|

Kieft Cars

Cyril Kieft, a successful industrialist, was born in

Swansea in September 1911. He followed his father into the steel industry,

and by 1935 was joint manager of the giant steelworks at Scunthorpe. At the

end of 1935 he left Scunthorpe and with his father Alfred purchased two

steelworks in Wolverhampton, and two in Shropshire. They were the

Wolverhampton Steel and Iron Company at Osier Bed Works, Horseley Fields;

Monmore Green Rolling Mills Limited, Cable Street; Haybridge Steel,

Wellington, Shropshire, and the Shropshire Iron and Steel Company Limited. In

1946 the four companies were combined under the name of the Wolverhampton

Iron & Steel Company (1946) limited, with Cyril as Managing Director. Before

the end of the year he sold his interest in the company, fearing that he

would become a civil servant when the industry was nationalised. |

| In 1939 he purchased W. H. Birkinshaw & Company Limited, drop

forgers and edge tool makers at Reliance Works in Derry Street,

Wolverhampton.

The company name was changed to Cyril Kieft & Company Limited

and products continued to be produced using Birkinshaw's "Pamax" brand name.

At the works Cyril produced forgings, including adzes, axles, bars, forks,

hammers, hatchets, hoes, mauls, picks, spades, tongs, wedges and drop

forgings for the Ford Motor Company. The new business was the country's

largest manufacturer of picks for coalmines. |

|

| In 1941 Cyril purchased Sellamn & Hill Limited of

Stewart Street, Wolverhampton, manufacturers of the "Crescent"

brand of aluminium holloware. During the Second World War he trained

as a bomb disposal officer in the Home Guard. After the sale of the

Wolverhampton Iron & Steel Company (1946) limited, Cyril purchased an ex

M.O.D. munitions factory at Bridgend, South Wales and closed the Stewart

Street works, moving production of the holloware to Bridgend. At

Bridgend he undertook general presswork, and added thermostats, electric

kettles, jelly moulds, Tilley lamps, hooks, components for the motor

industry, and locks of his own design to the product range. The venture

was very successful, employing about 450 people. Cyril also

purchased Orton and Smith Limited of Stringes Lane, Willenhall, who

specialised in the manufacture of meat cleavers.

Cyril's hobbies included collecting stamps and Welsh china, and

motorsport. His interest in racing cars probably came from his father.

He grew up listening to his father's stories about the great races at

Brooklands, where his father, Alfred was a frequent visitor. |

|

Photograph taken at RAF Cosford on 25th June 2000. |

In 1949 Cyril purchased a 500c.c. racing car and

unsuccessfully competed in the Lydstep hill climb. The previous

competitor rolled his car, and Cyril realised that entering such

competitions could be extremely dangerous. He decided that competing

was not for him, and being disappointed with the car he decided to build

a better machine of his own design. |

| All of the early cars were built at Bridgend. Cyril

offered Kieft single-seaters for sale, and took two cars, a 500c.c. and a

350c.c. to compete at Montlhery in France. Ken Gregory, Stirling Moss's

manager approached Cyril to ask if Stirling could drive one of the cars,

and both he, and Ken looked after the 500c.c. car. The 350c.c. model was

driven by John Neal. The cars were extremely successful and set a total

of 14 world records in their classes. |

| After their success Stirling and Ken suggested that they

should join forces with Cyril to form Kieft and Company Limited, and the

three became directors of the new company. Stirling had previously

planned to drive a new car that was to be built in London. Cyril took

over the debts and liabilities of the project, and the car was handed

over to him to be the basis of a production model for the future. |

Photograph taken at RAF Cosford on 25th June 2000. |

|

One of the cars from 1952 with a chassis built by

Keith Peckmore.

Courtesy of Keith Peckmore. |

|

Several cars were built, and the new Kieft won the

Formula 3 British Grand Prix at Silverstone, the Goodwood International,

the Dutch Grand Prix and many other events.

Don Parker joined as a

second driver, and was successful at many meetings, including the Daily

Telegraph International Race at Brands Hatch.

He had 22 wins in the 1952

season and won the Formula 3 championship. In 1953 he won 30 races and

the Formula 3 championship for the second year running. |

| The successes led to the Society of Motor Manufacturers

giving Kieft the opportunity to display cars on their racing car stand

at the Earls Court Motor Show, both in 1952 and 1953. In the meantime

Stirling Moss left to race for Coopers. In September 1952 the Bridgend

factory closed due to production difficulties caused by an intermittent

electricity supply, following the strikes in the South Wales coal mines.

Cyril announced that he intended to build a two litre sports racing car,

and all production moved to Derry Street to take advantage of the highly

skilled Wolverhampton workforce. |

| Cyril decided to employ a professional designer for the

new cars and approached Gordon Bedson, the Chief Experimental Engineer at

Vickers.

Gordon agreed to join Kieft, and Cyril provided him with a house

at Wolverhampton and made him a director of the company, which now became Kieft Cars Limited.

By early 1953 cars were in production at

Wolverhampton, and several models were built including a 500c.c. car for

Formula 3, a 2litre car for Formula 2 and a 4.5litre model for Formula

1. The new cars were a great success, and Kiefts gained first and

second places in the Lisbon Grand Prix. The company

also imported German-made scooters and mopeds, which

carried the Kieft brand name. |

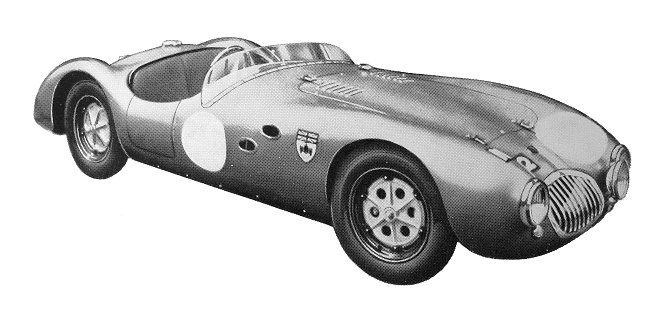

The Kieft car that's on display at the Motorcar

Museum in Coventry. |

The Kieft 1100 CC sports car.

| Cyril decided to

produce a car using the world's first one-piece fibreglass body. To

achieve this, a single moulding was made with cut-outs for the doors and

engine etc. The new car, the Kieft 1100 CC sports car, had a chassis

that was built using 3.5inch diameter steel tubing with

independent front and rear suspension, a Coventry Climax

1098c.c., 4-cylinder, overhead camshaft engine, and a

Moss gearbox. The engine delivered 72b.h.p. at

6,400r.p.m. It had a maximum speed of at least 110m.p.h.

and a fuel consumption of 50m.p.g. |

|

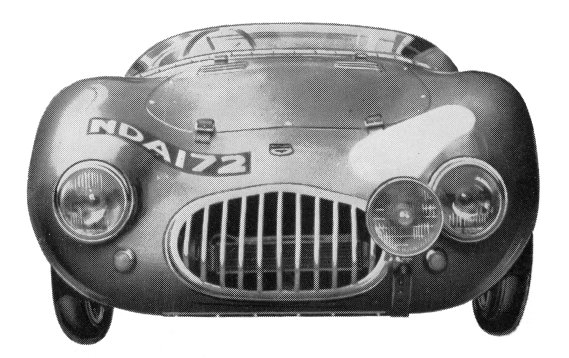

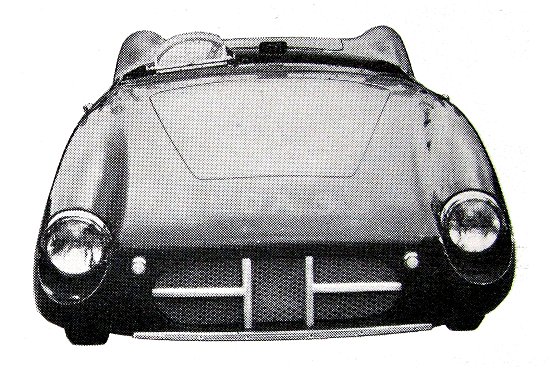

A front view of the Kieft 1100

CC sports car. |

| In 1954 two of the new cars appeared on the Kieft

stand (number 122), at

the Earls Court Motor Show on 20th to 30th October. Meanwhile a Formula 1 car had been built using a

Coventry Climax Godiva

V8, designed under the direction of Walter Hassan.

After several months of waiting, the engine had still not been delivered

and Cyril was getting a little fed-up.

The steel industry had been

de-nationalised and he wanted to get back into it. He was very busy at

the time in steel projects, and could devote no more time to racing. |

The Kieft 1100 CC specification.. |

| Cyril left the company after only six 1100 CC cars

had been built. He negotiated the sale of the car company to racing

driver Berwyn Baxter of the Baxter Screw and Rivet Company, Birmingham,

who took over all of the cars in production. Operations were moved to

Birmingham in 1956, but only a few cars were built, and the business

finally closed in 1961. |

The new styling of the Birmingham-built 1100

CCs.

|

The front view of a

Birmingham-built

1100 CC. |

| The specification of the

Birmingham-built cars. |

|

| By the mid 1950s demand for coal picks, the company's

main product at Derry Street had greatly reduced due to the

mechanisation of the coal industry. Cyril decided to concentrate on the

manufacture of tungsten carbon cutting heads for coal cutters, and

acquired two BECHE drop forging machines for the purpose. After

installation, the neighbouring businesses and residents complained about

the noise, and eventually he was forced to close the works. To keep

production going he purchased the Drop Forging

Company at Witton,

Birmingham and moved production there in 1956.

An advert from 1956.

An advert from 1957.

Although Cyril's business interests continued

in the form of the drop-forging company, Kieft Oil Products,

and Kieft & Company's thermostat division in Dudley

Road, Wolverhampton, he had one last venture into

vehicle manufacturing when he became involved with DKR

Scooters Limited in 1957. In semi-retirement Cyril enjoyed sailing both

at home and in the Mediterranean in his motor cruisers. He was a member

of the Royal Yacht Club, and very much a family man. In 2002 he moved to

Spain to live near his family, but sadly died on 10th May, 2004, after an

extremely successful career.

In recent times the formula 1 car has been completed by Bill Morris,

after finding sufficient spares to build an engine. It now competes in

racing events. |

|

The Kieft 1100 CC sports

car that can be seen at the Black Country

Living Museum, Dudley.

This particular car, built in 1954 was Cyril Kieft's 21st birthday present for his daughter Anne. |

| A close-up view of the the

1100 CC car at the Black Country Living Museum. |

|

|

A Kieft badge. |

|

|

|

Read Jim

Evans' article about

Cyril Kieft and his cars |

|

| A Kieft-Norton Formula 3 car in

action at Silverstone in 1955. Courtesy of Ferret Fotographics. |

|

|

A Kieft sports car at Donnington

in 2002. Courtesy of Jim Evans. |

|

|

Return to

the List of Manufacturers |

|