|

Clyno

Motorcycles

Clyno was founded in 1909 by two cousins, Frank and

Ailwyn Smith, at Thrapston, Northamptonshire, to produce a

variable speed drive for motorcycles, using a pulley with

inclined faces. The Clyno name is derived from the word

'inclined'.

The first part is a

history of the company from 1909 to 1916 that was written by

Ailwyn Smith. |

|

1909

During 1909 two cousins A. P. Smith and F. W. A Smith, sons of two

directors of the family business Messrs Smith and Grace Ltd.,

Transmission of Power Specialists and Iron Founders, Thrapston,

Northants, formed as a partnership, The Clyno Engineering Co., for the

purpose of marketing an adjustable belt pulley for Motor Cycles. |

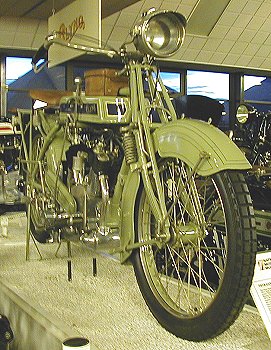

A Clyno machine from collection at the Black Country Living

Museum, Dudley. |

They rented a small workshop in Thrapston at 5/-

per week and first worked at the business part time only. The

pulley, adjustable by means of two inclined cam faces, one on

the adjustable flange and the other on the adjusting collar,

filled a need amongst motor cyclists and sufficient orders were

soon received to necessitate the partners devoting their whole

time to the business and eventually obtaining extra help.

The

pulleys sold at 12/6d each, bored to suit any make of Motor

Cycle engine. A point was made of invariably dispatching orders

the same day as received.

The plant employed in these early days

a 6.5inch centre lathe, a small sensitive drilling machine, and

a key slotter, converted from a carpenter's tenon machine. This

plant was driven by a very old Crossley 2.5h.p. gas engine.

Electric light, generated by a dynamo driven by the engine

installed. |

1910

Early in this year the partners thoughts turned to the

manufacture of complete Motor Cycles and a prototype was duly

built, using Chater Lea frame fittings and Stevens engines, made

by the Stevens Motor Manufacturing Company Limited, Wolverhampton.

It

was a belt driven 350c.c. machine of simple construction. A few

of these were sold locally. In these early days

successful participation in Motor Cycle Trials was felt to be

the best method of advertising. |

A close up of the engine in the machine

above. |

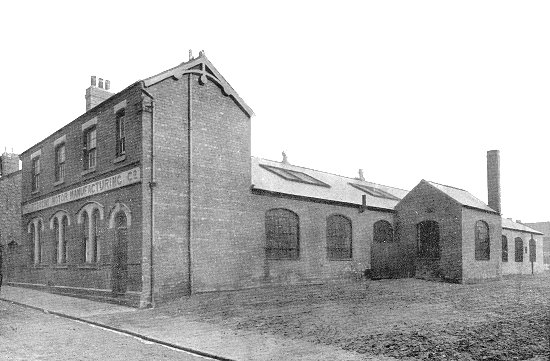

Clyno's original factory in Pelham Street, Wolverhampton.

|

Ailwyn Smith's home, Aboyne House,

Merridale Rd. |

This first machine was entered and ridden by Frank

Smith in the A.C.U. quarterly non-stop trials with repeated

success.

About this time a motor cycle stand was patented, this

consisting of telescopic tubes, independently adjustable so that

on uneven ground the machine would stand upright.

The stand did

not sell in large quantities and with the advent of the side car

combination was abandoned. |

How Aboyne House would have looked in Ailwyn's

day.

| The first Clyno 2.75hp. machine,

built at Thrapston, and displayed at the 1909 Stanley Motor

Cycle Show. Courtesy of Chris

Smith. |

|

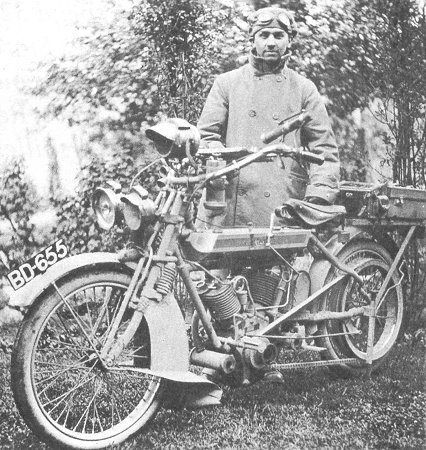

Frank Smith and his

6hp. Clyno V-twin in readiness for the 1910 M.C.C. London-Edinburgh trial. Courtesy of Chris Smith. |

Later in 1910 a more powerful machine was built

utilising the 5/6h.p. V-twin Stevens Engine, mounted in

a long, low (for those days) frame. This machine was run in the

quarterly trials, also in the M.C.C. London-Edinburgh and

London-Exeter trials.

Its low build, light weight (under 200

lbs) large engine and high gear ratio made it a very pleasant

machine to handle. It was the forerunner of the very successful

sidecar machine of later years, even in its belt driven form it

was capable of a good performance with a sidecar.

Meantime the orders placed with the Stevens Motor manufacturing

Company, resulted in a visit of their representative to Thrapston,

this visit being the prelude to negotiations for the purchase of

the Stevens concern, which was in Voluntary liquidation. |

| This purchase was eventually

completed and on 15th October 1910 the business was transferred

from Thrapston to Wolverhampton, and for a time was carried on

under the names of The Clyno Engineering Company, and The

Stevens Manufacturing Company, but the latter name was soon dropped.

The firm exhibited for the first time at the 1910

Motor Cycle Show at Olympia, showing Motor Cycles,

Adjustable pulleys and Telescopic stands. |

|

Clyno's original factory in Wolverhampton,

as seen in 2012. Behind the

offices was the spares department, under Mr. Heckford. |

1911

The limitation of a single fixed gear and belt drive were apparent in

1910, and with the increased manufacturing facilities at Wolverhampton,

a two speed, chain driven machine was evolved and it is thought to be

the first to enclose chains in pressed aluminium cases. It was this machine

that Frank Smith drove so successfully in all the important

trials in 1911, he also embarked on a programme of attacking

hitherto unclimbed and what were considered unclimbable hills,

all with the 5/6h.p. chain driven Motor Cycle and

sidecar.

Notable hills successfully climbed were Porlock and the

North Devon terrors, Honister as well as many other Lake

District hills etc., etc.

The question of a suitable sidecar

frame was given careful attention, hitherto sidecar frames were

very light flimsy affairs, clipped to the Motor Cycle frame,

generally in three places, they were quite

unsuited to strenuous trials and other use. A very robust

sidecar frame, attached to the Motor Cycle in four places by

taper plugs secured into appropriate sockets, solidly brazed to

the Motor Cycle frame, was made, this design remained virtually

unaltered for many years. It was imitated by all and sundry. |

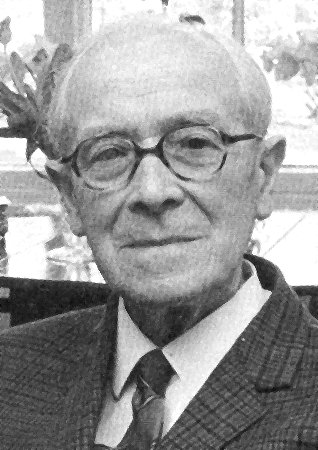

The late Ailwyn Smith. Courtesy

of Chris Smith. |

| 1912

The success of the

1911 trials policy had its effect in 1912 which was a very busy

year, orders in excess of the manufacturing capacity being

received.

During this year the Clyno Motor

Cycle Detachable and Interchangeable wheel was introduced and

fitted, this invention first fitted to Clyno Machines, was one

of the most important developments in Motor cycling history.

|

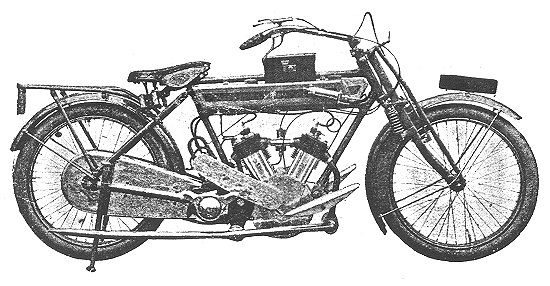

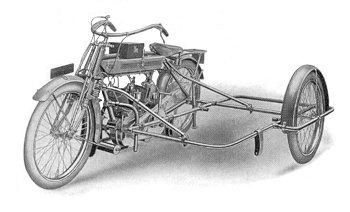

The 1912 6hp. V-twin.

|

In 1912, the company sold a

version of its sidecar machine for use as a commercial delivery

van.

The basic price of the machine was £81.10s.0d, the body was

extra and designed according to individual purchaser's

requirements.

The motorcycle could deliver 5-6hp. and sales of

the product were very high. |

| Opposite the offices of the Company

in Pelham Street

was the old Wolverhampton Humber Cycle factory, long

since unoccupied, and negotiations for its purchase were

started, these works were eventually taken over and laid out for

the manufacture of frames and the assembly of completed motor

cycles and sidecars. Engine and gear box manufacture continued in the original factory

across the road in Pelham Street. |

|

Clyno cars leaving Ashes Works and

entering Pelham Street. Ashes Works were previously occupied by

the Humber Cycle Company.

Photo courtesy of the late Geoff Stevens.

|

|

|

Ashes Works in Pelham Street, in 2012. Taken

from the same position as in the previous photograph. |

| Another view of Ashes Works,

which were also called Tower Works.

Part of the factory was destroyed in a fire

many years ago. The whole factory

has since been demolished.

|

|

| The factory was considerably

extended and the whole of the available ground space occupied by

work shops.

The policy of running in all important trials, not only

in Britain, but also abroad, was persisted in, with marked

success.

View the 1912

catalogue |

|

| |

|

|

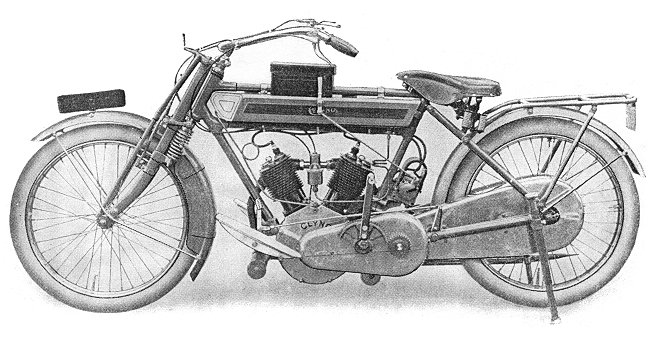

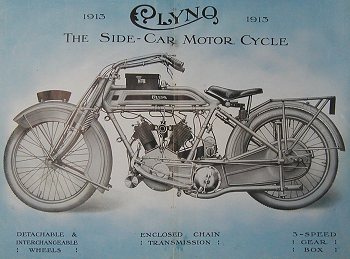

1913

Mr. W. Comery joined the firm as Chief Designer and

immediately set about redesigning the machine using basically the same

5/6h.p. engine but substituting a 3 speed gear box and an entirely new

frame. This machine was very successful and easily held its own against

increasing competition. |

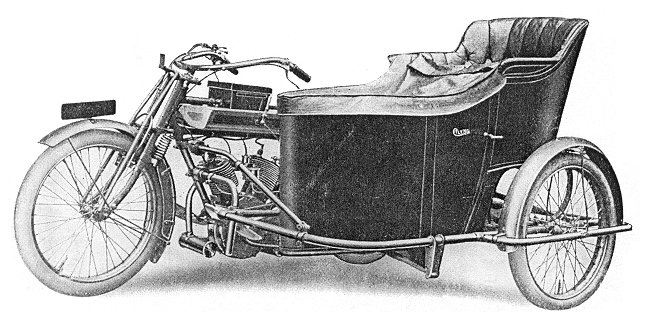

The 1913 V-twin.

The 1913 combination.

|

The running of machines in trials was intensified

and well known drivers with considerable trials experience

joined the staff, Hugh Gibson and Archie Cocks being amongst

them.

Two young works testers, C.V. Freeman (actually the first

employee of the company) and L. R. Pearson, both having great

success in many trials.

Rev. P. W. Bishoff and his wife also

participated privately in a number of trials using Clyno

outfits. Financial difficulties were not nonexistent during

1913. |

| Development was rapid and inclined to outstrip the financial

resources of the company, which was still a private partnership. Later

in 1913 it was decided to fill an obvious need for a light, simple and

cheap solo Motor Cycle, and a 250c.c single cylinder, 2 stroke machine

was designed.

This machine had a 2 speed gear and belt drive, and was

novel, in that the engine and gear box were of unit construction, chains

being entirely absent.

It was one of the first machines to be sold

completely equipped with lamps, horn and number plates, ready for the

road at an all in price. This was exhibited at the 1913 Motor Cycle

show, being very successful and sold in large numbers. |

The Clyno 750c.c. machine, built in 1914,

that is on display at the National Motorcycle Museum,

Birmingham. |

| |

| An article from 'The Motorcycle', 6th

November, 1913:

The Latest Clyno

Pear-shaped

cylinder, improved lubrication, and new design

sidecar.

The Clyno Engineering

Company have obtained a reputation second to

none for their sidecar models, and next year the

added refinements will keep this machine in the

forefront for passenger work.

The main alterations in the

engine which is a 50 degree twin-cylinder, 76

mm. by 82 mm. bore and stroke, giving a capacity

of 744 cc., is the casting of the cylinders

pear-shaped for next year's machines, for the

purpose of more perfect radiation. It also has

the advantage of giving a very neat-looking

cylinder. An alteration has been made in the

design of the crankcase, whereby an equal supply

of oil is assured to both cylinders. The neat

valve stem covers are retained. A new pattern of

front chain case has been, adopted, and the foot

brake has been improved in detail.

An excellent feature is the

provision of large fuel tanks; two and a quarter

gallons of petrol can now be carried.

The 1914 5 - 6 hp. Clyno. Observe

the new type sidecar, method of

carrying spare wheel, kick starter,

change speed gear, and footboard. |

The

Detachable Wheel

Of course, the detachable

wheels to both machine and sidecar are retained,

and probably no feature has gained such

universal popularity among riders. It is

literally but a moment's, job to take out and

replace any of the three wheels, the spare being

carried on a dummy hub on the sidecar rear

panel. A slight reduction has been made in the

total weight of the machine. A minor improvement

is the use of inverted levers for front brake

and exhaust lifter control. The three-speed car

type counter-shaft gear box is a really fine

piece of work, with its six-splined mainshaft.

The whole box is mounted with great rigidity,

and the transmission is particularly sweet as a

result. The ratios provided are 5, 9, and 15 to

1. On the top of the gearbox the magneto is

fitted, driven by an enclosed chain, easy

adjustment being afforded by sliding the

magneto.

Showing the clean lines of the

1914 Clyno. It will be noticed that

the radiating fins extend the whole

length of the cylinder. |

The New

Sidecar

Comfort, combined with a

handsome appearance, is the keynote of the very

fine sidecar for 1914. As already stated, the

wheel is of the Clyno patent detachable type,

and the spare is neatly mounted on the rear

panel on a dummy hub, and supported by a

bracket. A complete measure of protection is

provided for the passenger by a really well

fitted hood with side curtains and an adjustable

screen. When all is "storm rigged," the occupant

is almost as well protected as if in a car. An

attractive panel of cane work runs along the

sides of the coachwork. The design of the

sidecar body is a new one for the Clyo firm, and

is; we think, an improvement as regards

appearance on the 1913 models. Altogether, these

passenger outfits are among the finest to be met

with on the road, and their wonderfully

successful appearances in the big trials prove

them to be as reliable as they are handsome. |

|

|

| |

Another view of the Clyno 750c.c. machine, built in 1914,

that is on display at the National Motorcycle Museum,

Birmingham. |

1914

The machines marketed in 1913 were continued with

minor modifications. Several models of the sidecar bodies

were standardised and the running of trials continued.

The end of the summer brought the first World war, which

in view of the financial embarrassment mentioned earlier

was a blow to the concern. The death of Mr. N. Smith, father of

A. P. Smith in November 1914, increased these difficulties, as

Mr.

Smith was one of the guarantors.

1915

After an anxious time early in the year, the issuing of War

Contracts relieved the situation somewhat, and the manufacture

of a Motor Cycle combination with machine gun attached was

developed in conjunction with Messrs. Vickers Ltd.

It was known

as the Vickers-Clyno machine gun motor cycle outfit, and

together with the ancillary motor cycle machine gun ammunition

carriers, were manufactured in large numbers. |

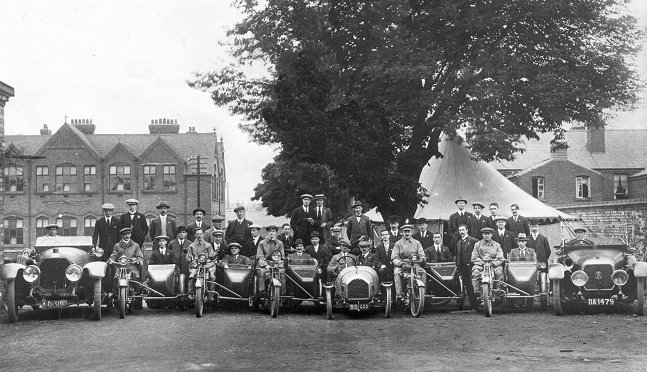

The Clyno Staff outing to

Stourport in 1915. The photograph is taken behind the Pelham

Street works, looking towards Great Brickkiln Street.

The

building on the left used to be a school, but is now a social

club. Frank Smith is on the extreme left in a Peugeot, and Ailwyn is on the extreme right in a Panhard. Photo courtesy of

the late Jim Boulton. |

1916

The product of the factory was still primarily the machine

gun outfits, together with a number of the two stroke solo motor cycles

for Army use.During the early part of the year the hitherto

successful partnership showed signs of strain and the question of a

dissolution could not be ignored.

Eventually this course was decided

upon, A. P. Smith retiring from the business, leaving Frank Smith in

charge.

A. P. Smith relinquished any active part in the running of the

business as from June 1916.

Dissolution agreement was

reached 4th July 1916 and the partnership was officially dissolved as

from 30th September 1916 by an indenture dated 4th October 1917. |

The Clyno First World War motorcycle

machine gun carrier at the National Motorcycle Museum. |

Below is a list of some of

the Clyno employees:

| W. Comery |

Chief Designer |

| S.C. Poole |

Assistant |

| J.M. Wylie |

Buyer |

| C. Franklin |

Records |

| H. Gibson |

Sales and Trial rider |

| C. H. Crole-Rees |

Sales Manager |

| A. Cocks |

Sales and Trial rider |

| F. Lloyd Parton |

Commercial Manager |

| Florence Gould |

Chief Clerk |

| H. Meadows |

Works Manager |

| H. Wiggett |

Machine shop Superintendent |

| J. H. Gould |

Assembly and Fitting

Superintendent |

| G. E. Newey |

Machine Shop Foreman |

| A. F. Knight |

Sales |

| I would like to thank

Chris Smith, Ailwyn's grandson for allowing us to include this important

document from his family archive. After leaving the company in

1916, Ailwyn Smith went on to pursue a highly successful

career with Samuel Taylor & Sons of Brierley Hill where he

designed staircases for the side of ships, chains and

anchors etc.

The First World War and

later

During the First World War, Clyno signed an agreement

with the Russian War Commission at the Savoy Hotel in London

for the supply of solo and combination machines for the

Imperial Russian Army. During the war large numbers of heavy

motorcycle combinations were produced for both the British

and Russian armies. They consisted of mobile machine gun

units, ammunition carriers and solo machines. During 1918

and 1919 Clyno also built a number of ABC Dragonfly aero

engines.

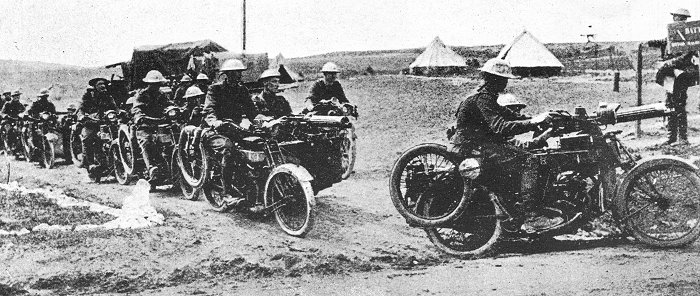

A Clyno machine gun battery, leaving

camp.

Mr. Heckford, Clyno's Service Manager remembered being

'roped-in' as a road tester for the Clyno machine gun

carriers, when they were ridden in convoys of 20 or 25 at a

time to Kempton Park, which continued for several months.

The machine gun was mounted on a tripod that could easily be

removed from the chassis. The wheels were detachable and

interchangeable. A spare wheel was carried beside the

pillion seat.

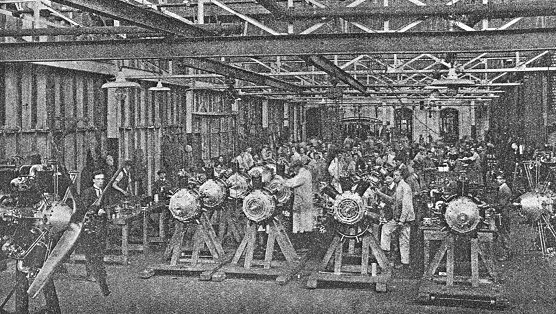

The Dragonfly had nine cylinders, weighed only 600lb, and

could deliver 365hp. Early in 1918, Clyno received an order

for 8 prototype engines and 500 production engines. Work on

the engines quickly got under way and the first engine was

delivered on 22nd April 1918, followed by another in June.

By the end of the year, 6 of the prototype engines and 4 of

the production engines had been completed. The final two

prototypes were delivered early in 1919, along with 47

production engines. The other 453 were cancelled. The orders

came too late in the day, because the war soon ended, and

the Ministry cancelled all outstanding items. |

|

Assembling ABC Dragonfly engines,

during the First World

War. Courtesy of the late

Jim Boulton. |

| After the war it seemed that the Clyno Engineering

Company would have a bright future.

A new motorcycle, the highly acclaimed 'Spring 8' with a

top speed of 50m.p.h. was launched in 1919 at the Olympia

show. Unfortunately it would be two years before the machine

went into production.

In 1920 the post-war motorcycle market collapsed, and the

original works manager Henry Meadows, left to form the well

known engine manufacturing company, Henry Meadows Limited at

Fallings Park. |

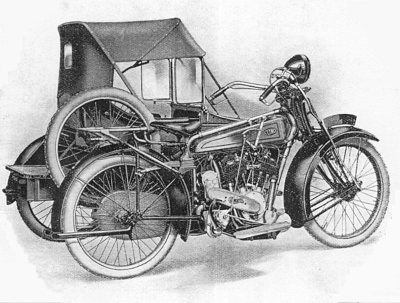

The Clyno 'Spring 8' 8h.p. de Luxe

Combination. From an advert. |

|

At the time, large numbers of cheap ex-W.D. machines were available. To

compound the problem, there were also shortages of materials, which

didn’t help production, and last but not least, the Russians failed to

pay for the military motorcycles they had received during the war. As a

result the company's financial backers withdrew, and the Clyno

Engineering Company went into liquidation.

Rebirth

Frank Smith very much wanted to produce cars, and with this in mind he

formed the Clyno Engineering Company (1922) Limited with a capital of

£100,000. Frank’s father, William Smith was chairman, and Frank became

managing director. Initially both cars and motorcycles were produced,

but by the autumn of 1923 motorcycle production had ended. The new

company stated that no Clyno machines would be displayed at the 1923

Motor Cycle Show.

Chris Smith (Ailwyn's grandson) and a Clyno motorcycle.

|

Many of

the motorcycles were designed by Arthur G. Booth.

Read a paper that was given by him and view some of his Clyno

photographs |

|

|