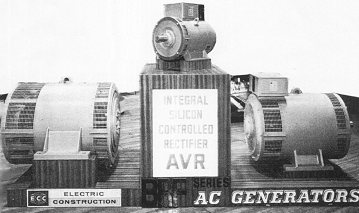

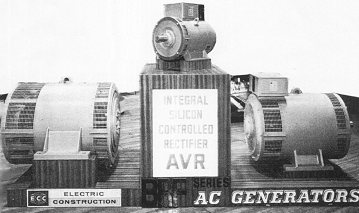

E.C.C.'s exhibit at the

1968 Electrical Engineers Exhibition. |

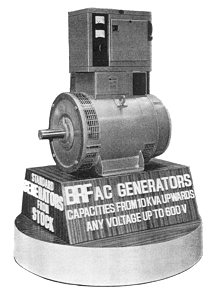

| BRF generators were designed for use as standby

power A.C. supplies. They were brushless, A.C. generators with a

built-in static voltage regulator that was designed by the

Static Plant Division. The output voltage was regulated to

within 2.5% of its rating and the generator was only about three

quarters of the size of a traditional unit.

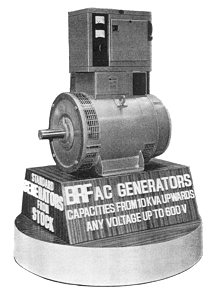

A BRF generator. |

|

|

Control valves and

pumping equipment that is driven by E.C.C. 1,500 r.p.m. and

3,000 r.p.m. squirrel cage motors.

This is part of an installation at the Hereford forging

works of Henry Wiggin. The equipment was installed early in

1963. |

The following is a list of some of the company's

other products. This demonstrates the wide range of items that

were produced by the company. The E.C.C. had a reputation of

being able to design and manufacture almost any piece of

electrical equipment.

| a) |

Remote control by

injecting signals into mains power lines |

| b) |

High frequency

alternators up to 100 kW at 10 kHz |

| c) |

60,000 volt

precipitator supplies with rotating switch rectifiers |

| d) |

400 Hz generators for

radar supplies |

| e) |

servo control systems |

| f) |

tyre heating machinery

for railway wheels |

| g) |

Electronic moisture

control systems for fabric and paper manufacture |

| h) |

Lift motors and

control systems providing controlled acceleration |

| i) |

High current

rectifiers |

|

|

|

| Return to the

Company's Products |

|

Proceed to Final

Expansion |

|