|

Introduction

John Neave was

one of the last letterpress printers in the area. He had

been in business since 1949 and celebrated his 74th year

as a printer in 2023. He had many memories of long-gone

printing companies, including suppliers to the trade.

What follows is the story of one of his best suppliers,

Mr. William A. Parkes of Wolverhampton. This is based on

John’s memories of Mr. Parkes’ business, which was just

around the corner from John’s workshop. As a young lad

John would often cycle there to buy type and various

consumables for his business.

Background

Until the latter

part of the 20th century there were many

letterpress printing companies using the traditional

printer’s type. There were both large and small

printers, which produced much of the printed material

that was used locally. Everything was produced from

table place names, business cards, letterheads, forms,

advertising literature, and posters, through to books,

which were printed by the larger companies. We must also

remember that much of the printing ink was produced in

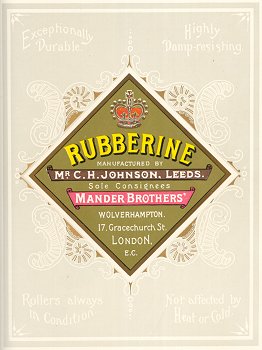

Wolverhampton by Manders. |

|

An advert for Mander's printing

inks. |

A look in the

old Red Books reveals a long list of local printers such

as Barford & Newitt, G.E. Lee, W. Gibbons, Alfred Hinde,

J. Mulliner, Paulton Bros., Steens Ltd., Whitehead

Bros., and many, many more. Printing was an important

industry, there were large numbers of local printers,

and like any other industry it required raw materials

and consumables.

A good stock of

type was essential for any printer. But there were times

when an urgent job would require an unusual font, an

extra large font size, or little used symbols, and so

access to a good reliable local type supplier could make

the difference between finishing the order on time, or

being late.

There were

several local suppliers in Wolverhampton and the

surrounding area who cast their own type, such as

Midland Creative Designs at 20 Queen Street,

Wolverhampton and Reliance Type Setting in Walsall, who

cast “Qualitype”. |

|

One of the best

type founders was William A. Parkes, of 56 Sutherland

Place, Wolverhampton. Unlike most of the others, he not

only cast his own type but also stocked an extensive

range of type and all of the local printer’s

consumables, except paper.

Beginnings

56 Sutherland

Place was the Parkes’ family home, opposite where the

back of the Royal Hospital is today, about half-way

along the modern car park. Until the end of the First

World War, William Parkes worked as a book keeper at the

Chillington Tool Company. Around the end of the war in

1918 he had a win on the football pools and decided to

set himself up in business. |

An impression of how Mr. Parkes' building

might have looked when it was first built. The houses in the

background are in Portland Place, which disappeared in the 1930s as

the Royal Hospital expanded.

| He purchased a large single

storey wooden building with a corrugated steel roof, and

it was erected diagonally opposite the family’s house in

Sutherland Place. The

building was between 40 and 50 feet wide, with two large

double doors on the front, and two rows of windows. It

occupied a site that had previously been used as a coal

yard. The interior was divided into two parts by a

partition, which separated the type foundry at the back

from the stock room and sales area at the front.

|

The approximate position of Mr.

Parkes' building. |

|

The front part

contained much of Mr. Parkes’ stock, stored on wooden

shelving. There were two wooden benches about 12ft.

long, one on either side of the room, with Mr. Parkes’

old desk in the centre. He would sit behind the desk on

an old wooden box with a piece of carpet on the top.

Heating was supplied by a coke stove, and when the

temperature fell, Mr. Parkes could often be found

warming himself by the fire. Mr. Parkes' wife Joan

constantly supplied the shop with hot tea and food from

their house across the road.

In the 1940s Mr. Parkes, his sons,

and a couple of cousins played snooker in the West

Midlands League as members of the Working Men's Club

team based in Cleveland Road. They represented the club

for a number of years, and were quite successful. When

opposing teams played them, they would say they were

playing the Parkes's. They won many prizes, and as a

result the women of the family never bought an iron,

because they were often given as prizes in the various

competitions.

The Business

He had three

sons, Archie, Bob, and Jack,

all of whom worked in the business for a time. For many

years the business sold type to Australia, which was

very lucrative. Unfortunately the Australian Government

increased their import duty to such an extent that

orders fell, and the business could no longer support

both sons. As a result one of them had to find work

elsewhere. Archie, the son who stayed at the business,

had many duties including casting type, casting rollers

for printing machines, and looking after the post. |

|

They had a large mail-order

business with customers from all over the country.

Each day Archie would go the main

post office in Lichfield Street to put the day’s orders

in the post. Every order would be neatly wrapped in

brown paper and tied up with string. |

|

|

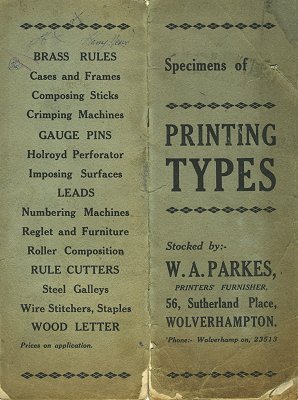

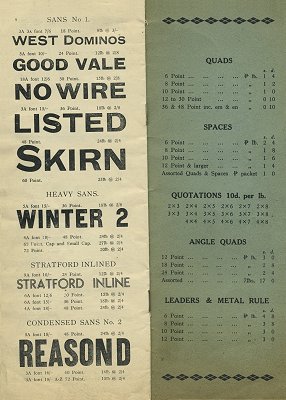

A

Parkes type catalogue. Courtesy of Stephen

Howard, Black Country Living Museum. |

|

|

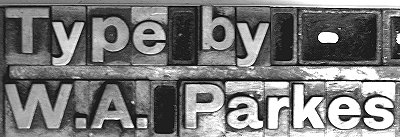

Some of Mr.

Parkes' type. |

|

| Mr. Parkes was an agent for type

founders Stephenson, Blake & Company, and kept a very

large stock of type from 6pt. to 72pt. in many different

fonts. |

|

More type from Mr. Parkes.

|

The type was wrapped in brown

paper and stored on the shelves in the front room. Some

of the older stock had been there since the 1920s.

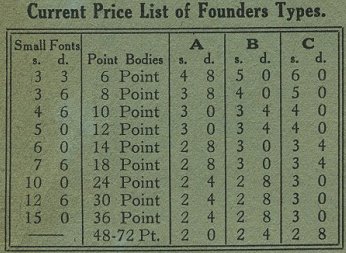

His prices were very competitive

and the type was extremely good value for money, a whole

font only costing between 3 shillings and seven

shillings and sixpence. |

A Parkes' price list. The A

and B

refer to different fonts and C is for symbols. |

| Mr. Parkes was also an agent for

Mander’s inks and sold most of the consumables that were

needed by the local trade, including brass rules, cases

and frames, composing sticks, crimping machines,

galleys, gauge pins, mallets, numbering machines,

perforators, planers, roller composition, rule cutters,

staples, tweezers, and wire stitchers. He was

well-known, and his customers came from all over the

Black Country.

Although Mr. Parkes always had a vast collection of type

in stock, he also produced his own. His type, cast in

the back room, became well known for its hard wearing

properties. He used Davies casting machines, which were

gas heated and hand operated. They cast type in a row of

single letters, which were dressed to remove any rough

edges, and planed on the back.

The casting

machines produced up to 5 letters a minute, and so were

very slow when compared with the high speed monotype

casting machines, which were commonly used at the time.

Mr. Parkes’ alloy however, was far superior to that used

in the monotype machines, due to its hard wearing

properties. He also produced at least one font of his

own, called Borghese, a very old style font, which was

designed by a professor of calligraphy at Nottingham

University. |

The Borghese Font.

| Mr. Parkes sold Mander’s roller

composition, which could be melted in a glue pot and

cast into replacement rollers for printing machines.

He also produced replacement rollers made from Mander’s

composition, which were very cheap and could be

purchased at almost the same price as the composition

itself, so they were well worth buying.

Archie used to melt the

composition in a glue pot that stood on a stand above a

coke fire. His rollers were popular and Archie could

often be seen casting rollers for some old platen

machine. |

An advert for

Mander’s roller composition. |

The small type of printing

machine that Mr. Parkes would sell. |

In order to supplement his

income, Mr. Parkes also sold second-hand printing

machines, and a few new machines that were made by

Taylors of Leicester. The

old machines were usually purchased very cheaply from

printers that had gone out of business. He kept a lot of

machines in stock, mainly old Cropper machines or Arab

platens, some of which were treadle operated and had a

flywheel.

The machines could be quite large,

in sizes such as Foolscap Folio (13” x 8”), or Crown

Folio (15” x 10”). Many of the machines dated from

around 1900 and a lot were exported to Africa. |

|

The End

William Parkes

died in the late 1950s when he was well into his 80s. He

never retired, and had worked hard for many years, for

little money, in a demanding, laborious, and highly

skilled job. After William's death Archie ran the

business single-handed. His brother Bob is believed to

have got a job at Chillington Works, where he died of a

heart attack at the age of around 40. Jack moved to Ever

Ready in Lower Walsall Street where he operated a lathe.

He finished his working life at Lucas Aerospace at

Fordhouses and lived into his seventies, dying due to

complications from Emphacemia.

During most of

his time in the business Archie lived in Whitmore Reans

and used to cycle to and from work. Sadly his wife died

young and he eventually moved back to Sutherland Place,

living in a house opposite the premises. The business

started to slow down during the war years, and was later

affected by the emergence of offset litho printing which

soon dominated the industry and took over from

traditional letterpress.

Over the years

the Royal Hospital had greatly expanded, and in the

early 1960s it was decided that a new Accident and

Emergency Department would be built. Land for the new

department, including that occupied by Mr. Parkes, was

acquired in about 1964, two years before the completion

of the project. Archie sold the printing business to

Raymond Jones of Tipton and the building soon

disappeared.

When the

business closed, Archie went to see John Neave to ask if

he could have a job. Sadly John had to refuse because he

was still getting established himself. Luckily Archie

managed to find a job with an engineering firm in

Sharrock Street and worked there for around two years.

I would like to thank Ian Parkes

for his help in producing this section.

If anyone can add to the story, or

has a photograph of Mr. Parkes, or his building, please

contact the

webmaster. |

|

Return to

the

Printing Hall |

|