| The following photographs, possibly from the 1930s

were kindly supplied by Darlaston historian Tony

Highfield. They were taken during the company's heyday,

when Imperial Works was supplying nuts, bolts,

fastenings, and tools to countries throughout the world,

and Darlaston was still the capital of the nut and bolt

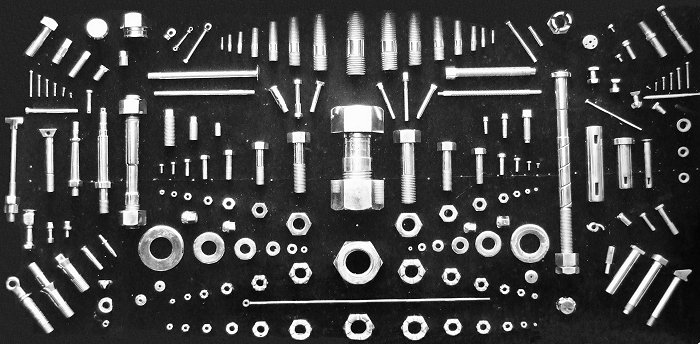

industry. Charles Richards & Sons product range

included the following:

Black, bright, and cold-headed

bolts, nuts, studs, and set pins of all kinds.

Carriage bolts and nuts.

Permanent way railway fastenings.

Telegraph ironwork.

High tensile bolts and nuts.

Precision repetition work from 4BA to 2 inches in diameter.

Wheel studs and dome nuts.

Alloy steel stud bolts, studs and carbon steels, nuts

for the petroleum industry.

Washers, bright and black.

Straining eye bolts.

Rivets.

Stampings.

Bright-drawn steel.

Roofing and gutter bolts and nuts.

Foundation bolts.

Moorhouse patent lock nut.

Burston rapid action cam spanner.

Items could be galvanised or plated in all finishes.

The company had many representatives throughout the

UK, and in the following countries:

| South

Africa |

New Zealand |

| Kenya |

Egypt |

|

Tanganyika |

Ceylon |

| Uganda |

India |

|

Zanzibar |

Norway |

|

Rhodesia |

Sweden |

|

Nyasaland |

Finland |

|

Australia |

Denmark |

Bright mild steel studs were

produced up to 1¼ inches

diameter, Hexagon head bolts, and hexagon head set

screws were made up to 1 inch diameter, Hexagon huts

and locknuts were made up to 2 inches in diameter

(Whitworth thread), and square head coach bolts were

made up to ¾ inch diameter.

|

|

A vast number of small

machines producing the smaller nuts and set

screws.

The noise must have

been deafening when the machines were running,

all from overhead line shafting, and an immense

array of belts. |

| A corner of the

packing department, overflowing with a large

number of Hessian bags, all filled to the brim

with nuts and bolts of all kinds.

Notice the scales for

weighing each bag, and also the array of

heaters, which would have been a necessity in

the cold winter months. |

|

|

A fine view of Heath

Road and Imperial Works from the 1930s.

It still looks much the

same today, although part of the factory is now

derelict, and so its future must be uncertain. |

| Charles Richards at

his desk. |

|

|

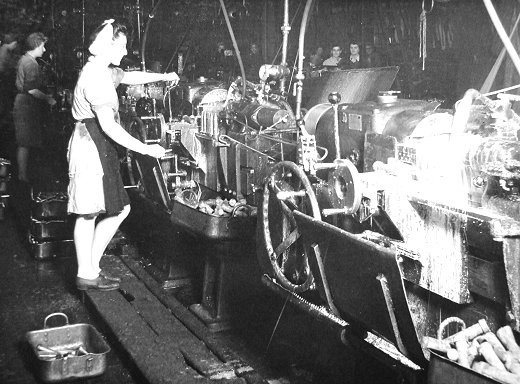

An example of

repetition work, turning what appears to be

round-head bolts before the thread is cut. |

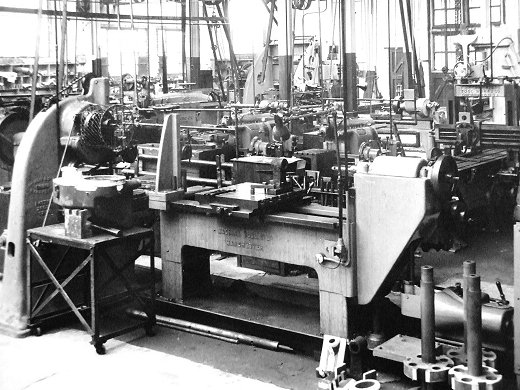

| The corner of a

machine shop, possibly in the maintenance

department where parts and tools would be made

for the production machines. |

|

|

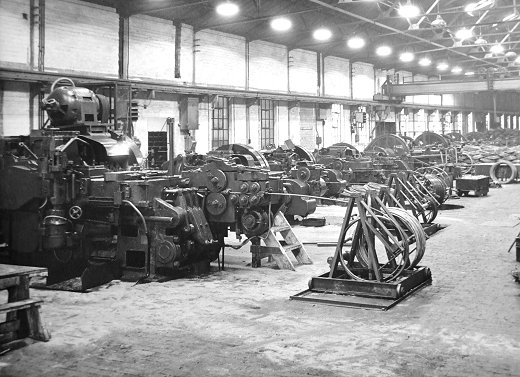

Large diameter

coils of steel are threaded into machines,

possibly to be cut and threaded for studs.

|

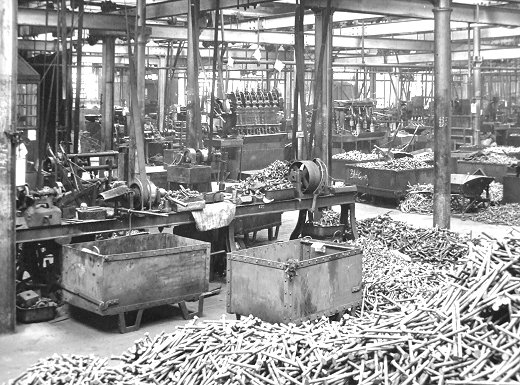

| Part of the factory

where long bolts are in production.

In the 1950s the company's

standard range was up to 9 inches in length, but

longer bolts could be made to order. |

|

A fine display of some of the many

products made at the works.

| If you have any further information about

the photos, or the company, or have any photos

that we can add, please contact the

webmaster

who will be delighted to hear from you. |

|

Return to

the

previous page |

|