|

It has often been wondered why Enoch Tonks & Sons never made

padlocks. The reason was that Enoch Tonks (born 1827) started

making padlocks when he was nine, for twelve hours a day and,

after a few years, was apprenticed to padlock making and then,

when out of his time, vowed he would not make padlocks again.

So he left the padlock trade and started himself making rim

locks.

Soon his father George (born c1801) and brothers joined him,

and so started the firm in 1877 at Bloxwich Road, making rim

locks which were sold in Wolverhampton and Birmingham, being

sent there each week and the money for them collected each

Saturday to pay the wages. Having made some progress the firm

was moved to Temple Bar, where two houses were bought with a

small shop, later the spring shop, with a second floor over it

which was used as an office and warehouse. |

| A wooden shop was built from this to where the polishing shop

would later stand, in which worked about ten men with a few hand presses

and a pair of shears. Then another wooden shop was built backing

on to this one and, after a short time, a large press was bought with a

12ft swage, which enabled the firm to blank and raise pressed steel lock

cases for mortice and rim locks. (This would have been similar to the

one that can be seen in the Locksmith's House). |

|

|

This press was operated by two persons running round

about ¾ of a circle to get up enough speed and pressure to blank the

case, then walking back and repeating the process. This was the

start of steel case locks which, being easier and cheaper to produce,

commanded more trade and enabled the business to expand. So more

land at the back was bought, reaching as far as Cemetery Road. A steam

engine was then fitted and a large shop erected, and power presses

bought, and everyone had to do what they could. |

|

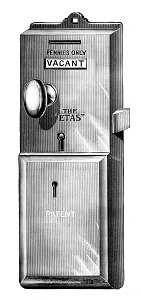

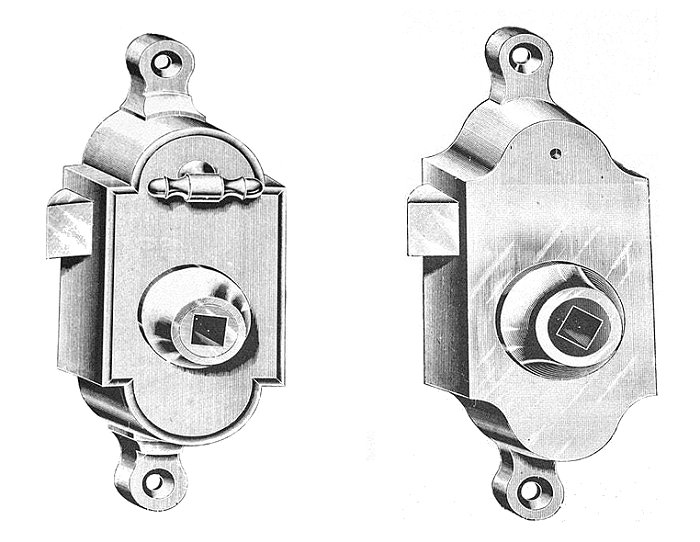

A lock for public lavatories. |

Enoch was a member of Little London Baptist Church

in Willenhall and was baptised there in 1853. He resigned his

membership in 1863 but rejoined again in 1888.

He died on the 14th

March 1897 and was buried in the grounds of Little London Church

along with his wife Lydia who died on the 25th May

1893 age 63. His sons Arthur George, Charles William and

Enoch continued to run the business and in 1899 presented an

organ to Little London Baptist Church in memory of their father

One of the sons remembers being given a hammer and

chisel and working all Saturdays and Sunday’s chipping scale from inside

the boiler. In 1898 the wrought steel action for mortice and rim locks

Number 8604 was patented.

This enabled the company to improve the

manufacture and with cheaper production of many mortice and rim locks,

helped considerably to increase the trade of the firm, whose customers

were now to be found in most towns of England, Scotland and Ireland. The locks made with this action found a ready sale,

and some of the numbers are well remembered by the workpeople, 604, 860,

626, 487, etc. And so, with this progress, a gas engine was

purchased and was in what was later the tool room. Brass casting shops

were built for the firm to do their own casting.

Still making progress a piece of land was bought at

the back of the large shop and the first four bays of the machine shop

erected, and the gas engine moved and another one bought to cope with

the increasing trade. Then, after the fire in 1914 which gutted the

machine shop and nearly overwhelmed the works, the machine shop was

re-built and enlarged and electric motors fitted to replace the gas

engines.

|

|

This ETAS lock for

public lavatories came with instructive brass plates for the

inside and outside of the doors.

Locks such as these gave

rise to the British euphemism "spend a penny".

Most were removed during

the 1960s and 70s, though seaside resorts often kept them

because the daily takings gave a good indication of the number

of visitors to the resort. |

|

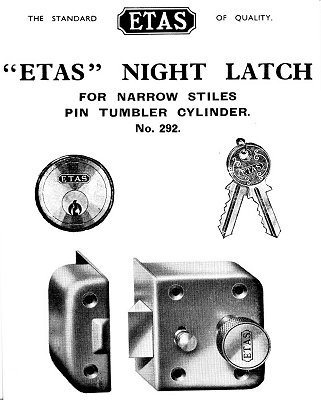

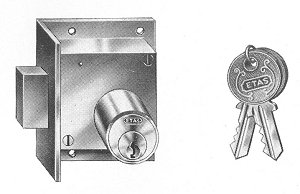

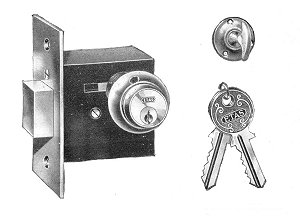

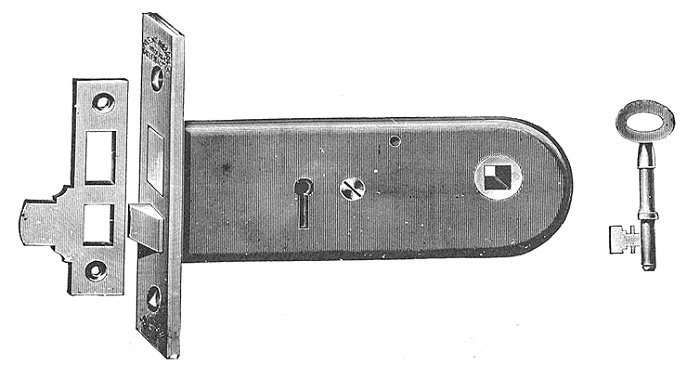

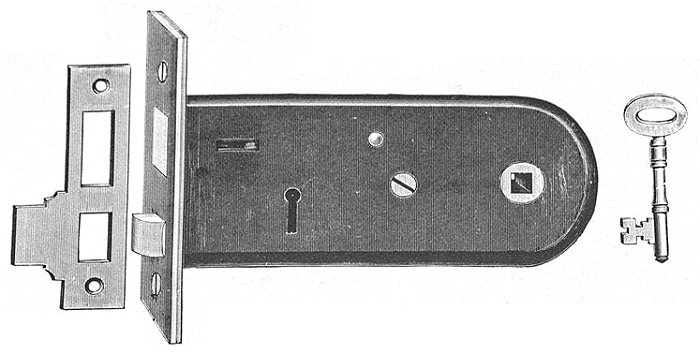

An ETAS Japanned centre-bit mortise lock.

An ETAS Japanned steel case mortise lock.

ETAS shop door latches.

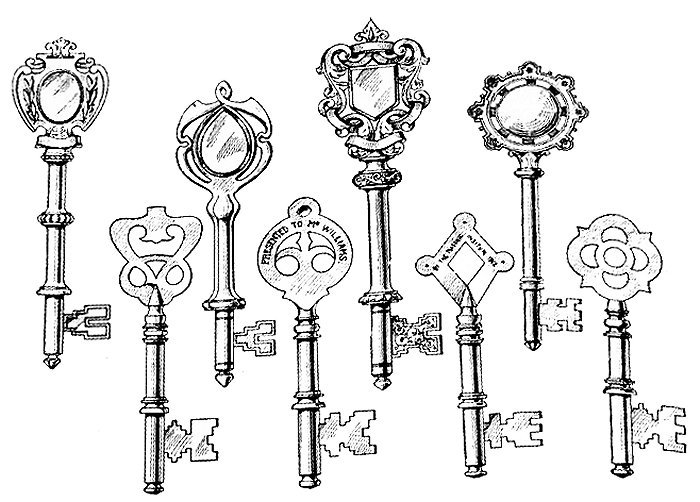

Presentation Keys.

About the same time the firm started making all kinds

of builders brass foundry, which meant a development of the polishing

and plating shop. Next they made brass iron cabinet locks and knocked

down the four small houses at the front of the works for this

department. In 1921 they became a limited company and started to

make cylinder locks and soon had to increase the cylinder latch and lock

department. With all this increased output the old fashioned varnish

stoves could not cope with the work, so a conveyor varnishing plant was

installed and also, as time passed along, new improvements were made in

all departments and range of manufacturers had been increased in all

departments, such as penny-in-slot locks, shop door locks, etc.

The goods now became well known in all quarters of the globe as reliable

and of the best quality and this enabled them to guarantee, because of

the loyalty and pride of workmanship, which has been instilled into the

employees and which they have loyally carried out.

|

E. Tonks & Sons Ltd. was a family business, all

partners and directors taking a personal interest, not only in the work

they produced but in all the employees, of which the greatest proof is

the length of service given.

The company was taken over by Yale and Towne Ltd in

1963 and by 1965 they had stopped making most of the range of ETAS

locks. The premises were demolished and replaced by a new die-casting

factory, for the Yale group. The ETAS locks they continued to make were

made in the Yale Wood Street factory but shortly afterwards they ceased

to make any of the ETAS range.

|

|

The die casting factory was demolished at the end of

2000 and residential properties erected on the site.

An advert for the ETAS trade mark.

From 'The Ironmonger', 1961. Courtesy of Trevor Dowson. |

The text of the Gazetteer entry above is as Jim Evans

wrote it in 2002. In February 2005, in Melbourne, Peter Hoyne

examined a lock which his maternal grandparents, Alfred and Fanny

Meachem, had brought with them to Australia when they emigrated from

Willenhall in 1926. The brass padlock, which is about 65mm wide

and 80mm long, is still in good working condition. It is

inscribed: "E. Tonks & Sons Willenhall" and "4 lever" with the

numerals 19, followed by two other numerals, of which the last may be 1

or 4.

|

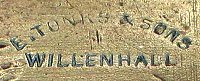

Peter Hoyne's padlock (photos by courtesy of Peter

Hoyne).

The inscription (right) can just be seen on the lock (left)

in a vertical position to the left of the keyhole. |

|

On reading the opening lines of this entry in the

Gazetteer, Peter says that he "became somewhat perplexed. Did my

Grandfather engineer an elaborate hoax which was only to be revealed

fifty years after his death; or did Enoch Tonks, even with his

strong distaste for padlocks, manufacture at least one inscribed with

his company name? Is this a padlock which Enoch Tonks disavowed?".

It seems to me that there might be many explanation

of what is going on here. The idea of Alfred Meachem making a hoax

lock and then not telling anyone, seems unlikely. It may be that

the locks were made by someone else for Tonks. It may be that it

was only in Enoch's time that his firm did not make padlocks. It

may be that the story Jim Evans had was only a legend.

All further information or suggestions would be very

welcome.

|

Return to the

list of makers |

|