|

Much has been written about the locomotives built by the G.W.R. at

Stafford Road, Wolverhampton and also the early goods engines

built by John Smith at Coven. There was however, another

manufacturer of locomotives in Wolverhampton who has largely

been overlooked. He was Thomas Parker, the greatest electrical

engineer in the Black Country whose locomotives were

electrically powered long before this became the norm.

After designing many of the early electrical trams and tram

networks in the country, he was one of the leading engineers who

worked on the Liverpool Overhead Railway, designing all of the

electrical equipment. When electrification of the London

Underground was planned, he became the leading consulting

engineer, followed by a directorship at the Metropolitan Railway

Company.

The locomotives described below were initially built by the E.C.C.

and then by Thomas Parker Limited, his large manufacturing

business in Wednesfield Road.

The

following is a brief description of several locomotives that

were designed by Thomas Parker. The information was kindly supplied

by John Middleton, Ph.D., a mining engineer who has

carried out research on the mine railways of South Africa, where

he worked for a number of years.

Unfortunately

little is known about the locomotives,

which are of great interest to locomotive historians. If anyone

has any further information about the locomotives, perhaps from

contemporary periodicals, please contact me by clicking

on the link at the bottom of the page.

Locomotives exported to South

Africa

In South Africa one of

the key early influences was J. Hubert Davies who emigrated

there in 1889 and quickly established himself in the engineering

field. The company bearing his name went from strength to

strength and survives to this day as a multi-faceted engineering

concern. The first electric railway in South Africa was built

under Davies’ auspices and was on the Crown Reef Gold Mine.

The railway was first mentioned

in the South African Mining Journal (SAMJ) of 3rd

June, 1893 in a report which stated that two electric locos were on

order. On 9th September, 1893 the same journal

reported that two 20hp. Elwell-Parker electric

locomotives had arrived. By 24th February, 1894 trial runs were

taking place, and by 10th March, 1894 they were in

service. On 10th November, 1894 the journal reported

that the locomotives were working satisfactorily, and a similar

installation had been ordered for Langlaagte Royal.

The locomotives operated on a

previously horse-drawn 2'0" gauge railway, which was 6,000 feet

long (approx 1.8 km), laid with 20 lb/yard rail, and with a

ruling gradient of 1 in 40. It was electrified with a 500V DC

overhead line. Each locomotive weighed 10,000 lb (4.5 tons), ran at a

speed of 10 mph, and could haul 10 loaded or 20 empty

trucks of 30 cubic feet capacity, each weighing

1.5 tons. They are recorded as hauling 600-700

tons per day.

It now seems fairly clear that

the locomotives were probably built by the

E.C.C. (initially the Electric Construction

Corporation, becoming the Electric Construction Company in July

1893). Contemporary E.C.C.

adverts record the supply of an electric railway to

Crown Reef, which seems to confirm the company as the builder of the locomotives.

An article in the South African

Engineering Journal for May 1904 described a locomotive

built by E.C.C. but it is not certain whether this was

the same or different to those at Crown. Contemporary photos show outside framed

4-wheel locomotives, with a complete canopy roof and waist

high bodywork.

An advert for a Crown Mines E.C.C.

locomotive. From John Middleton's collection.

The locomotives were clearly a great success.

Hubert Davies soon built other

electric tramways including a line for the

Langlaagte Royal Gold Mining Company Limited which

used an identical locomotive to the ones in use in the Crown

Reef Gold Mine. It was in operation by 1896.

The 'British & South African Export Gazette'

for February 1897 stated that the Wemmer

Gold Mining Company Limited had ordered an electric

locomotive from Hubert Davies

that was similar to those working in the Crown

Reef, and Langlaagte Estate Company's mines. It is

possible however, that the Langlaagte

Estate mentioned in the report should actually be Langlaagte Royal

which closed in November 1896. Its locomotive, being virtually new, was likely sold to

another mine.

The Transvaal Government Mining

Engineers report for 1897 stated that seven

electric locomotives were in use, which probably included

at least four by E.C.C. / Parker (The two at Crown Reef and

at least one each at Langlaagte and Wemmer). It

would be nice to know how many were actually exported to South

Africa.

|

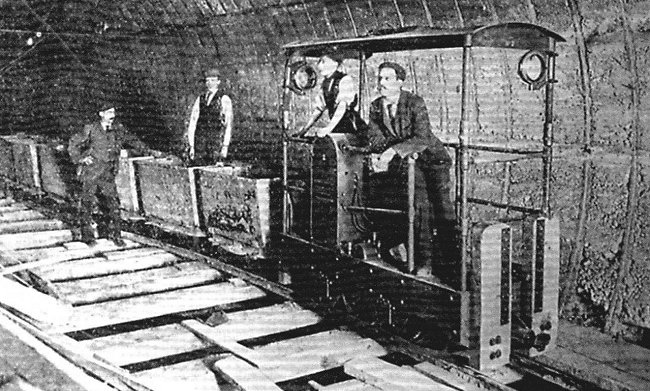

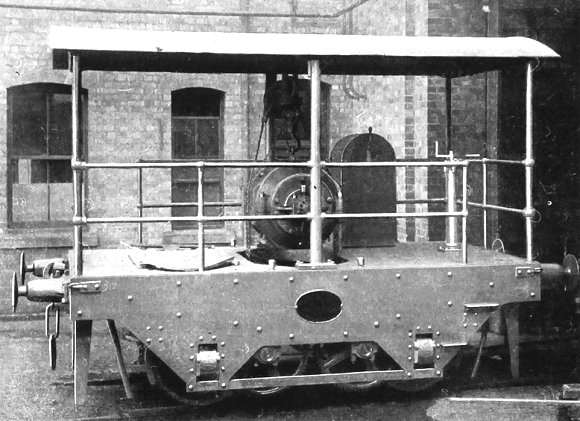

A Thomas Parker Locomotive in

the workshop: 'Cassiers Electric Railway 1899'. From

the collection

of Chris West.

|

The photograph opposite is from

'Cassier's Electric Railway' from

1899 and is captioned 'A locomotive built for the

South African Gold Fields by Messrs Thos. Parker

Ltd., Wolverhampton, England'.

The picture is in an

article titled 'The Electric Locomotive' by George R. Mair. Unfortunately Mair does not give his sources.

The builder's plate carries the

name Thomas Parker Limited at the top, with Wolverhampton at the

bottom. |

| The following text from Mair's article may be of

interest: The position of

the electric locomotive amongst the general mining

apparatus is illustrated in the South Africa gold

fields. The discovery of these fields is so recent

that the equipments for working them naturally

afford examples of the highest development in the

special class of machinery required. In one of the

first systems of mechanical haulage on the Rand

electric power was adopted. Two locomotives of

British make were installed at the Village Main Reef

Mine, where they have been in operation for a number

of years. While these machines are not used for

underground service, their general construction is

of the character employed for mine locomotives, and

the results shown have been so excellent in this,

the first plant in the Johannesburg district, as to

warrant the belief that in the near future the

electric system will be generally adopted on the

Rand.

It is possible that Mair is referring to the

Wemmer locomotives which ran through the Village Main

property. It is quite possible that the photo of

the Thomas Parker locomotive might be the Wemmer

locomotive of 1897 or another, yet to be identified.

Other Locomotives

A Thomas Parker locomotive

was supplied to Broken Hill Proprietary in Australia in

1902. It has a similar frame to the South

African locomotives, which is a distinguishing feature of Parker locomotives, as was the

large size and position of the builder's plate.

A number of standard gauge versions are known to

have been used in the UK and can be seen in photos

that appear in various

Industrial Railway Society publications.

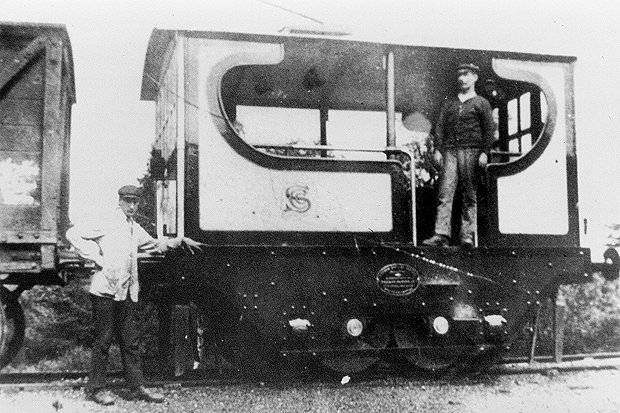

A standard gauge

locomotive

built by Thomas Parker around 1895. It

worked at Henry Bruce & Sons Limited, Kinleith Paper

Mills, Currie (off the Caledonian Railway's Balerno

Branch). It was scrapped in the mid 1960s.

Courtesy

of Richard Horne. |

|

From 'The Engineer',

27th January, 1899:

Contractors'

Electric Locomotive

Thomas Parker Limited,

Wolverhampton, Engineers

Contractors'

Electric Locomotives

Six contractors'

electric locomotives for the

Baker Street and Waterloo

Railway are being made by

Messrs. Thomas Parker, Limited,

of Wolverhampton. Our

illustrations show a general

view and details of these

locomotives. They have been

specially designed to meet the

conditions of Messrs. Burstall

and Monkhouse's specification,

which among other things

provides that the maximum width

overall should not exceed 3 ft.

The result has been that space

has had to be economised to the

utmost extent, and an extremely

handy locomotive produced.

No working parts

are uncovered, though all

portions of the machinery are

easy of access, and there is a

glass window over the commutator,

by means of which the behaviour

of the brushes can be observed.

The current will be obtained

from an overhead wire, from

which it will be collected by a

long contact roller bar, instead

of the

more usual grooved wheel, thus

permitting of a greater sideway

deviation of the conductor wire

without fear of breaking

contact. The wire conveying the

current to the switch passes

down from the roof of the

vehicle through one of the

upright tubes placed at each

corner of the footboard.

Each locomotive

is fitted with a series motor,

the armature of which is wound

with Messrs. Parker's patented

Eickemeyer coils, and connected

by double helical gearing to

both the axles. The locomotive

develops 15 to 20 brake

horsepower when supplied with

current at an electromotive

force of 200 volts, and it is

designed to run at ten miles an

hour on a level track. The gauge

of the rails is 18in. The

starting and reversing motions

are controlled by one handle.

This handle works a throw-over

reversing switch, fixed at the

top of an enclosed box, and is

also geared to a resistance

switch, the contacts of which

are connected to resistance

coils of platinoid inside the

box.

A light iron

detachable canopy or roof is

fitted so that it can be taken

off in case it is required to

pass the locomotive through a

small opening. The motors are

entirely enclosed in the frame

of the locomotive, to protect

them from dust and wet. Lamps,

efficient brake and sand boxes,

together with buffers which form

part of the

drawbars, render these

locomotives complete in every

detail. A dimensioned outline

plan and elevation of the

locomotive are given, and the

view above represents the

locomotive in working order. It

will be noticed on reference to

these illustrations that the

arrangement is very compact, and

that the driving is intended to

always be from one end of the

locomotive, the controlling and

brake handles and the two sand

box levers being all accessible

from one place.

|

|

| |

|

One of the

locomotives in use during the

construction of the Bakerloo Line.

Courtesy of John

Browning. |

| |

|

From 'The Engineer',

31st May, 1901:

Standard Gauge Electric Locomotive

Thomas Parker Limited,

Wolverhampton, Engineers

The accompanying illustration

represents a new electric locomotive

recently designed and built for

Lowdon Brothers and Co., of Dundee,

by Thomas Parker, Limited, of

Wolverhampton. It is full gauge,

4ft. 8½

in., and is intended for hauling

trucks from the main line into a

goods siding. It is to be capable of

taking 45 tons up a gradient of 1 in

100 at about four or five miles an

hour, and lighter loads up the same

gradient at correspondingly higher

speeds up to a maximum of eight

miles an hour.

In general construction the

locomotive is very similar to that

made by the same firm for working in

the Waterloo and Baker Street

Railway tunnels, of course, it is on

a much larger scale. The smaller

locomotive we illustrated. The

present illustration shows how the

driving motor can be lifted from its

place for inspection or repair

without taking the locomotive under

a crane. In the roof there is a ring

fastened to one of the supports. To

this a set of pulley blocks can be

attached, and the motor raised by

means of an eye bolt on the top of

the casing. Ordinarily speaking, of

course, the motor is lowered down so

as to be in contact with the gear

wheels, and is, in fact, below the

footboard, and the hole covered in

with chequer plates.

The motor is of the 4-pole enclosed

ironclad type, with carbon brushes.

The armature is wound with

Eickemeyer coils, as are all the

machines made by this firm. The

magnet yoke and the cover are cast

together, with the joint on the

horizontal diameter. The motor

develops from 40 to 50 brake

horsepower when supplied with

current at 200 volts. It is made

both water and dust proof, but lids

are arranged so that access may be

obtained to the brushes. As will be

seen, the general design is quite

simple. There are two buffers

instead of the single buffer of the

earlier and small locomotive already

referred to. There are also sand

boxes and powerful brakes. Hooks are

provided at the four corners for

rope traction. The frame proper is

built up of a heavy cast iron body,

with bearings for the countershafts

cast on the underside. The bearings

are provided with loose caps. On the

cast 1ron body are bolted rolled

steel plates,

¾

in. thick carrying cast steel

hornblocks for the axle boxes. The

gear is double reduction with two

countershafts. The motor gears at

each end of the spindle into these

countershafts which are on the same

horizontal line as the centre line

of the axles so that the moving of

the locomotive on the springs does

not affect the teeth which are in

gear with the axle gearwheels. The

diagram below shows the arrangement

and size of the wheels.

The controlling gear is placed in a

box at one side and fastened to the

hand railing. The starting,

stopping, regulating and reversing

switches are all operated by one

handle. Quite near by is the brake

handle so that both are within easy

reach of one driver. The complete

weight of the whole locomotive is 12½

tons. The current is collected by a

trolley arm, which does not appear

on the engraving. An ordinary

tramcar trolley base is fixed on the

locomotive footplate and rises

through a hole in the roof.

|

|

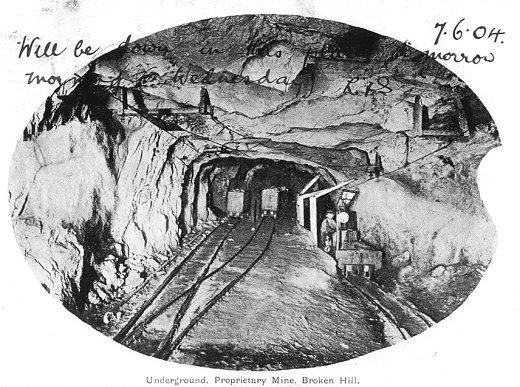

Locomotives in Australia

The following

reports from various newspapers were sent to John

Middleton by John Browning of Brisbane. They tell

the story of the installation at

Broken Hill

Proprietary Mine, New South Wales.

|

The

Barrier Miner, Saturday 25th January, 1902

THE B. H. PROPRIETARY

Electric Trains Underground.

ARRANGEMENTS are now proceeding for the introduction of

electric tramways underground at the 650ft. in place of the

present horse traction, and for this purpose an engine and

dynamo are being installed on the mine. The cables are now

being laid, and operations will be started in a few weeks.

At present 52 horses are being used for truck work at the

300ft. and other levels to the 650ft, and these are being

sent up and down every shift, each horse working eight hours

daily. Provided the new system proves a success at the

650ft., it will also be extended to the other levels. Mr.

O'Neill, of J. A. Newton and Co., Melbourne, is

superintending the installment.

|

|

|

The Barrier Miner, Thursday 6th

February, 1902

THE B.H. PROPRIETARY

The Electric Installation.

IN connection with the electric traction at the Broken Hill

Proprietary's 650ft. level, the overhead trolley wire is

laid, and men are now making copper connections across the

fishplates, with the object of reducing the resistance of

the rails which carry the return current.

Driving is proceeding at the 650ft., and the connections at

that level should be made in five or six weeks.

The electric locomotive specially built for the company by

Thomas Parker and Co., Limited, Wolverhampton, to suit the

undulations underground has arrived on the mine. It is of 15

h.p., and is capable of hauling 25 tons at a speed of five

miles an hour. It is understood that pending the completion

of the 650ft. drive this locomotive will be run on the dump

in place of horses to take out tailings.

|

|

|

The Advertiser, Monday 17th

February, 1902

BROKEN HILL, February, 16

Some interest was taken on Saturday in the trial run of the

electric motor, which is at work at the Proprietary mine's

principal dump. The result was most satisfactory, the motor

drawing eight full trucks of tailings with ease. It is

expected that next week the system will be in full working

order.

|

|

|

The Barrier Miner, Wednesday 26th

February, 1902

The Broken Hill Proprietary

New Processes and Economies

The electric locomotive is now regularly removing tailings

from the old mill, and has drawn at one time as many as 16

loaded trucks. This locomotive is capable of doing the

traction work of both mills if wiring was laid; as it is, it

does away with the services of eight or nine horses.

The connections have been made at the 650ft. level, between

McBryde and Patterson shafts, and also with Patterson and

Delprat shafts, thus making through communication from

Delprat shaft to Block 11. A station plat will be excavated

at Stewart shaft, and when this is done the work of laying

the electric traction and cables and bonding the rails will

be completed.

|

|

|

The

Barrier Miner, Tuesday 11th March, 1902

The Broken

Hill Proprietary.

The installation of the electric traction plant at the 650ft

at the Proprietary will be completed on Saturday next. The

length of line laid is about 2500ft., giving communication

with Delprat and McBryde shafts and the workings on the

south boundary of Block 11.

The electric

locomotive which has been running lately on day shift with

tailings from the Proprietary's old mill on a trial of

strength yesterday evening took out 25 full trucks. From

appearance it could readily draw from 30 to 35 trucks if

required.

|

|

|

The Register, Wednesday 19th March, 1902

BROKEN HILL

March 18. The electric locomotive had a trial

run yesterday at the 650 level on the Proprietary. It travelled from McBride's to Patterson's and then on to

Delprat's shaft. Although the track was not quite completed

it ran very satisfactorily. Afterwards it conveyed a rake of

twenty full trucks at the rate of five miles an hour from

McBryde's to Delprat shaft, returning with empties. Mr. T.

Mars, a local electrician, supervised this installation for

Newton and Co., electrical engineers, of Melbourne.

|

|

The Thomas Parker locomotive

at

Broken Hill Proprietary. Courtesy of Richard Horne.

|

The

Barrier Miner, Wednesday 14th May, 1902

ELECTRIC TRACTION UNDERGROUND.

The electric traction plant lately installed at the 640ft.

will this week be put into regular service and will run over

approximately 5500ft. of track already laid, including cross

cuts extending from Delprat shaft to nearly as far as Block

10 boundary. The plant comprises a small electric

locomotive, developing about 15 h.p and on a level track

runs at about eight to 10 miles an hour. Its maximum width

is 3ft., the working parts being all covered over, but easy

to get at. The motive power is obtained from a continuous

generator at 220 to 240 volts, put down for this purpose,

developing a power sufficient to supply two or three locos

of the same size. It can easily handle 20 trucks or more, if

wanted, whilst one horse could not conveniently draw more

than five or six full trucks. Should this principle be

extended throughout the mine, on surface and

underground, and this is more than probable, although it is

too early yet to compare cost with that of horse traction, it

would throw over 100 horses out of service, and would

relieve the workings of the trouble and many disadvantages

of animal traction. About 15 horses are employed below

surface each shift, and these have to be caged up and down

at every change, which entails considerable expense and loss

of time, beside which they make a mess of the track ; and

unless the ventilation is complete they foul the air.

Mr. F. Mars, engineer and part proprietor of the local

Electric Light and Power Station, who supervised the

installation of the Proprietary's plant, supplies some

details of the work. He explains that the current at 220

volts is collected from an overhead trolley wire by a roller

rubbing contact, which allows ample sideway deviation on the

trolley wire for any irregularities of the track. The track

gauge is 18in. The rails weigh about 24lb. per yard, and one

rail of the track is electrically bonded throughout and used

as the return circuit. Bonds of 7-14 S. W. G. cable 15in.

long, the ends being sweated into ½in. brass thimbles, are

fitted into holes drilled in the rails at each end of the

fish- plates and expanded tightly therein. The trolley wire

is suspended 6 ft. 9in. from the rails by insulated

"hangers" sweated on to the wire and bolted to Oregon pegs

driven into holes drilled in the crown rock of the drives.

The hangers are spaced 20ft. apart on the straight track,

and 6ft. to 8ft. apart at the crosscuts and curves; both the

trolley wire and rails are fed from the generator (on the

surface) down 650ft. of shaft by 19-14 S. W. G. cable,

which is of ample size at present. The overhead wire has

switches arranged at each crosscut leading into the ore

faces, to enable these sections to be cut out of circuit in

case of damage caused when shooting down the ore, otherwise

the

whole track would be unworkable until repairs could be

effected. The whole of the plant for this installation has

been supplied from Messrs. Thomas Parker, Limited, of

Wolverhampton (England), by Messrs. J. and A. Newton, of

Melbourne. |

|

|

The

Barrier Miner, Saturday 17th January, 1903

Electric Traction Underground.

For about nine months the Broken Hill Proprietary has been

using electric traction in the place of horses at the 650ft.

It was, however, found that the locomotive used was

cumbersome, and there was at times some trouble in

negotiating the short drives and curves; so it was decided

to replace it

|

|

|

Kalgoorlie. The Western Argus, Tuesday 19th January, 1904

The electric locomotive of 15 h.p. has been removed from the

600ft. level, where it has been working for some time, to

the surface, at the Broken Hill Proprietary, where it is now

taking the place of horses. Recently it started with a rake

of from 20 to 25 trucks, and has been found to answer

admirably.

|

|

|

Sydney Morning Herald, Monday 8th February, 1904

The electric motor continues to work satisfactorily

resulting in considerable economy, many horses having been

displaced by the motor.

|

|

Mines are dangerous places, and people do

occasionally get hurt. The following

newspaper reports are of accidents involving

the Thomas Parker locomotive.

|

|

The Advertiser, Wednesday 18th February, 1903

BROKEN HILL, February 17

Thomas Matheson had a peculiar experience at the Proprietary

mine last night. Just before the afternoon shift knocked off

he was carrying some steel bars along a drive at the 640-ft.

level on block 11, when his burden came into contact with an

electric wire. Matheson received a severe shock, which

prostrated him for some time, but afterwards he appeared

sufficiently recovered to go home when the shift knocked

off. After reaching the surface he was again overcome by the

effects of the shock, and was removed to the hospital.

|

|

|

The

Barrier Miner, Sunday 30th April, 1905

ACCIDENTS

Charles Partridge, employed on the Proprietary mine, was

working on the dumps on Saturday evening when he caught hold

of a live electric wire and received a bad shock. Three of

his fingers were severely burnt. Partridge was removed to

the Hospital in the ambulance. |

|

|

The

Barrier Miner, Monday 6th March, 1908

MINE ACCIDENTS.

At about 6 o'clock last night William Gourlay, a motor boy

employed on the electric motor at the Proprietary mine, fell

off the motor and had his ankle badly crushed by the trucks. Gourlay, who is 17 years old, was conveyed to the Hospital.

|

|

|

The

Barrier Miner, Friday 10th March, 1908

MINE ACCIDENT.

At about 6.30 last night T. B. Radbone, a motor boy at the

Proprietary mine had his leg broken through being run over

by the motor. Radbone, who is 19 years old, was working on

the electric motor drawing trucks out over the dump. He

jumped off the motor and fell, und it passed over his leg,

which was broken just above the knee.

|

|

|

A final view of the Thomas Parker

locomotive. Courtesy of Richard Horne.

| A Thomas Parker

locomotive that worked on the Cheddleton

Hospital Railway in Staffordshire. Courtesy of

Mark Cornwell. |

|

|

I must thank John Middleton for supplying the

fascinating information about the Parker locomotives. If you have

any other information about the locomotives, or can add to this

section, please send me an email.

Anything you can add will be most welcome.

|

|

|

Return to the

previous page |

|

Read about

Thomas Parker |

|

|