|

|

|

The original factory

was built on part of the old Horseley Estate,

on an area known as ‘Finch’s Devisees’ which

contained a windmill, a blade mill (known as

Partridges Mill and later, Finches Mill),

and a pool. In 1792 the estate was purchased

for £10,000 by bankers Edward Dixon and

Joseph Amphlett, who were partners in their

banking business at Dudley, and

William Bedford from Birmingham, a

solicitor. They purchased the estate to mine

some of the plentiful coal.

Joseph Amphlett became

Chief Manager and Director with a salary of

£200 per year and an allowance of £600 to

spend on his home, Horseley House. Between

1780 and 1796 he had an ironmonger’s

business in High Street, Dudley. He

died on 14th January, 1801 and his one third

share of the Horseley partnership was

inherited by his son and daughter. Edward

Dixon became High Sheriff of Worcestershire

in 1799. He died on 10th August, 1807 at the

age of 66. William Bedford was a solicitor

to the BCN (Birmingham Canal Navigations company).

He died in 1832.

The BCN built a branch

from the canal to the company’s mines with

three locks. Because of the large amount of

mining in the area, the locks soon began to

suffer from subsidence and so the canal was

rebuilt and extended to overcome the

problem. Two Newcomen pumping engines were

built to pump water out of the mines. It was

used to fill the locks. By 1813 the firm had

two blast furnaces in operation, with two Boulton and Watt blowing engines for the

blast, as well as a puddling furnace, a finery, three

cupolas and six mines. The business became

the Horsley Coal and Iron Company (with an

unusual spelling of Horseley).

Between 1815 and 1816

an engineering works was built alongside the

ironworks, beside the canal. The partners in

the venture were Joseph Smith, a local man,

and his managing partner, Aaron Manby, who

had been a banker on the Isle of Wight

before becoming an ironmaster at

Wolverhampton. In 1813 he took out a patent

for making bricks from furnace slag and

began development of a retort for the

production of coal gas. He was

a member of the Institution of Civil

Engineers.

The Horseley furnaces

remained in use until 1842 when only one was

in operation. In 1843 the furnaces ceased to

be used and remained that way until the site

was leased in 1852.

|

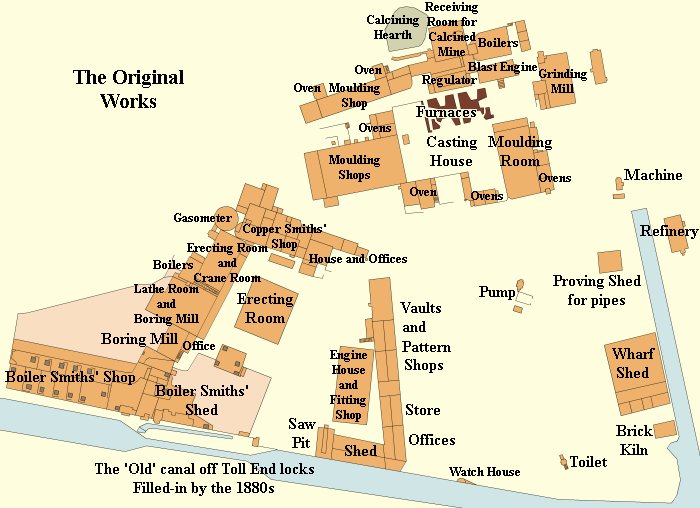

The original Iron Works and Factory. It stood

to the east of Upper Church Lane, north of Tipton Brook, south of

where Arthur Road is today. |

|

Thanks to Aaron Manby,

the engineering business quickly developed.

Some of the earliest products were marine

steam engines. On the 9th July, 1821, Manby

took out a patent for an oscillating marine

steam engine and for the use of oil to

get-up steam. He also took out a French

patent for the design and for an iron ship.

He formed a company in France with Charles

Napier to operate steam boats on the Seine

between Rouen and Paris. Their first iron

boat was built at Horseley and registered on

the 30th April, 1822 as ‘Manby’, although it

was generally known as the ‘Aaron Manby’.

After successful trials, the ship crossed

the channel and became the first iron ship

to put to sea. It successfully operated on

the Seine for about thirty years.

Aaron Manby left

Horseley and moved to Paris where he opened

a factory at Charenton. A second iron hull

was built at Horseley, and completed at

Charenton. Manby’s leaving had a bad effect

on the Horseley business, resulting in a

lack of orders. The problem was made worse

because Manby offered jobs in France to many

of the best men in the factory. The

colliers’ strike in 1822 also had a great

impact on the business, which shut-down for

a time.

| |

|

Read about Aaron Manby,

his paddle steamer and its

commemoration in 2022 |

|

| |

|

After Manby’s

departure, the firm began to build

steam locomotives. In 1832, several engines

designed by Cornish engineer, Matthew Loam,

were built for the St. Helens & Runcorn Gap

Railway. The engines were unreliable and

Loam left. He was replaced by Isaac Dodds

who designed a locomotive for the Liverpool and

Manchester Railway in 1833. The engine

worked well in trials, but was derailed and

considerably damaged. The railway company

decided not to purchase the engine, but did

agree to pay damages. On the 2nd September, 1833,

the locomotive was offered to the Dublin &

Kingston Railway at a price of £700. The

offer was declined, but the railway company

sent an order for a locomotive called

‘Star’. After delivery in 1835 the pair of

small wheels was found to be unsound, so Horseley provided a replacement. After the

new wheels were fitted, the locomotive

derailed and was damaged.

Horseley supplied a

stationary engine to the Leicester &

Swannington Railway in 1833. It was designed

by Robert Stephenson. The engine was later

modified and continued in operation until

1948. It is now in the collection at the

National Railway Museum at York.

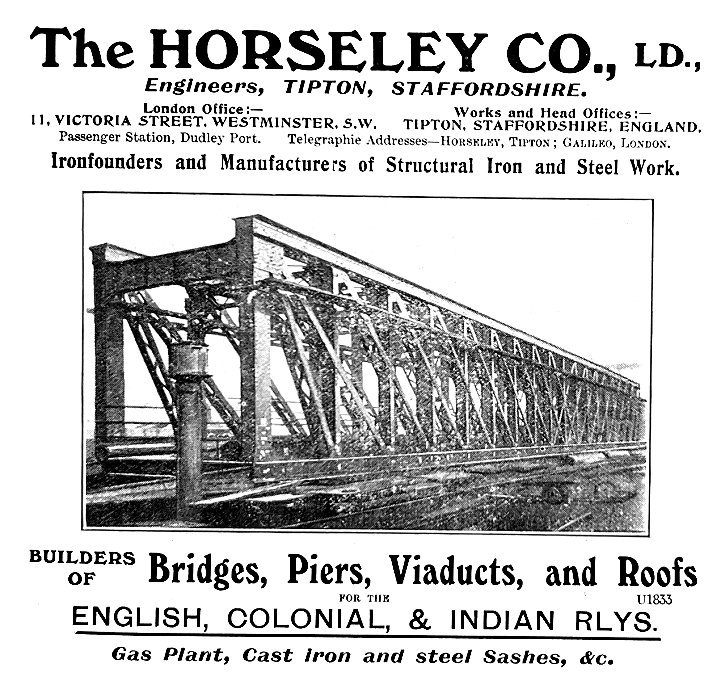

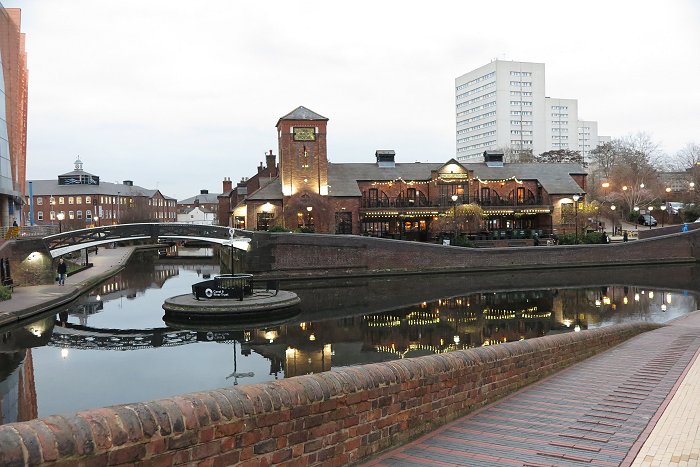

The firm is best known for its cast iron

bridges. One of the first was a swing bridge

built for the East India Docks in 1816. Many

of the firm’s bridges can be seen on the BCN

network, including the 'Old Turn' canal

bridge built in 1827, (now beside the Malt

House pub in Birmingham) and Galton Bridge

at Smethwick, built in 1829. At the time it

was the highest bridge in the world. Bridges

were also built for many canals including

the Oxford Canal, the Grand Union Canal, the

Birmingham and Fazeley Canal, and the Wyrley

and Essington Canal.

In the 1840s Horseley

Works ran into financial difficulties and in

about 1846 went into liquidation. The business was

put-up for sale and advertised on at least

three occasions in the Wolverhampton

Chronicle. The adverts include a detailed

description of the site and so are of great

interest. The site was eventually

purchased by three local ironmasters, J. J. Bramah, Deeley, and Cochrane,

who leased it to Broad and Tierney for 21

years in 1852.

|

| |

|

| Read a

description of the original factory from the

sale adverts in the Wolverhampton Chronicle |

|

| |

|

|

The New Works

In 1864, Robert Broad

purchased two pieces of land on which to

build a new foundry. The old factory was

outdated and the blast furnaces were no

longer required. Lack of rail access to

the old site may also have been a factor.

The new factory buildings were designed by

William Dempsey of London and John Weller of

Wolverhampton. They were built by David

Murray.

There were pattern

shops; a foundry, boiler shops, fitting shops

and offices. All of the cast iron work for

the new buildings was cast in the old

factory.

Early orders included a

water tank, sent to Berlin and a gas holder,

sent to Vienna. Orders were also received from

Bombay, Argentine, Birmingham, Portsmouth,

Aberystwyth, Chester, Conway, Croydon,

Crystal Palace Gas Works, the London & North

Western Railway; and the London & South

Western Railway. Most of the orders were for

gas holders and gas plant.

|

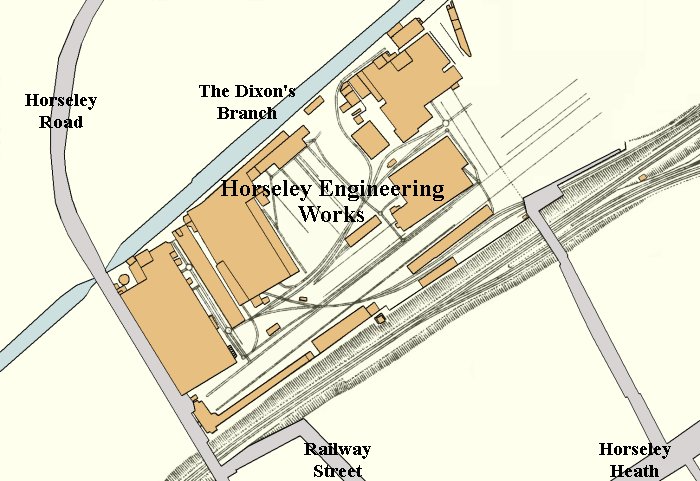

|

The location of the new factory, as it was in

1913. |

|

In January 1874 after

eight years as a private company, the

business went public under the name of The

Horseley Company Limited. The Chairman was

Tipton ironmaster, Robert Broad, with

Frederick Ernest Muntz, of Gloucester Terrace,

Hyde Park, as Joint Chairman and John

Cochrane, an ironmaster from Park Gate

London, as Vice Chairman. The other

Directors were: George Frederick Muntz, who

was also Chairman of the Birmingham Stock

Bank Limited; James Holcroft, a Stourbridge

iron and coalmaster; Joseph Scrivens Keep,

from Birmingham, who was also Director of the Midland

Wagon Company; and Thomas Short, based at London and

Birmingham, an East India merchant. John

Spencer remained as Secretary and George

Edward Jones remained as Works Manager.

On 2nd January, 1874,

Robert Broad died. He was replaced as

Chairman by John Cochrane. Thomas Short

became Vice Chairman. A new steam riveting

machine was installed in the boiler shop in

1876, and in 1877 John Cochrane resigned. He

was replaced by Peter Duckworth Bennett, a

West Bromwich ironfounder. The firm acquired

his business and decided to sell his loss-making Spon Lane Foundry in 1880. James Holcroft

resigned in April, 1877. Peter Duckworth

Bennett died on 28th November 1885 at the age of

60, in a lunchtime accident in Birmingham.

He went to a lunch at the Birmingham Council

House during the Prince of Wales’ visit to

the City. He climbed onto the portico to get

a better view of the proceedings and fell to

his death. He was replaced as Chairman by

Joseph Scrivens Keep.

In 1878 the company’s

products included ironwork for four gas

holders at Manchester, Ryde Pier on the Isle

of Wight, and a warehouse at Heaton Norris.

In 1879 ironwork was produced for Harwich

Pier, and in 1880 for a gas holder at

Poplar, for two gas holders for Tipton Gas, and

three bridges for the London & South Western

Railway Company. In 1882 iron work was

produced for a large jetty at Port

Elizabeth, South Africa, a bridge over the

River Itchen near Southampton, and a bridge

over the River Aire for the Hull, Barnsley &

West Riding Junction Railway.

In 1883 orders included

ironwork for two gas holders for the Gas

Light & Coal Company, Westminster, one gas

holder for the Bilston Gas Light & Coal

Company, and a warehouse at Huddersfield for the

London & North Western Railway. In 1884,

ironwork was produced for the widening of

Charing Cross Bridge, London, and Medway

Bridge, Rochester. In the following year,

ironwork was produced for Rugby Railway

Station extension, Monument Lane Station,

Liverpool,

Brunswick Dock, also at Liverpool, and Birkenhead

Gas Works. Other orders for bridges in the

1880s included Osney Bridge over the River

Isis at Oxford, a swing bridge over the

River Dee, two jetties for Table Bay, Cape

of Good Hope, a pier for Port Elizabeth,

South Africa, and a bridge for Japan.

Working in an ironworks

could be a dangerous business. In October

1878 two men lost an arm when a girder

slipped, and two men were seriously injured

at the Ryde Pier site. In May 1879 a man was

killed in the works when a bar of iron fell

from a wagon, a man was also killed on the

Manchester Gas Works site, and another man was

killed at the Commercial Gas Works site at

Poplar, Tower Hamlets, London, followed by a

second fatality in 1881. Between 1877 and

1881 there were 23 accidents at the factory.

There were also fatal accidents at the

Liverpool Alexandra Dock Warehouse and

Dudley Gas Works.

In 1890 an order was

received from the Admiralty for 133

cylinders, with diameters of 7, 8, and 10

feet. Columns and guides for Montevideo Water

Works at Rio de Janeiro were also ordered,

along with ironwork for Beckton Gas Works, the Great Eastern

Railway, Daventry & Leamington Railway,

Colombo Harbour Jetty, and Liverpool Street

Station roof, in London. In 1892 the company

had a staff of 730, along with 171 outworkers. A new

planning machine was purchased for the

boiler shop in 1900 along with a 50hp. gas

engine. The company continued to purchase

extra land adjacent to the factory,

something that had been going on since the

1870s. The land had previously been used for

coal mining.

|

|

Much of the girder work

had always been done in the factory yard, in

an area known as the races. In 1904 two

large workshops, 150 feet long and 40 feet

wide were built so that the girder work

could now be carried out under cover. Joseph Scrivens Keep who had been Chairman since

1877, died on 13th April, 1907. He was

replaced by Frederick Ernest Muntz. In

February 1910 Rowland Hill, of The Firs,

Kidderminster became a Director. He remained

as such until January 1915 when he died.

Another Director, Charles Holcroft, died on

11th March, 1917 and was replaced by his

nephew, S. H. H. Henn.

In 1916 the firm became

The Horseley Bridge & Engineering Company

Limited, a name which was thought to be

more appropriate. During the First World War

the company produced mines, mine sinkers,

steel barriers for Scapa Flow, sheds, steel

buildings, buoys for the Channel barrage,

and booms and paravanes that were used by

ships to clear mines.

In 1919 J. W. Baillie became Secretary (he

would eventually become Managing Director).

The boiler shops were extended, new machines

and a new weighbridge were installed and

alterations were made to the offices. In

November, the following year, the Chairman,

Frederick Ernest Muntz died. He was replaced

by J. T. Daly in January, 1921.

In the early 1920s, a shortage of orders led

to a recession, which lasted for many years.

In 1925, orders included six bridges for the

Southern Railway, and in 1926 lift bridges

for Nechells Power Station and steelwork for

the LMS. The final profit for the year was

only £6,000 so no dividend was paid. The

General Strike in 1926 and the continuing

miners’ strike led to the closure of the

factory from May until the end of December.

During this time a lot of maintenance work

was carried out on the site.

The orders for 1927

included swing bridges for the Port of

London Authority, crane runways for Derby

Locomotive Works, a bridge for the Southern

Railway and a rolling lift for Tilbury

Docks. A rolling lift bridge was ordered for

the docks at Manchester Road, Millwall in

1928, along with a purifier for Stourbridge

Council and cast iron troughs for Bradford

Council.

J. T. Daly retired as

Chairman in June 1928 after 42 years on the

Board. The Horseley Company had decided to

amalgamate with Thomas Piggott & Company

Limited, Spring Hill, Birmingham, at a time

when both companies were short of work. The

amalgamation took place in June 1928 and

office staff from both companies were moved

to a new company office at 28 Lionel Street,

Birmingham. Sir Sydney Henn became Chairman

and the following new Directors were

appointed: T. P. Barker, A. Dyson, T. W.

Horton, Henry Bewlay, T. O. Lloyd, and J. W.

Baillie.

The foundry at Tipton

took over the work of Piggott’s foundry at

Spring Hill. The foundry foreman at Tipton

was dismissed and replaced with the foreman

from Piggott’s Foundry. Many orders arrived

for steelwork for the National Grid which

was being extended. This resulted in the

opening of a transmission tower steelwork

facility at Tipton. Orders were also

received for structural steelwork for

cinemas, which were becoming very popular at the

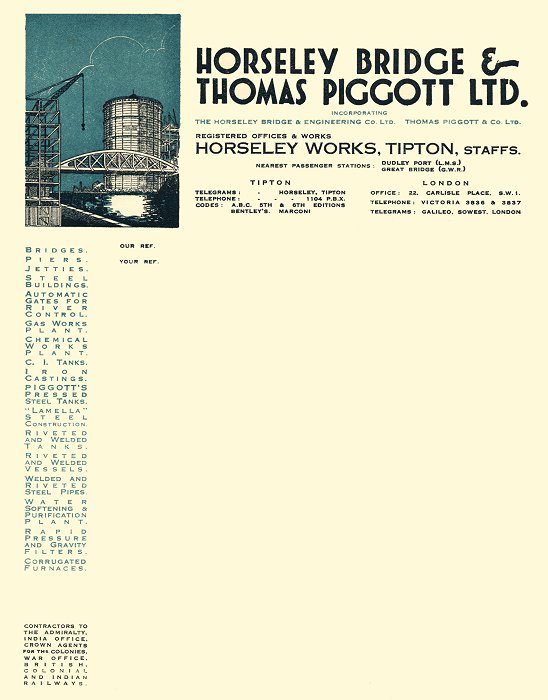

time. Other orders were for gas lamp columns

for Belfast and Liverpool, a landing stage

at Neyland, Wales, and Ammonia stills for

Belfast.

|

|

From 'Structural Steelwork'. |

In 1929 Sir George Holcroft resigned from the Board, and in

1931 the light construction shop was

extended.

In 1931 there were orders for the

Bute West Dock lock swing bridge at Cardiff,

a bridge for the LMS, and the reconstruction

of Meadow Hall, Sheffield, for the LNER.

The

recession continued; staff reductions were

made and there was a three day working week.

The situation became desperate. The only

orders in February 1932 were for electricity

transmission towers and so there were

further reductions in staff. The bank

refused to honour Piggott’s cheques and so

it was decided that an amalgamation of the sites

was essential. Piggotts went into voluntary

liquidation and the office staff were moved

from Birmingham to Horseley Works where the

office was redecorated.

In May 1933 an order

was received for the 900 feet high radio

mast at Droitwich and another for the repair

of Colwyn Bay pier. By the end of the

financial year the company had made a loss of

£530.

|

| On 1st January, 1934

the business became The Horseley Bridge &

Thomas Piggott Limited. It was decided that

a replacement factory for Piggott’s foundry

at Spring Hill should be built at Tipton, on

the site of the works’ sports ground on the

Great Bridge side of the railway line, where

there would be rail access. The factory was

known as Pipe Works. In 1934 Spring Hill

works were closed and work was well underway

at the new site. Spring Hill factory was

demolished in 1935 and Pipe Works was

completed and in full production by June

1936. |

|

In 1935 an order was

received for a swing bridge at Exeter and

trade began to increase. In 1936 an order

was received for a 2 million cubic foot

Klonne gas holder, from the Ford Motor

Company, along with an order for a one million

gallon water tank for a hydroelectric scheme

in Devon. By the end of the 1936 financial

year, a small profit had been made.

A letterhead from

1936.

On 13th October, 1936,

Sir Sydney Henn died after he broke his

thigh in a fall. On 11th March, 1937, the

Earl of Dudley was elected as a Director and

Chairman of the company. Orders in 1937

included 1,000 tons of steel for Imperial

Airways, London, steel for steel-framed

buildings for Cadburys, and 5,000 tons of

steel for aircraft hangars for the Air

Ministry. During the year, further

improvements were made at the factory

including a reorganisation of the girder

shop, and the building of new offices, which

had been completed by February 1939. While

building work was in progress, a temporary

drawing office was set up in a wooden

building in Horseley Road. This then became

the canteen.

In January 1938, T. W.

Horton, one of the Directors, died and

orders included a Scherzer lift bridge for

London County Council, and large amounts of

dovetail sheeting for air raid shelters. In

July 1938 a week’s paid holiday for all

employees was introduced, and air raid

shelters were built at the factory for the

employees. Business was improving, more

orders were received and a good profit had

been made by the end of the 1939 financial

year.

|

|

Galton Bridge, Smethwick, built in 1829. |

|

World War 2

At the beginning of the

war, the London office

closed and some of the staff were

transferred to Tipton, where the company

purchased Lansdowne House in Horseley Road,

for their occupation. 500 mines were produced each week

in the factory for the Admiralty, and new

machinery was installed for their

production. In July 1940 pipe contracts at

Pipe Works came to an end, because of the

war, so new contracts were sought in

order to keep the factory in operation.

The Horseley Platoon of

the Home Guard had 160 men who mounted

nightly fire watches at the works. The

company purchased 1,000 steel helmets for

them to wear during air raids. Enemy bombs

badly damaged gas holders at Coventry,

Smethwick, and Cardiff. The company received

orders for repairs to the damage. A new

dressing shop was built at the works and in

May 1941 the company was included in the

Ministry of Labour's Protected List under

essential work.

By October 1941, there

were 45 female factory workers on the site,

many of whom were trained as welders. New

toilets and cloakrooms were built for them.

In August 1941 an order was received for 300

small armoured plate bodies for ‘Beaverette’

tanks, and in November of that year an order

was received for 4,000lb. bombs.

On 14th April, 1942 the

Duke of Kent inspected parts of the factory

and on the 1st July, a new canteen was

officially opened by the Earl of Dudley. New

chemical and metallurgical laboratories were

built, complete with x-ray machines. In May

1942 the factory completed an order for six

stern ends for tank landing craft, more of

which were built in 1943. In December 1944

an order was received for 2,900 tons of

steel for the new Ocker Hill power station.

|

|

The 'Old Turn' Horseley canal bridge in

Birmingham. |

|

A close-up view of the bridge in the above

photo, built in 1827. |

|

The Post-War Years

In 1945 an order was

received for 700 tons of Calendar-Hamilton

bridge units for Dutch railways and in May

1946 an order was received for 7,000 tons of

steel for Walsall Power Station. Another

order was for a number of steel frames for

houses.

In January 1947 the 5

day working week was introduced, at which

time the factory was having problems due to

a shortage of steel. In February 1947,

Thompson Brothers of Bilston ordered a steel

portal framed building and in March an order

was received for two bridges at New Street

Station requiring 800 tons of steel. They

were the last bridges built at the works

using riveted construction.

|

Sutton Coldfield television

mast. |

In June 1948, J. W. Baillie became Managing

Director and on 20th December, 1948, the

Earl of Dudley officially opened the new

foundry.

In April 1949 the company’s

largest built-up girder was made for the

Sutton Coldfield television mast. It was 785

feet high and weighed 80 tons.

The company

received an order for the base supports for

the ‘Dome of Discovery’ at the Festival of

Britain in November 1949. It required 232

tons on aluminium and 133 tons of steel. In

October 1949 the company took over George M.

Carter (Erectors) Limited and renamed the

company Carter-Horseley (Engineers) Limited. |

At the end of 1949 an order was received

from Port Talbot for a gas holder of one

million cubic feet, and in May 1950 J. S.

Christie became Company Secretary. The

company purchased a new sports ground from

Triplex Foundry Limited, in 1952, having

shared it with them for five years.

In 1953 the company

constructed Ince Power Station. At the end

of the year J. W. Baillie retired, but had a

short retirement. He died in July 1954. On

his retirement James Christie and Vincent

Senior became joint Managing Directors.

Orders received in 1954 included the

building of a portal bridge over the Walsall

canal and a fatigue testing tank for

aircraft built at Farnborough.

The company acquired

Mechans Limited, on the Clyde, in 1957. The

firm only survived for six years after

take-over because of the decline in Scottish

shipbuilding. The factory closed in 1963 and

some of the products including water-tight

doors for ships were transferred to Tipton.

The 100th Powermaster boiler was produced at

Tipton in 1957 for G.W.B. Limited of Dudley,

and during the year, Concrete and Structural

Products Limited was acquired as a

subsidiary of Carter-Horseley.

The first all-welded

high strength steel bridge was built at

Maidenhead over the River Thames in 1960,

along with the head and tail sluice gates

for the flood control scheme at Dover and

Kings Lynn. The company acquired G. H.

Whitehouse & Son Limited in 1961. Their

plant was moved to the Horseley factory to

become the company’s new machine shop.

During the year, orders were received for two

major power-line crossings, one over the

River Severn and another over the River

Thames.

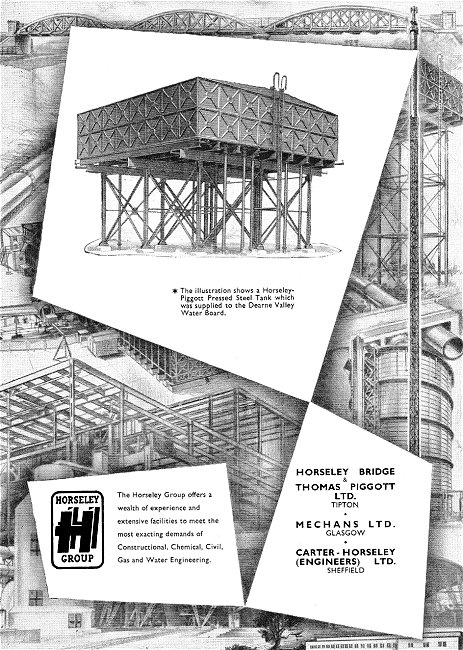

A letterhead from

1936.

In 1964 three radio

telescopes with a diameter of 60 feet where

built for Cambridge University, and a

significant investment in new plant was made

at Tipton, including a 2,000 ton press for

the hydraulic shop, an updating of ‘A’ bay

into a Class 1 welding shop, the building of

an x-ray shed, shielded with lead sheets, new

welding sets and a hydro test pump. The Dixons

Canal Branch was removed in order to

increase the tower storage area and a Merlin

gas cutting machine was purchased for the

Pipe Works. Investment continued in 1965

with the purchase of large lathes, radial

drills, a rail crane, 600 amp welding sets,

a large hole cutting machine and a new

layout for the hydraulic shop.

A large contract was

received in 1965 for work on Rugeley ‘B’

Power Station. The firm’s main products were

now pressure vessels, heat exchangers, and

process vessels in many materials, including

stainless steel. Some of the vessels and

heat exchangers had tubes with sides that

were twelve inches thick. Further investment

in 1966 included a Merlin gas cutting

machine for stainless steel, Wadkin tape

drills, argon arc and MIG welding sets,

grinding machines, and a plasma arc torch

for the Pipe Works. The welding shop became

the special products shop, a Unionmelt

vessel welding machine was acquired for ‘A’

bay and the old coke braziers in the factory

were replaced with gas heaters.

Two moving footbridges

were built for the Madras Port Trust and

work was completed on the replacement Marlow

Bridge, over the River Thames. Horseley-Piggott

(Coatings) Limited was set up to use a new

system of pipe coating and on the 29th March,

1966 a holding company, Horseley Bridge

Limited was set up. The last issue of the

firm’s magazine, Horseley Group News was

produced at Christmas, 1967 and a training

school opened at the Carter-Horseley

offices.

|

|

Another Horseley footbridge over the BCN in

Birmingham. |

|

The latter Years

In September 1968,

Horseley merged with the John Thompson

organisation at Ettingshall, Wolverhampton.

The organisation agreed to acquire the whole

of the issued capital of Horseley Bridge

Limited. Many orders were received at that

time, including one for Class

1 pressure vessels and another for the

reconstruction of Marlow and Hammersmith

suspension bridges. Other orders were for complex pipe work for a

wind tunnel at RAF Bedford, the pipe bridge

and road crossing over the River Severn at

Hampton Loade and a high level box girder

bridge at Milford Haven.

The pipe industry began

to decline due to lack of investment because

of the proposals for nationalisation. As a

result the Pipe Works closed and the site

was sold. Horseley then concentrated on

structures, cranes and bridges, but times

were difficult due to a shrinking market.

The light construction shop was demolished,

but attempts to sell the land failed. The

land across the road, where the canteen and

garage stood was sold.

Because of the

deepening industrial depression in the

country, the order books contained many

loss-making contracts. At the time, the

industry as a whole, had been quoting ever-low prices

which resulted in the closure of 190

fabrication companies in the 15 months prior

to April 1992. The Horseley factory was

put-up for sale and demolition contractors

were appointed, while the factory was still

in operation. The business formally closed

on the 15th May, 1992 with a loss of 350

jobs, which must have been heartbreaking for

many of the ex-employees, because jobs were

in short supply due to the industrial

depression. This was a sad end and a bitter

blow to a company that had achieved so much

during a lifetime of 200 years.

|

|

Return to

the

previous page |

|