F. H. Lloyd & Company

Limited - The 1960s

|

| |

|

| Read an article about

'The Good Old Days' from the Christmas 1960 edition

of 'The Steel Casting' |

|

|

|

| In 1962 the Lloyd group

acquired railway coupling manufacturer ABC Coupler,

shortly after it had gone into liquidation.

Read about

ABC Coupler Limited. |

|

| |

|

|

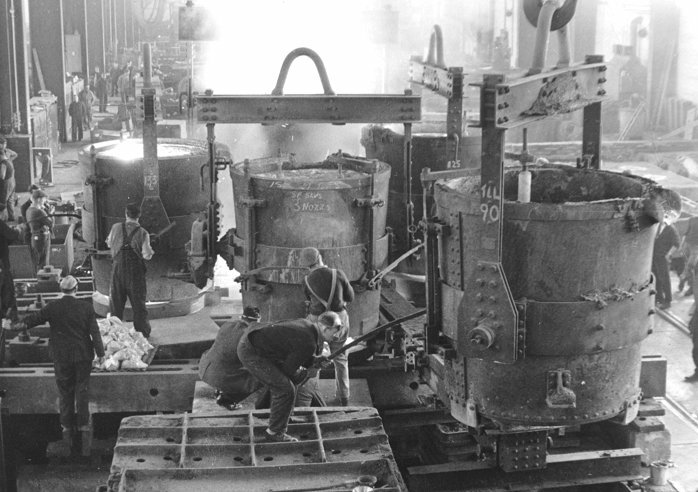

Using multi-ladles for a

large casting. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

Casting another

multi-ladle job in the foundry. Courtesy of

Wendy Marston. |

|

|

|

|

Two more

views of the casting process.

Courtesy of Wendy Marston. |

|

|

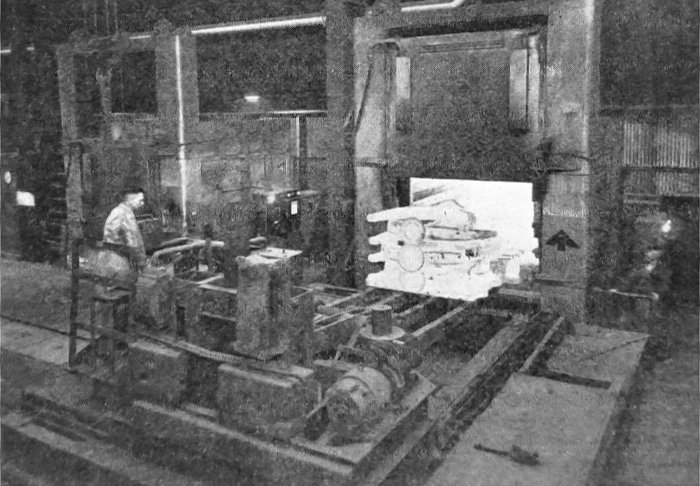

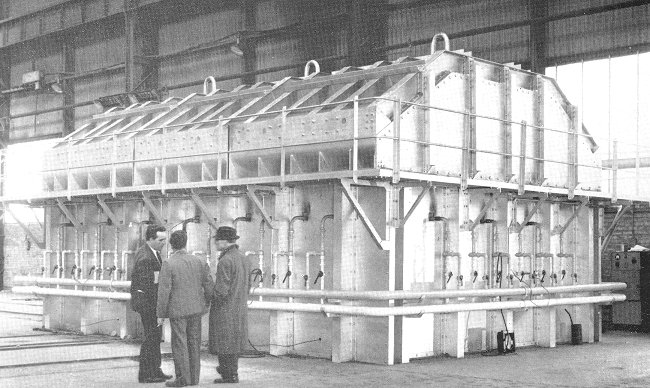

A batch of tyre presses in the

Machine Shop awaiting despatch in 1960. From 'The

Steel Casting', courtesy of Wendy Marston. |

|

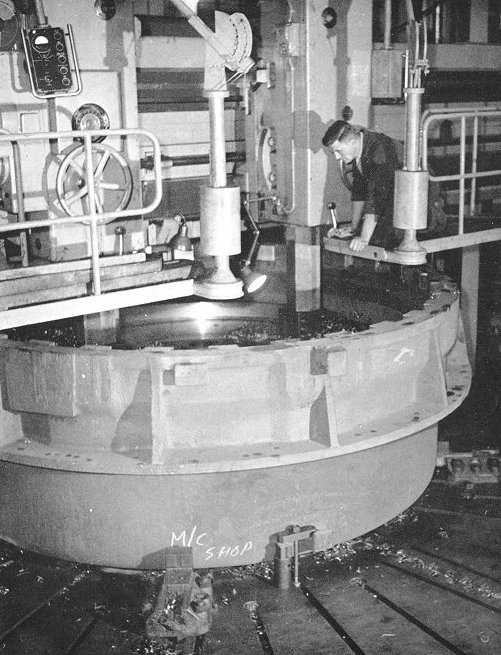

Precise machining in the

Machine Shop. From

'The Steel Casting', courtesy of Wendy Marston. |

In July 1961, Mr. F. N. Lloyd

(centre) presented retirement gifts to four long

serving employees, Jack Davies, George Powell,

Roland Lavender, and Harold Parsons.

From 'The Steel Casting', courtesy of Wendy Marston. |

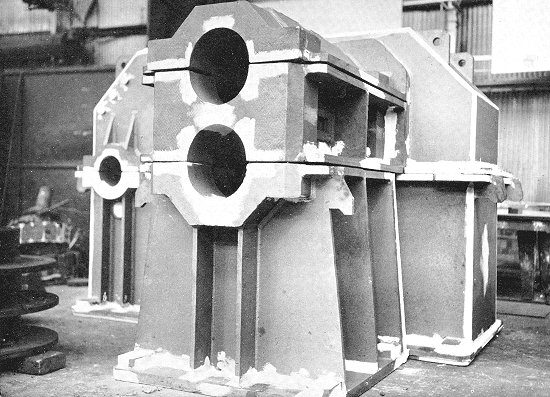

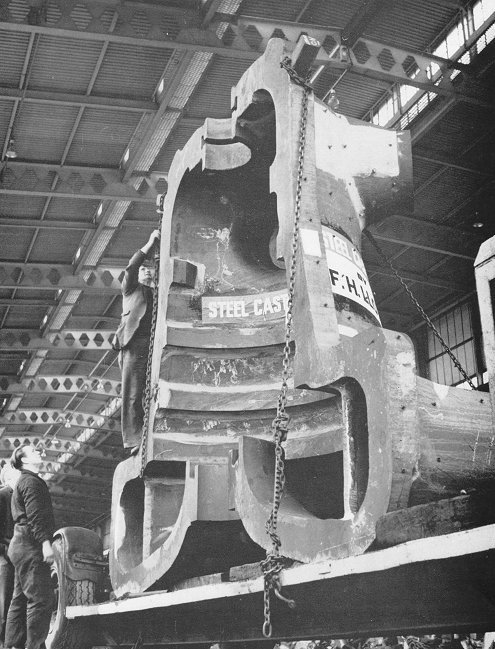

A Lloyd 400 ton press. The

presses were designed and built at the James Bridge

Works. The innovative design featured vertical and

horizontal rams, and a moving table, which were all

electrically controlled.

From 'The Steel Casting', courtesy of Wendy Marston. |

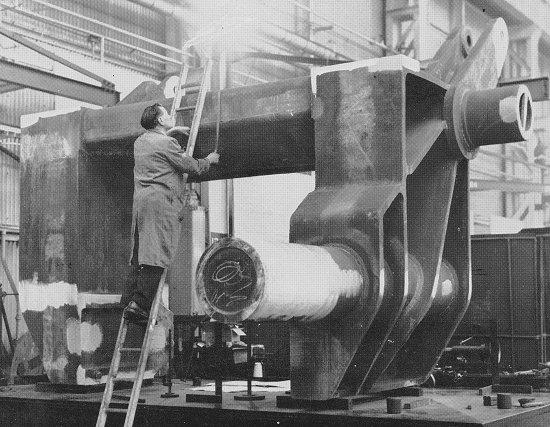

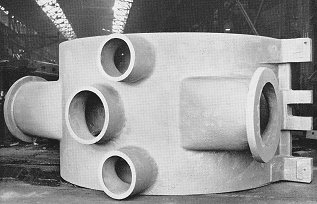

| A huge steel

casting weighing 30 tons, designed and cast at James

Bridge in 1962. It is

part of a coil handling machine. |

|

|

|

|

|

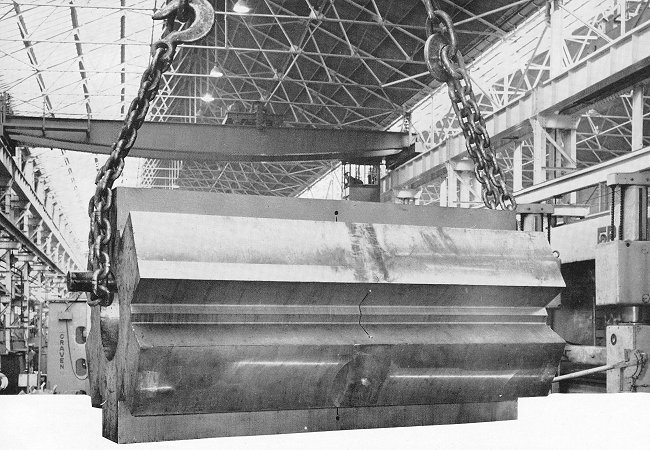

Two

large castings, cast at Burton and machined at

James Bridge. |

|

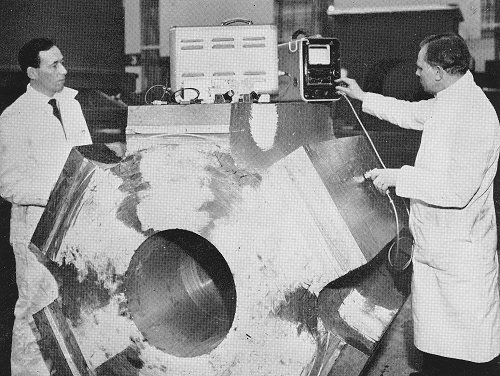

The first magnet wheel for the

C.E.G.B. to be cast in two halves and successfully

welded together at James Bridge. |

|

The 28 ton magnet wheel being

ultrasonically tested for cracks. |

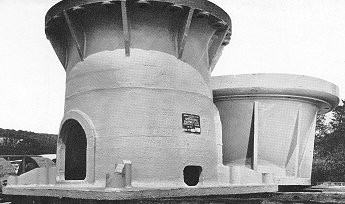

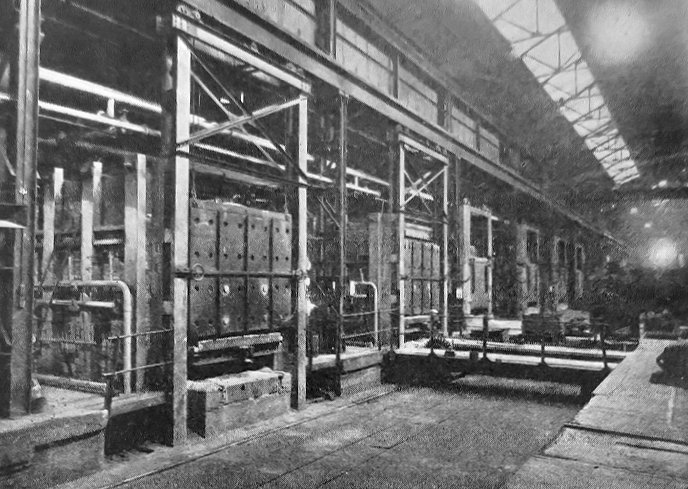

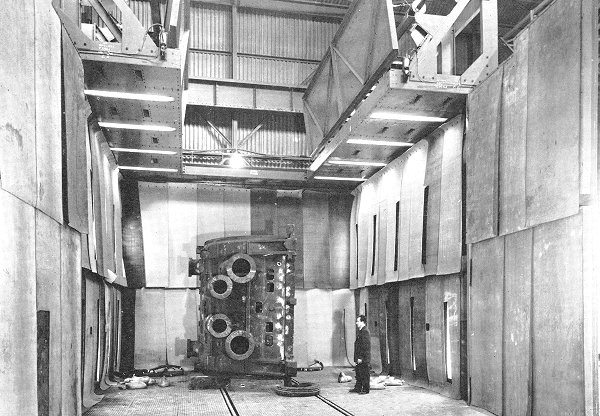

The electric heat treatment

furnaces at James Bridge were the best of their type in

the country. They had an accurate temperature range of

over 1,000 degrees Centigrade. |

|

Removing castings from one of the

heat treatment furnaces. |

|

|

|

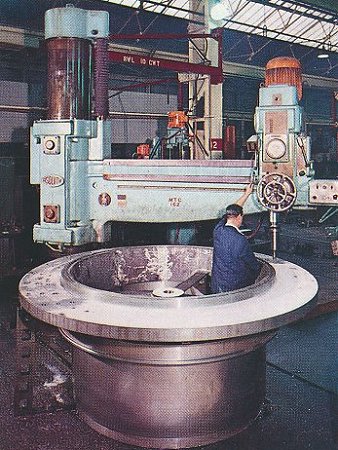

| The firm's

largest radial drilling machine, an Asquith OD4,

at work on a power station feeder head. |

|

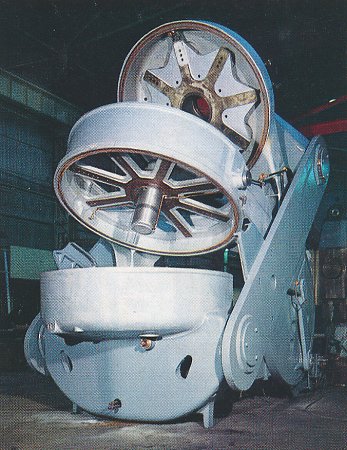

The

impressive MacLloyd 75 twin tyre press, designed

and built by the company. |

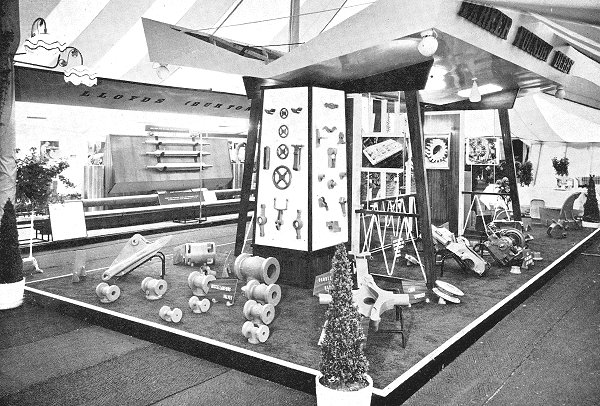

| Part of the display

put on by Lloyds (Burton) Limited in 1962 at the

second Engineering Materials and Design

Exhibition and Conference at Earls Court. |

|

|

|

|

|

|

Another

part of the display. |

|

Mr. F.

N. Lloyd and V. T. Grantham. |

|

|

The works entrance with the

machine shop on the right. |

|

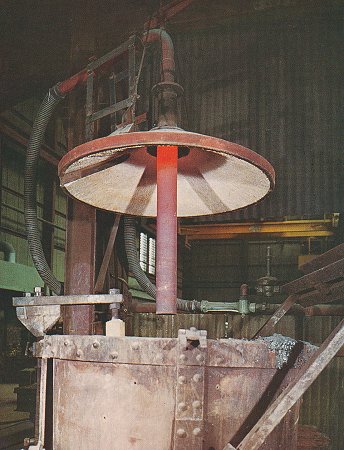

The ladle pre-heater unit. |

In 1962 one of the problems facing many foundries

was overcome at Lloyds (Burton) Limited. The ladles used

to transport molten steel around the foundry had to be

heated to ensure that there was no moisture in the

lining. Failure to do so could result in an explosion, if

the molten metal came into contact with moisture in the

lining. Ladles were usually heated using a large

burner, similar to a blowlamp, which was wasteful in

fuel and energy. Lloyds developed a radiant tube heater

using a special nickel-chromium steel, which was

resistant to oxidisation and wear, and did not distort.

The new pre-heater reduced ladle heating costs from

7s.6d. per ton to 1s.6d. per ton. 100 ton ladles could

now be heated to 600ºC. in

five hours. The first ladle heater unit was supplied to

the English Steel Rolling Mills Corporation Limited, at

Sheffield. |

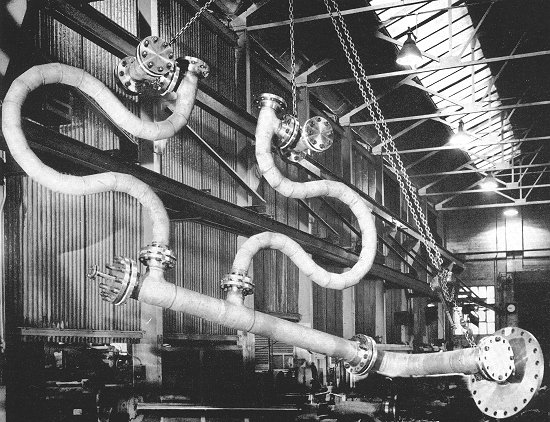

| An interesting job carried out

at Lloyds (Burton) Limited in 1962 was the building of

the twin expansion loop shown opposite, for the

Power-Gas Corporation of Stockton-on-Tees.

It was made of sections of

centrifugal tube that were welded together to form a

loop.

After completion it was

successfully pressure tested to 1,500 lbs. per square

inch. |

|

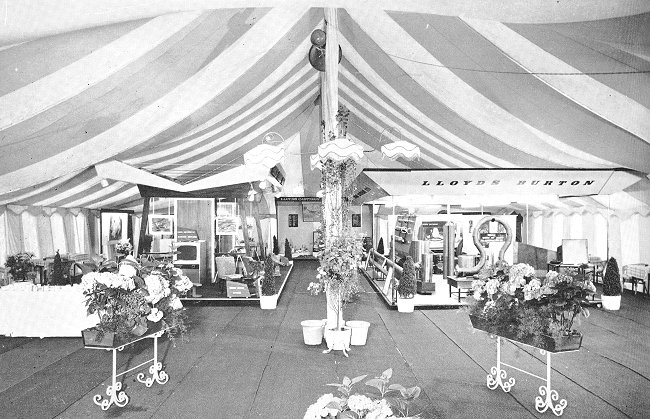

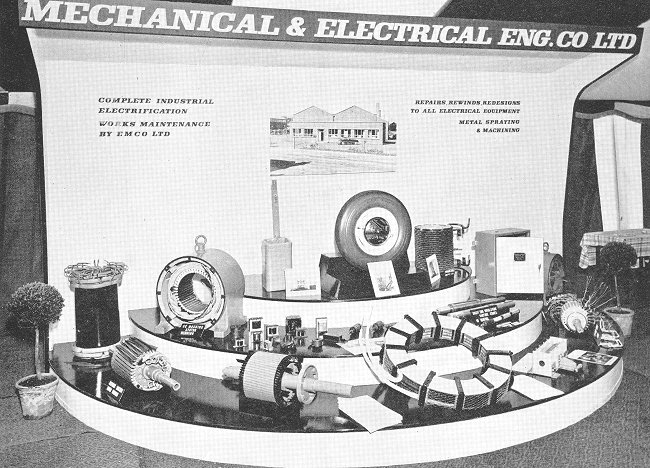

1962 was British Foundry Year,

commemorating the centenary of the opening of the first

steel-making furnace. Lloyds celebrated the event with

an exhibition, and works open days for the general

public. Vast marquees were erected on the sports ground

to display exhibits from the whole of the Lloyd Group.

During the three days of the exhibition, over 1,000

visitors and guests enjoyed the displays. |

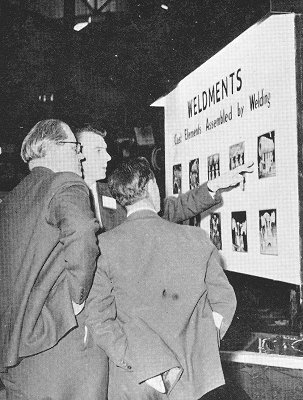

| Viewing the company's display

about a new technique called casting-weldments which

enabled Lloyds to produce a wider variety of

fabrications. Mild steel

castings and mild steel plate, varying in thickness from

1 inch to 12 inches were welded-together to form

fabrications which were then machined. |

|

|

A casting-weldment

consisting of a fabricated rolling mill drive gearbox

produced for Henry Simon (Engineering Works) Limited.

It weighed 14 tons. |

|

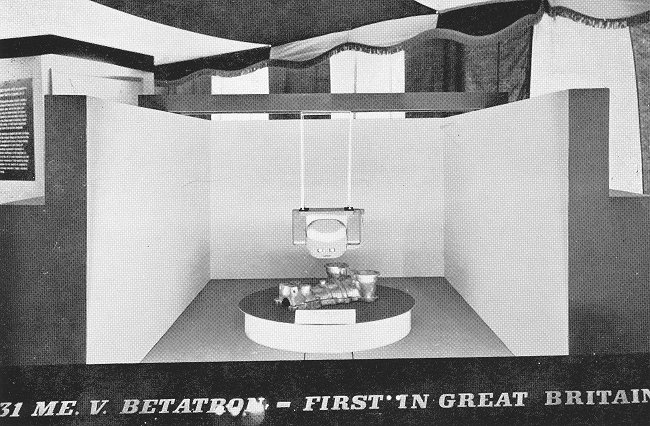

A model of the 31 MeV Betatron

that was installed at James Bridge Works. |

|

The Parker Foundry display. |

|

The Lloyds (Burton) display. |

|

The Mechanical & Electrical

Engineering Company's display. |

|

E. C. & J. Keay's display. |

|

In 1962 the old cottages adjoining

the Park Lane entrance were demolished. |

| In 1962 the Radiography Proving House opened at

James Bridge. It contained one of the latest pieces

of equipment for non-destructive testing, the

Betratron. The Brown Boweri 31 MeV Betatron is a

very powerful x-ray machine that was used for

radiographic inspection of thick-walled castings. It

produces x-rays of a shorter than normal wavelength

which is far more penetrative. Castings of up to 18

inches thick could be inspected. This was the first

installation of its kind in the country. |

|

The Radiography Proving House.

From 'The Steel Casting', courtesy of Wendy Marston. |

|

The Brown Boweri 31 MeV

Betatron. From 'The Steel Casting', courtesy of

Wendy Marston. |

|

A large turbine casting is

got ready to be transported from the Wednesbury

site. From 'The Steel

Casting', courtesy of Wendy Marston. |

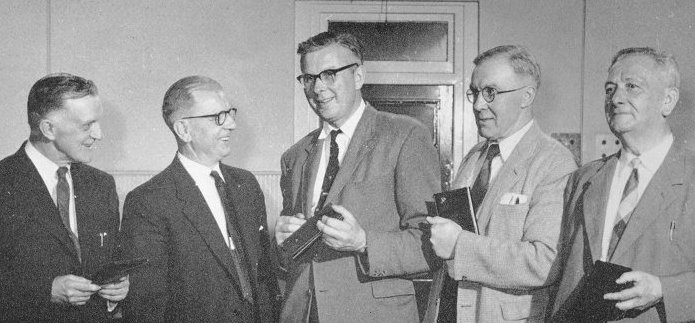

The Works Agents Committee.

Left to right: J. Rickuss, G. Williams, E. Green

(Chairman), S. Brookes, and

R. Bayliss. From 'The Steel Casting', courtesy of

Wendy Marston. |

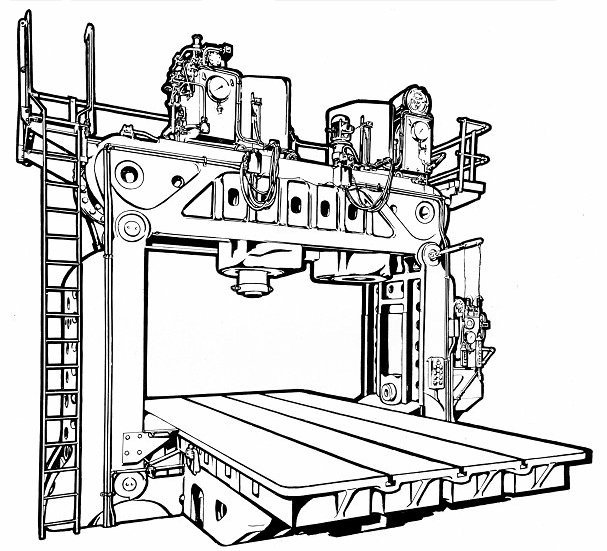

A new acquisition in the

Machine Shop in 1967 was an Asquith ram borer, seen

here machining a revolving frame for a Ruston

Bucyrus excavator. The machine had a maximum

vertical travel of 19 feet and a maximum horizontal

travel of 35 feet. It carried out both milling and

boring. From 'The Steel Casting', courtesy of Wendy

Marston. |

| The Tipton Factory On 4th November, 1963 a team of men from James Bridge

works moved into the two empty bays of Wright's Forge in Factory Road, Tipton. Lloyds acquired the site in order

to fettle large turbine castings which were occupying

valuable space at James Bridge. Heading the team of ten was

George Wilkinson who had the task of setting up the

operation there. Initially there was no shotblast or heat

treatment facilities, just hard work.

Within twelve months, a shotblast plant and a heat

treatment furnace had been installed, and by the end of 1964

there were 13 welders, 17 finishers, 3 burners, 3 shotblasters, 2 heat treatment furnace men, 2 crane drivers,

and 1 labourer. By the 1970s the building had grown to four

bays covering 100,000 square feet. Around 3,000 tons of

fabrications were produced annually under the control of

George Roberts, Production Superintendent. Machinery in

the factory included a 700 ton twin 'C' frame hydraulic

press, designed and built at the James Bridge factory. It

could handle steel plate up to 16 feet wide and

¾ inch thick. There were 4

automatic gas profile cutters and fully automatic welding

machines. The Fabrications Section moved to Tipton

in 1966, and became a separate division of F. H. Lloyd and

Company Limited in 1967. Lloyds Steel Fabrications became

one of the country’s leading manufacturers of welded steel

fabrications. It was a great success.

Dick Howett was general manager, in charge of sales,

estimating and process planning, costing, buying and

production. The production superintendent was George Roberts

who was responsible for all production and work schedules.

He maintained liaison with customers on delivery and ensured that the right materials were in stock for the job.

Colin Hammond was chief planning

engineer at Tipton. His department prepared estimates

against enquiries, from which quotations were submitted. The

department also translated orders and drawings into detailed

working instructions for manufacture. George Arnold oversaw

quality control, which included checks on raw materials,

work in progress, and completed fabrications, using special

test equipment.

Muriel Simmons was secretary to Mr.

Howett, and the young lady, known as the voice of the division,

Barbara Potter, was the telephonist.

Plate preparation equipment in the

factory included four automatic gas profile cutters, a

Hancoline HL.3 and HL.4, a Hanco-ordinate c.90 and BOC

Bison, which were giant pantographs to exactly reproduce on

a sheet of steel a design or profile which was read from a

specially prepared drawing by an optical sensor. There were

also a number of straight-line cutting machines, and twin

C-frame hydraulic presses, designed and built by Lloyds.

Four welding processes were used:

manual arc, cored wire CO2, submerged arc and electra-slag,

the last two being fully automatic. The electroslag machine

is a prototype and the only one of its kind in this country,

manufact:ured by ESAB of Sweden. It could butt weld plates

up to 15 inches thick.

There was a North Sea gas fired heat

treatment furnace with a capacity of 24 ft. x 16 ft. x 11

ft. where fabrications were heated to a temperature of 650°C

to relieve any stresses set up by welding. The shot blast

plant was in a heavily shielded room measuring 27 ft. x 24

ft. x 18 ft. high with an opening top to permit the craning

in and out of fabrications. Steel pellets were 'shot' from a

nozzle by compressed air at high speed to scour the surface

scale from the fabrication and reveal the pristine grey

metal that is steel. |

|

George Wilkinson and the new

shotblast at Tipton. |

|

George Wilkinson on the left and

the heat treatment furnace, larger than the one at James

Bridge. |

|

George Wilkinson and his team. |

In the autumn of 1965 a new

canteen opened on the Tipton site. It became known

as the 'Wilkeyville' canteen, named after the boss,

George Wilkinson. On the opening day, hot meals were

brought from the James Bridge canteen by Ted

Hardingham, and Wilf Vann. At 12.30 the doors

opened, and in a few minutes 31 piping hot meals

were served, consisting of hot pork with all the

trimmings, followed by blueberry pie. From 'The

Steel Casting', courtesy of Wendy Marston. |

|

Mrs George Wilkinson gives a

helping hand. From 'The Steel Casting', courtesy of

Wendy Marston. |

Mr. and Mrs George Wilkinson and the canteen staff

get ready for the official opening. Left to right:

Mrs Keatings, Mrs Wilkinson, George Wilkinson, Wilf

Vann, and Ted Hardingham. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

The meal is greatly enjoyed by

all of the diners. From 'The Steel Casting',

courtesy of Wendy Marston. |

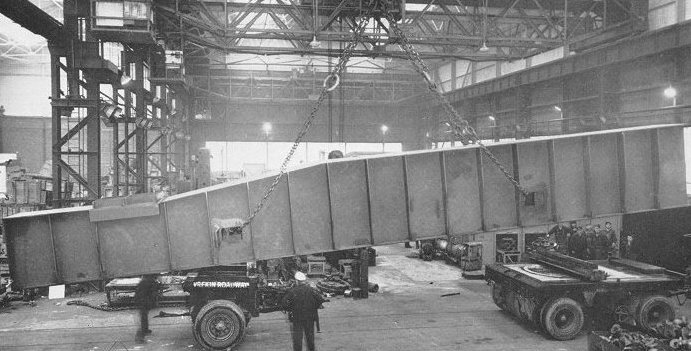

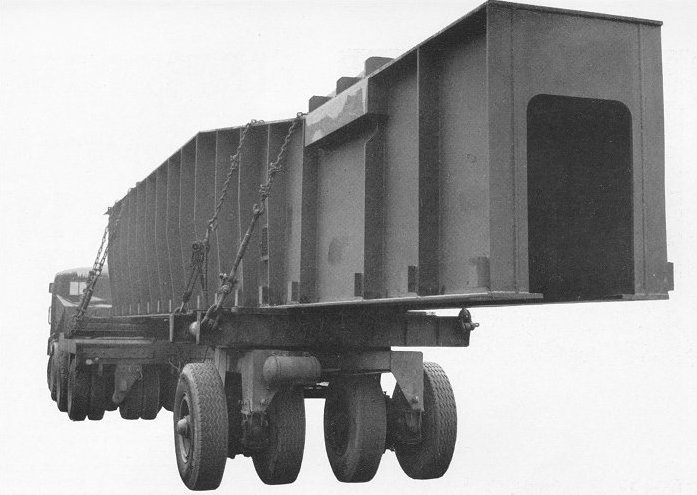

A large fabrication built at

the Tipton site, being readied for transportation.

It is a half measuring beam for a rolling mill,

weighing 40 tons, with a length of 106 feet. It is

destined for Brightside Engineering Company of

Canada. From 'The Steel Casting', courtesy of

Wendy Marston. |

|

The fabrication gets underway.

From 'The Steel Casting', courtesy of Wendy Marston. |

|

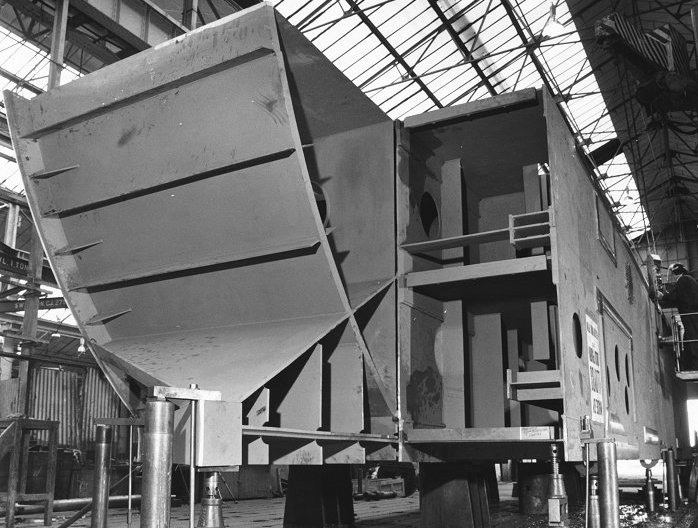

A view inside the Tipton

factory. Courtesy of Wendy Marston. |

|

A large fabrication

nears completion in the Tipton factory.

Courtesy of Wendy Marston. |

|

The fabrication is readied

for transportation. Courtesy of Wendy Marston. |

|

The fabrication leaves the

Tipton factory. Courtesy of Wendy Marston. |

|

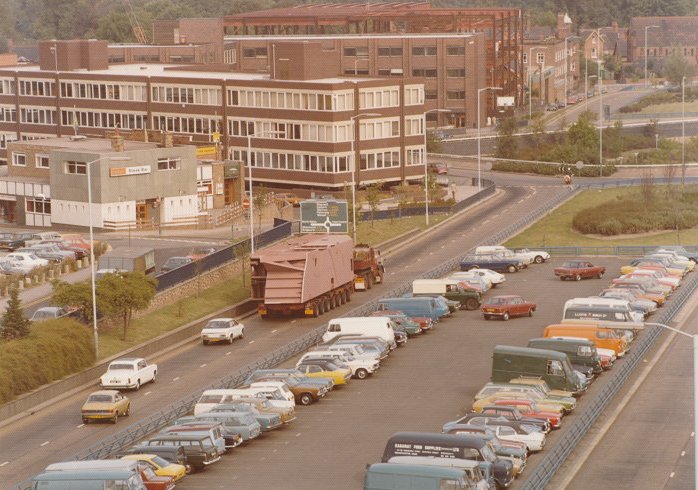

The fabrication leaves

Penn Road in Wolverhampton and enters the Ring

Road. Courtesy of Wendy Marston. |

|

The journey continues as

the vehicle approaches Chapel Ash island.

Courtesy of Wendy Marston. |

|

Barbara

Potter, Receptionist & Telephonist at the Tipton

factory. |

|

Dick

Howett, the General Manager at the Tipton

factory. |

A 50 ft.

fabricated revolving base for a Bucyrus

Erie walking dragline which was built at

the Tipton site in 1975. From 'The Steel

Casting', courtesy of Wendy Marston. |

The largest British tyre mould ever

made. Produced by Lloyds (Burton)

Limited for Dunlop. |

Around 1963 the Lloyd Group expanded with the formation

of F. H. Lloyd & Company Limited, Cardiff, and new

techniques were introduced including the CO2 sand

process, particularly for cores. Also shell moulding and

shell core making, and the use of CO2 as a gas

shield for wire welding. On 1st April, 1966 the local

boundaries changed as a result of the Local Government

Reform Act, after which the whole of the James Bridge site,

except for the sports ground was in Darlaston.

|

|

Visitors study the welding of

centrifugally-cast thermalloy tube during a two day

seminar at Lloyds (Burton) Limited. |

| |

|

| Read an article about

the new heavy foundry |

|

| |

|

| In 1966 The Lloyd Group acquired the group of

companies owned by N. Hingley and Sons including M. and

W. Grazebrook, Dudley; John Bagnall and Sons,

Wednesbury; Wright Hingley, Netherton; and Brown, Lenox

and Company (Pontypridd). Hingleys had previously been run by

a relative of the Lloyds, Cyril Lloyd, a descendant of

the Lloyds banking family, who died in 1963. Brown

Lennox, based at Pontypridd, were an ideal addition to

the Lloyd Group. They produced steel castings from a few

pounds to four tons in weight, in all compositions from

carbon steel to low and medium alloy steel. They had

excellent testing facilities including gamma ray,

ultrasonic, and magnetic crack detection, and a proving

room for testing chain up to 400 tons.

On 25th October, 1967 Lloyds acquired another

company, Thomas Summerson & Sons Limited of Darlington.

The company, which had been producing steel castings

since 1910 became Lloyds (Darlington) Limited. |

|

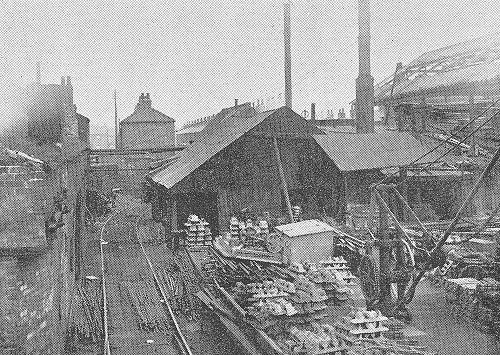

Thomas Summerson & Sons

original foundry at Albert Hill Works, Albert Street,

Darlington. |

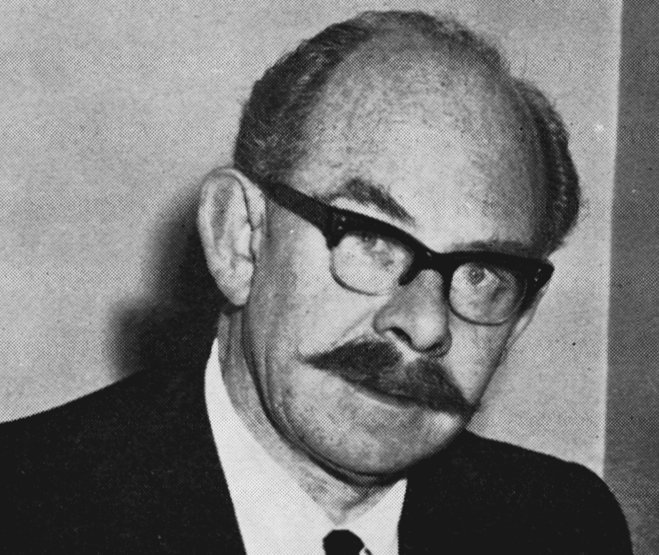

| Cecil Whitehouse, Managing

Director of Lloyds (Darlington) Limited, an old

foundryman whose passions included cricket, football,

and golf. It was thanks to his efforts that the old

company survived for so long. |

|

|

Tapping the 25 ton melting furnace

that began operating at James Bridge in January 1967. |

| On 12th August 1969 F. H. Lloyds

became part of F. H. Lloyd Holdings Limited. In

August 1969 F. H. Lloyd Holdings Limited was created to

oversee the various companies in the Lloyd group. The

Managing Director was Mr. Francis Nelson Lloyd. On 5th

September, 1970, Francis Nelson Lloyd retired and

handed-over to his younger brother Mr. Michael Charles

Lloyd. |

|

|

|

|

|

Return to the

late 1950s |

|

Return to

the contents |

|

Proceed to the

later years |

|