|

From the December 1908 edition of

'The British Printer':

With the Ink Makers. Manders' New Auxiliary Works

As further testifying to the remarkably strong

position attained by the house of Mander-not merely in respect

to varnishes, colours and paints, in all of which directions its

output is of huge proportions, but more particularly in the

printing ink section and its essentials in respect to colour,

varnish and so on-have we pleasure in placing on record some

impressions of the establishment gleaned during a visit early in

November last.

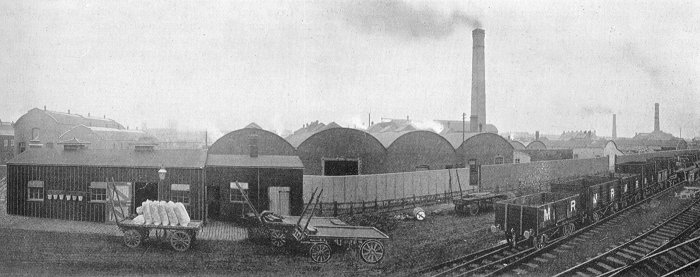

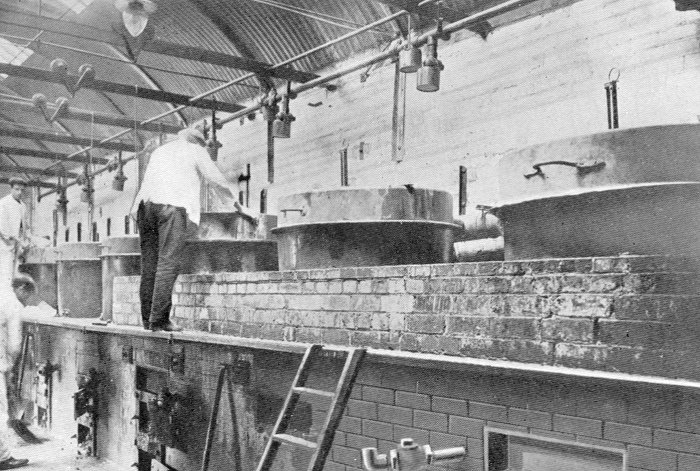

Wednesfield Works in 1908.

The headquarters and chief works are situated

round and about St. Johns Street, Wolverhampton, but out at

Wednesfield, some two or three miles away, is situated a further

large establishment, in itself much larger than most factories

associated with the allied industries. To refresh our memories

in respect to colour, we look in at the Town Well and School

Street Works paying special attention to the department 'devoted

to colour making. These show open, single-story rooms with

gallery, enormous vats at one end, and a long row of huge tanks

of colourful length of the floor.

After filtering, tramlines

bear the trucks carrying the colour into steam-heated or

vacuum chambers. The lighter colours, the deeper lakes,

and the darker shades are confined to their respective

departments, and it is very interesting to note how,

after mixing, the development of colours is succeeded by

unnumbered washings of pure water, whilst from beginning

to end is felt the control exercised by the laboratory.

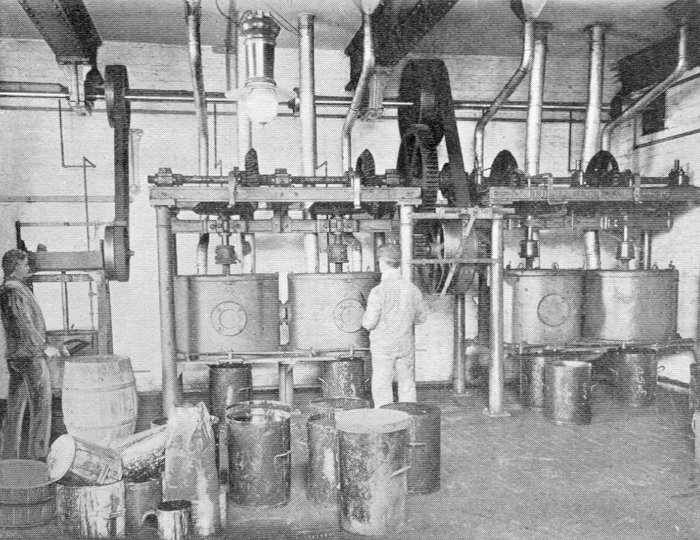

Black Ink Mixing.

The chemists' department

seems to us to be one of the most striking features of

these works.

It controls test by test, all supplies of

goods coming into the works, all results obtained at the

various stages of manufacture, warrants the sale of the

finished article, whilst, above and beyond this, it is

constantly at work on new colours, colour combinations,

new methods of treating colours and oils, of suiting

inks to papers.

The Ink Grinding

Department. The permanency of colour seems to be an ever

present aim, and, walking out on to the flat roof facing the

laboratory windows, we notice many slips of paper attached to

the windows, all bearing colours under test in some degree for

permanence in connection with atmospheric effects. Some of the

slips are dated nine and twelve months ago.

The Wednesfield Works

On the outskirts of Wednesfield a seven-acre

piece of land, bordered by canal on one side and railway on the

other, easily reached also by the electrical tramway, is the

property of Messrs. Mander Bros., and a very considerable area

of ground is covered by various specially-erected buildings. We

find that since our visit of some years ago the buildings have

been entirely re-modelled and large new departments added. The

firm is in the enviable position of possessing ample

accommodation to carry out its own ideas in respect to the most

desirable arrangement of works, and we are to find that the aims

and ideas of experts have been actually carried out here. The

premises are regarded as the ideal of their class.

The Colour Mixing Room.

The main buildings run

along the water-side, with others at right angles. The

first are devoted to colour mixing and to ink making, in

fact, forming an ink making plant complete; the other

series of buildings nearer the railway is allotted to

varnish manufacture, also complete. These works are, we

understand, chiefly used for supplying the materials

made up at the Wolverhampton departments.

A tree-bordered main road sweeps

round two sides of the works area, and affords access for vans

to all parts. Each of the buildings is allowed ample space round

about, and the structures, more particularly the new ink works,

are most substantially built, with stone staircases, concrete

floors, and fireproof generally.

The electric light is used

throughout, and, as at the Wolverhampton works, a

marvellous degree of cleanliness and tidiness prevails,

for although all departments are evidently very busy,

untidiness is never apparent, and many a printing office

with far less excuse for the appearance of its rooms

might take a lesson from the ink maker.

The general scheme with regard to

these works seems to be the elimination of dry colour from the

grinding rooms, realizing that dust floating in the air and

being deposited on grinding rollers may seriously neutralize the

efforts to provide thoroughly pure and finely-ground colour.

Thus a long room is devoted entirely to ink grinding, a heavy

door shutting off the ink-mixing department with its closed-up

machinery. Printers will appreciate this point.

A low screen across the centre with the driving motors to left

and right divides the floor area. Around and against the walls,

with ample space about, is arranged a continuous series of large

three-cylindered ink-grinding machines, a battery of some

five-and-twenty of large size being already in full operation.

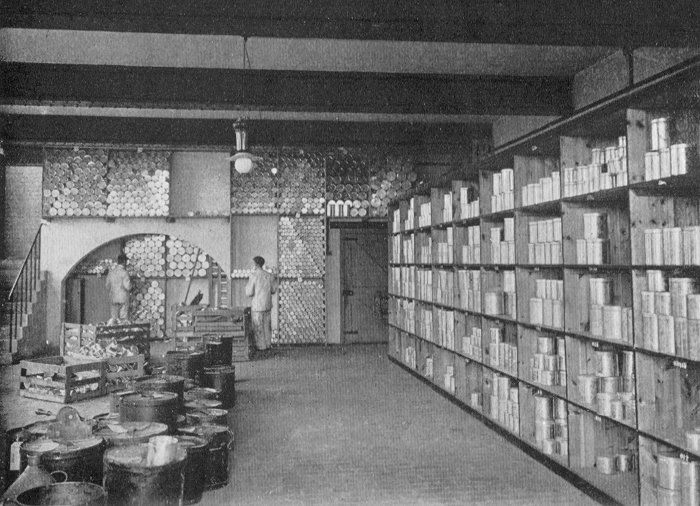

The Can and Drum Store.

It is interesting to go from

machine to machine and to note well-known colours in soft,

oily curves rolling away from the pressure of the cylinders,

the white coated operators, each with his magic broad-bladed

knife charming or threatening-whichever you like his machine

into uniform pressure and even flow. Well-known blacks,

blues, and greens in one section are shown as on regular

order for well-known magazines, whilst other colours are

equally popular for illustrated work.

The facility for handling

cans, for frequent tests and arrangement

generally, speak of an ideal system. Driving is obtained by short

belts driven from overhead shaft on either side of the room,

power being supplied by a couple of 50h.p. motors.

Contrasted with the roar and roll

of so many grinding machines, the mixing department alongside is

positively restful. Judging by the piping which comes from the

ceiling the tall mixing machines are fed from above, and we find

this to be the case, varnish and dry colours being fed through

their respective channels. This further explains the entire

absence of dust, that is dry colour, in the air. The mixers are

mechanically operated, the cleverly arranged blades of the

paddle mixers making short work of the compounds of oil and

colour. Besides the series of large sizes there are smaller

cylindrical mixers, and we note particularly the curious looking

litho blacks in their steam-heated pans. This department is

devoted to blacks.

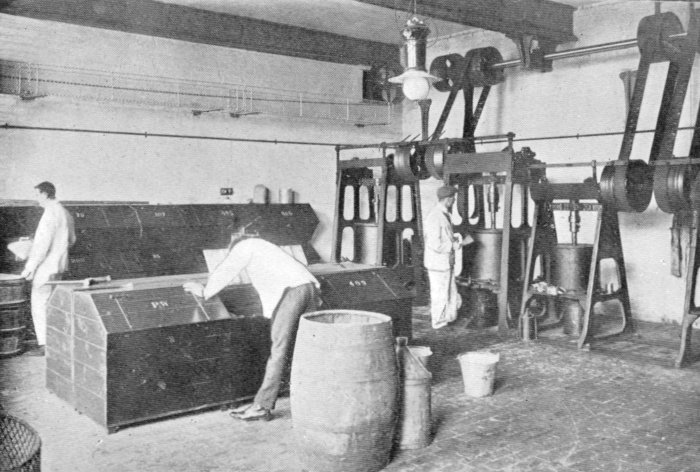

Colours

In the next building across the yard is a department much

more pictorial in effect. Again carrying out the idea of freedom

from dry colour or dust, this room is fitted down one side and

the centre with a series of bins with closely fitting lids. In

these bins dry colours are stored, and the effect is to keep one

colour to itself when the supply is being drawn upon, for, of

course, neighbouring stocks would not be opened at one and the

same time. Along the further side of the wall is a series of

mixers, and we find these to embody some very ingenious ideas in

apparatus for mixing. There are small-sized circular mixers

ready to tackle small quantities of special colour fitted with

scientifically arranged knives which scrape the sides, vessel

and knives being revolved separately. To complete this as a

mixing department, on a third side is a row of varnish tanks

holding the pale, transparent varnish used for mixing colour.

This department, as with the others, is self-contained, and

possesses its own motor for driving purposes.

The Varnish Boiling Works.

Stores

Stepping now into a large roomy

building, shelved from floor to ceiling along the walls, and

with tables and benches, we find a can and drum store. The

familiar tins in a variety of sizes are arranged in their

respective sections, and all readily accessible. This is not a

tin store, but an ink warehouse, and in spite of the chief

chemist's confidence as to the absolute uniformity of new inks

and those made for some time, it is quite clear that he makes no

mistake as to keeping up substantial stocks of all colours. This

we are glad to see, for we know only too well how commercial

conditions so frequently require the printer to order inks for

immediate use. Here once again we have the assurance that the

laboratory maintains rigid fulfilment to standards, so that

absolute reliance may be placed on receiving the same colour at

any time of ordering.

The floor above is used as a

storeroom for important sundries such as pomade and

ink-easers. A steam-heated pan for solidifying oil is also

noticed, the odour of the place being rather pleasant than

otherwise. On looking out from the crane platform at the far

end a fine view of the edge-bordered fields is obtained, for

we are really on the fringe of the country here, with all

the real country advantages of fresh air and spaciousness

generally.

An adjacent room, the dry black

room, is situated directly over the black mixers, to which

earlier reference is made. The whitewashed walls are rapidly

assuming the artistic mottled effect of a busy chimneysweep's

countenance through contact with the piled-up sacks of carbon

blacks lodged here. The receptacles over the mixing cylinders

are filled from here, and again there is every facility for

minimizing any waste and preventing dust and trouble resulting

there from.

The isolation of blocks of

buildings is carried out with a thoroughness which must be the

envy of those confined within small and often cramped areas. To

reach the place of storage where the casks of colour, tins, and

supplies of this character are safely put out of the way, and

yet easy of access, we cross the yard again and enter a long

single story building filled with casks and crates, tins and

drums.

The Varnish Side

In totally distinct buildings,

separated by considerable yard space, is carried on the

operations concerned with varnish making. First to the actual

cooking. Without referring to the varnish

works in detail, as this department represents rather a

re-organized section than a new works, we may refer to some

impressions gained whilst witnessing the various operations of

manufacture. The varnish-boiling works show a long row of pans

set in brick with closed fires. A large cowl or hood is

fitted to each to carry off fumes, and conspicuously

placed thermometers record temperatures.

|

From the 'British Printer',

November 1939. |

Conscientiously

climbing the steps to sniff at the odours each successive one

surely more pungent than its predecessor we are able to note the

great heat used, and to observe the working generally, returning

with an enhanced impression of the infinite care taken to

prepare varnish.

At the rear of this building is

one of similar size, the tubing whence escapes the fumes from

the pans being here in evidence, and we are shown a clever

device automatically coming into operation at each pan in case

of fire from any individual boiler.

Following the varnish as it

runs off in pipes across the yard to the oil stores, we find on

the second floor of a substantial building several dozen

thousand gallon tanks, each equipped with gauge for showing

depth of varnish contained in the tall cylinders, and with pump

for filling or removal of the contents. Large as would appear to

be this stock, as we are aware from visits to varnish stores,

this represents but a fraction of the tremendous amount of oil

always maturing in the firm's stores. |

Fire Fighting

The various buildings are

disconnected, partly for convenience for manufacturing purposes

and largely to minimise the risk of and the scope of damage by

fire. Expecting to find full provision made to meet emergencies,

for the fire fiend is ever a possible foe where oils are being

treated, we found that every possible safeguard was adopted and

each section provided with appliances for fighting that which is

a good servant but a bad master. The works also possess their

own fire brigade-already tried once on their own area and again

at a neighbouring concern. Whilst we were present an alarm was

raised and instantly men swarmed out of the buildings, each to

his allotted task seizing section after section of hose pipe,

bucket, or "stood by" hydrants exactly where duty required, and

all with a celerity which it would be difficult to surpass.

The District

would appear decidedly popular

with the workpeople, and so healthy as to form quite a

sanatorium for those employed at headquarters. Leaving the works we are struck

by the appearance of a fine new building, an attractively built

school in style, with a handsome villa attached.

Inquiry as to

this led to the production of keys, the opening of doors, and we

found the building to be a messroom for the workpeople. The

floor is coated with a special linoleum-like terracotta coloured

concrete, warm and clean in appearance. The tables and seats are

painted a pleasant green and with the large cloakroom and

lavatory make up an eminently neat and attractive picture.

To Sum Up

We come away with the impression

that "this is surely Mander-like" - well thought out, well

carried out, sound in conception, finished in every detail. No

wonder the house maintains its place in the confidence of

friends and customers. |