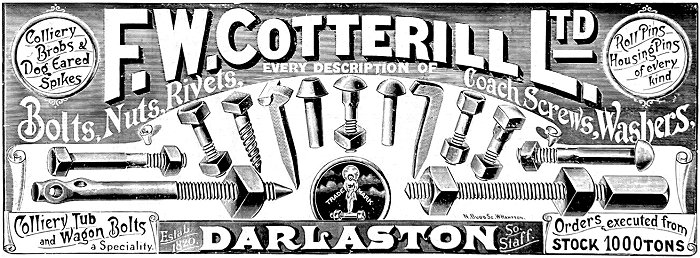

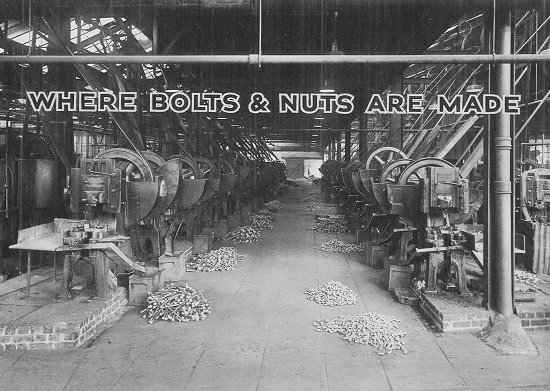

| Darlaston was well known for its nut and bolt

manufacturers, most of which have long disappeared.

One of the largest and longest surviving of them was

F. W. Cotterill, later to become part of G.K.N. The

company was founded by Alexander Cotterill between

1800 and 1810, and by 1818 he was listed as a tool maker

at Butt Croft Works. His son Frederick took over and the

company rapidly grew in size, utilising the latest

powered machinery. |

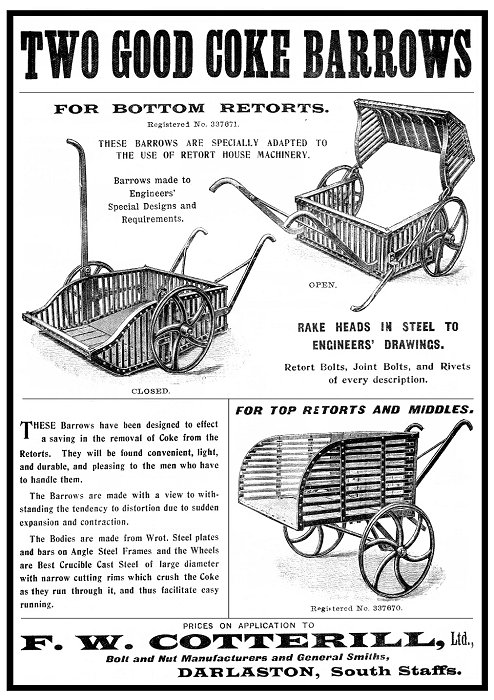

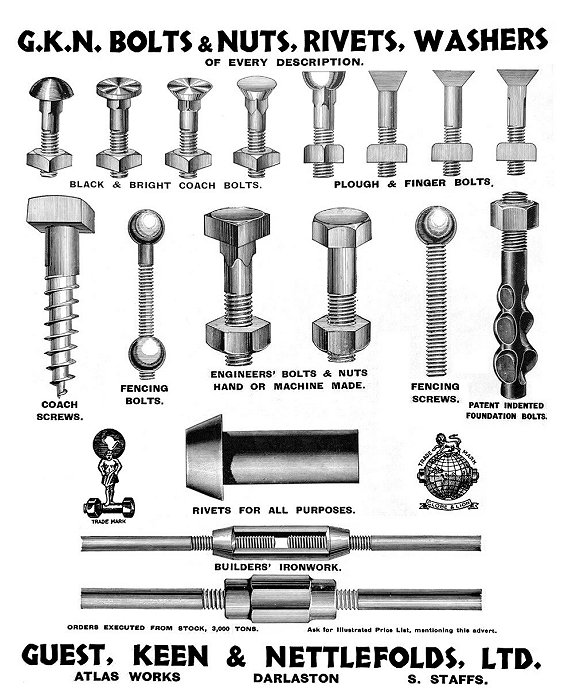

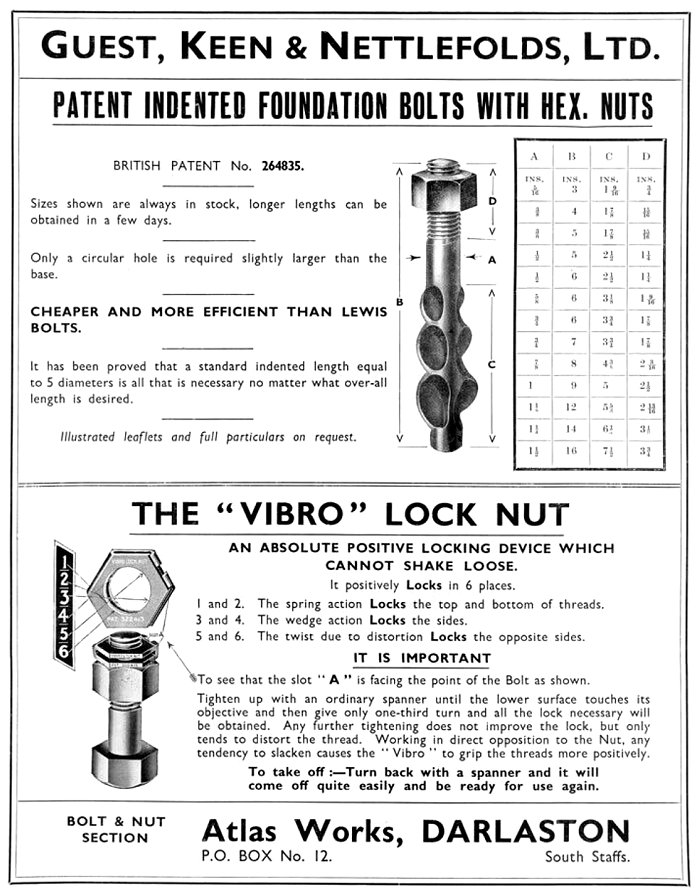

An advert from 1922. |

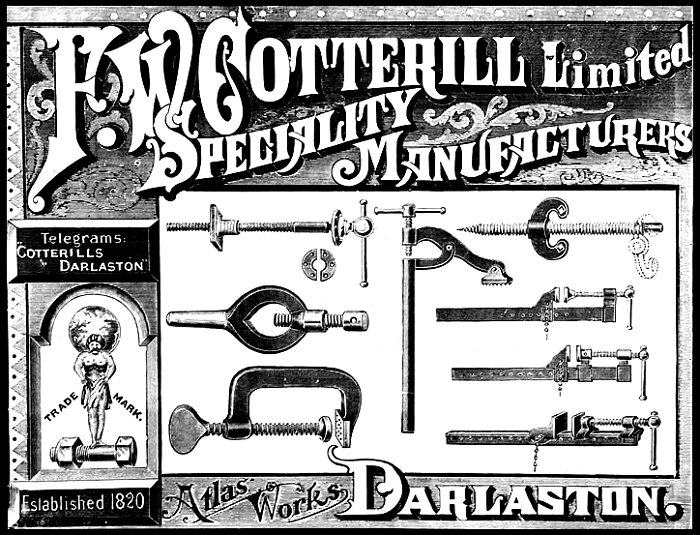

An advert from 1896.

Cotterills

produced many products including the

coke barrows seen in the advert

above, from 1899. |

By 1850 they were making nuts and bolts and in

the early 1860s they were also manufacturing

machines. In 1874 the company moved to its Station Street

site and the Atlas Works were built. The company's

trade mark depicted Atlas standing on a nut and bolt

while holding the world on his shoulders.

The 1870s

were not good years for the company due to a bolt

forger's strike and a recession. In order to make

the manufacturing processes less labour intensive,

many automatic machines were installed.

In 1880 the business became a private limited

company and in 1900 Tom S. Peacock, who joined

Cotterills as Company Secretary in 1892, became the

new Managing Director. He had been General Manager

since 1893.

|

|

An advert

from 1895. |

An advert from

1908.

An advert from

1916.

|

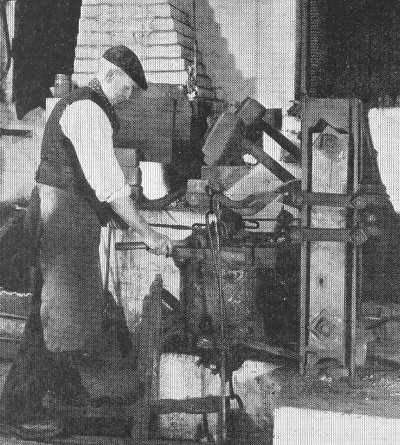

The early

days.

A

treadle-operated 'Oliver' bolt forging

machine in operation.

From the 1948

catalogue. |

|

| The company purchased the

forging works of John Garrington and Sons in 1912 and in August,

1919 the whole concern was taken over by G.K.N. The

business went through difficult

times during the recession after

World War 1 and took some time to

recover. In October 1921

Peacock reported that the company had a scarcity of

orders and was in a price-cutting war which led to

heavy losses. In order to ensure the future of Atlas

Works, G.K.N. took over the neighbouring Vulcan

Works, run by

Jabez Yardley and Company, to extend the screwing shop.

The company also

decided to take-over and control some of the major

competitors in Darlaston to gain control on

manufacturing and pricing.

As a result, in 1923 G.K.N.

purchased the Alma Works of Horton & Son, the

Britannia Works of Enoch Wilkes & Company, and the

Acorn Works of James Simpson & Sons (the last two of

which closed during the recession in 1929 to 1930). |

|

Details of the 1923 acquisitions:

The three companies went into

voluntary liquidation in the summer

of 1923, and by October 1923 had

been acquired by G.K.N. The

liquidator was Albert Enoch Horton

of Alma Works. |

An advert from 1884.

An advert from 1861.

An advert from 1884.

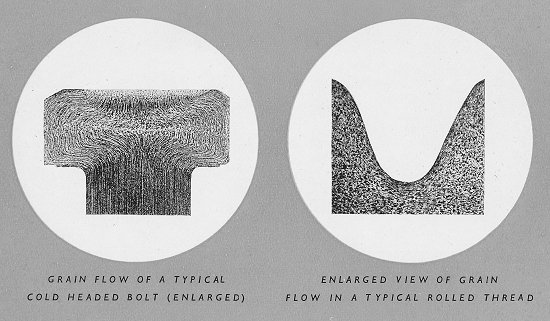

| One of the reasons that

Darlaston's nut and bolt

manufacturers were so successful was

a high degree of mechanisation.

Horton & Son Limited developed some

of their own machinery which greatly

improved the manufacturing process.

The machines allowed vast numbers of

nuts and bolts to be produced

quickly and cheaply, and also

ensured a greater uniformity in the

size and shape of blanks, reducing

the amount of scrap and waste metal,

and increasing the life of tools. On

26th November, 1903 the company

took-out a patent for an improved

machine to manufacture nut blanks.

It consisted of a vertical die

plate, into which a heated bar of

iron or steel was fed, and worked-on

by cam-operated tools. Two hollow

punches, acting in conjunction with

a die, fashioned the nut blank,

which was then cut-off, and fed out

of the machine. |

Horton's improved

machine for making nut blanks.

| Enoch Horton had been designing

machinery for producing nuts and

bolts for many years. In 1861 he

produced the machine shown below,

which is fully described in the

edition of 'The Engineer' dated 26th

April, 1861. |

|

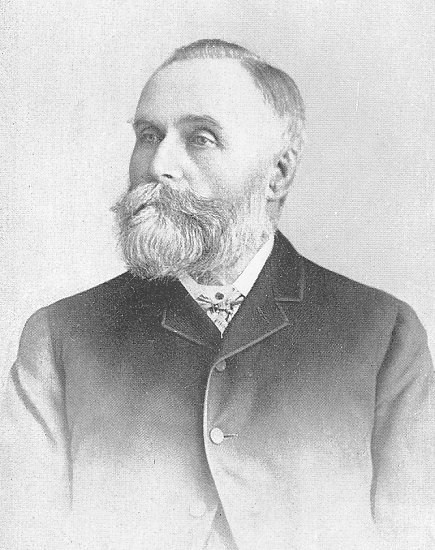

Enoch Horton,

J.P. |

Enoch Horton was

born in Darlaston on 10th April 1829

and educated locally. His mother

died at an early age, and so Enoch

started work at the age of seven,

making waxed hemp threads for

shoemakers.

Over the next ten

years he had a variety of jobs. For

about five years he worked at

Darlaston Green Ironworks, owned by

Samuel Mills, then becoming a

bellows blower for a local gunlock

maker, and later finding employment at a foundry in Spring

Vale.

At the age of

seventeen he became a nut and bolt

forger working with an Oliver, and

in 1849 entered into partnership with his

father, and they started business in

Bell Street.

The venture was so

successful that a larger factory was

soon acquired, and so in 1852 the Old Alma

Works were converted from a

wire-drawing mill into a nut and

bolt factory. |

| The

partnership with his father ended,

on his father's retirement in

1864, and in 1870 work began on the

first part of New Alma Works in

Station Street. The business grew to

become one of the largest

manufacturers in the trade. In

addition to being managing director

and sole proprietor of Messrs.

Horton & Son, Limited, Mr. Horton

became sole proprietor of Messrs.

Enoch Wilkes & Company, Britannia

Works, Darlaston, and also for over

thirty years, manufactured bricks.

New Alma Works was extended to join New Britannia Works,

and by

the early years of the twentieth

century, the firm employed over 600

people.

He was a director of a number of

local companies, and became a member

of Darlaston Local Board, and

succeeded Mr. James Slater as

chairman. On the formation of the

District Council, Mr. Horton was

elected a member, and retained his

seat until the time of his death,

twice becoming chairman.

He was a

member of the School Board

throughout the whole of its

existence, and was chairman for

twelve years. He was also a member

of Staffordshire County Council,

defeating Mr. J. Yardley in a

memorable election to fill the

vacancy caused by the death of Mr.

James Slater.

|

An advert from

1900. |

|

Mr. Horton was also a County

magistrate, and an ardent Liberal.

He was a Wesleyan Methodist, and

gave many thousands of pounds to the

cause. He was also largely

instrumental in the erection of

Pleck Methodist Church, giving and

collecting £2,000 for the building,

and erecting, at his own cost, a

handsome choir vestry.

Enoch became a wealthy man, and

acquired Bescot Grange which was

opposite Bescot Hall, the home of

James Slater. He was also Chairman of the West Gloucester

Water Company, a member of

the Institute of Mechanical

Engineers, and a member of the Iron

and Steel Institute.

In the latter part of his life he

suffered from heart

problems, and died at Bescot Grange

at the age of 76, on the evening of

Monday 15th May, 1905 after an attack of

pneumonia . Shortly before

his death, a fund was set up pay for

a portrait in oils, which would be

presented to him in recognition of

his long public service. The sum of

£385 was quickly raised. When he

died he left behind an estate valued

at £160,808. |

|

|

|

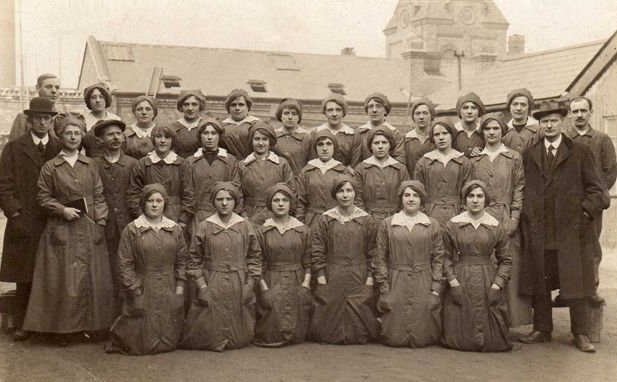

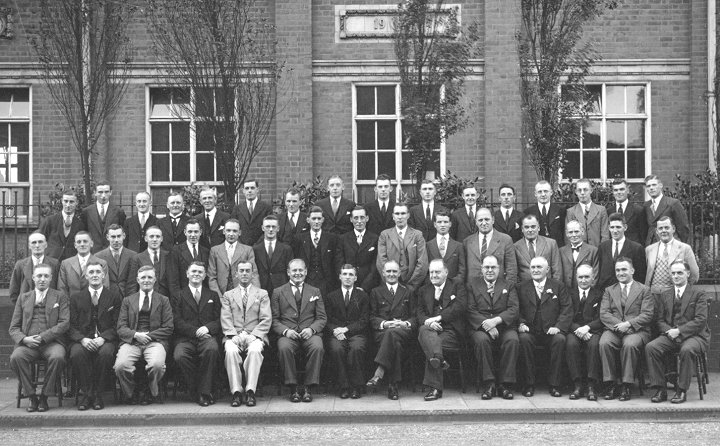

Some of the staff at

Horton & Son's Alma Works in about 1910.

Courtesy of Irene Bishop. Irene's grandmother

Sarah Ann Smith is 3rd from the left in the back

row, and her sister Florence Norwood is on the

extreme right of the front row, kneeling.

Horton's Managing Director was Leonard Wilson

Horton. |

|

| Sarah Ann Smith who

is in the photograph above. Courtesy of Irene Bishop. |

|

|

|

Unfortunately even after all these measures

were taken G.K.N. still continued to record

losses in their nut and bolt factories and so

Tom Peacock decided to allow competition, to

eliminate surplus capacity through the

bankruptcy of weaker producers. The G.K.N. Board

gave him full control of the nut and bolt and

railway fastening departments of the Midlands

and Cwmbran so that he could make drastic

changes where necessary and close any

loss-making factories. As part of the

reorganisation, individual company names were

abandoned and every factory traded under the

Guest, Keen and Nettlefolds' name. The

head office of the nuts, bolts and fastenings

division would be at Atlas Works and a new

warehouse was built there at a cost of £40,000.

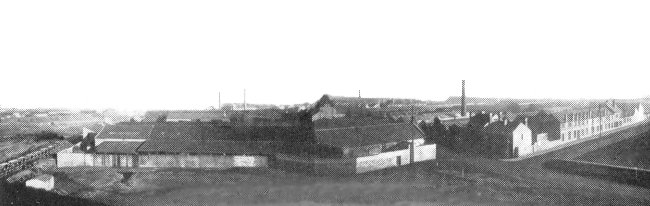

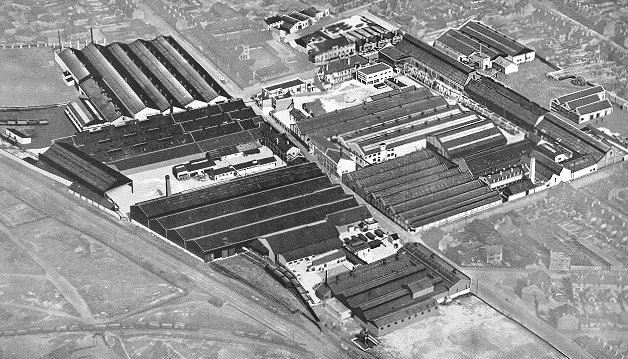

View

some of the company's products

from 1926 |

|

|

Atlas Works in 1926.

| Tom Peacock also recommended that in the future

steel should be purchased from the cheapest

source, rather than from G.K.N. steelworks.

In

the early 1920s the Darlaston Steel & Iron

Company had been acquired by G.K.N. from Tolley,

Sons and Bostock in order to gain control of the

source of raw materials.

The works was very old

fashioned and of limited size and so

difficulties arose in competing with the larger

companies. As a result Tom Peacock recommended its

temporary closure. |

The offices. |

|

The canteen and works

institute. |

Tom Peacock also closed the

London Works at Smethwick and its manufacturing

capacity was transferred to Atlas Works. Numbers

of staff were also reduced by making

long-serving employees redundant.

By 1925 Tolley, Sons and Bostock at Darlaston Steel and

Iron Works took over the company's puddling and

rolling operations in order to reduce transport

costs. |

|

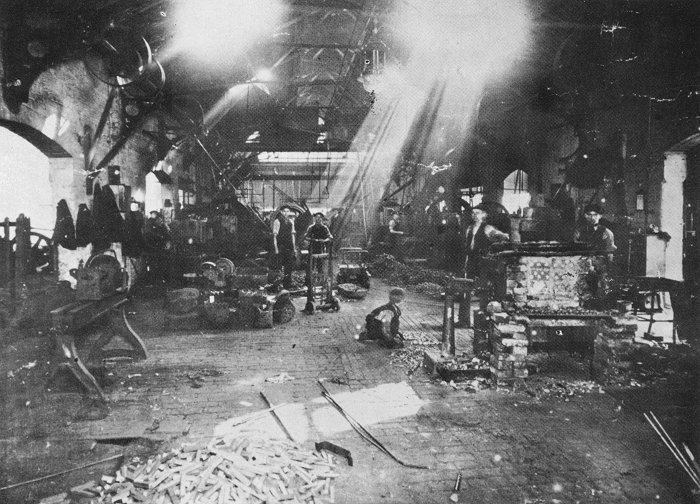

The bolt-making shop

in 1914. |

| F. W. Cotterill was put into voluntary

liquidation in 1925 and its assets were

incorporated into G.K.N. so that the company's

nuts and bolts could be marketed under the

G.K.N. name.

At the time Cotterills was valued

at £600,655.

In 1926 Peacock personally

purchased a piece of land and donated it to G.K.N. on the understanding that a recreation

ground would be built there for the employees of

Atlas Works.

He also persuaded the company to

install a heating system at the works and

improve the toilets. |

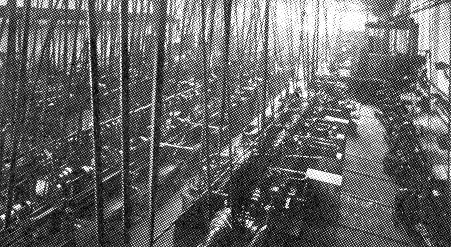

The screwing shop. |

|

The automatic shop. |

The worldwide recession continued and by the

late 1920s short-time working was introduced and

G.K.N. continued to buy-out some of its smaller

and less efficient rivals.

By the early 1930s things began to improve

and Atlas Works soon became busier than it had

been for sometime, but not yet fully up to

capacity. |

|

The finishing shop. |

A letterhead from 1927.

|

An advert from 1935. |

| In order to aid the recovery a new cold

forging shop was built at the cost of £40,000.

By 1936 many more orders flooded in, and in

October of that year the building of a new hot

press shop, costing over £30,000 was approved. |

|

An advert from 1937. |

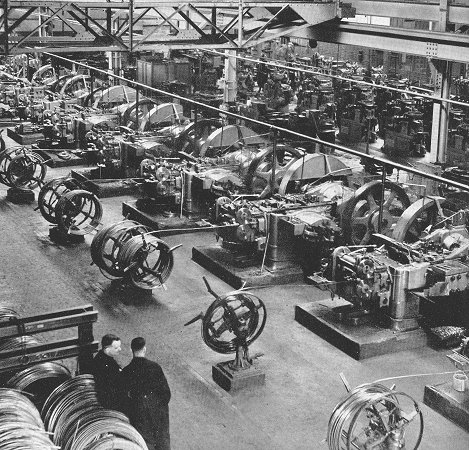

The demand for nuts and bolts rapidly grew

and in January 1937 many employees were asked to

work overtime to enable orders to be fulfilled.

In May 1939 a modernisation scheme costing

£60,000 was introduced. Four National bolt

making machines were installed along with two

open die headers, and in December of that year

the decision was taken to build a new fitting

shop and central toolroom and to demolish the

existing antiquated shops. |

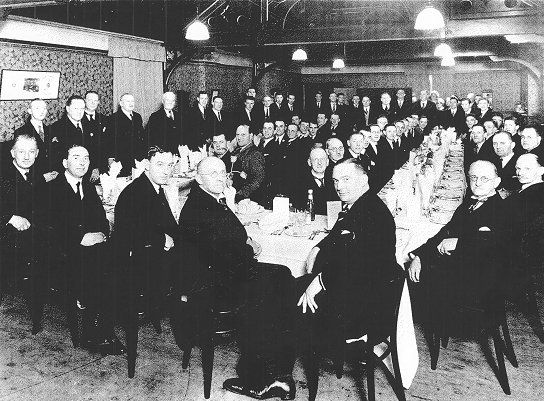

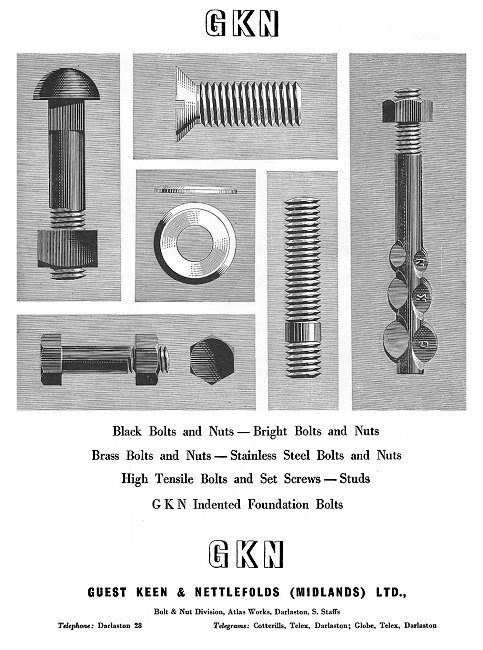

A dinner for the G.K.N.

Male Voice Choir, on February 24th, 1934. It was

at the Anchor Hotel, Wednesbury. Brian Groves

supplied the photo, and Norman Newton kindly

passed on the details. |

Courtesy of Brian Groves.

|

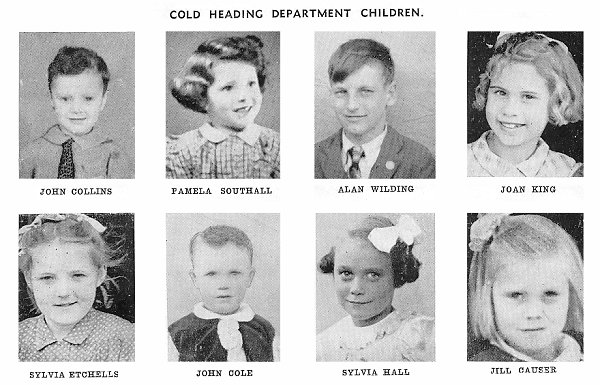

During World War 2 great demands were put on

the factory. In November 1942 the Ministry of

Supply asked the works to double its output of

cold forged nuts and bolts, which resulted in

double shifting and the extension of the works

at a cost of £29,000 (half of which was paid by

the Government). By the end of the war Atlas

Works covered an area of over 20 acres and

employed about 3,000 people. Nuts and bolts were

sold world wide and included the following

products:

black,

bright, high tensile, alloy steel, stainless

steel, brass and aluminium bolts, set screws,

studs and stud bolts, coach screws, push rod

pins, bolt ends, washers, and railway

fastenings, including spikes, clips, and keys.

In the late 1940s the Darlaston

company became Guest, Keen & Nettlefolds

(Midlands) Limited, a subsidiary of GKN.

The extended factory in

the late 1940s. From the 1948 catalogue.

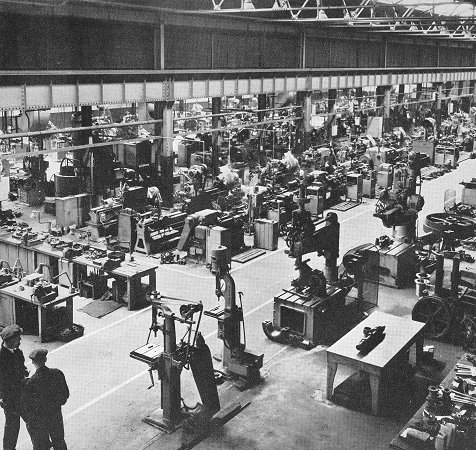

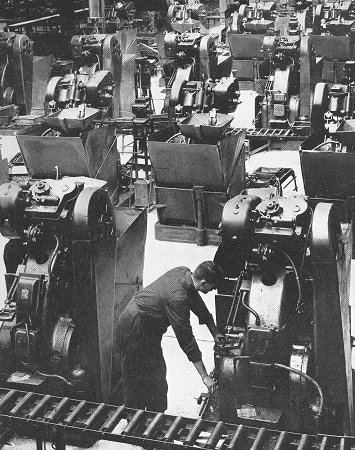

| A section of

the Plant Department.

From the 1948

catalogue. |

|

|

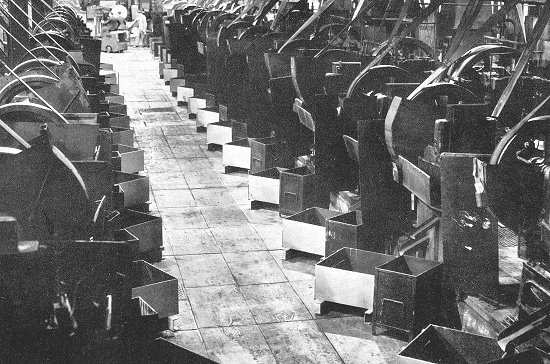

Part of the

Cold Nut Department.

From the 1948

catalogue. |

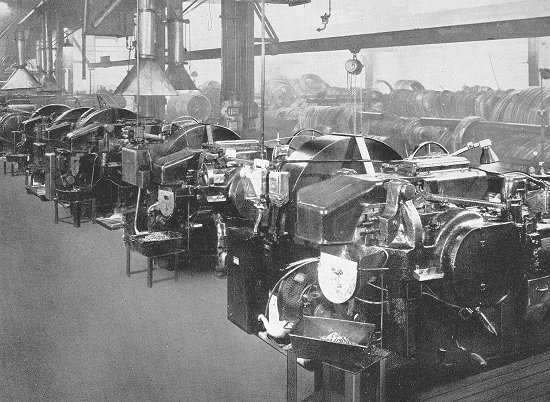

| A battery of

bolt makers.

From the 1948

catalogue. |

|

|

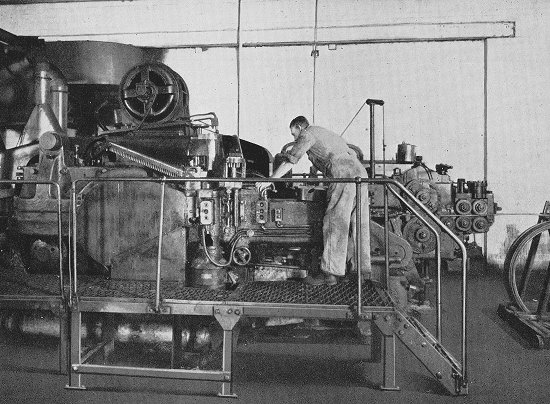

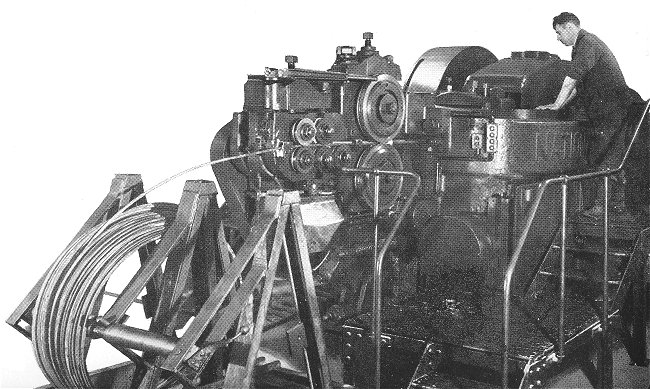

A bolt making

machine.

From the 1948 catalogue. |

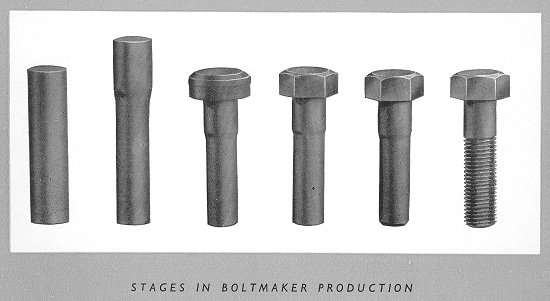

From the 1948 catalogue.

From the 1948 catalogue.

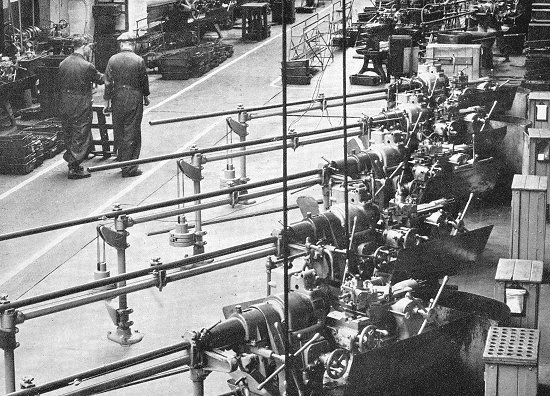

| A battery

of bolt pointing and threading

machines.

From the 1948

catalogue. |

|

|

Part of the

Forging Department.

From the 1948

catalogue. |

| A corner of

the Bright Department.

From the 1948

catalogue. |

|

A bolt making machine.

From the 1948 catalogue.

|

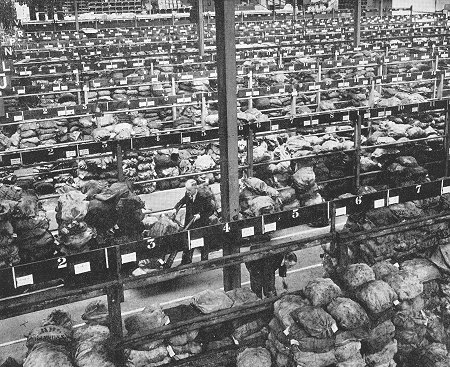

Part of

the vast Warehouse.

From the 1948

catalogue. |

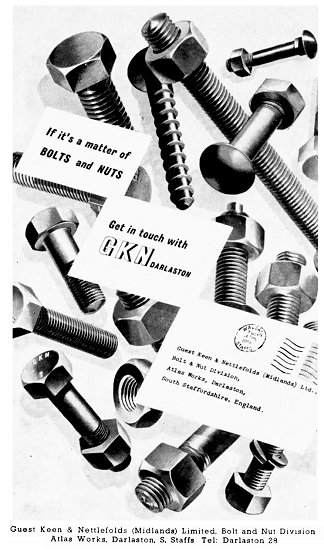

| An advert

from the mid 1950s.

Courtesy of

Christine and John Ashmore. |

|

| |

|

View

some of the products from

the 1948 catalogue. |

|

| |

|

|

An advert

from 1951. |

Warehouse staff. Courtesy

of Brian Groves.

Central tool room staff.

Courtesy of Brian Groves.

Stationery department

staff. Courtesy of Brian Groves.

Sports and Social

Activities |

| Guest, Keen and Nettlefolds opened the sports

ground in Hall Street, which is now the Darlaston

Community Association's Sports and Social Centre. It

was home to the company's cricket club, football teams,

netball teams, bowls teams, and keep fit groups. The

pavilion was used for all kinds of social events, the

work's dance band, and the male voice choir. |

Sports teams and friends outside

the pavilion at the Hall Street sports ground. |

The G.K.N. (Darlaston) cricket

team on June 1st, 1946. Back Row, left to right: J.

Russon,

N. Marsh, L. Bagbee, H. Winfield, R. Kendrick, J. Gough,

and H. Davis. Front Row, left to right: D. Hood, J.

Shakespeare, A. Thursfield, T. Lowe, H. Sirdefield, and

A. Harris. |

Activities were organised by the General Sports

Committee which held regular meetings. One popular

event was the departmental cricket knock-out competition

in which only one G.K.N. cricket team member was allowed

in each departmental team, to encourage non-cricketers

to have a go. |

| Up to twelve teams took part, each encouraged by

the great rivalry between individual departments.

There were two main football teams, the senior team

which played in the Wolverhampton Works League, and

the junior team for youths between 14 and 18, which

played in the Walsall Minor League. The recreation

ground was used by several netball teams, including

the works first VII, second VII, and teams from

local youth clubs and factories. The bowling green

was used by several G.K.N. teams who played in the

Staffordshire Cup Competition, the Wolverhampton

League, the Darlaston Works League, and the annual

sports day bowls competition. The bowling green was

also used by competitors in the Staffordshire County

Individual Merit Competition.

A works dance band was formed in 1946. It

performed in the pavilion and consisted of two

violins, an accordion, a piano, and drums. G.K.N.

also had a male voice choir which competed in events

such as the Leamington Festival. In the 1940s the

soloists were W. Ford, C. F. Jones, Albert Webb, and

Reg. Morgan. |

The male voice choir's annual dinner on 1st

June, 1946.

| There was also a G.K.N. angling club which held many

contests, and a works rifle club that practiced on the

range at Nuts and Bolts Limited in Foster Street on

Monday and Wednesday evenings. There was a club

championship, a handicap competition, and team members

entered the Black Country Small Bore League. |

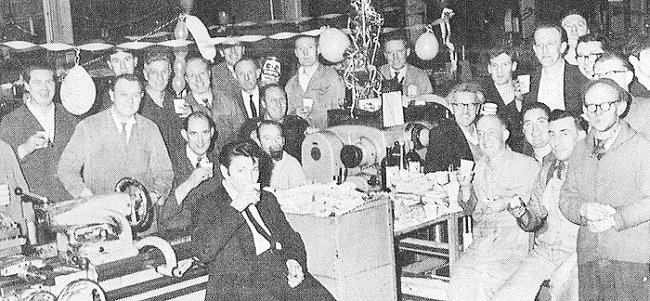

Children of G.K.N. staff that are featured in the July

1946 edition of the company's Sports and Social

Magazine. |

|

The photograph opposite is of

Rosemary Holmes, one of the switchboard operators who

worked at GKN Darlaston.

The following six photographs are of people from the

factory who Rosemary knew in 1947. Unfortunately the

names of the people are not known. If you can recognise

anyone in the photographs,

please send me an

email.

The photographs were kindly

sent by her second cousins, Christine and John Ashmore. |

| |

Rosemary and Ada Dallaway on the

switchboard. Ada (born in 1905, and died in 2002)

married Major Herman C. Wilkes in 1951. I must thank

Norman Newton for the information. |

| Another view of Rosemary and

Ada at work. |

|

|

More of Rosemary's friends at

GKN. |

| |

Another group of workers. |

|

Rosemary (2nd left) and four ladies, possibly from the

office. |

|

| Another member of staff, again

possibly from the office. |

|

|

An advert from 1956. |

The Cost Department Rifle Club, in

about 1962. Courtesy of Norman Newton. They were

runners-up in the Inter Departmental Rifle Competition.

They were as follows:

Left to Right: ?, Norman Newton, Mr. Silk, the Financial

Director, Gerard Machin, Ken Churms, and Gerry Evans. |

| GKN Darlaston had a male voice choir. The photograph

below shows the choir in 1937. |

|

Courtesy of Norman Newton. |

| |

|

| View a copy of the GKN

(Darlaston) Sports and Social Magazine, and some annual choir

concert programmes |

|

| |

|

|

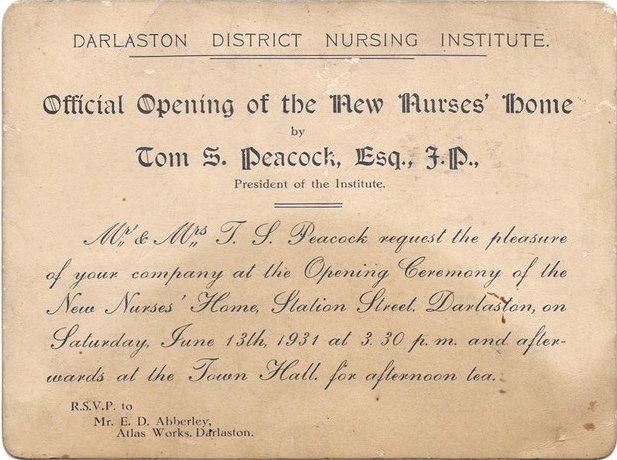

An invitation for Tom Peacock.

Courtesy of Norman Newton. |

The sports ground was the venue for the company's

annual sports day in July, which featured many of the

teams mentioned here, and also racing events on the

running track. In the evening a dance was held in the

pavilion. The ground was also used for school sports

days by local schools, including Pinfold Street J.M.I.

Unfortunately G.K.N. suffered during the depression in the 1970s.

The factory closed in 1979 and

has now been broken up into smaller industrial

units. |

|

From The Gazette, 27th October

2015. |

The eastern half of the site became

Caparo Atlas Fastenings, with local factories at

Dudley, West Bromwich, Cradley Heath and Oldbury.

Unfortunately there were insufficient orders to keep

production going and so on the 30th October 2015,

all of the 122 staff were called to a

meeting with the administrators at 10am. to be told

that they were all laid off with immediate effect.

The meeting was over in five minutes. That day

323 members of Caparo

staff in the Black Country lost their jobs.

Plants in Hartlepool and Tredegar also closed. The

total number of redundancies was 452. |

|

Caparo Atlas Fastenings. |

|

Return to

the

previous page |

|