| F. H. Lloyd & Company

Limited - The 1940s and Early 1950s |

| During the Second World War,

castings were made for tanks, and for bomb casings. By the end of the war

James Bridge Steel Works could produce over 26,000 tons

of castings a year in 60 different grades of steel. |

|

The apprentice training scheme

In 1943 the company directors

approved the introduction of an apprentice training

scheme, which began in January 1944. Initially only

certain parts of the factory were involved in the

scheme, but within a few months all the departments

were involved. A carefully planned schedule of work

was planned for each apprentice, specifying the

different operations to be learnt, and the time that

would be spent on each. This ensured that the scheme

would ultimately produce skilled moulders, core

makers, pattern makers, fettlers, electricians,

mechanics and fitters. It was hoped that some of the

successful apprentices would eventually become

foremen, or senior management.

Talks were held with local

schools, and the Ministry of Labour in the hope of

attracting what was described as the 'better type of

boy'. |

|

Pupils in the Foundry School

at work. From 'The Steel Casting', courtesy of Wendy

Marston. |

|

An important feature of the

scheme was the method of wage payment to the

apprentices. All under eighteens were paid on a

special time rate basis. Every four weeks, marks

based on timekeeping, general behaviour, progress at

work, etc. were awarded to all apprentices. The pay

rate depended upon the marks awarded. If anyone

persistently failed to achieve the required standard

of proficiency, their contract of employment was

terminated.

The scheme was divided into two

main classes, Craft Apprentices, and Engineering

Student Apprentices. Craft Apprentices were trained

to become craftsmen in one of the following

departments: the Foundry, the Pattern

Shop, the Fettling and Finishing

Departments, the Maintenance Engineering

Department, or the Machine Shops. It was intended that

all boys embarking on a craft apprenticeship course

would enter the school on joining the company and

spend from 6 to 18 months there, before passing to

other sections of the factory.

|

|

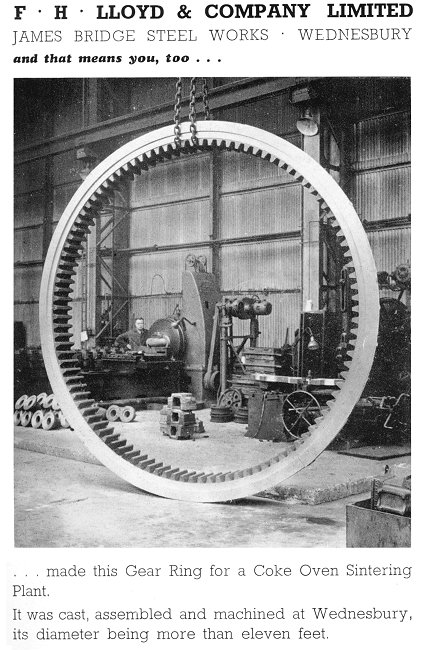

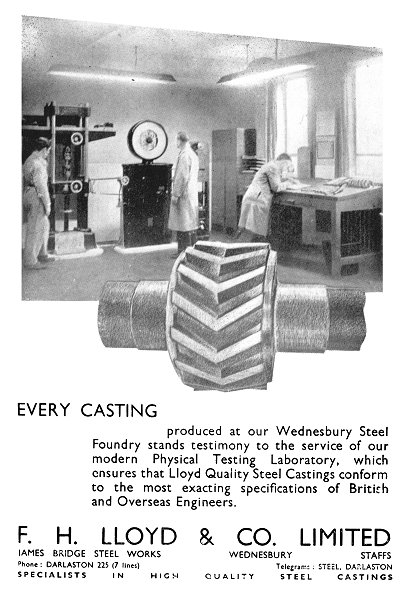

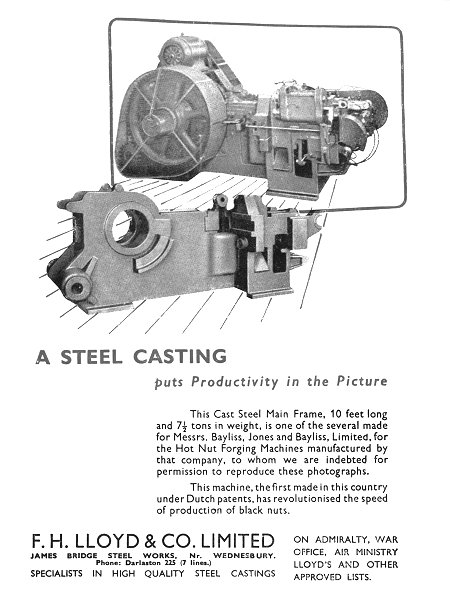

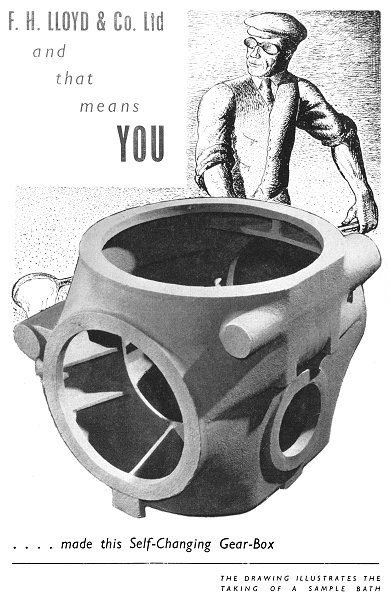

An advert from 1949. From 'The

Steel Casting', courtesy of Wendy Marston. |

Engineering Student Apprentices came from

technical and secondary schools, usually at 16 years

of age, and had to possess at least a School Leaving

Certificate. They were trained to become

draughtsmen, chemists, time study or planning

engineers. To this end a special schedule of

training was drawn up covering a wide range of

subjects. Apprentices were encouraged to

attend evening classes. All fees and expenses were

paid by the company and prizes were presented to

successful students at the end of the year.

Records

relating to all apprentices were maintained in the

Personnel Department, and on completion of the

course, all apprentices having achieved marks of 65

percent or higher received a certificate. Those who

achieved marks of 85 percent or higher, were classed

as being in the honour grade.

In 1946 the company acquired a

competitor, Parker Foundry Limited of Derby and doubled

production there. Plans were made for the modernisation

of the Darlaston works, and for equipping the foundry at

Burton for the production of railway castings. |

|

The site of the extension

to the Foundry Training School. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

The Foundry Training

School in 1957. From 'The Steel Casting',

courtesy of Wendy Marston. |

At the apprentice

prize distribution in 1959, Brian Franks

receives the Sportsman of the Year Cup

from Mr. M. C. Lloyd. From 'The Steel

Casting', courtesy of Wendy Marston. |

At the

apprentice prize distribution in

1959, Roy Degville receives the

Rosebowl Trophy from Mr. M. C.

Lloyd, on behalf of the foundry

apprentices. From 'The Steel

Casting', courtesy of Wendy Marston. |

First year

foundry apprentices and their

instructor Jim Platt examine

castings produced at the Foundry

School in 1961. From 'The Steel

Casting', courtesy of Wendy

Marston. |

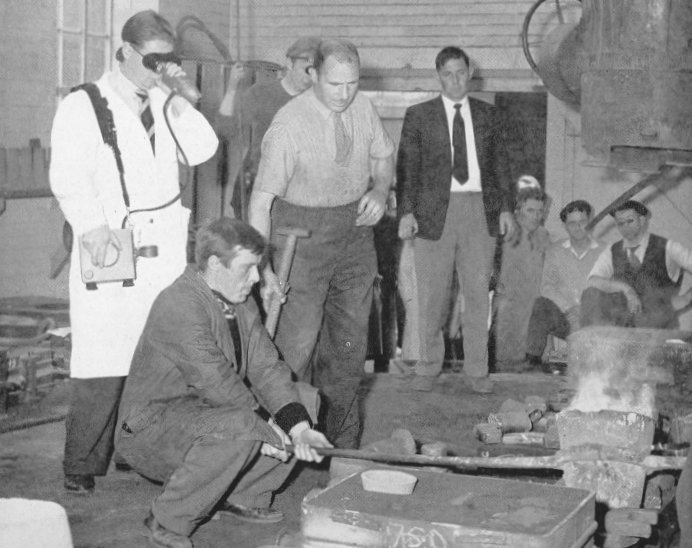

The first

of a series of experimental

heats is cast at the Foundry

School in 1961. From 'The Steel

Casting', courtesy of Wendy

Marston. |

Young

foundry apprentices listen

attentively to instructor

Geof Burns in 1964 as he

describes some of the

problems associated with

moulding. From 'The Steel

Casting', courtesy of Wendy

Marston. |

|

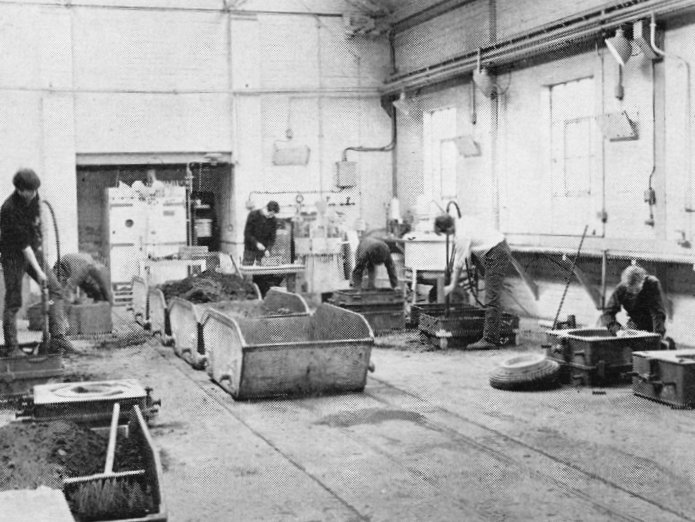

First year foundry

apprentices working in

the Foundry Training

School. From 'The Steel

Casting', courtesy of

Wendy Marston. |

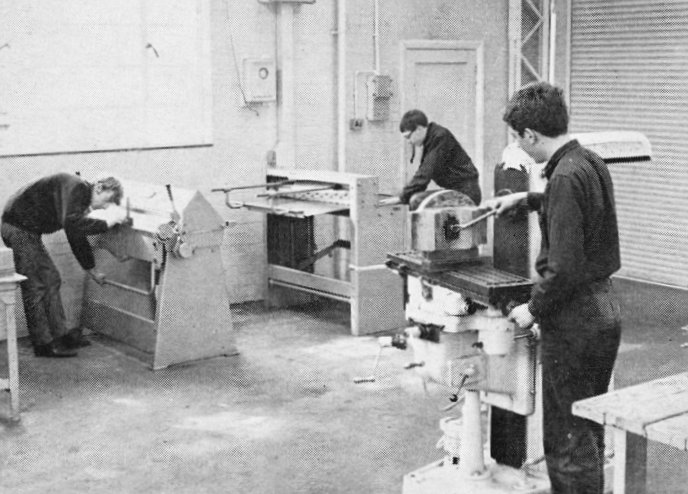

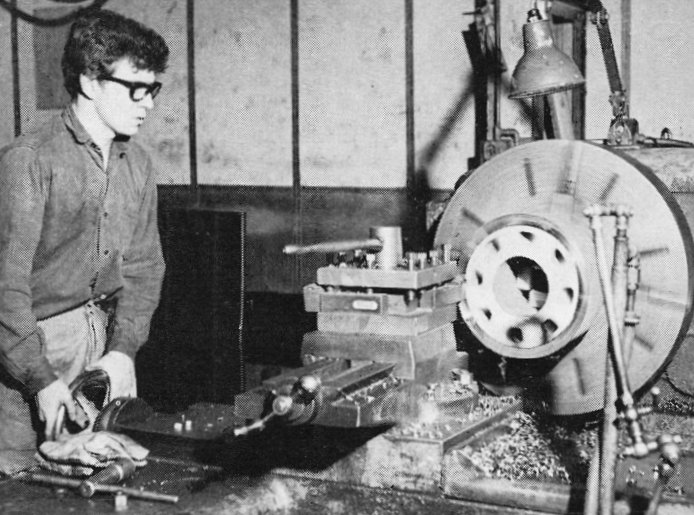

First year 'off the

job' engineering

apprentices engaged

in sheet metal work

and horizontal

milling. From 'The

Steel Casting',

courtesy of Wendy

Marston. |

|

First year

machinist and

fitting

apprentices at

work on bench

fitting and

lathe practice

in the

Engineering

Training School.

From 'The Steel

Casting',

courtesy of

Wendy Marston. |

A third year

machinist

apprentice

working on

advanced

turning

practice in

the Lathe

Section of

the Machine

Shop.

From 'The

Steel

Casting',

courtesy of

Wendy

Marston. |

Mr. M.

C. Lloyd

presenting

his son

Mr. D.

C. Lloyd

with his

apprenticeship

certificate

on 22nd

November,

1967.

From

'The

Steel

Casting',

courtesy

of Wendy

Marston. |

Mr. M.

C. Lloyd

presenting

Mr. G.

Mills

(Machine

Shop)

with his

apprenticeship

certificate

on 22nd

November,

1967.

From

'The

Steel

Casting',

courtesy

of Wendy

Marston. |

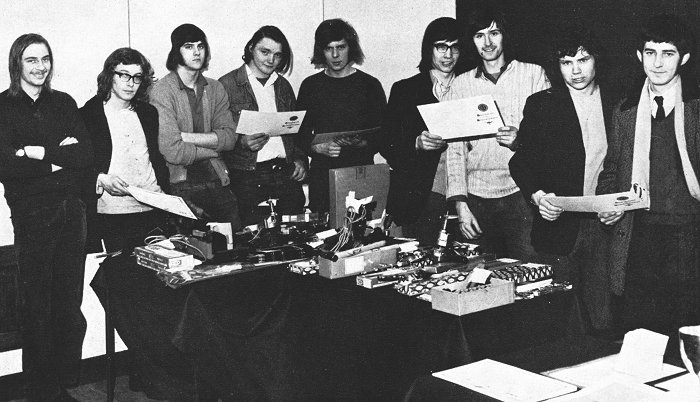

Apprentices

receiving

their

awards

in

1973.

Left

to

right:

Mick

Williams,

Peter

Jenkins,

Robert

Lee,

Stephen

Greaves,

Paul

Sheppard,

Derek

Loundes,

Dave

Nicholls,

John

Spragg,

and

Edward

Humphries.

From

'The

Steel

Casting',

courtesy

of

Wendy

Marston. |

|

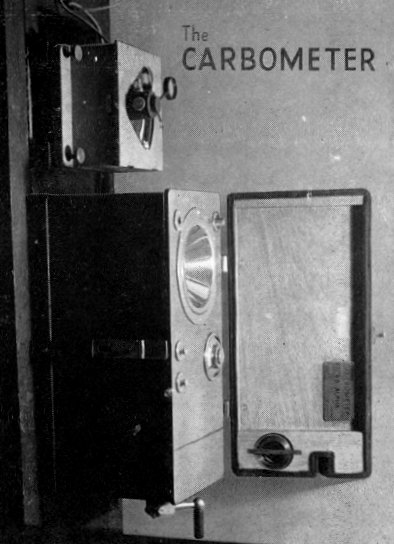

The tiny amounts of carbon

in steel have a profound effect on its

properties, so much so that it must be

controlled to the nearest .02 percent.

In the early days of steel

making a furnace man would withdraw a small

molten sample from a turbulent bath of white-hot

steel, and pour it into a flat mould. After

cooling, it would be broken in two with a

seven-pound hammer and the bright silver-grey

fracture would be examined in the blazing light

from the furnace door.

Skilled workers could

forecast the carbon content of several tons of

molten steel from the closely knit grain of the

broken sample.

The method was unreliable,

and so in the late 1940s it was just used to

obtain a preliminary estimate of carbon content.

The furnace men at F. H.

Lloyds now relied on the accurate reading from a

carbometer, which provided a rapid method of

measuring carbon content, free from the vagaries of human

error. Even so, a sample had to be taken from

the furnace and used to cast a perfectly sound

test piece. |

|

|

|

|

|

Thomas Hale, reading a fracture.

From 'The Steel Casting', courtesy of

Wendy Marston. |

|

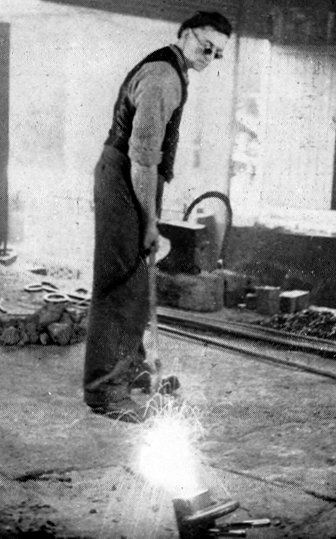

V.

Blythe casting a carbometer sample.

From 'The Steel Casting', courtesy of

Wendy Marston. |

|

|

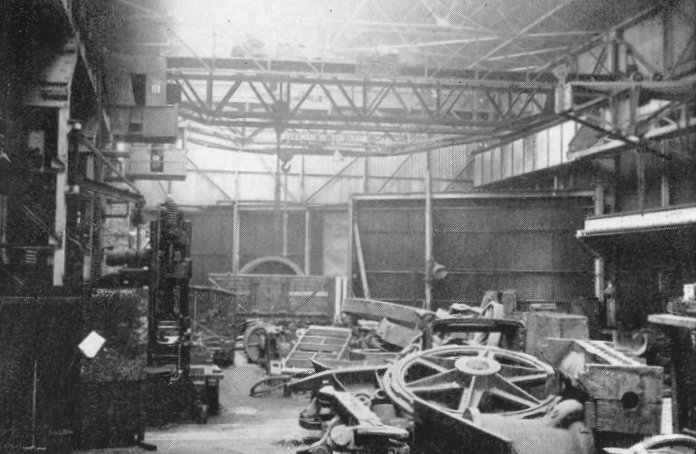

The Heavy Dressing Department.

From 'The Steel Casting', courtesy of Wendy Marston. |

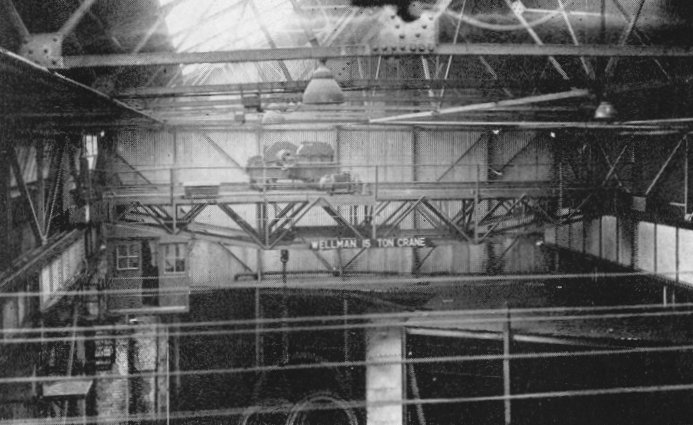

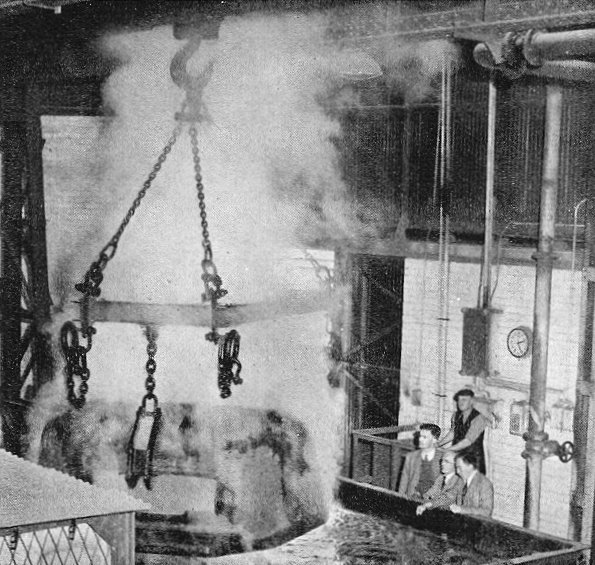

The new Wellman crane

installed in the the Heavy Dressing Department in

1949. From 'The Steel Casting', courtesy of Wendy

Marston. |

|

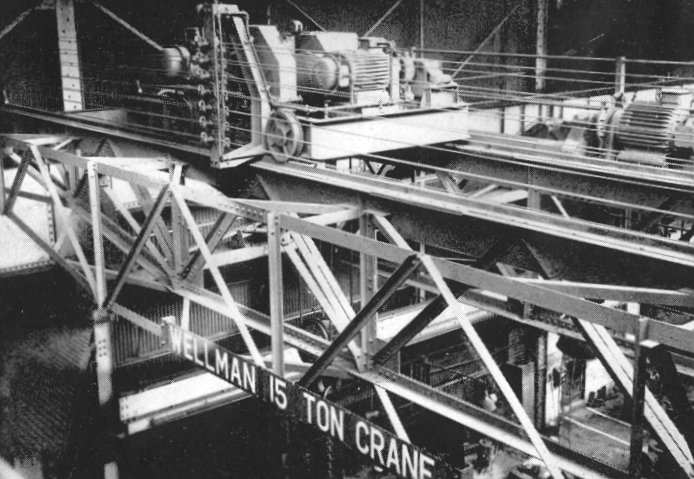

A close-up view of the new

crane. From 'The Steel Casting', courtesy of

Wendy Marston. |

|

An advert from 1949. |

|

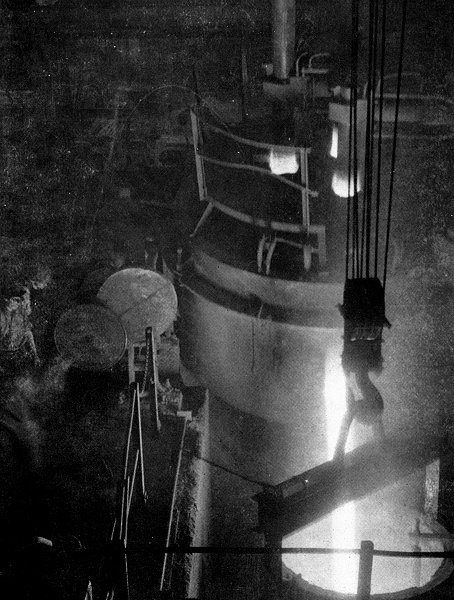

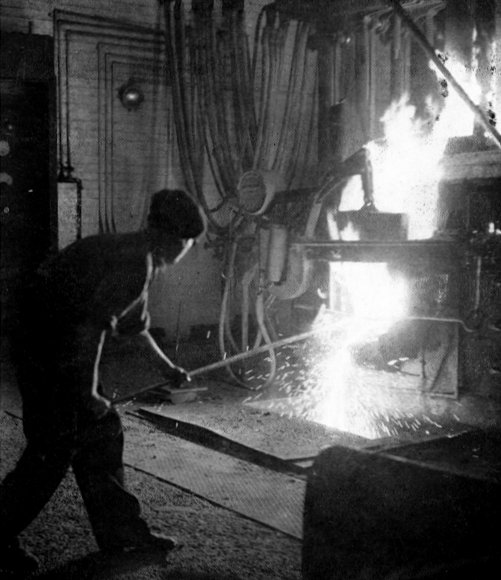

Tapping an electric arc

furnace. From 'The

Steel Casting', courtesy of Wendy Marston. |

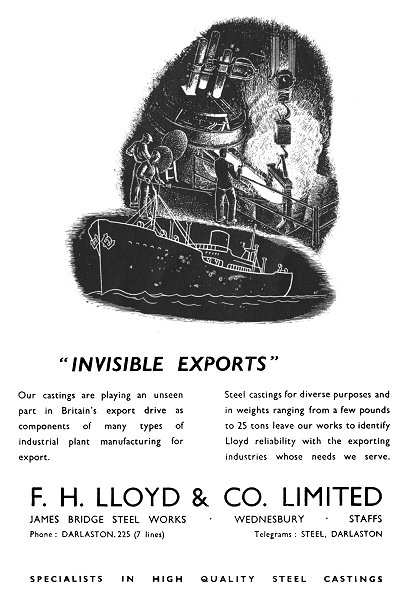

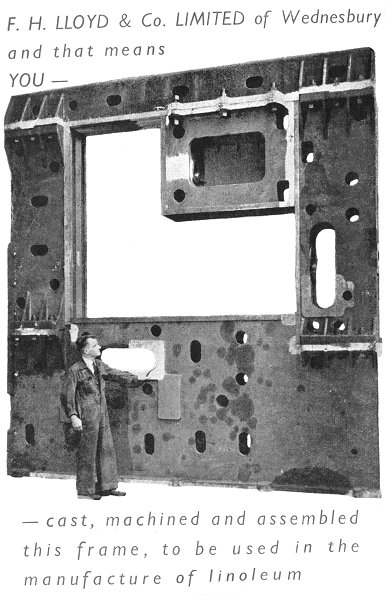

| An advert from 1950.

From 'The Steel Casting',

courtesy of Wendy Marston. |

|

|

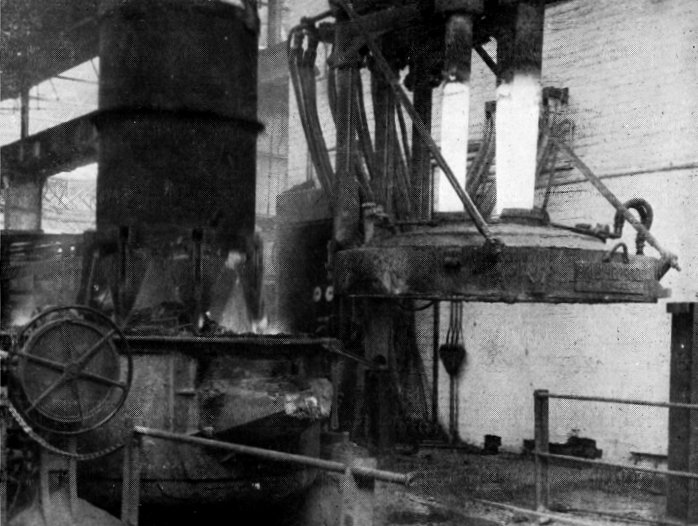

Charging an electric furnace

with steel scrap. From 'The Steel Casting', courtesy

of Wendy Marston. |

|

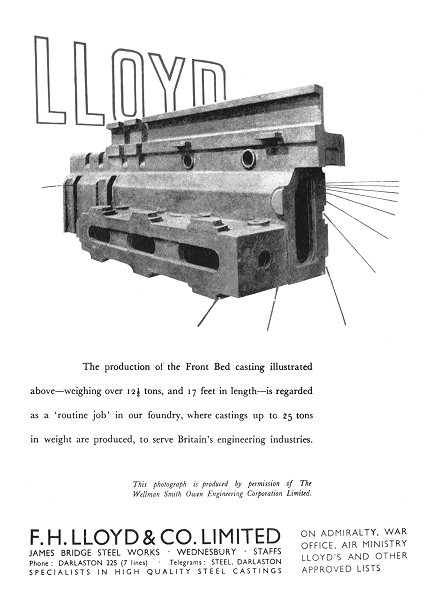

An advert from 1950.

From 'The Steel Casting',

courtesy of Wendy Marston. |

| An advert from 1950.

From 'The Steel Casting',

courtesy of Wendy Marston.

|

|

|

Removing the oxidising

slag in the course of a basic electric heat.

From 'The Steel Casting',

courtesy of Wendy Marston. |

| An advert from 1950.

From 'The Steel Casting',

courtesy of Wendy Marston.

|

|

|

Mr. Victor William Bone

who was a Director of the company until 1949, and

Chairman from 1941 until 1949.

He died on 12th October, 1951

and was buried at Lincoln.

From 'The Steel Casting',

courtesy of Wendy Marston. |

|

Radio Outside Broadcast

On 9th September, 1952 a BBC

radio outside broadcast team came to the James

Bridge site to record part of a programme about the

manufacturing of Centurion tanks. At the time the

turrets were cast at the factory, in one piece, in

armour steel. The programme included a section about

the heat treatment process, and the quenching

necessary to produce a turret from steel with the

required strength and toughness.

An interview took place in the

Heavy Heat Treatment Department beside the water

quenching tank, during which the well known radio

presenter Mr. "Jim" Pestridge talked to Mr. F. N.

Lloyd, Horace Taylor, supervisor of the Heavy

Foundry, and Arthur Reynolds, supervisor of Heavy

Heat Treatment Department. |

The interview in the Heavy

Heat Treatment Department as a turret is quenched.

From 'The Steel Casting', courtesy of Wendy Marston. |

|

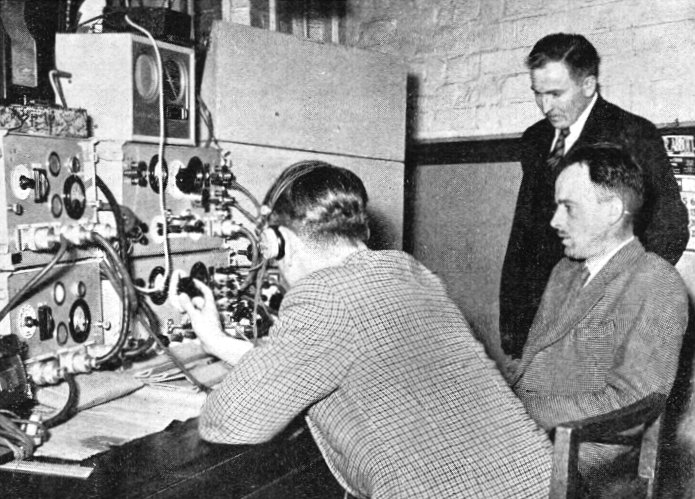

Members of the BBC team adjust

their equipment. From 'The Steel Casting', courtesy

of Wendy Marston. |

Work gets underway on the new

bowling green alongside Park Lane in the spring of

1952. From 'The Steel Casting', courtesy of Wendy

Marston. |

|

The new bowling green, just

after completion. From 'The Steel Casting', courtesy

of Wendy Marston. |

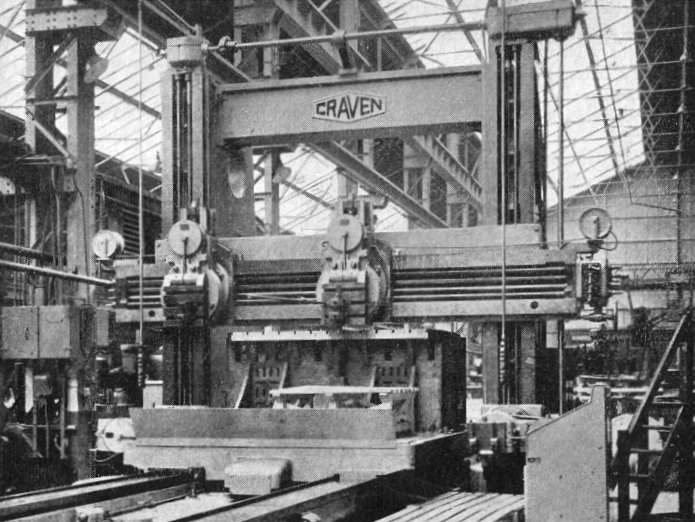

The new Craven planing machine

that was installed in the Machine Shop in 1952.

From 'The Steel Casting', courtesy of Wendy Marston. |

|

The new factory road, built in

1952. From 'The Steel Casting', courtesy of Wendy

Marston. |

|

Another view of the new road.

From 'The Steel Casting', courtesy of Wendy Marston. |

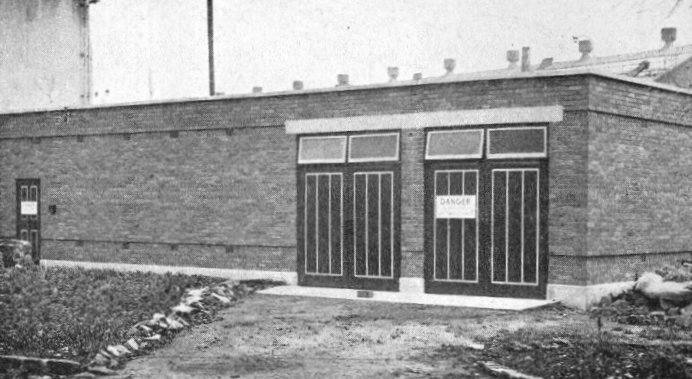

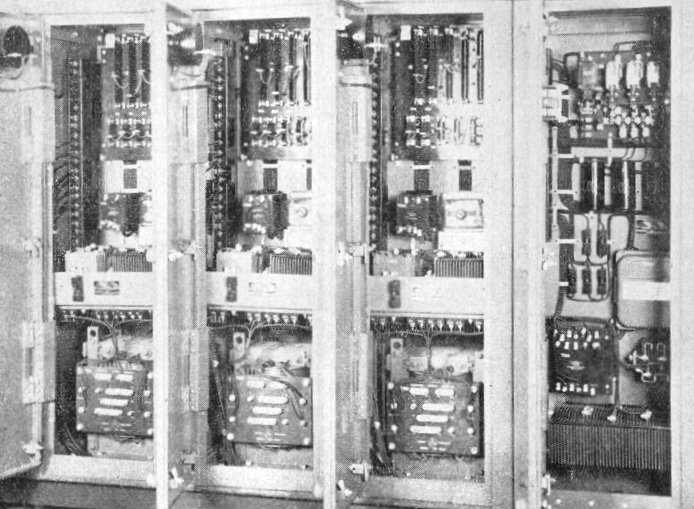

The new electricity sub

station built in 1952 that supplied electricity to

the whole of the site. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

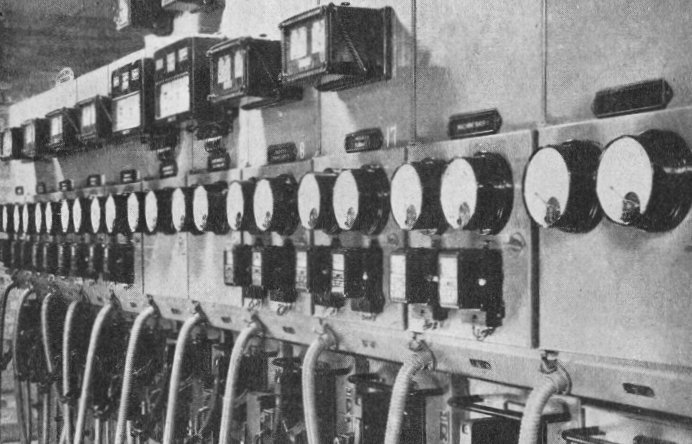

Some of the electrical

equipment in the new sub station. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

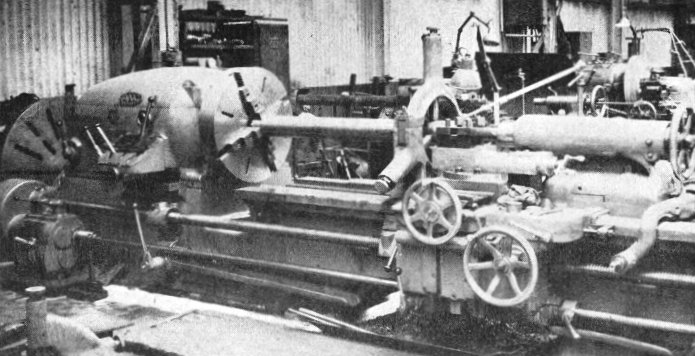

The Lang lathe that was

installed in the Machine Shop in 1952. From 'The

Steel Casting', courtesy of Wendy Marston. |

|

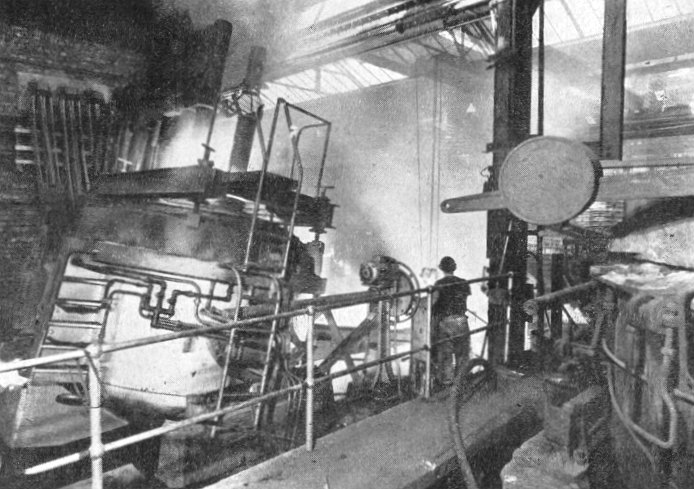

A new 3½

ton electric melting furnace installed in 1952.

From 'The Steel Casting', courtesy of Wendy

Marston. |

|

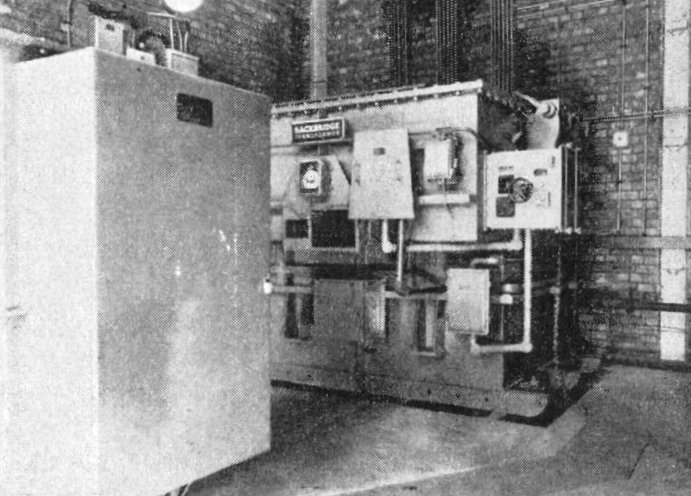

The transformer

for the new 3½

ton electric melting furnace. From 'The

Steel Casting', courtesy of Wendy

Marston. |

The Amplidyne control

gear that controlled the electrodes in the

new new 3½

ton electric melting furnace. From 'The

Steel Casting', courtesy of Wendy Marston. |

|

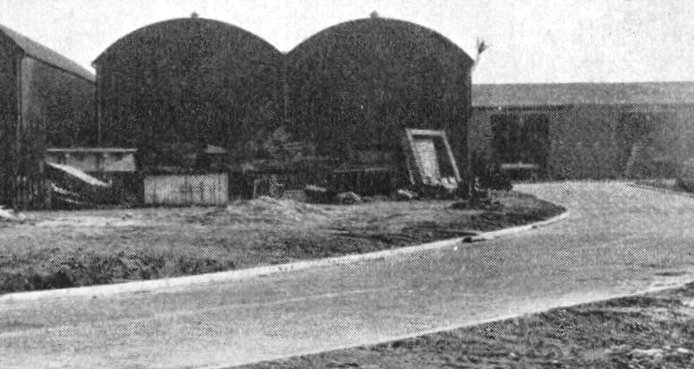

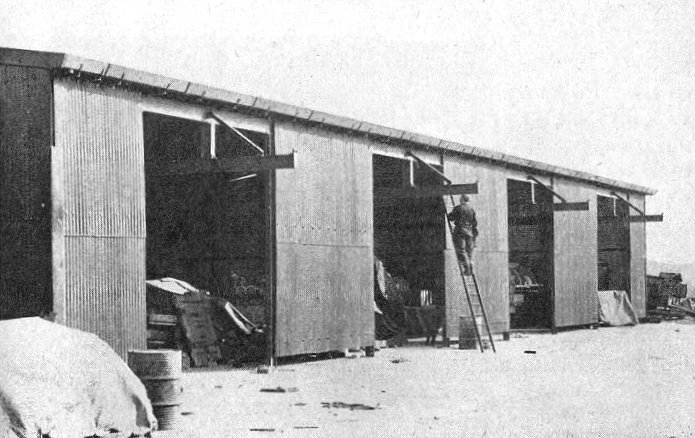

The new 96 feet by 70 feet

pattern storage barn built in 1952. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

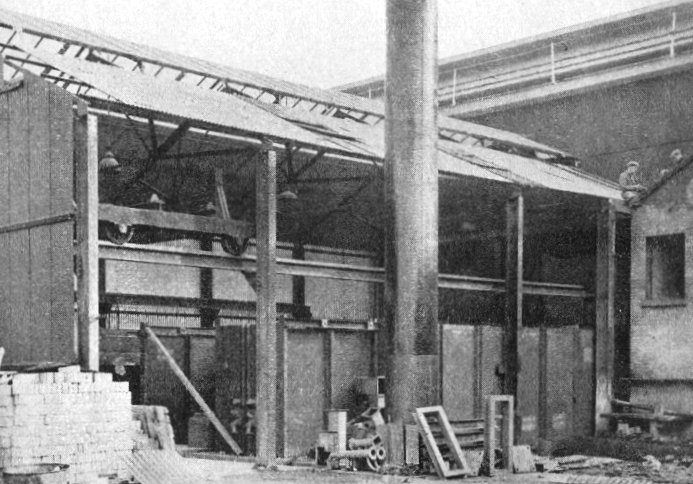

The building housing two mould

stoves, erected in 1952. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

By 1952 when the company's last

open hearth furnace was scrapped, Lloyds had 6 electric

arc furnaces with a capacity ranging from 2½

to 12 tons.

The

foundry could turn out very large castings, and

machine them to individual customer's requirements

in an

up-to-date machine shop.

Around

this time large machines such as tyre presses were produced

in the factory.

|

Mr. A. B. Lloyd (on the left)

presents a silver tankard to Robert Thynne. |

| During the financial year ending on the 31st March, 1952,

Lloyds produced more than 23,000 tons of black or

un-machined castings, consisting of over 650,000 single

castings. Large numbers of machined castings, patterns,

and ingots were also were

produced. Some of the largest castings produced were

steam chests for the electricity generating industry. They

weighed up to 60 tons. Two cranes would be linked

together with a lifting beam to take them out of the

casting pit. When freshly cast with the pouring heads

still attached, they weighed around 70 tons. |

|

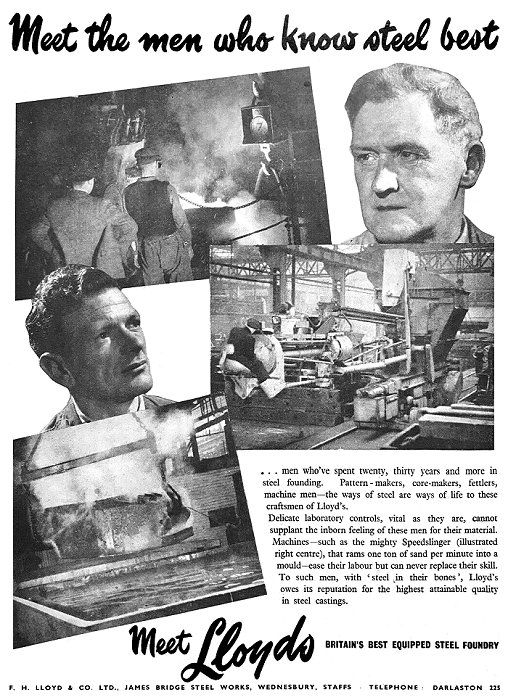

An advert from 1952. |

The advert on the left is

worded as follows:

The output for steel castings at Lloyds for this

year is expected to reach 26,000 tons, an

increase of one hundred percent over 1948. Does

this large output mean that craftsmanship is

being forgotten? On the contrary, it is because

of the traditional dexterity of Lloyds craftsmen

that this great increase is possible.Modern

machines - and no other steel foundry in Europe

is better equipped with them than Lloyds - are

certainly speeding the many foundry processes,

but it is the craftsmen of Lloyds with their

time-honoured knowledge and skill, who wed

hand-made perfection to machine-made efficiency.

Patternmakers, moulders, core makers, metal pourers,

fettlers, and machinists, craftsmen all, many with 40

years' experience; these are the men whose skill makes

steel castings of optimum accuracy, finest finish and

exactly to specification. |

|

|

|

| From the spring 1953

edition of 'The Steel

Casting':

The year 1952 showed a

marked increase in the

number of fires which

occurred in the works

compared with the previous

two years:

1950 - 15, 1951 - 22, 1952 -

26

Fire fighting materials used

in the extinction of some of

these fires included carbon

tetrachloride foam, carbon

dioxide, hose branches etc.

After each fire a full

survey and inspection was

carried out to find the

cause whenever possible, so

that improvement could be made

to eliminate any further

outbreaks.

I found that seven fires out

of the total number during

1952 should never have

happened if precautions had

been taken by workmen

concerned.

May I advise everyone,

whether at home or work, not

to take any risks that will

start or cause an outbreak

of fire. |

|

|

|

Fire extinguishers are

checked at regular intervals

by the Fire Dept., but there

are still one or two cases

where extinguishers are

being used and left empty.

Please inform the fire

station or your foreman.

During the past year members

of the Brigade carried out

drills and maintenance work

as well as attending water

exercises, lectures and

competitions, which had been

arranged by the Darlaston

and Wednesbury Works Fire

Brigades Group.

Special duties covered by

the Works Brigade included

the gala and sports day and

children's Christmas

parties.

The F.H.L. Brigade will take

part alongside other works

brigades in the district

during the coming year and

some of the items planned

are:

Jan. 18th films and quiz

Feb. 8th lecture; "pumps and

water"

Mar. 22nd large scale

exercise.

Chief Officer J. S. REA, F.

H. LIoyd & Co. Ltd. Fire

Brigade.

|

|

|

An advert from 1953. From 'The

Steel Casting', courtesy of Wendy Marston. |

|

An advert from The

Engineer, 15th May, 1953. |

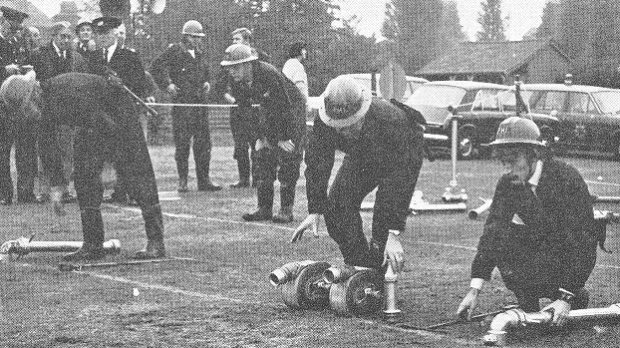

Three members of the four

man team competing in the hydrant drill at the

sports ground on Sunday 20th September, 1959.

Left to right: G. Wilkinson, E. Danks, and W.

Langley. From 'The Steel Casting', courtesy of

Wendy Marston. |

The F. H. Lloyd Fire Brigade in

action during the 21st Annual Fire Brigade Competition

that was held at the work's sports ground on Sunday, 8th

October, 1972. The event was won by the Rubery Owen

team. The four-man F. H. Lloyd team shown in the

photograph are left to right: Trevor Baker, Alan

Bytheway, Basil Reed, and John Lloyd. |

|

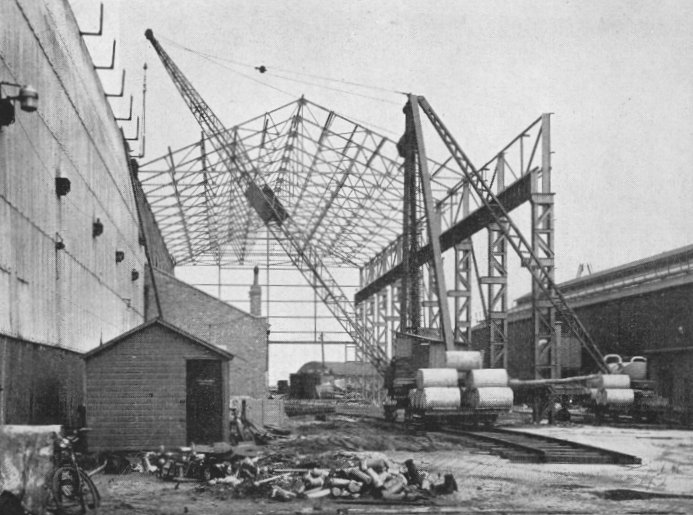

The Machine Shop Heavy Bay

during erection in 1954. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

The Heavy Bay nearing

completion. From 'The Steel Casting', courtesy of

Wendy Marston. |

| An advert from 1953.

From 'The Steel Casting',

courtesy of Wendy Marston. |

|

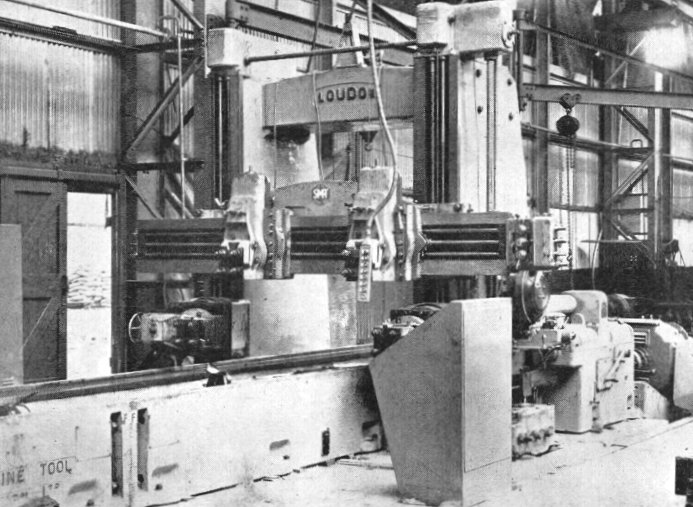

The Loudon planing machine

that was installed in the Machine Shop in 1954. It

was manufactured by the Scottish Machine Tool

Company, and had a maximum capacity of 5ft. by 5ft.

by 14 ft. From 'The Steel Casting', courtesy of

Wendy Marston. |

|

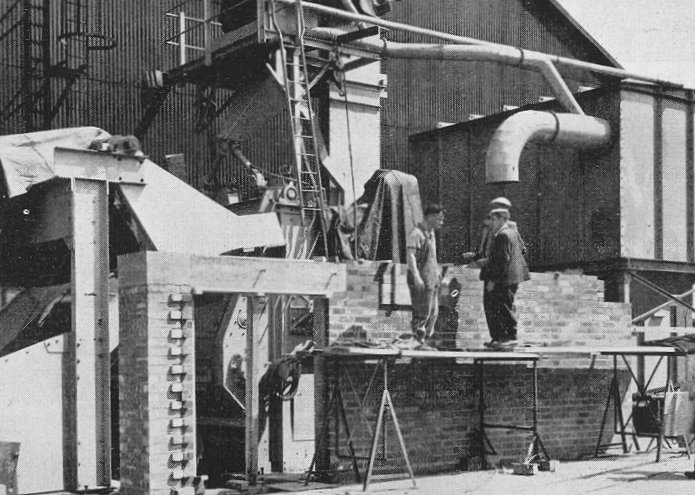

The 182ft. extension to the

New Dressing Shop nears completion in 1954. From

'The Steel Casting', courtesy of Wendy Marston. |

The completed extension to

the New Dressing Shop with its new 5 ton

overhead crane. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

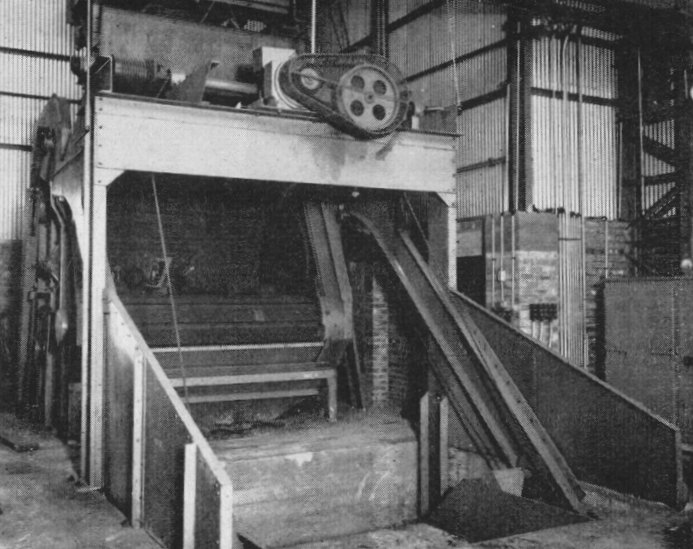

The new building for the

Tumblast Wheelabrator in 1954. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

The Tumblast Wheelabrator,

the largest in the country. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

Another view of the new road.

From 'The Steel Casting', courtesy of Wendy Marston. |

|

|

|

|

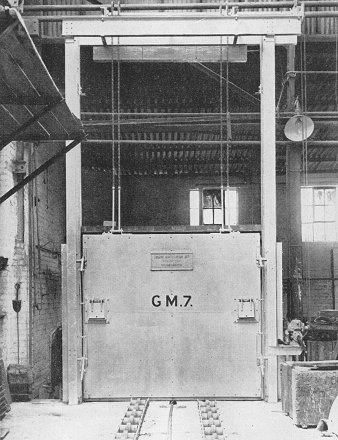

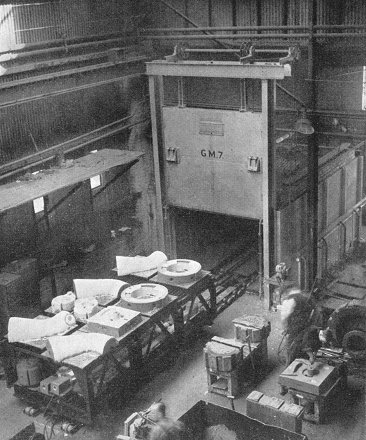

The 16ft. by 8ft. Mond gas-fired drying

stove, installed in 1954. From 'The

Steel Casting', courtesy of Wendy

Marston. |

|

Another view of the Mond gas-fired

drying stove with the

double-tier bogey. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

Preparing the ground for the

new road/rail weighbridge and the extension to the

railway, as seen in 1954. From 'The Steel Casting',

courtesy of Wendy Marston. |

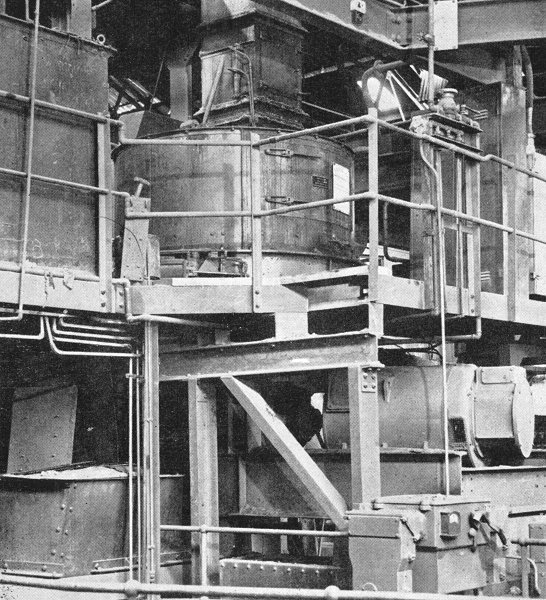

The model 70 Speed Muller sand

milling plant installed in 1954. From 'The Steel

Casting', courtesy of Wendy Marston. |

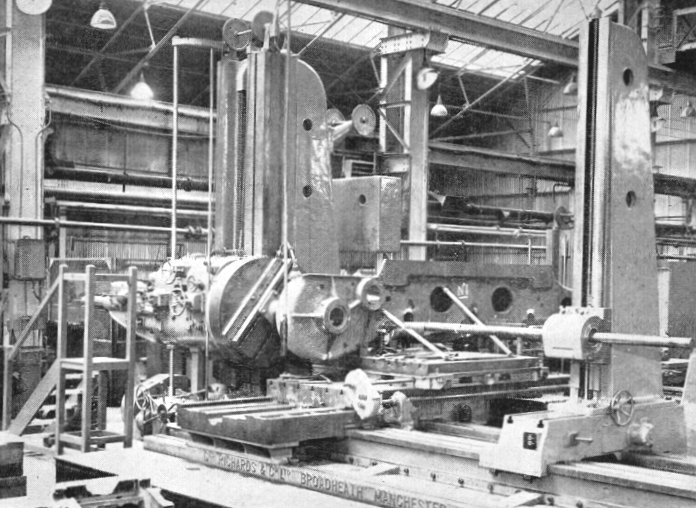

The number 6 horizontal boring

machine manufactured by George Richards Limited that

was installed in the Machine Shop in 1954. From 'The

Steel Casting', courtesy of Wendy Marston. |

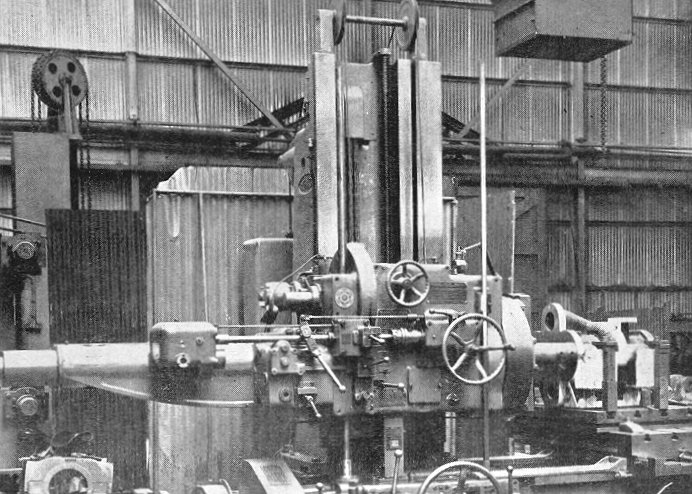

The number 3 horizontal boring

machine manufactured by George Richards Limited that

was installed in the Machine Shop in 1954. From 'The

Steel Casting', courtesy of Wendy Marston. |

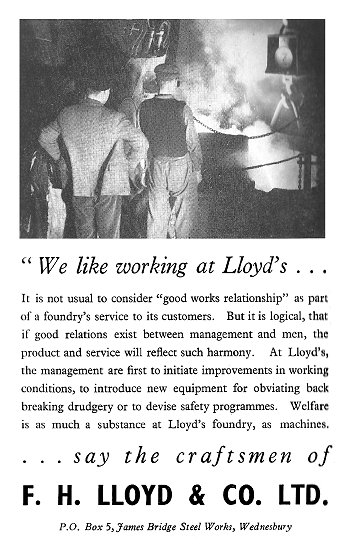

An advert from the mid 1950s. Courtesy of

Christine and John Ashmore. |

|

Mr. M. C, Lloyd, M.B.E.,

A.I.Loco.E. |

In January 1954 Mr. Michael Charles Lloyd was invited

to join the business as Works Director, by his elder

brother Francis Nelson Lloyd, Chief Executive. At the

time, the factory produced around 30,000 tons of castings

a year, with about 2,700 staff. |

|

Casting in the

foundry. From a 1954 works photo.

Courtesy of Wendy Marston. |

|

|

|

|

|

Return to the

early 1930s |

|

Return to

the contents |

|

Proceed to the

late 1950s |

|