| Most of Wolverhampton’s great industries have now

disappeared and very little remains to remind us of our

wonderful industrial heritage. Many manufacturers are fondly

remembered by their ex-employees and often their names crop up

in conversation. One if these is the A.B.C. Coupler and

Engineering Company Limited who had a sizeable factory in

Park Lane, Fallings Park.

The Automatic Buffing Contact Coupler and Engineering Company

(a public limited company) was formed on 3rd March 1904 as an agency that

sub-contracted work to outside manufacturers and developed

products that were made by outside companies under licence.

ABC’s head office was at Queen Anne’s Chambers, Tothill Street,

Westminster.

One of the first products was the automatic coupler that was

invented and patented by J. T. Jepson. The patent application,

number 25,511 is dated December 1905 and this was accepted on 16th

August, 1906. |

J. T. Jepson's original design for an

automatic coupler. The Railway Engineer, November 1906. |

The invention consists of a pair of automatic couplers that

are locked together by a shackle and a hook.

There are two shackles that overlap when in the coupled

position. The lower one is engaged over the hook of the opposite

coupler and the upper shackle overlies the lower and secures it

in its coupled position.

Uncoupling is achieved by raising the upper shackle into its

inoperative position through a recess in the buffer. |

| When the upper shackle is raised, a tail lever on

its lower surface lifts the lower shackle clear of the hook and

the coupling is disengaged.

The automatic couplers were ideal for use on narrow gauge

light railways and large numbers were sold to the British

Colonies. By 1911 the ABC coupler had been adopted as the

standard type on the 2ft.6inch gauge Bauchi Light Railway in

Northern Nigeria and 4 locomotives and 55 vehicles using the

couplers were constructed by order of the Crown Agents for the

Colonies. At the same time the couplers were in use in Ceylon,

Honduras and on the Kalka-Simla State Railway in India, which

has gradients of 1 in 33 and curves of 120ft. radius. |

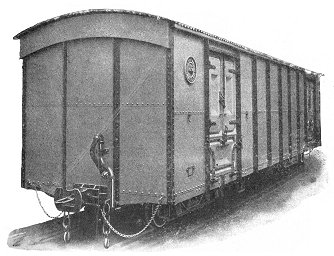

One of the wagons built by the Leeds Forge

Co. for the Kalka-Simla Railway showing the ABC coupler. These

were identical to the standard type except that chains were used

instead of locking bars. The Railway Engineer, July 1911. |

| The improved

coupler with rotating disc hooks. The Railway Engineer,

March 1912. |

|

By 1912 the coupler had been greatly improved and

continued to sell well, especially to railways that used centre

link and pin couplings. The design was robust and simple with

few moving parts.

It could automatically couple vehicles on straight or curved

track and cope with height differences of 4 inches on standard

gauge stock and from 2.5 to 3 inches on narrow gauge stock. |

| The smaller size had a breaking strain of 50

tons, which increased from 65 to 70 tons with the standard size.

The new design used disc hooks that were designed to open

automatically during uncoupling. When vehicles are coupled the

shackle rotates the disc hook into the locking position and is

held by a spring-loaded locking bar. Uncoupling is simply

achieved by pulling a chain or handle to disengage the locking

bar. |

| A plan view of the

new coupler. The Railway Engineer, March 1912. |

|

|

The new coupler. The Railway Engineer,

March 1912.

|

ABC's works in the late 1920s or early

1930s with Guy Motors in the background. Courtesy of Ken Foster. |

The company opened its Park Lane factory in 1915

and by 1951 the site covered approximately four acres.

By 1919 a non-automatic coupling had been added to the

product list, patent number 123,636. It consisted of a sliding

link that engaged with a coupling link. |

| All types of railway coupling devices were

manufactured at Park Lane including the standard British hook

and shackle with a three-link chain, the “Instanter” link, an

automatic mine car coupler designed for tipping cars, and

various screw and shackle designs, although the company was best

known for the ABC automatic couplers. Other railway products

manufactured under the ABC name included the “Lockyer” balanced

regulator valve, buffers, by-pass valves, drawgears, main

pistons for locomotives, and brake slack adjusters. |

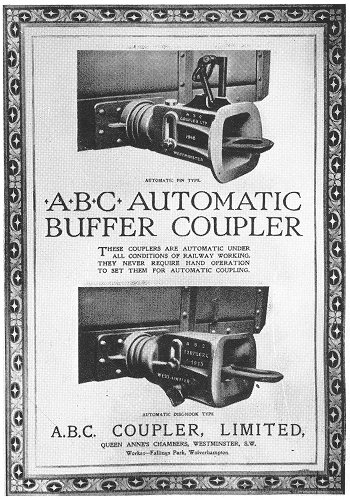

An advert from 1916. |

|

Other railway components were manufactured

at Park Lane under the “WOTA” (Wonder Of The Age) name. Wota

Limited was a wholly owned subsidiary company that produced a

large range of products including axle boxes, bearings, by-pass

valves and regulators, some of which were manufactured under

licence.

In 1939 the registered office moved from

London to Wolverhampton. Sales were high and the company had an

extensive export trade supplying railways in India, Pakistan,

Australia, Nigeria, Kenya and Uganda. During World War 2 this

suffered because of trade restrictions, but once the war was

over things soon recovered because of the vast amount of railway

reconstruction work that took place at the time.

|

An advert from The Locomotive magazine,

15th December, 1927. |

|

|

|

Return to

F. H. Lloyd |

|

Proceed to

the

next page |

|