The Villiers Engineering Co. Ltd.

From bicycle parts to engines

In 1912 the company was turned in to public limited company,

The Villiers Engineering Company Limited. Why the company was called

Villiers in the first place is not certain. It may simply be that it

was on or near Villiers Street. It may be that John Marston named it

after the long serving Wolverhampton M.P., Sir Charles Pelham Villiers.

Since the street was named after the politician it may be that both factors

were taken into account.

After the free wheel the next vital step in the

development of Villiers was the introduction of the making of petrol

engines. Where the idea that Villiers might do this came from is

not known for certain but Villiers' own publication "Sixty Progressive

Years" attributes it firmly to Frank Farrer. Probably Farrer had made an

assessment of where the future of two wheeled transport might lie.

The story is told by Charles Marston's daughters in these words:

| At Villiers an extremely advanced design was produced

in prototype by an engineer specially engaged for that job - actually it

was an important achievement, but too revolutionary: one Coventry firm

describing it as ‘the engine with hot and cold water laid on’. Privately

at Villiers it was considered also to be too complicated. The machinery

there was not suitable for this kind of work, neither were the necessary

skills available. It was also felt that the future of the motor cycle

lay in the cheap, simple light-weight machine. |

|

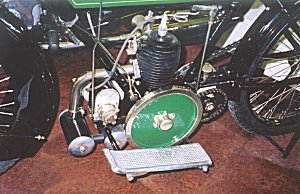

The Villiers 269cc engine in a 1922

Sparkbrook motorcycle, at the National Motorcycle Museum. |

The problem then was to find the right type - Farrer

suggested a two-stroke engine, but a conference of experts at first

turned this down claiming that already the two-stroke had been proved a

failure. However Farrer persisted to such a degree that Charles wrote in

the Works’ book, ‘to oblige Mr. Farrer make him a two-stroke engine!’ No

one else was very enthusiastic. |

But the engine was built - unkindly described as a

‘Flying Bedstead’ - and Farrer went to test it. He came back to Charles

jubilant, saying they could sell thousands of these - a complete

understatement as it turned out, for to the Jubilee date (1948) over

three-quarters of a million had been sold. Possibly the very simple

little ‘Levis’ two-stroke, made by Butterfields in Birmingham, inspired

Farrer - who was an expert judge in these matters - to go for extreme

simplicity. It had only three moving parts, viz. a piston, connecting

rod, and crankshaft. ... It was not really a question of ‘pioneering’ a

new engine - Villiers saw the possibility of producing this simple type

of engine at a very low cost thus opening up a large market for very

cheap motor cycles within the pocket of ‘the working man’ of that time. |

|

Farrer conducted his test on the Bridgnorth Road and

the story is that he was so enthusiastic about the engine after this run

that he told Marston that he could "sell thousands of them". In the

end they made well over two and a half million of them.

Production started in 1913 and was an immediate success, but

was interrupted by the First World War, when the firm was making munitions.

The First World War

It seems that there was some production of the

two-stroke engine during the war but the factory was mainly engaged in

making munitions. In any event engine makers were confronted with a

problem in that nearly all magnetos came from Germany and supplied stopped.

Frank Farrer came up with the idea of combining the magneto with the fly

wheel which not only overcame the supply problem but was a success in its

own right, becoming a standard feature of all Villiers engines. The

idea had been tried before but not on a motor cycle engine. After the

war the idea was further developed, especially by the new Chief Engineer,

Frank Pountney. Frank Farrer also looked ahead to the post-war

period and designed and planned the production of new engines ready for

post-war production.

|

|

|

|

| Return to the

beginning |

|

Proceed to

1919 to 1939 |

|