|

The

Beginning

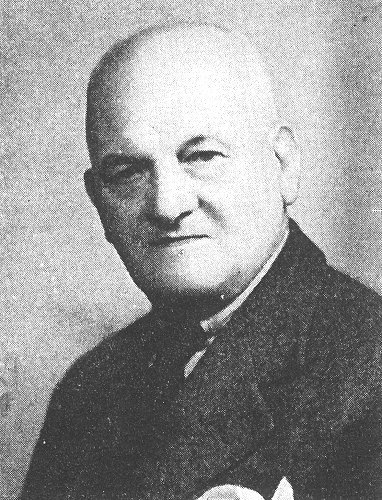

The company’s founder, Charles

Richards, was born in Wednesbury in 1838. He was a younger

son of Silas Richards, a coachsmith, born in 1803 and died

in 1869. Charles served an apprenticeship with a local firm

of nut and bolt makers and by the late 1860s was a stocktaker at Bayliss, Jones and Bayliss of

Wolverhampton. Charles and his wife also kept a paper and

stationers shop, selling books to local preachers, teachers,

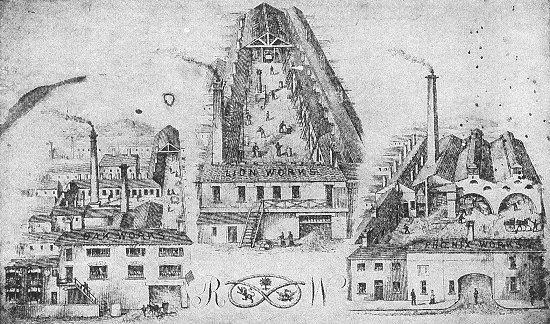

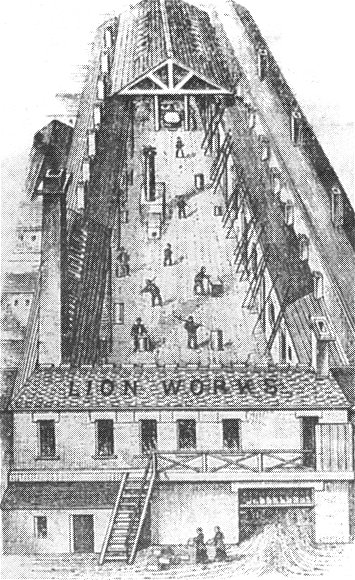

etc. In 1870 he joined forces with William

Butler and started making nuts and bolts at Lion Works in

Foster Street. They employed around 40 people, mainly in the

production of carriage nuts and bolts, which were supplied

to railway companies, and many of the leading manufacturers

of horse-drawn vehicles. The factory workers had a long

working day, starting at six o’clock in the morning, and

ending at five or six o’clock in the evening, with a half

hour break for breakfast and an hour for lunch. The firm

soon gained a high reputation throughout the world for its

superior products that were made from

high quality Swedish iron. After several years, William Butler left the company and

in about 1883, Charles Richards went into partnership with Mr.

W. Wynn. Due to a huge demand for the company’s products,

Oak Works and Phoenix Works were purchased. The business

employed around 250 people across the three sites. |

|

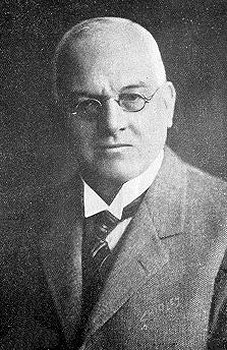

Mr. Charles Richards, founder of the

company. |

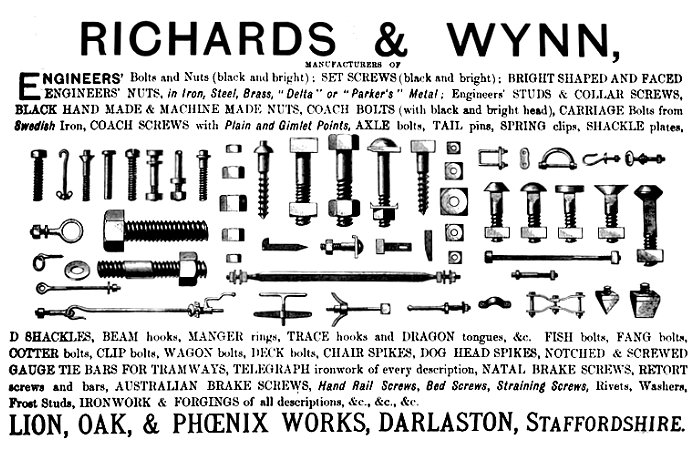

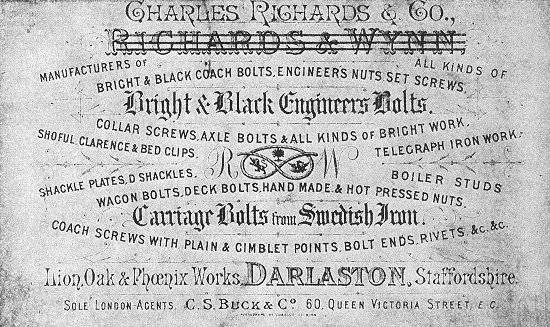

The firm became known as Richards and Wynn and produced a

much wider range of products, including bright and black

engineer's bolts, coach bolts, nuts and set screws, collar

screws, axle bolts, shoful, clarence and bed clips, boiler

studs, shackle plates, "D" shackles, carriage bolts, deck

bolts, handmade hot pressed nuts, bolt ends and rivets, and

telegraph iron work.

By 1859 Charles had married Louisa

Green (1836-1899), who

also came from Wednesbury.

They lived at 45 Bull Street, Darlaston

and had 7 sons and 3 daughters:

William, Silas, Charles, Arthur,

Samuel, Ernest, Frederick, Alice, Bertha, and Louisa.

Their youngest daughter, Louisa, born in

1878 married Walter Wilkins in 1908, one of the founders of

Wilkins and Mitchell. By 1870 the family

were living in John Street, Ettingshall. Charles used to

walk to the factory at Darlaston daily. In about 1875 the

family moved to Walsall Road, Darlaston and about three

years later moved to Rose Cottage, Bull Street, Darlaston,

which was a bigger house with a very large garden. |

|

In the early 1880s, William Butler died

and the Richards family purchased his house, "Hill View",

Kings Hill, Wednesbury and moved there.

Their eldest son, William Henry, owned an iron foundry in

what is now Richards Street. It occupied both sides of the

road. William’s younger brother Ernest worked there for

several years as a "general factotum", sweeping the office,

weighing in quantities, keeping the time sheets and working

out wages. He then became an apprentice midshipman with

Cowie & Company, of Liverpool and later a journalist and

author, before studying for the clergy as a Methodist

Minister in New Jersey, USA. He finally became a minister

with the United Reform Church of Scotland.

Charles’ youngest son Fred (George Frederick), born in 1875,

died at an early age. He worked for the London & North

Western Railway as a carpenter and joiner. On Saturday

21st March, 1901, whilst working on the construction of a

parapet, he was struck by the 12.26 train from Princes End

to Ocker Hill and was fatally injured.

Charles’ other four sons worked at his

factory throughout their working lives. They were Silas,

1859 – 1906, Charlie (Charles Junior), 1860 – 1945, Arthur

Samuel (known as Sam), 1862 – 1929 and Samuel, 1866 – 1902.

Silas and Arthur were responsible for the management of the

works, Charles looked after the commercial side, and Samuel

looked after outside sales.

Between the 30th December 1899 and the

21st May 1907 Charles junior lost both parents and 4 of his

6 brothers.

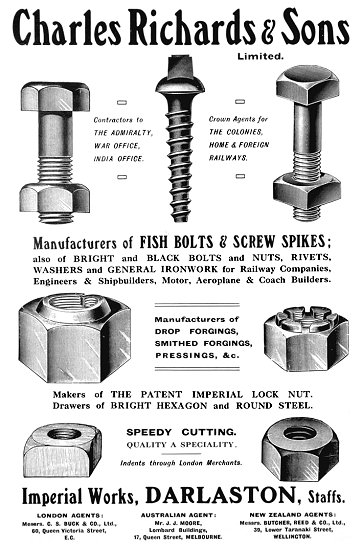

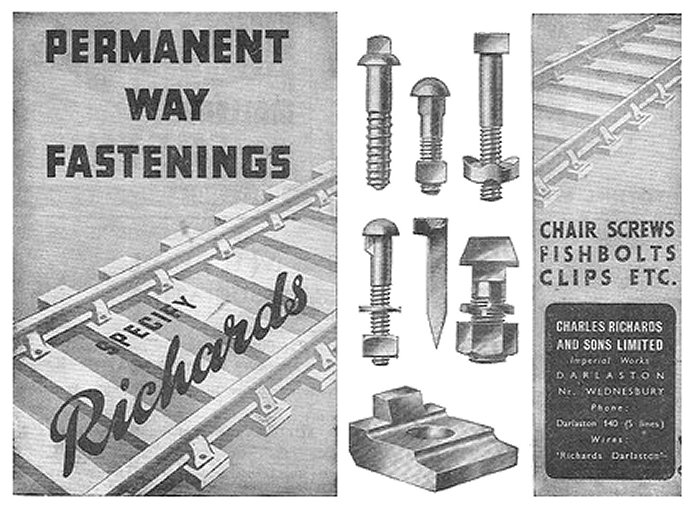

An advert from 1884.

Mr.

Wynn retired in about 1886 and the business became Charles

Richards & Company. The business prospered and soon

outgrew the three

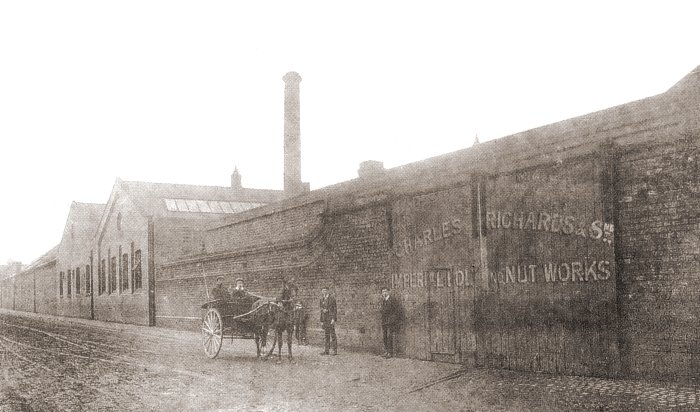

factories. On 1st October, 1886, Charles Richards purchased

Imperial Works in Heath Road for £1,625 under a conveyance

dated 7th November, 1886. There was sufficient scrap metal

there to equal the purchase price.

Imperial Works had been owned by the Darlaston Steel & Iron

Company, which went into liquidation in 1882, during the depression

in the iron trade. The factory, which included a railway

siding was auctioned at Wednesbury Town Hall. The factory

was initially called the Imperial Bolt and Nut Works, later

abbreviated to Imperial Works. The

three original factories closed, although in 1904 the newly formed Wilkins and

Mitchell rented Phoenix Works for a time. |

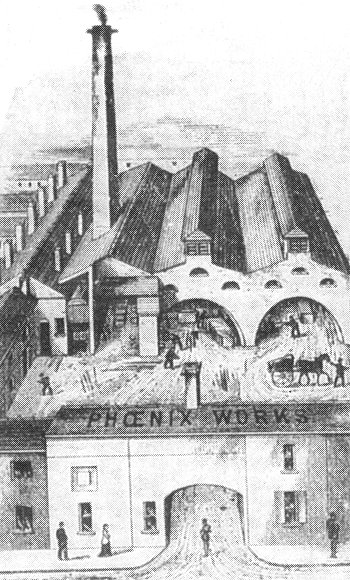

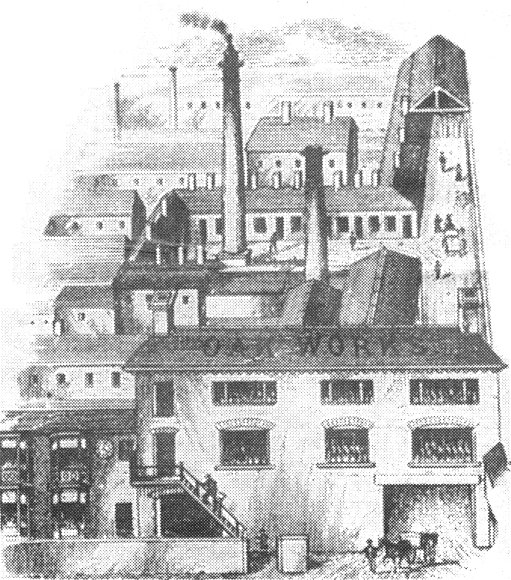

The company's first business card.

The other side of the card showing the three

factories.

|

Lion Works. |

Phoenix Works. |

Oak Works.

The original trade mark with three symbols inside the

Staffordshire knot representing the company's first three

factories - Lion Works, Oak Works, and Phoenix Works. |

|

Imperial Works covered three acres and included stock and

packing warehouses occupying a space of 150ft. by 40ft., an

Oliver shop 200ft. long, and a large machine shop for making

blanks. The factory also included an extensive blank

warehouse, a screwing shop 140ft. by 80ft., blacksmith's

shops, and forges etc. On the 22nd August, 1901, Charles

Richards' sons, Charles junior, Silas, Arthur and Samuel

became partners in the business, which then became Charles

Richards & Sons.

Modern machinery was used throughout the factory

including powerful engines to drive the machinery, varying

from 20 to 60hp. Goods were transported by the adjacent

canal and railway sidings from the nearby London & North

Western Railway. Only the best raw materials were used

including Swedish iron.The land alongside the site, known as

The Flatts Estate, an area of approximately 30 acres, full

of old coal mines and spoil heaps was also acquired with

future expansion in mind. At a much later date part of the

land was given to Darlaston Council, and Richards Street was

built there.

|

| Following the death of William Henry Richards in 1906,

Charles Richards & Sons purchased W. H. Richards & Company,

based at Vulcan Foundry, Lower Green, Darlaston (opposite

Imperial Works) for £954.9s.9d. By the 1940s it had become

part of Imperial Works. |

|

Imperial Works as it is today. |

|

An Oliver in operation. |

The bolts and nuts were originally forged with the

treadle-operated Oliver, a foot-operated hammer, a sort of

glorified anvil, which made

light work of the forging process. There were two hammers

and so two treadles. The Oliver had been invented in the middle ages, and

adapted for bolt and nut making in the early nineteenth

century. It revolutionised the manufacturing process,

reducing production costs, and greatly increasing the

output.

The men who operated the Olivers had to blow their

own coke fires when heating the metal. They often brought their

children along to do this work for them. The Oliver

operators tended to suffer from ruptures caused by operating

the treadles and standing on one leg for long periods of

time. The working day was at least nine hours long.

|

| The larger nuts and bolts were first forged under a steam

hammer, before being taken to the Oliver operators to be

hand- dressed. Due to the great demand for the company’s products, new

types of machines were installed, including open and closed

die, and vertical heading machines for making bolts, and hot

nut forging machines.

The new machines didn't completely

supersede the Olivers, which continued in use for many years. |

A close-up view of an Oliver. |

|

A final view of an Oliver. |

The nuts and bolts produced at this time all carried a

Whitworth standard thread.

The hot nut forging machines easily handled 2½ inch

diameter nuts which measured nearly four inches across the

flats. They were forged from rectangular bars measuring just

over 3½ inches wide by 2⅜ inches high, and weighing around 2

cwt.

Each ton of nuts produced, was made from 35 cwt. of bars. |

| An advert from the 1890s:

One of Darlaston’s most enterprising and successful

firms, and one which has gained a splendid

reputation in all parts of the world for its

productions, is that controlled by Messrs. Charles

Richards and Co., manufacturers of bright and black

coach bolts, engineers’ nuts, set screws, bright and

black engineers’ bolts in iron and special steel

etc., etc. (late Lion, Oak and Phoenix Works),

Imperial Works, The Green, Darlaston. Since its

inception about twenty years ago, it has had a

prosperous career, which speaks to the ability,

energy, business, shrewdness and diligence shown in

its management from the commencement, and which

testifies to the firm’s sound judgement and

administrative abilities, and the fact that they now

control one of the best known concerns of this

character throughout the United Kingdom, and whose

high-class manufactures are known in all parts of

the world, for their excellent quality, workmanship

and finish.

In consequence of their large

and increasing business, Messrs. Charles Richards &

Co. have recently taken over very extensive premises

known as the “Imperial Works”, The Green, covering

over three acres of ground. They are splendidly

constructed on the very best lines, and specially

adapted for the various qualities of goods made, no

expense being spared in order to get everything as

perfect as human skill can procure for the

production of Darlaston’s famous industry – “Bolts

and Nuts” etc. The works comprise extensive, lofty,

modernly built, stock and packing warehouses, one

hundred and fifty feet long by forty feet wide,

admirably equipped and arranged; oliver shop, two

hundred feet long; large machine shop for making

blanks; extensive blank warehouse, parallel with

screwing shop; very commodious screwing shop, one

hundred and forty feet long by eighty feet wide,

fitting and blacksmith shops, forges, stores, etc.

The whole of these buildings are laid out in a most

systematic manner – the manufactures being commenced

at one end of the range, and finished at the other

end, from its most crude form.

There are powerful engines of

the best type, ranging from twenty to sixty nominal

horsepower, replete with the most modern machinery

in every variety for the different departments

throughout the works. A costly plant of the most

advanced style has been fitted up with all the

necessary appliances of the trade. There is every

facility for the transmigration of goods either by

water, rail, or road to any part of the world –

sidings of the London and North Western Railway

Company run right into the works. The firm have

their own wharf of canal in the works for loading of

goods by boats to their different destinations with

mechanical apparatus for loading and unloading, etc.

Messrs. Charles Richards and Co. make a special

feature in their manufactures, using only the best

materials in steel and iron for making their goods,

including the finest brands of Swedish iron; great

care being exercised by the members of the firm in

the selection of materials for their celebrated

specialities. They manufacture every description of

black and bright coach bolts and nuts, set screws,

bright and black engineers’ bolts from one-eighth to

four inches; also carriage bolts from Swedish iron.

A leading line is their coach

and engineers’ bolts and set screws, which are made

from specially prepared steel; and their increasing

demand by coach builders and engineers, testifies to

the satisfaction they are giving by their

superiority over other goods of a like kind in the

market. They also manufacture collar screws, axle

bolts, and all kinds of bright work, shoful,

Clarence and bed clips, telegraph ironwork, shackle

plates and D shackles, boiler studs, wagon bolts,

deck bolts, hand-made and hot pressed nuts, coach

screws with plain and gimlet points, bolt ends,

rivets, etc., etc.

The firm do an extensive home

and large foreign trade; these splendid goods

becoming very popular with home and foreign buyers,

in consequence of their excellency in manufacture.

There are a handsome suit of offices, well

appointed, with an adequate clerical staff to carry

on the extensive business of the firm. A keen

personal supervision is exercised over every

department by the proprietors to the minutest matter

in every detail; practical foremen are appointed for

each of the different branches, and a large staff of

experienced workmen are employed. In home and

foreign commercial circles Messrs. Charles Richards

and Co. are known for their strict probity and

honourable dealing. |

|

|

An advert from 1909. |

The early years of the twentieth

century were a sad time for the Richards family. Samuel died

in 1902, whilst still in his mid thirties, followed in 1905

by Charles senior, the founder of the company, who died at

the age of 67. In 1906, Silas passed away at the

early age of 47.

The business was then run by the two

surviving brothers, Charles and Arthur. Charles looked after

sales, whilst Arthur managed production.

They worked long hours. At the end of the working day

Charles would take home all of the day’s correspondence and

enquiries, and without any reference to price lists, make

out quotations and reply to letters. |

Mr. Charles Richards junior. |

|

Charles Richards junior in

younger years. |

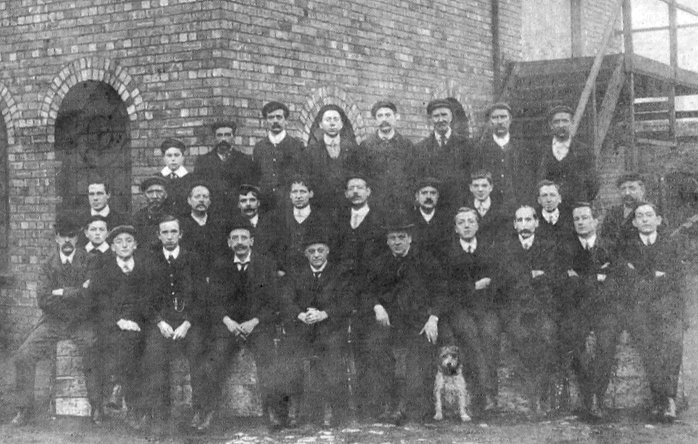

The office staff and foremen in about 1910.

| Another member of the Richards

family who joined the company was Arthur Richards. |

|

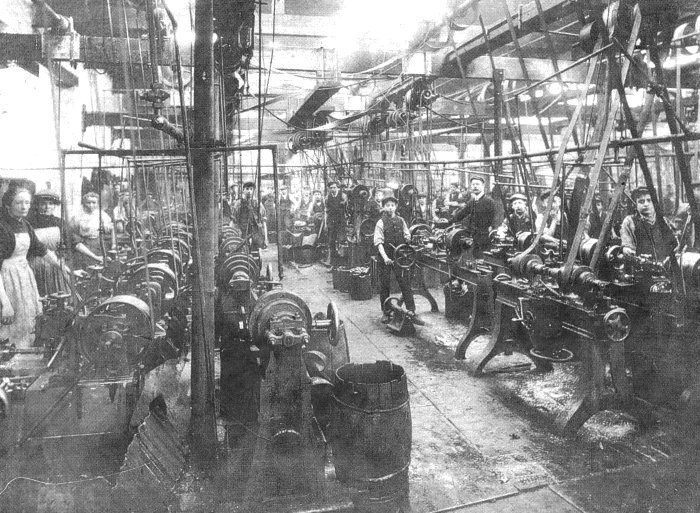

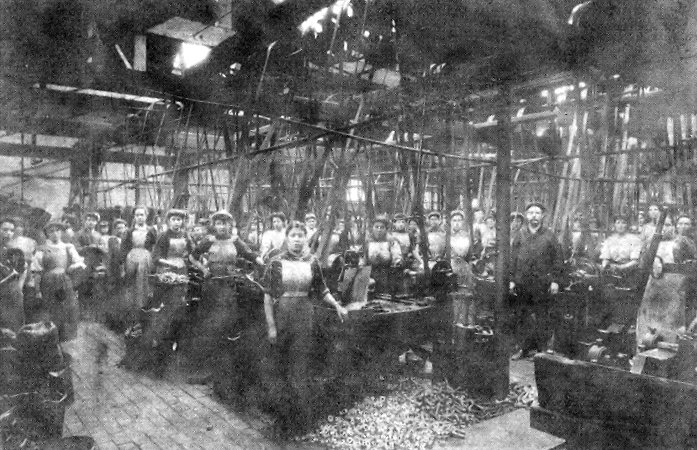

Part of the factory floor.

Part of the factory.

A Charles Richards adjustable spanner.

|

An advert from 1913. |

|

An advert from 1916. |

|

|

He

sat up until the early hours of the morning to ensure that

everything was done. He was assisted by one of his sisters

who addressed envelopes and stuck stamps on them so they

could be posted next morning.

Around this time two sons of Charles

Richards junior joined the company. They were Harry Richards

who started work in 1904 and took an active part in the

production side of the business, and Mr. Charles W.

Richards. Machine technology continued to

improve, and new machines were acquired to increase

production, including cold heading machines, and automatic

screwing and pointing machines, which carried out the

operation in just two cycles.

Another machine, called the “Boltmaker”

produced a finished bolt from a coil of wire which was

automatically fed into the machine. Previously three

separate machines had been used for this operation. Nut

forming machines were also installed, which made nuts from a

round bar without applying heat.

The new machines ensured that the

products were made to a high standard, at an economic price.

They were essential to keep the manufacturing process

profitable because at the time the cost of raw materials

greatly increased, and higher wages were expected.

The new machines also allowed the

company to produce the vast quantities of nuts and bolts

that were ordered by the growing number of vehicle

manufacturers. |

|

Some of the workforce. |

|

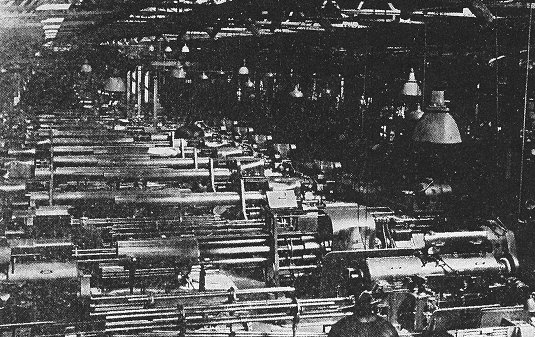

One of the nut and bolt shops. |

| A new heat treatment plant was installed using the

latest type of electric furnaces for hardening and

tempering, and the facilities in the test house, and the

laboratory were improved.

The careful heat treating of machine tools greatly

extended their life, and alloy steels were used instead of

carbon tool steel. |

A section of the Bright and Automatic

Shop showing multi-spindle automatic machines. |

|

An advert from 1922. |

A new firm called The Midland Bolt, Nut & Rivet Company

Limited was formed by Charles Richards and Sons, and a group

of other Darlaston manufacturers. It had a range of new

machinery which was used for the benefit of the local

manufacturers. The company installed cold heading machines

for making hexagon, square, and carriage bolts in two

operations on two machines. The first machine headed the

material to form a round head, which was trimmed on the

second machine to form a hexagon or square. In 1926 the

company went into liquidation and was purchased by Charles

Richards. The whole operation and plant was moved to a new

building erected on the Flatts Estate, in Richards Street,

which still retained The Midland Bolt, Nut & Rivet Company

Limited name.

Another section called the New Imperial Works, also in

Richards Street, was added for the screwing of bolts and the

tapping of nuts, repetition parts, and special turned bolts

made from hot or cold forgings. All of the existing plant

for the production of bright nuts and bolts was moved there

from Imperial Works. |

|

Charles Richards and Sons also made

advances in screwing equipment. A section was set aside for

the manufacture of die heads, ground thread taps and dies,

and thread rolling dies.

The ground thread taps and dies were

essential to ensure great accuracy in the screw threads. All

gauges were hardened and ground to guarantee close

tolerances and uniformity.

The material used in the Bright

Department was drawn in the Bight Drawn Steel Section,

started in 1911. Thousands of tons of black bars, of free

cutting quality were purchased from America for the raw

material because at that time they were not made in this

country.

Extensions were made to Imperial Works

after the company purchased an adjoining factory in 1935,

containing a rolling mill for the production of wrought

iron. The factory was used to extend the Screwing Shop, and

to provide a site for a new Black Warehouse, and Steel

Stockyard. Work on the new extension was completed in 1938. |

Mr. Charles Richards junior. |

|

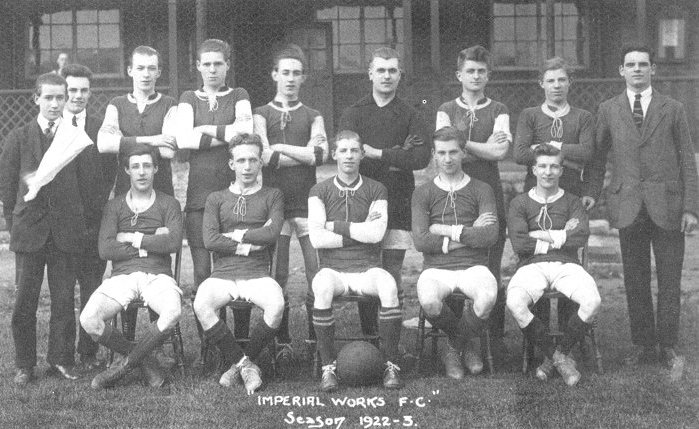

The Imperial Works Football

Team in the 1922 - 1923 season. From an old

postcard. |

A letterhead from 1954.

An aerial view with Imperial Works

in the background, and the Midland Bolt, Nut & Rivet

Company Limited in the foreground. |

Some of the workers at

Charles Richards on 9th January, 1933.

Courtesy of Ian Stubbs. The names are

believed to be as follows:

Back Row - left to right:

Alfred Cadman, Joseph Ball, Fred Lamsdale,

Cyril Fellows, Jack Page,

Fred Parker, Sam Parker, Bernard Warden, and

Herbert Dean.

Front Row - left to right:

Will Randel, George Stanton, Arthur Day,

Jack Oldfield, and George Evans. |

|

An advert from 1938. |

|

An advert from 1937. |

| Extensions were also made to the Engineering Department,

where repairs were carried out, and new special purpose

machines were developed for use in the factory, to improve

production and quality.

Facilities were added for the training of apprentices,

and the most modern machine tools were acquired. Everything was done to encourage youths to join the

company’s apprentice scheme where they were given a thorough

training to prepare them for any future role.

|

|

The Engineer. 29th March, 1940.

Lighting in a Nut and Bolt Factory.

It is just over

a hundred years since Joseph

Whitworth set up his own Machine

tool shop in Manchester and started

his collection of screwed bolts with

a view to standardising the

relationship between the diameter of

the bolt and the threads. Previously

when a machine needed new fixing

bolts the repairer had to make and

thread special bolts, for the

original maker of the machine used

whatever diameter or thread he

fancied. Today, not only have

Whitworth's standards been adopted

throughout the world, but nut and

bolt manufacture has been made

either an automatic or

semi-automatic process.

When the firm

of Charles Richards and Sons,

Darlaston, was founded in 1870, nuts

and bolts were made by the method

called the ‘Oliver’ process,

entirely by manual labour through a

treadle. At this time the firm

employed some 70 or 80 hands and

possessed only two bolt-making

machines. By 1914 the number of

employees had increased to several

hundred, and it was then decided to

scrap the obsolete gas lighting

installation for electricity. Since

those days the firm has grown to

well over a thousand employees,

making all types and sizes of nuts

and bolts. Many additions and

improvements have of necessity been

carried out in the lighting.

Some twelve

months ago the management decided to

have a complete lighting survey of

the entire factory, and as a result,

it was arranged to replace the

multiplicity of local lighting units

over the machines by a general

lighting scheme of ‘Metrovick’

mercury discharge lamp units.

Considerable care was necessary in

the layout to eliminate shadows from

overhead belting, and the changeover

has been found a great improvement.

Output has increased, and operatives

have expressed satisfaction with the

improved lighting. The general

standard of illumination averages

10-12 foot-candles, and in special

sections it is 20-25 foot-candles.

Up to the present about one hundred

125, 250, and 400 watt mercury

discharge units have been installed,

but a considerable part of the

lighting still remains to be

converted.

In addition to

general lighting, Metropolitan

Vickers have been responsible for an

interesting A.R.P. lighting

installation. In each of thirty

shelters is installed an automatic

set, consisting of a metal rectifier

fed from the mains. The rectifier

can supply current to the lamps in

the shelter, through a transformer

in the set itself. When the mains

voltage is cut off, the load is

automatically transferred to an

alkaline battery, which is also

mounted in the set. This battery is

capable of maintaining the full

lighting in the shelter for six

hours, or half light for twelve

hours.

It is pointed

out that although the first cost of

this arrangement is rather high,

there are no maintenance charges,

whereas if duplicate sets of

batteries are used, they must be

regularly charged, particularly if

the acid type of battery is used. |

|

|

|

An advert from 1949. |

|

In 1945 Charles Richards junior died,

leaving his son Charles W. Richards in charge, aided by his

nephews Harry Richards and Philip Richards. Sadly Philip

died just two years later.

Charles W. Richards, the new Managing

Director continued in his father’s footsteps, looking after

sales.

He was also Vice Chairman of two nut

and bolt associations, Chairman of the Newport River Company

Limited in South Wales, Director of Criterion Stampings

Limited in Willenhall, where Philip Richards was Chairman,

and Chairman of Garratt & Bunch Limited of Willenhall.

Charles Richards and Sons had an interest in all of the

three companies.

By the early 1950s the fourth generation of the family

had become directors of the company. They were Charles Peter

Richards, son of the Chairman, John Richards, great grandson

of Arthur Richards, and David Richards, eldest son of Arthur

Samuel Richards. |

Mr. Charles W. Richards. |

|

An advert from the mid 1960s. |

It was a family business in every way. The Richards

family treated the employees extremely well. They almost

became an extended family. They looked after their welfare

and provided social activities for them.

The canteen opened in 1918 to provide meals and act as a

base for the sports and social activities. A bowling green

was laid on which county matches were played, and there were

facilities for tennis, football, and indoor games.

A fully equipped surgery was also opened with a nursing

sister and two assistants. |

An advert from 1958.

|

An advert from the mid 1950s.

Courtesy of Christine and John Ashmore. |

To show their appreciation of long serving employees,

certificates were given to people with thirty years or more

service. Because of the prevailing family atmosphere in the

factory, it was an enjoyable place to work, so that many

employees spent the whole of their working lives there.

For

instance, Mr. J. W. Reed, the Company Secretary worked there

for over sixty years and retired at the age of eighty nine.

Mr Joseph Perkins, who joined the company in 1891, worked

there for around seventy years. |

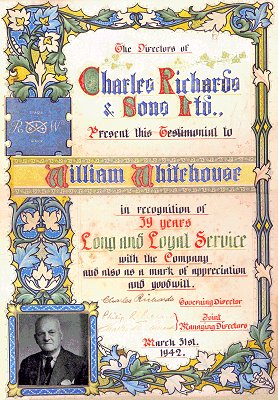

| A long service award that

was presented to William Whitehouse on his

retirement from Charles Richards in 1942. It is

signed by Charles Richards junior and includes his

photograph.

Courtesy of the late Bill Whitehouse. |

|

|

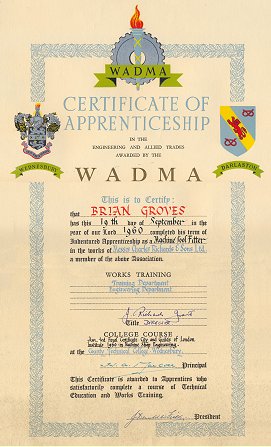

Brian Groves

certificate of apprenticeship, dated 19th

September, 1960.

It was awarded after he

completed his term of indentured apprenticeship

as a machine tool fitter at Charles Richards &

Sons Limited.

They were a member of

WADMA the Wednesbury and Darlaston Manufacturers

Association.

Courtesy of Brian

Groves.

|

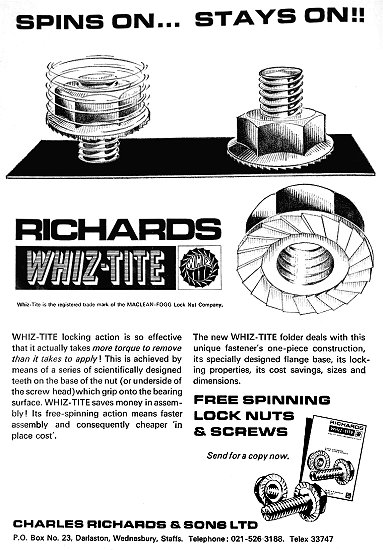

| In the 1960s the main

products were black, bright, and high tensile

bolts and nuts, high strength torque bolts for

use in the construction industry, and repetition

parts including fishbolts, screw spikes, rail

clips and parts for the permanent way, and

telegraph ironwork.

Screw spikes had long been a

successful product. Back in 1932 the company

received an order for five hundred tons of them

from China.

The firm’s products were

sold throughout much of the world. In the early

years there were many customers in Australia,

New Zealand, and South Africa, but as time

progressed customers were found in nearly all of

the countries in the world.

The company kept an eye on potential global markets and

produced fastenings to suit. By the late 1950s the oil

industry had greatly expanded, and so specialised fastenings

were produced, which were used throughout the industry.

The

home market was not forgotten. In the 1950s the company had

agencies in every part of the country, and Charles Richards

& Sons became one of the largest private bolt and nut makers

in the world. |

An advert from 1968. |

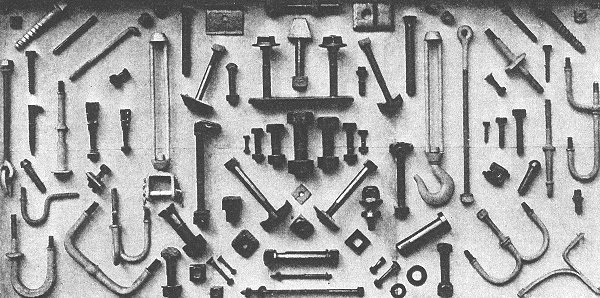

A display of galvanised black hot-forged

products, and railway and telegraph fittings.

| The various buildings eventually covered many acres and

were equipped with the most modern tools and machinery

possible, including a galvanising plant.

A new office block was built in Heath Road, and blade hot

forged products were added to the product range.

The company became one of the largest employers in the

area. |

Charles Richards & Sons

offices, Heath Road, in 1976. |

| |

|

| View some

photographs of Imperial Works |

|

| |

|

A photograph of a

presentation of long service awards in the

canteen, possibly in the 1950s. It is from a

newspaper cutting, from an unknown newspaper.

The awards were presented by Mr. C. W. Richards,

and the recipients were thanked by Mr. P. H.

Richards for their long and devoted service to

the firm. Awards for 50 years service were

presented to: Mr. W. C. Hill, Mr. E. Goodman,

Mr. J. E. Williams, Mr. I. Mander, Mr. A. Green,

Mr. C. Reed, and Mr. H. Cotterill. Awards for 40

years service were presented to Mrs. M. M. Lee,

Mr. G. Alldritt, Mr. R. Gibbs, Mr. H. Evans, Mr.

C. H. Martin, and Mr. D. S. Jones. Awards for 30

years service were presented to: Mrs. M. A.

Wiles, Mrs. P. I. Russell, Mr. J. J. W. Arnold,

Mr. H. J. Day, Mr. A. E. Griffiths, Mr. G. S.

Orson, Mr. C. H. Kynaston, Mr. E. E. Hubbard,

Mr. D. Walters, Mr. J. Jones, Mr. H. T. Halford,

and Mr. T. Kirk.

Courtesy of Christine and John Ashmore.

|

|

Another photograph

from a newspaper cutting from an unknown

newspaper, possibly from the 1950s. It shows

Stores Foreman, 84 years old Joe Perkins who

lived at 455 Darlaston Road, Pleck.

He was in his 67th year

with the company, and about to retire. This was

believed to be a long service record.

Courtesy of Christine

and John Ashmore. |

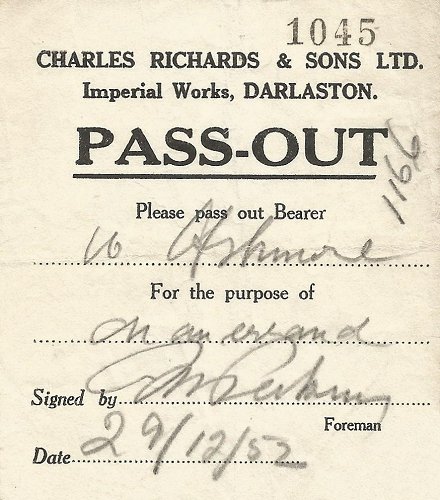

| In order to leave the

factory during working hours, employees had to

get a pass-out to present to the security people

at the factory gate. This one appears to be

signed by Joe Perkins who is in the photograph

above. Courtesy

of Christine and John Ashmore. |

|

A presentation of long service awards.

Courtesy of Brian Groves.

| The photograph above was taken at a long

service awards presentation and dinner in about

1960. Charles W. Richards can be seen on the

left at the front. The dinner, an annual event,

was attended by about 180 people, many of whom

were retired. Certificates and cheques were

presented to Mrs Elsie Stain and Mr. Horace

Stevenson, both of whom had worked at Charles

Richards & Sons for 50 years. Mrs. Stain worked

in the welfare department, and Mr. Stevenson was

in the wages department. Five people received

awards for 40 years service, they were: Miss

Kate Garrett, Mr. Frederick Atwell, Mr. George

Wells, Mr. John Hardwick, and Mr. William

Skidmore. Others who received awards for 30

years service were: Mr. Elijah Bailey, Mr.

Frederick Gittings, Mr. James Thorpe, Mr. James

Fisher, Mr. Thomas Hutchinson Groves, Mr. Sidney

Underhill, Mr. George Powell,

Mr. William Fletcher, Mr. John Holdcroft, Mr.

John Blackhouse, and Mr. Victor Parsons. |

|

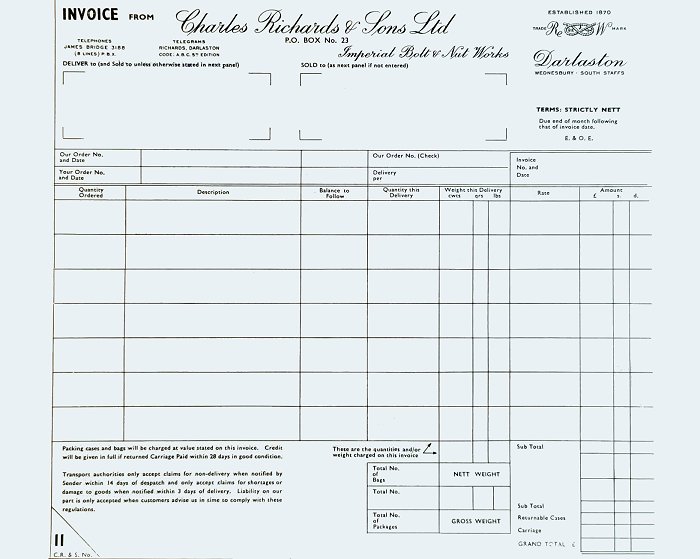

An invoice from the

1960s. |

|

Another view of Imperial Works. |

|

A medallion produced

by the firm in 1970. Courtesy of Bill

Whitehouse. |

|

The future looked bright until

the beginning of the 1980s when things went badly

wrong. In June/July 1980 the company

was taken over by a South African firm which

disposed of Richards' assets and closed the

Darlaston factory, bringing 100 years of successful

manufacturing to an end.

The company is still liked and well remembered

today, particularly by the ex-employees.

Occasionally they have get-togethers which are

always well attended, but inevitably with the

passing of time the numbers slowly fall. Although much of Imperial Works is now derelict,

some parts of the factory are now used by other

companies, as is most, if not all of New Imperial

Works. |

|

Looking down Heath Road at

what remains of Imperial Works. |

This building, which still

stands, was used as a storeroom in the factory.

It overlooks the canal, and was built by the

Darlaston Steel and Iron Company. It must be the

only surviving building from the old ironworks. |

|

A final view of the works,

showing the extension built in 1936. |

| I must thank Robin Richards for his invaluable help

with this brief history. |

|

Return to

the

previous page |

|