| An article from The Engineer, 9th

November, 1934:

Villiers Engineering Works

In a recent visit which we paid to the Marston Road

Works of the Villiers Engineering Company, Ltd., at Wolverhampton, our

attention was drawn to the fact that in addition to producing a weekly

output of tens of thousands of free wheels and sprockets, the firm has a

manufacturing capacity of no less than 1,100 small two-stroke engines per

week. The works have been newly built and planned, and are complete with the

latest specialised machinery for their work, and some account, therefore, of

their history, their technical equipment, and the engines manufactured will,

we feel, be of interest to many of our readers.

Plan of the Marston Road Works.

Beginnings and Development

The Villiers Engineering Company, Ltd., was formed in

1898, and its original works were on small premises in Upper Villiers

Street, Wolverhampton. Its first products, were pedals for bicycles, but the

making of these was later discontinued, and in 1904 the manufacture of Villiers free wheels was

begun. That side of the firm's activities has continued to increase

steadily, and today the company is, we are given to understand, one of the

largest manufacturers of free wheels in the world.

That the firm has not

stood still in this side of its work is shown by the fact that there is

being exhibited at the nineteenth International Bicycle and Motor Cycle Show

at Olympia this week a new type of Villiers two-speed gear. It consists of

two sprockets mounted on the rear hub of a cycle, and connected by a free

wheel, so that one sprocket can overrun the other. The drive from the main

sprocket is transmitted through two further sprockets mounted on a

countershaft, and by means of three driving pins the hub sprockets can be

run independently or connected, this action representing a change of gear,

giving an increase of speed of about 25 per cent.

It is, however, rather with the engine side of the

firm's work that we propose to deal. The first Villiers internal combustion

engine using petrol was produced in 1912, and was a small single-cylinder,

four-stroke unit with an overhead inlet valve which worked in conjunction

with a two-speed gearbox. That design was, at that date, the directors felt,

somewhat ahead of its time, and it was immediately decided to produce a very

simple two-stroke engine, which was built shortly afterwards in the same

year. Since that time the firm has concentrated on the production of

two-stroke engines alone, and from small beginnings, when a good deal of

prejudice had to be overcome, the demand for such engines has steadily

increased, and now requires a works capacity of 1,100 engines per week.

We shall describe later some of the principal engine

types, and enumerate some of the varied uses to which they are put. Before

doing so, however, reference may be appropriately made to the firm's

patented flywheel magneto, which forms an integral part of Villiers engines,

and is fitted to many engines, both industrial and marine, of other makes.

The early Villiers engines were all equipped with horseshoe pattern flywheel

magnetos, which at that time were principally produced in Germany. During

the war period, however, the firm started to manufacture its own magnetos,

and after careful consideration it was decided to adopt a flywheel type,

which, as the engine was already fitted with a flywheel which would house

it, saved a projecting bracket, a chain, and two driving sprockets. After

extensive experiments, the Villiers flywheel-type magneto was adopted in

1919 as standard equipment on all engines, and is now supplied for all

British outboard-type marine engines, and for several Continental makers of

similar motors.

A Flywheel Magneto.

The drawing of this device above, shows the general robust construction adopted,

with the large coils and magnets, and the absence of all delicate parts. The

magnetos, which we inspected in course of assembly and testing, gave an

intense hot spark, which, in these small engines, ensures easy starting with

reliable running under varying loads.

The Works

The foundry, which is specially equipped to deal with

repetition aluminium alloy and bronze work, is accommodated in the old

Villiers Street works. We noted the general high standard of the castings

produced and the good finish secured. The engine and freewheel works is

complete with its own stamp shop, which accommodates ten drop hammers fed by

oil-fired furnaces. The parts are drop forged from strip bar and after

machining and finishing pass to the hardening department.

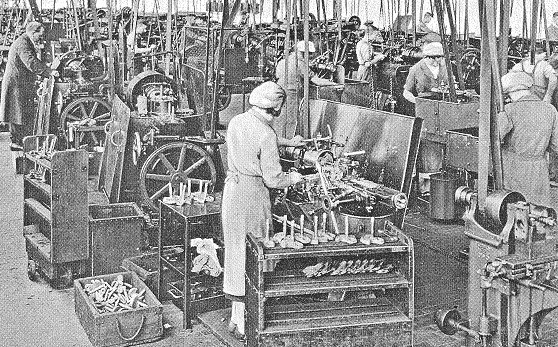

The general and

automatic machine shops are equipped with power presses, milling machines,

and full-automatic and semi-automatic special purpose lathes and machines

which nave been specially designed to manufacture commercially all the

component parts required down to the smallest pin, nut, or washer. These

parts are subjected to a single high-grade standard of supervision

throughout the different processes of manufacture and assembly.

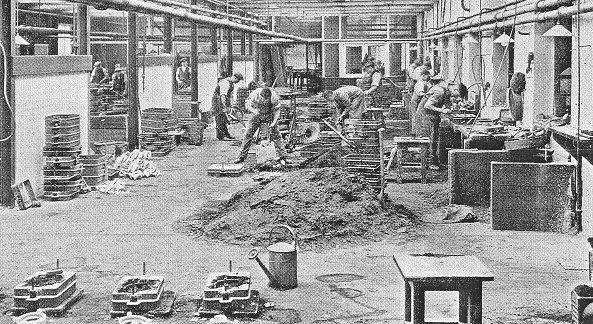

The Foundry.

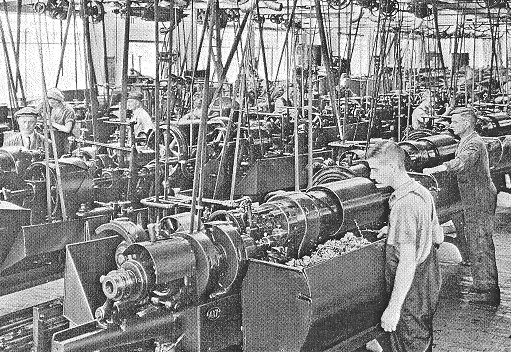

The Automatic Machine Shop.

About eight years ago the Villiers Engineering Company,

Ltd., decided to produce its own type of carburettor, specially adapted to

the needs of the small two-stroke engine and designed to give a compensated

mixture over the whole range of power of the unit. These and other detailed

parts called for an increase in the machinery capacity of the plant, and in

order to meet the new requirements a separate machine shop, specially

equipped for producing the small components and screws from bar, &c., was

built and equipped only last year.

The General Machine Shop.

As the machine tools are largely occupied on repetition

work, a particularly well-equipped tool department is maintained, and there

is a die sinking department to deal with special stamping dies. Attention

has been specially paid to appropriate finishes for the engines and their

component parts, and we noted that many of the brass and bronze components

were being finished by dull chromium plating, while in certain other

instances polishing was resorted to. This finishing work is carried on in

special sections of the factory.

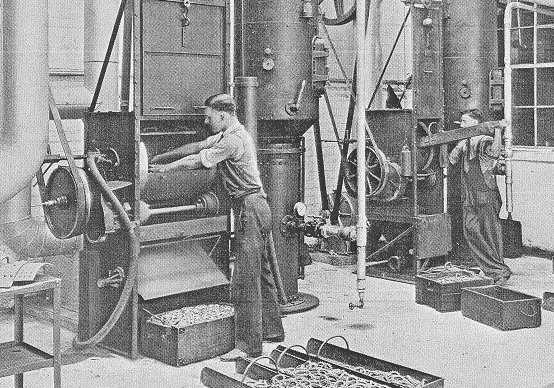

An important new section which has recently

been put to work and which supersedes the original sand blasting equipment

is the shot blasting department, equipped by Tilghman's Patent Sand Blast

Company, Ltd., of Broadheath, near Manchester. The plant consists

essentially of a rotating barrel which is mounted upon four

rubber-covered rollers and is belt driven through spur

gearing. The barrel itself is furnished with a removable

door, through which the castings, stampings, or other

components to be cleaned are introduced.

After it has been loaded and the door fastened the

contents are tumbled and at the same time are brought under

the action of shot blast jets. As the barrel is formed of

perforated steel plates the abrasive material can fall into

a hopper arranged below the barrel, from which it is drawn

up into a cyclone separating chamber by the suction of the

fan. When the shot has been separated from the dust it falls

for re-use into the shot blast machine below, which is

controlled by the setting of the operating levers.

The abrasive is carried along an interior mixing tube and

is delivered by compressed air through the jets into the

barrel. Meanwhile the lighter dust is taken from the top of

the cyclone to a rigid screen type dust collector in which

the dust is arrested and is collected in bags which are

periodically emptied. Clean air passes through the screens

of the dust collector and into the suction of the exhaust

fan and is delivered again to the atmosphere through the

exhaust fan outlet.

The Shotblast Installation.

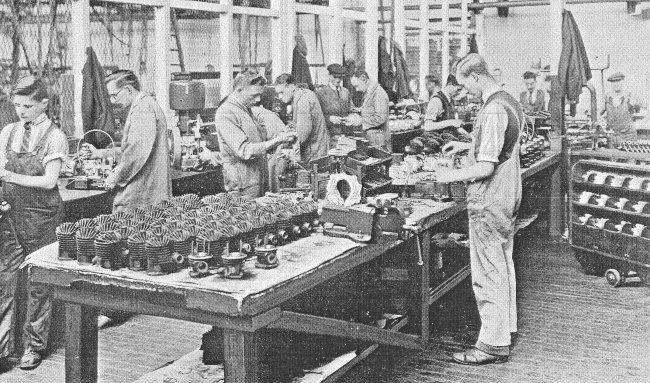

Brief reference

may also be made to the method of engine assembly. The completed components

and other parts, such as magnetos and carburettors, pass direct to finished

stores, from which they are drawn in batches for assembly. We observed that

following the very close inspection during manufacture very little further

adjustment or fitting was needed, and that practically as soon as the

engines left the assembly bench they ran smoothly on the test bench, which

is modelled on automobile factory lines.

The Engine Assembly Shop.

Some typical engines

Besides a standard range of petrol engines specially

designed for motorcycle work, which we do not propose to refer to, the firm

manufactures a wide range of small power units, both air-cooled and

water-cooled, which have found the widest world use. In addition to pumping,

ventilating, air compressing, and lighting plants, industrial driving, and

so on, there is a large range of agricultural engineering uses, including

the driving of forestry saws, fruit-spraying plant, and rabbit-exterminating

machines, in which the exhaust gases of the engines are turned to use. The

engines are also used as auxiliaries on transport vehicles, for starting

other gas and oil engines, for field telegraph sets and for other services.

|

|

|

|

3½

hp. Air-Cooled, and 1½ hp. Water-Cooled Engines. |

|

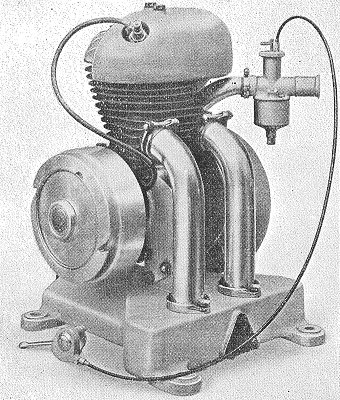

"Mar-Vil" 0.6 B.H.P. Engine. |

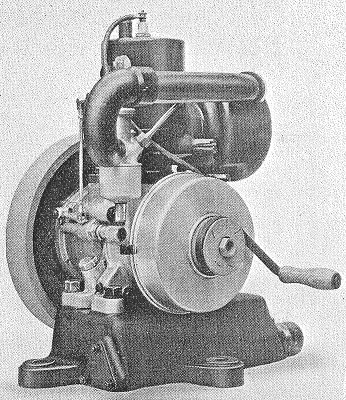

One of the smallest engines Villiers have built,

the "Mar-Vil" units, have a designed output of 0.6

B.H.P. at 1750 r.p.m., with a speed range of 1,200

to 1,800 r.p.m. The horizontal cylinder has a bore

of 2in. with a stroke of 1½ in.

Our drawing shows clearly the neat arrangement of

the principal parts, including the compact

flywheel-type magneto previously referred to, and

the firm's special carburettor. The arrangement of

the flywheel is such that not only does it protect

the magneto from water and dust, but also forms an

efficient fan for cooling the ribbed cylinder head,

which is made in an aluminium alloy.

Cast iron is employed for the piston, which

carries two pressure rings, and an inertia ring.

Lubrication of the cylinder is effected by adding

oil to the petrol in the proportion of about 1 part

of oil to 16 of spirit. The ball-bearing crank shaft

may be noted.

The engine is governed by a specially designed

regulating device incorporated within the magneto,

and it is equipped with a novel type of recoil

spring starting handle. A fuel tank is formed within

the base of the engine, and has sufficient capacity

for about 2¾ hours running. |

| The complete weight of the engine, including the

tank, is only 29¾ lb. There is also a larger

water-cooled model, which is made in two sizes

designed to develop 1.5 B.H.P. at 1,000 r.p.m., with

a bore of 67 mm. and a stroke of 70 mm.,

corresponding to a cylinder capacity of 247 c.c.,

and 2.6 B.H.P. at 1,400 r.p.m., the corresponding

bore and stroke being 79 mm. and 70 mm., with a

capacity of 343 c.c. Attention may be drawn to the

design of the lipped piston, and the expansion

chamber, which leads by a tube into a base-type

silencer, which gives, we observed, a very quiet

exhaust. The cooling water spaces are quite large,

and they can be easily cleaned. |

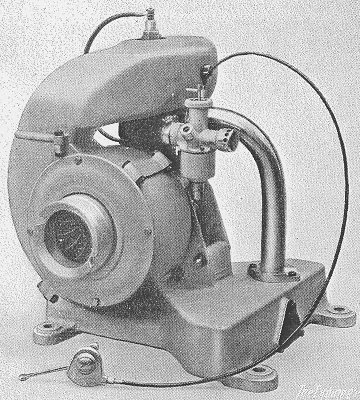

1 hp. Air-Cooled Engine. |

1½ B.H.P. Water-Cooled

Engine.

The carburettor is furnished with a mixture control cam,

and is attached directly to the cylinder casting. We may

mention the provision of a single thin ring, called the

inertia ring, above the top of the first pressure ring on

the piston. This ring is free to rotate and to move up and

down slightly, and it has been found to be very effective in

keeping the rings free from gumming deposits. The governor

is of the centrifugal crank-shaft pattern, and it acts

directly on the carburettor through link gear. The extensive

use of ball and roller bearings may be noted. |